Performance of TEC Cooler Box using Water Cooling and Coolant

Luh Putu Ike Midiani

1a

, I Wayan Adi Subagia

1b

, Made Ery Arsana

1c

,

Augus Sahada Permana Putra

2

, Kadek Suata

2

and Okky Dwiyon Prasetyo

2

1

Bali State Polytechnic, Kampus Bukit Jimbaran, Badung, Bali 80361, Indonesia

2

Student of Refrigeration and Air Conditioning Engineering Study Program, Bali State Polytechnic,

Kampus Bukit, Jimbaran, Badung, Bali 80361, Indonesia

Keywords

:

Cooler Box, TEC, Performance, Water, Coolant.

Abstract

:

Research on cooler boxes using thermoelectrics has been widely carried out because of the advantages of

these coolers which are easy to carry and environmentally friendly. The cooler box in this study measures 750

x 400 x 400 mm, using two thermoelectrics measuring 4 x 4 mm. The cooler box material is polyurethane,

aluminum foil and plywood on the outside. The hot side of this cooler does not use fins and fans, but utilizes

water cooling and coolant. Data collection is carried out to find the performance of the cooler box. The

measurement data is the thermoelectric cold and hot side temperature data, the inside of the cooler box, the

load and the environment. The performance of the water cooler and coolant will be compared to the

performance of the cooler with air cooling. The room temperature that can be achieved by the cooler when

using water and coolant as a cooler is 21.5°C and 19.9°C, respectively. And their respective performances are

0.41 and 0.31 for water and coolant.

1

INTRODUCTION

Research on thermoelectric coolers (TECs) is

growing rapidly to date, because TECs are a

promising future in other refrigeration applications.

TEC is the most desirable alternative cooling

technology and is possible to be developed because it

is able to control temperature precisely in various

applications and is able to overcome problems in size,

weight, performance, noise and environment. TEC

has the advantages of small size, silent operation,

limited maintenance requirements, long life, no use of

flammable or toxic refrigerants, possibility of use in

various positions and flexibility of use through

optimized control (Patel, 2016), (Atta, 2018) and

(Enescu, 2018).

TEC applications have been applied in various

fields such as electronic cooling, laser diodes,

superconducting systems, food industry, medical

equipment, military, biotechnology,

telecommunications and HVAC for specific targets.

______________________________________________________

a

https://orcid.org/0000-0002-2256-6035

b

https://orcid.org/0000-0001-9261-3549

c

https://orcid.org/0000-0002-6647-6621

For cooling small volumes of applications TEC is an

alternative, where cooling requirements are not too

high and low COP is not a real disadvantage.

Commonly, the hot side of thermoelectric cooled

by fan, in this study the thermoelectric hot side cooled

by water and coolant. The purpose of this research is

to explain the design of thermoelectric based cooler

box, to get thermal performance and effectiveness.

2

METHODOLOGY

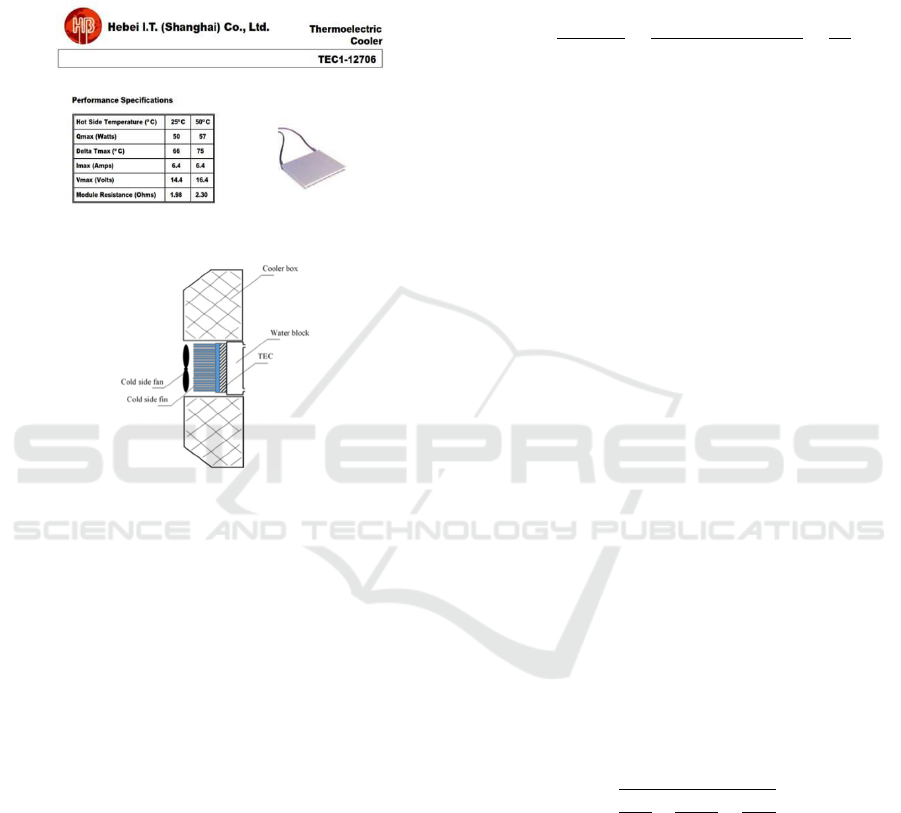

2.1 Cooler Box Construction

This cooler box has dimensions 750 x 400 x 400 mm.

Cooling box material consists of polyurethane coated

aluminum foil and plywood. The thermoelectric used

is TEC1 12706 with a size of 4 x 4 mm as many as 2

pieces, with specifications as shown in Figure 1

(Hebei 2010).

The heat dissipation process uses forced

convection on the cold side of TEC, aluminum fins

and fans and water blocks to cool the hot side of TEC.

The water block will be filled with water for the first

test and then filled with coolant. The schematic

Midiani, L., Subagia, I., Arsana, M., Putra, A., Suata, K. and Prasetyo, O.

Performance of TEC Cooler Box using Water Cooling and Coolant.

DOI: 10.5220/0010958100003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1019-1022

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1019

diagram of the cooler box test can be seen in Figure

2.

In this test the TEC working voltage and current are

measured using a multimeter. The temperature of

the

cooler and the room was measured with the NI

9714 data acquisition instrument and the NI 9213

module.

Figure 1: Specification of TEC1-12706.

Figure 2: Cooler box test schematic diagram.

Based on the purpose of this cooler box testing,

the first test was carried out in two test groups,

namely testing the cooler with water cooling and

coolant. The working voltage and current provided

are the same, namely 12V and 6A.

2.2 COP Analyzing

2.2.1 TEC

TEC performance can be analyzed by finding the

amount of heat absorbed on the cold side of the

thermoelectric (Qc) and the amount of heat dissipated

on the hot side of the thermoelectric. The amount of

heat absorbed and the amount of heat dissipated (Qh),

is expressed by the following formulas

(Jugsujinda,2011):

=

− 0.5

2

−

(

ℎ

−

)

(1)

ℎ

=

ℎ

+ 0.5

2

−

(

ℎ

−

)

(2)

Where α is Seebeck coefficient (VK

-1

), Tc and Th

are temperature of cold side and hot side of

thermoelectric, respectively. By comparing the

amount of heat absorbed to the difference between the

amount of heat wasted and the amount of heat

absorbed, TEC performance is expressed as follows

(Zhao, 2014):

=

−

=

(

−

)

+

=

(3)

Based on the TEC specifications, the Seebeck

coefficient (α) = 0.0425 VK

-1

and the thermal

conductivity of the thermoelectric material (K

t

) =

0.495 Wm

-1

K

-1

.

2.2.2 COP of Cooler Box

In this test the total power consumption of the

cooler box must take into account the power

consumption of the cold side fan, because the power

consumption of the cooling side fan will turn into hot.

This can be used as the main basis for determining the

optimal operating conditions of this cooler. The

calculation is as follows (Cengel, 1998) and

(Mirmanto, 2009):

=

+

+

(4)

=

∆

(5)

=

∆

(6)

=

+

(7)

where Q

l

is heat load, Q

t

is transmisi load, A is the

total heat transfer surface of cooler box, U is the

overall heat transfer coefficient. The overall heat

transfer coefficient is calculated below:

=

1

1

ℎ

+

1

+

1

ℎ

(8)

3

RESULT AND DISCUSSION

The cooler box temperature phenomenon is shown in

Figures 3 and 4. Temperature denoted by T

1

-T

6

, T

c

,

T

h

, T

L

, T

E

represent the temperature of cooler box,

thermoelectric cold side, thermoelectric hot side,

cooled load, and environment, respectively.

The T

L

, decreases from 0 to 355s, and then it gets

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1020

nearly constant. The same phenomenon also found by

previous researchers that used a fan as a

thermoelectric hot side cooler (Jugsujinda, 2011) and

(Mirmanto, 2009).

Based on Figure 5, the COP obtained by the cooler

for cooling the hot side of the thermoelectric using

water and coolant are 0.38 and 0.29, respectively. The

COP obtained is still within the standard COP

thermoelectric.

After one hour, cooling water on the hot side of

the thermoelectric obtained T

c

, T

h

, T

L

and COP of 26

o

C, 31

o

C and 25.4

o

C and 0.49, respectively. Cooling

with coolant on the hot side of the thermoelectric

obtained T

c

, T

h

, T

L

and COP of 25.5

o

C, 31

o

C and

25.4

o

C and 0.48, respectively.

Finally, obtained COP 0.38 with water cooling

when T

c

, T

h

, and T

L

are 22.1

o

C, 39.3

o

C and 21.5

o

C,

respectively. The COP of cooling with coolant on the

hot side of the thermoelectric is 0.29 with T

c

, T

h

, T

L

and COP of 16.9

o

C, 44

o

C and 19.9

o

C, respectively.

Figure 3: Temperature versus time trend with water

cooling.

Figure 4: Temperature versus time trend with coolant.

Figure 5: COP for cooling by water and coolant.

4

CONCLUSIONS

TEC cooling with water and coolant has similar

temperature trend as cooling using fan. The cooling

capacity decreases with the time. The conduction

heat

transfer rate increases with the time. The total

heat

transfer rate (Q) decreases with the observation

time.

The COP of the TEC cooler box is still within

the

allowed COP TEC, which is 0.3 It is necessary

to

regulate the flow of water and coolant in order to

get

better cooling.

ACKNOWLEDGEMENTS

The author would like to acknowledgements the Bali

State Polytechnic for funding this research through

the Penelitian Unggulan Dana DIPA PNB 2021

scheme with contract number 888/PL8/PG/2021.

REFERENCES

J. Patel, M. Patel, J. Patel, and H. Modi. (2016).

Improvement in the COP of Thermoelectric

Cooler.

International journal of scientific & technology

research, vol. 5, pp. 73-76.

R. M. Atta. (2018). Thermoelectric Cooling. in

Bringing Thermoelectricity into Reality, ed:

IntechOpen, , pp. 247-267.

D. Enescu. (2018). Thermoelctric refrigeration

principle.

Patricia Aranguren P, editor.

Bringing

Thermoelectricity into Reality,

INTECH Publishing,

pp. 221-246.

I. Hebei. (2010) . Co., Ltd., Peltier Thermoelectric

Cooling Modules. Online: http://www.

hebeiltd. com.

cn.

Performance of TEC Cooler Box using Water Cooling and Coolant

1021

S. Jugsujinda, A. Vora-ud, and T. Seetawan. (2011) .

Analyzing of thermoelectric refrigerator

performance.

Procedia Engineering, vol. 8,

pp. 154-159.

D. Zhao and G. Tan. (2014) . A review of

thermoelectric

cooling: materials, modeling

and applications.

Applied Thermal

Engineering, vol. 66, pp. 15-24.

Y. A. Cengel, S. Klein, and W. Beckman. (1998) .

Heat

transfer: a practical approach vol.

141: McGraw-Hill

New York.

M. Mirmanto, S. Syahrul, and Y. Wirdan. (2019) .

Experimental performances of a

thermoelectric

cooler box with

thermoelectric position variations.

Engineering Science and Technology, an

International Journal, vol. 22, pp. 177-184.

APPENDIX

Q

c

= heat absorbed on the cold side

Q

h

= heat dissipated on the hot side

Tc = temperature of cold side thermoelectric

Th = temperature of hot side thermoelectric

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1022