A Comparison of Mini Pile Bearing Capacity based on Sondir Data

and Experimental Test

Efan Tifani

a

, Alamsyah

b

and Indriyani Puluhulawa

c

Department of Civil Engineering, Politeknik Negeri Bengkalis, Jl. Bathin Alam Sei Alam Bengkalis, Riau, Indonesia

Keywords: Mini Pile, Pile Capacity, Static Loading Test.

Abstract: The problem that arises due to the use of Mahang wood as a pile foundation is the exploitation of forest

products on a large scale. This is because building a two-story building requires 2-3 Mahang wood for every

square meter of the building. The replacement of Mahang wood into Mini Pile for building foundation is one

alternative solution to overcome this problem. In the implementation of the test, four mini piles measuring

12x12x250 cm were made, erection at two points with an embedded depth of 4.5 m. Static loading test has

been carried out to determine the actual capacity of the mini pile by loading the design load calculated using

the Bagemann method with CPT test data. The results showed the actual capacity of one point was 4.137 tons

with a settlement of 1.77 mm. This value was 2.81 times higher than the ultimate load (Pu) for the single pile

design based on the CPT test.

1 INTRODUCTION

One type of foundation that is commonly chosen by

the community in Bengkalis Regency to build a 2 to

4 story building is Mahang wood (Macaranginae)

with a length of 6 to 7 m. The use of that wood as a

foundation is almost the same as a concrete pile,

including the method of erection by a Drop Hammer.

This wood has been estimated to be strong in bearing

loads, easy to acquire and economical in its

application, especially in clay soil areas such as

Bengkalis Regency. Nevertheless, there has been a

problem of using forest products on a large scale only

to build 2 to 4 storey buildings which require 2-3

mahang wood for every square meter of building.

Replacing mahang wood with mini pile concrete for

building foundations is an alternative to reduce these

problems. Where the mini pile has dimensions that

can be adjusted to the needs, has strong resistance and

quality can be controlled.

a

https://orcid.org/ 0000-0001-9358-3513

b

https://orcid.org/0000-0002-0766-1712

c

https://orcid.org/0000-0001-6588-1345

2 LITERATUR STUDY

Mini Pile is one type of pile foundation that is used to

support the foundation of a construction such as

bridges, docks, buildings, dolkens and others. The

shape of the mini pile is generally in the form of a box

or triangle with a cross section variation of 20 x 20

cm to 40 x 40 cm and a length variation between 3m

to 9m. If a longer length of the mini pile is needed, it

can be connected to a welded iron plate (Pamungkas

E.T, et al, 2021).

2.1 Sondir Test

Sondir test, also known as Cone Penetration Test

(CPT) is often used to estimate the bearing capacity

of soil in deep foundations. However, it is sometimes

also used to estimate the bearing capacity of shallow

foundations. This has been confirmed by Eslami

2020, that the conus end resistance in the CPT test is

the same as the pile end resistance. The test is carried

out by pushing the cone into the ground. The soil

resistance at the tip of the cone as well as the soil shaft

friction was measured. So that the value of the cone

988

Tifani, E., Alamsyah, . and Puluhulawa, I.

A Comparison of Mini Pile Bearing Capacity based on Sondir Data and Experimental Test.

DOI: 10.5220/0010957700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 988-994

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

resistance (q

c

) and friction data (f

s

) is obtained

(Fahriani F, 2015).

There are two types of sondir, the first is the light with

a capacity of 0-250 kg/cm² and the second is the

heavy with a capacity of 0-600 kg/cm². The type of

soil that is suitable for sondir with this tool is soil that

does not contain rocks (Hairina R).

2.2 Bagemann Method

According to Yusti, 2014, piles on cohesive soil

generally have conical resistance (q

c

) related to

undrained cohesion (c

u

), namely:

.

=

(kg/cm

2

)

(1)

The value of N

k

ranges from 10 to 30, depending on

the sensitivity, compressibility and adhesion between

the soil and cone. Generally in design calculations

using Nk between 15 to 20. The pile end resistance is

taken at the average q

c

value calculated from 8D

above the pile base to 4D below the pile end. Safely,

the frictional resistance of the unit area (f

s

) of the pile

can be taken as equal to the frictional resistance of the

cone side (q

f

):

=

(kg/cm

2

)

(2)

The ultimate capacity of the pile, expressed by the

equation:

=

.

+

.

(3)

Where

is area of the bottom end of the pole (cm

2

);

is pile blanket area (cm

2

);

= f

is conus

resistance (kg/cm

2

);

is frictional resistance of cone

side (kg/cm

2

).

The ultimate bearing capacity of the pile (Q

u

), is

calculated by the general equation:

=

+

=

.

+

.

(kg)

(4)

Where

is pile unit end resistance (kg/cm

2

);

is pile

unit friction resistance (kg/cm

2

).

2.2.1 Ultimate End Resistance

The ultimate capacity of the pile embedded in the

cohesive soil is the sum of the side frictional and the

end resistance of the pile. The amount of frictional

resistance of the pile depends on the material and

shape. Generally, for homogeneous soils, the

frictional resistance of the walls in the form of

adhesion between the pile side and the soil will have

a large effect on the ultimate capacity.

=

.

(5)

=

(6)

Where

is cohesion in undrained soil conditions

located below the pile end whose values are taken

from undisturbed soil samples (kN/m

2

);

isbearing

capacity factor (function of φ).

For cracked clay, c

b

must be taken from the shear

strength of cracked clay. Reduction due to cracked

soil conditions needs to be given, because this effect

reduces the contact between the pile side and the soil.

For piles embedded in soft to medium clay soils, the

end resistance value is usually not large, so the

method of calculating the bearing capacity of piles in

cohesive soils is generally more focused on

determining the pile frictional resistance (Q

s

).

2.2.2 Ultimate Wall Friction Resistance

To determine the frictional resistance of piles driven

in clay, the adhesion factor (α) collected by

McClelland (1974) is used as shown in Figure 1. The

frictional resistance of piles is expressed as follows:

=

.

(7)

=

=.

(8)

Where

is ultimate friction resistance (kN);

is

adhesion between the pole and the soil (kN/m

2

); is

adhesion factor is taken from Figure 1;

is average

undrained cohesion along the pile (kN/m

2

).

Figure 1: Adhesion factor (α) collected by McClelland

(1974).

2.2.3 Pile's Ultimate Bearing Capacity

The ultimate bearing capacity of the pile is calculated

by the following equation:

=

.

+

.

.

−

(kg)

(9)

A Comparison of Mini Pile Bearing Capacity based on Sondir Data and Experimental Test

989

Since the self-weight of the pile (W

p

) is close to the

weight of the soil displaced by the pile, A

b

.p

b

can be

considered equal to W

p

. Therefore, the pile bearing

capacity in cohesive soils becomes:

=

.

+

.

.

(kg)

(10)

Where

is shape factor of pile (equal to 1 for

uniform pile diameter).

2.3 Pile Foundation Settlement

According to Fahriany 2015, the estimation of

settlement that occurs in pile foundations is a

complicated problem caused by several factors, such

as disturbances in soil stress during erection and

uncertainty regarding the distribution and position of

load transfer from the pile to the soil.

=

100

+

(11)

Where S is single pile foundation settlement; D is pile

diameter; Q is pile bearing capacity; L is pole length;

A

p

is pile cross-sectional area; E

p

is modulus of

elasticity of concrete pile material.

2.4 Static Loading Test

According to Hardiyatmo, 2002, the static loading

test was carried out with several objectives, such as:

Determine the graph of the load and settlement

relationship, especially in the load around the

expected design load.

Ensure that foundation failure will not occur

before the target load is reached. Its value is

several times the design load. This value is used

as a safety factor.

Determine the actual ultimate capacity, check

the results of the calculation of the pile capacity

obtained from the static and dynamic formulas.

The standard test method for deep foundations

under static axial compressive load consists of 7

procedures, one of which is the slow maintained test

load method.

The Slow Maintained test load Method (SM Test)

is recommended by ASTM D1143-81, this method is

generally used in field research before further work is

carried out, the testing procedure consists of:

a. Pile load is divided into eight equal stages,

namely 25%, 50%, 75%, 100%, 125%, 150%,

175% and 200% design load

b. Each increase in load must maintain the rate of

descent which must be less than 0.01 in/hour

(0.25 mm/hour)

c. Maintain 200% design load for 24 hours

d. After the required time is reached, reduce the

load by 25% with a gap of 1 hour between

reduction times.

e. After the load has been applied and removed,

reload the pile for load testing in increments of

50% of the design load, allowing 20 minutes for

additional load.

f. Then increase the load in increments of 10% of

the design load.

3 METHOD

The research stages are divided into several stages as

shown in Figure 3, and are described as follows:

a. Manufacture of mini pile specimens in the form

of a square cross section with a size of

12x12x250 cm, using 4Ø10 main reinforcement

and D6-200mm stirrup reinforcement as seen in

Figure 2. The composition of the mixture refers

to the regulation of the Minister of PUPR No. 28

of 2016 for the quality of K225. In addition,

several specimens of concrete cubes of

15x15x15 cm were also made to determine the

quality of the mini pile concrete.

b. Sondir testing was carried out at the location of

the mini pile to determine the cone resistance

data (q

c

) and cone side friction resistance (q

f

).

c. Calculate the amount of design load that will be

given to the mini pile during testing.

Determination of the carrying capacity of the

plan (Q

u

) using the Bagemann method by

analyzing the sondir test data.

d. Mini pile erection at a predetermined location

using a Drop Hammer (Figure 4). One point of

the foundation using two mini piles with steel

plate connection as shown in Figure 5. The

depth of the pile is 2x2.5 m but the embedded

depth of the mini pile is 4.5 m, which is 0.5 m

not embedded as the set up of loading test.

e. The loading test was carried out based on the

SM Test. Static load testing was carried out for

two days with a load of 25, 50 ,75 and 100% of

the design load. Then let stand for 24 hours and

the load was reduced gradually. This load was

given to determine the actual settlement that

occurs in the mini mile based on the carrying

capacity of the plan achieved. To facilitate load

application, two mini pile points were placed at

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

990

a distance of 10 D or 120 cm as shown in Figure

6.

Figure 2: Mini pile specimens.

Figure 3: Research flow chart.

Figure 4: Erection of mini pile by drop hammer.

Figure 5: Steel plate connection.

Figure 6: Static loading test of mini pile.

f. During loading, settlement that occurs in the

mini pile was recorded using a dial installed on

the mini pile (Figure 7).

A Comparison of Mini Pile Bearing Capacity based on Sondir Data and Experimental Test

991

Figure 7: Recorder settlement using dial gauge.

g. The last stage is to determine the actual carrying

capacity (Q

u

) based on the real settlement during

testing and the actual mini pile's Elasticity

Modulus. Then compare the value of the actual

carrying capacity with the carrying capacity of

the plan.

4 RESULTS AND DISCUSSION

The results obtained are Sondir data, the quality of

mini pile concrete, the value of the ultimate bearing

capacity (Q

u

) of the single pile used as the design load

(P

u

), the settlement (S) of the test results by the SLT

method and the value of the actual ultimate bearing

capacity (Q

u

actual). The allowable load (P

a

) of a mini

pile/single pile with dimensions of 0.12 m × 0.12 m ×

4.50 m which is embedded on soft clay.

4.1 Sondir Test Results

The Sondir test was carried out to a depth of 12

meters, with a groundwater level of ± 0.75 m from the

ground level. Visual identification of soil types

categorized as soft clay. The data presented is only at

a depth of 1 to 5 meters, where the values of q

c

and q

f

have been averaged every one meter depth, as shown

in Table 1.

Table 1: q

c

and q

f

value.

Depth

(z = m)

average q

c

(kg/cm

2

)

average q

f

(kg/cm

2

)

0 – 1 1,3 0.073

1 – 2 0.9 0.04

2 – 3 0.4 0.020

3 – 4 0.4 0.0213

4 – 5 1.1 0.153

According to Galang M et al, 2017, the calculation of

pile capacity using CPT data shows the results closest

to the real capacity.

4.2 Concrete Quality Test

The results of testing the concrete cube at the age of

28 days obtained the average value of the concrete

compressive strength of 283.65 kg/cm

2

. This value

was 26% higher than planned. Furthermore, with this

value, the actual value of the concrete's modulus of

elasticity was 22804.93 MPa.

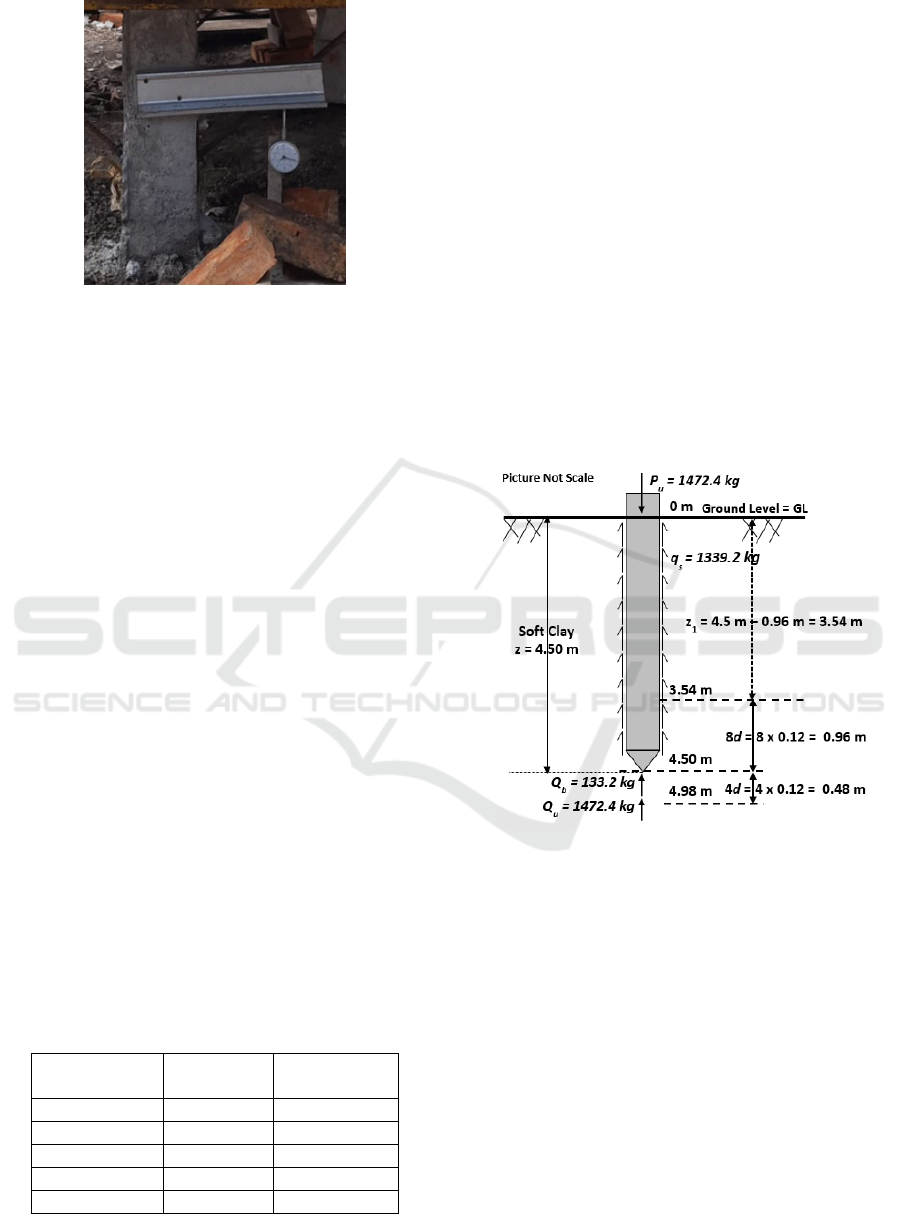

4.3 The Ultimate Bearing Capacity

Design (Q

u

) of Single Pile

The value of the ultimate bearing capacity (Q

u

) of a

single pile was obtained using the Bagemann method

as shown in Figure 8.

Figure 8: Mini Pile embedded.

=

+

=

= 0.0144

=

&

= 0.925/

=

×

= 0.0144

+ 92.5/

= 1.332~133.2

= 2.16

=

.

= 0.062/

=

×

= 2.16

+6.20/

= 13.392~1339.2

= 133.2 + 1339.2

=

= 1472.4~1.472

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

992

The value of Q

u

was applied as the ultimate load

design (P

u

) for the single pile to obtain the actual

settlement value of the pile during loading.

4.4 Settlement Value (S) Single Pole

Static loading test with full scale 1:1 was carried out

one day after erection. The ultimate load is Pu=1.472

tons ×2= 2994 kg for two single piles with a distance

(s) = 10d = 1.2 m. Although the application of the load

by the 2 poles is in one plate holder to facilitate load

balance, but with a distance between the poles of 10d

resulting in an efficiency value (E) of the pole = 1

(Hardiyatmo, 2012), the loading received by each

pole is still based on the load. The ultimate design for

the single (P

u

) pile is 1472 kg (not the group), as

shown in Figure 9.

Figure 9: Application of loading to the final settlement of

single pile.

The result of full loading of 1.472 tons per pile shows

the final actual settlement value of (S) = 1.77 mm or

equal to the ratio of 0.0147d (1.475% of the pile

width). Where the test results are depicted in a graph

of the relationship between the load and the

settlement, as shown in Figure 10.

The settlement shown is less than that required by

ASTM D 1143/D 1143M-07 in procedures B and C,

where the maximum pile settlement is 0.15d (15% of

the pile width), along with the failure of the pile.

Likewise with the 2015 Wrana Bogumil the

settlement that has occurred was not higher than 0.1d

when the maximum load has been reached.

Figure 10: Relationship between load and single Pile

settlement.

4.5 Actual Ultimate Capacity (Actual

Q

u

) Single Pile

This value is obtained by using the Vesic method

which is based on the final actual settlement (S) that

occurs, involving the value of the Elasticity Modulus

of the mini pile material (E

p

).

= 22804.93~22804930/

Furthermore, the value of the actual ultimate bearing

capacity (actual Q

u

) is as follows:

=

−

100

×

×

=

0.00177m −

0.12

100

4.50

× 0.0144

× 22804930/

= 0.000126 × 0.0144

× 22804930/

= 41.377~4.137

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

1,00

1,10

1,20

1,30

1,40

1,50

1,60

1,70

1,80

0 150 300 450 600 750 900 1050 1200 1350 1500

Settlement of mini pile (S)= mm

Loading (P) = kg

A Comparison of Mini Pile Bearing Capacity based on Sondir Data and Experimental Test

993

The data above shows that the value (actual Q

u

) is

2.81 times higher than the ultimate Q

u

(P

u

design) for

single pile.

4.6 Allowable Load (P

a

) Single Pile

The value of the allowable load (P

a

) is obtained from

the actual Q

u

by involving the safety factor (SF = 2.5).

The mini pile in this study was obtained as follows:

=

=

=

4.137

2.5

= 1.65

The value is a safe load value (P

a

) of 1.65 tons, in

accordance with what is required to be held by one

mini pile.

5 CONCLUSIONS

The results of the above studies can be concluded that

the actual final settlement value of the pile S = 1.77

mm has been obtained from the SLT test at the

ultimate load (P

u

) = 1472.4 kg for one pile. The

settlement value is less than that required by ASTM

D 1143/D 1143M-07 of 0.15d and is still below the

allowable settlement tolerance limit for pile

foundations of 25.4 mm (1 inch). If the continued

loading is higher than 2.994 tons for 2 piles, then the

highest actual Q

u

(close to field conditions) can be

achieved when the pile settlement approaches the

ASTM limit value and the allowable tolerance limit

value for the pile foundation, this can be seen from

the slope of the curve in the graph (Fig. 10) which is

getting steeper and the pile settlement is still large as

the load increases.

ACKNOWLEDGEMENTS

We would like to offer the special thanks to the

Bengkalis State Polytechnic (P3M) for funding this

research activity.

REFERENCES

Fahriani, F & Apriyanti, Y (2015). Analisis Daya Dukung

Tanah dan Penurunan Pondasi Pada Daerah Pesisir

Pantai Utara Kabupaten Bangka, Fropil Universitas

Bangka Belitung, 3(2), 89–95.

Galang M, Ferry F dan Muhardi, 2017. Analisis kekuatan

daya dukung pondasi Helical menggunakan data sondir

pada tanah gambut, Jom FTEKNIK, Vol.4 No.1, 1-7

Hardiyatmo, HC. (2010) Analisis dan Perancangan Pondasi

bagian II. Yogyakarta: Gadjah Mada University Press.

Yusti, A & Fahriani, F (2014). Analisis Daya Dukung

Pondasi Tiang Pancang Diverifikasi dengan Hasil Uji

Pile Driving Analyzer Test dan Capwap, Fropil

Universitas Bangka Belitung, 2(1), 19–31.

Wrana B., 2015. Pile Load Capacity – Calculation Methods,

Studia Geotechnica et Mechanica, Vol.37 No.4, 83-93.

ASTM. 2013, Standard Test Methods for Deep Foundations

Under Static Axial Compressive Load. ASTM D

1143/D1143M-07

Eslami A, Mosdfeghi S, MolaAbasi H, and Eslami M, 2020.

Piezocone and Cone Penetration Test (CPTu and CPT)

Applications in foundation Engginering, Elsevier, 1

st

edition.

Pamungkas E T, Gardjito E, Winarto S, Azhari F M., 2021.

Meningkatkan daya dukung tanah dengan pondasi mini

pile pada Gedung PT. Maju Jaya Kecamatan Ngasem

Kab Kediri, JURMATEKS, Vol.4 No.1, 30-43.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

994