SCADA Dynamic Application Design Equipped with Multi

Connections

Agus Khumaidi

1

, M. Basuki R.

1

, Hananta Adhi R.

1

, R. Y. Adhitya

1

, Jossianto Eko P.

1

,

Arie Indartono

2

and P. N. A. Nugroho

2

1

Department of Marine Elctrical Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

2

Department of Marine Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

joessianto@ppns.ac.id, arie.indartono@ppns.ac.id

Keywords: Dynamic Applications, Modbus, IoT, GUI, MQTT, SCADA.

Abstract: Advances in information technology have been widely implemented in the field of industry 4.0. In its

development, the role of the automation system becomes very important. The use of automation and data

monitoring in the industry aims to help and improve the effectiveness of human work. The need for software

that is easy, and can be used on many communication protocols is very high due to the need for supervision,

control systems, and data acquisition in the industry. The output of this research is producing Graphical User

Interface (GUI) of SCADA software which is equipped with various features, and we called it SCATO

(SCADA Teknik Otomasi). In addition, a GUI is needed to display data and configure a multi-connection

network between hardware and software to make it easier for users to monitor, control systems, and data

acquisition in the industry. The use of Modbus TCP/IP, Modbus RTU, and MQTT communication protocol

as the input protocol have an average accuracy rate of 100%. MQTT prioritizes data efficiency and it has a

small size that is able to support IoT (Internet of Things) systems and its appropriate to be implemented in

industrial plans for remote monitoring. Database purposes are using MySQL, Firebase, and CSV files as input

with an average data reading speed of 0.51 seconds. In addition, there is a Graphical User Interface for

designing HMI which can be used as an interface to support systems in industry or as modules or teaching

materials, especially in the field of Automation Engineering.

1 INTRODUCTION

Advances in information technology have been widely

implemented in the industrial world. The use of

automation control systems in industry aims to help

and improve the effectiveness of human work. Today

we are in the middle of the industry 4.0 period where

the number 4.0 indicates the Industrial Revolution

which has entered the 4th wave. The characteristics of

the model from Industry 4.0 are a combination of

several of the latest technological developments which

include information and communication technology,

communication networks, big data, and cloud

computing as well as equipment developed to facilitate

human interaction with computers (Karacay, 2018).

All aspects of industrial computing can communicate

with each other by utilizing communication protocols,

one of which is Modbus. Communication Protocol is a

language to communicate with each other between

hardware, and software. Modbus is a two-serial

communication protocol method, where

communication can occur with the Modbus master and

Modbus slave systems (Wenzhu You, 2019). Modbus

can be transmitted via serial communication (Modbus

RTU), via Ethernet communication (Modbus TCP/IP),

via ASCII (Modbus ASCII), and Modbus Plus.

Modbus RTU is also equipped with a cyclic

redundancy error (CRC) mechanism that functions to

reduce errors and ensure data reliability. In practice,

Modbus supports many modems and gateways to work

(Chandra, 2016).

2 METHODOLOGY

2.1 Research Flow

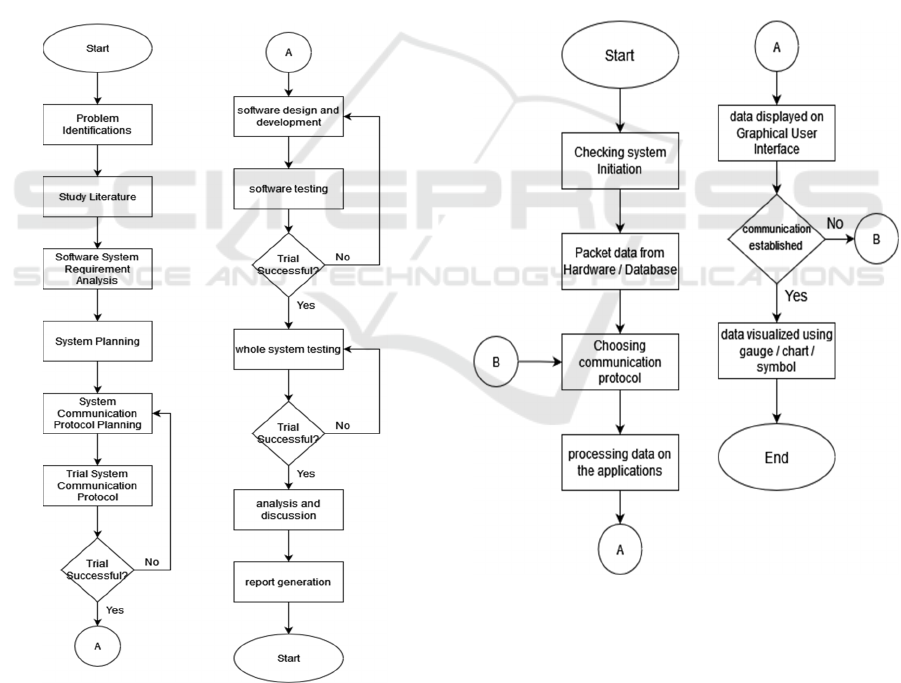

The initial system design was made in the form of a

flow chart as shown in Figure 1. Based on the

Khumaidi, A., R., M., R., H., Adhitya, R., P., J., Indartono, A. and Nugroho, P.

SCADA Dynamic Application Design Equipped with Multi Connections.

DOI: 10.5220/0010958500003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1039-1044

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1039

flowchart diagram, the design of the system is a guide

in the design of the system framework and software.

To ensure that the entire system that has been

designed runs as expected, system testing is carried

out. After the system testing is successful, the next

stage is making a report book.

2.2 Identification of Problems

In this system, the problem raised is an effort to in

order to be able to design dynamic applications with

multiple connections as well as a graphical user

interface to create Human Machine Interface (HMI).

Based on Graphical User Interface (GUI) with efforts

to apply Modbus TCP/IP protocols, Modbus RTU

and MQTT for module data communication with

applications and integrating MySQL, Firebase, and

CSV databases for data transactions from server to

application.

Figure 1: Research Flowchart.

2.3 Study of Literature

At this stage, the authors seek as much information as

possible about the concepts that will be used in the

study. The search was carried out related to

information about the Modbus Communication

Protocol (Kelong Wang, 2014), MQTT (Atmoko &

Yang, 2018), and MySQL as a Database (Gorskis,

2018) (Fahmi, 2013) (Subiyanto, 2015).

2.4 System Planning

The dynamic application system is running on the

ASP .NET MVC framework. Supported by Modbus,

MQTT connectivity, and several DBMS for data

transactions, including MySQL, Firebase, and CSV.

presentation of data on objects such as gauges or

charts is done by linking variable names on the tag

manager. The system flowchart in this study is shown

in Figure 2.

2.5 Object Oriented Programming

Figure 2: System Flowchart.

In these dynamic applications, the system uses the

Object-Oriented Programming as the basis for the

preparation of the program structure. The steps taken

to detect objects are as shown in Figure 3.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1040

Figure 3: Object Oriented Programming.

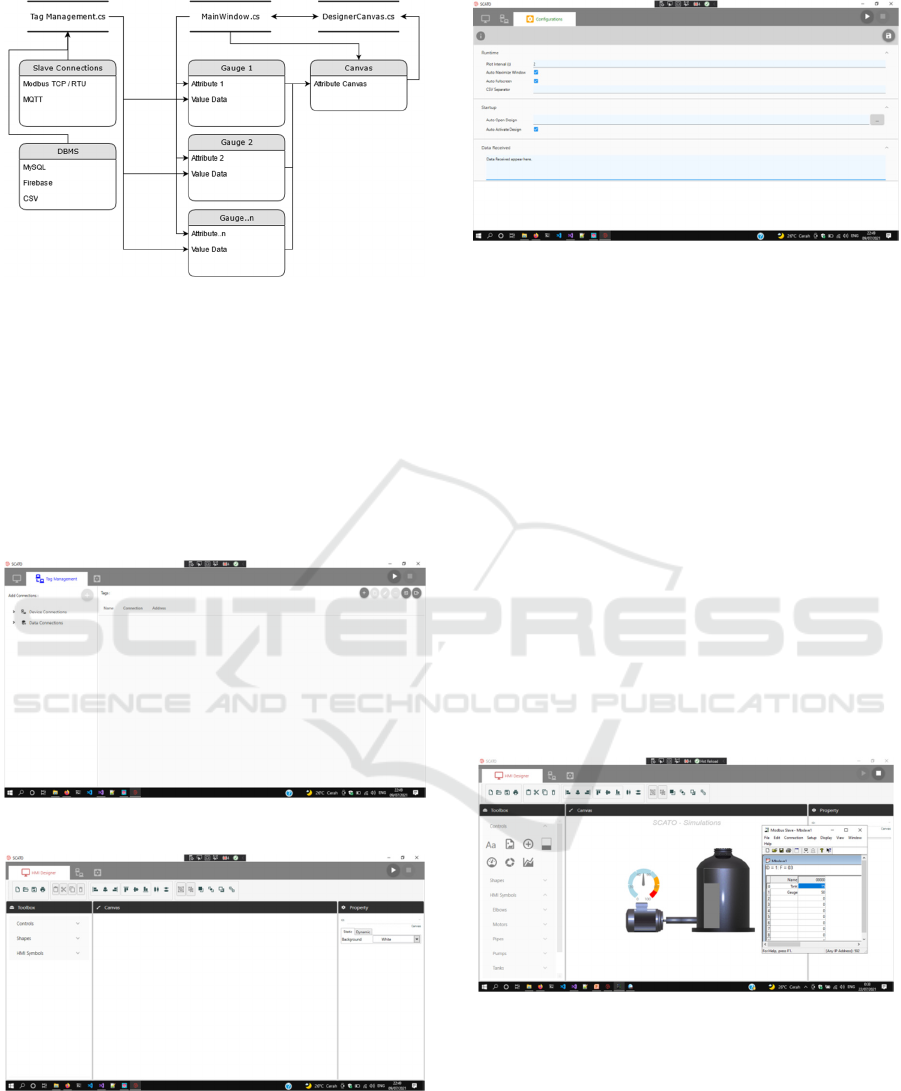

2.6 Software Design

The SCATO application has three workspaces,

including:

1. The Tag Management tab.

2. Graphic Designer thickness and design applied

3. Configurations

where each workspace tab has a different function as

shown in Figures 4, 5, and 6.

Figure 4: Tag Management Of SCATO.

Figure 5: Worksheet Of SCATO.

Figure 6: Configuration Tab Of SCATO.

3 RESULT

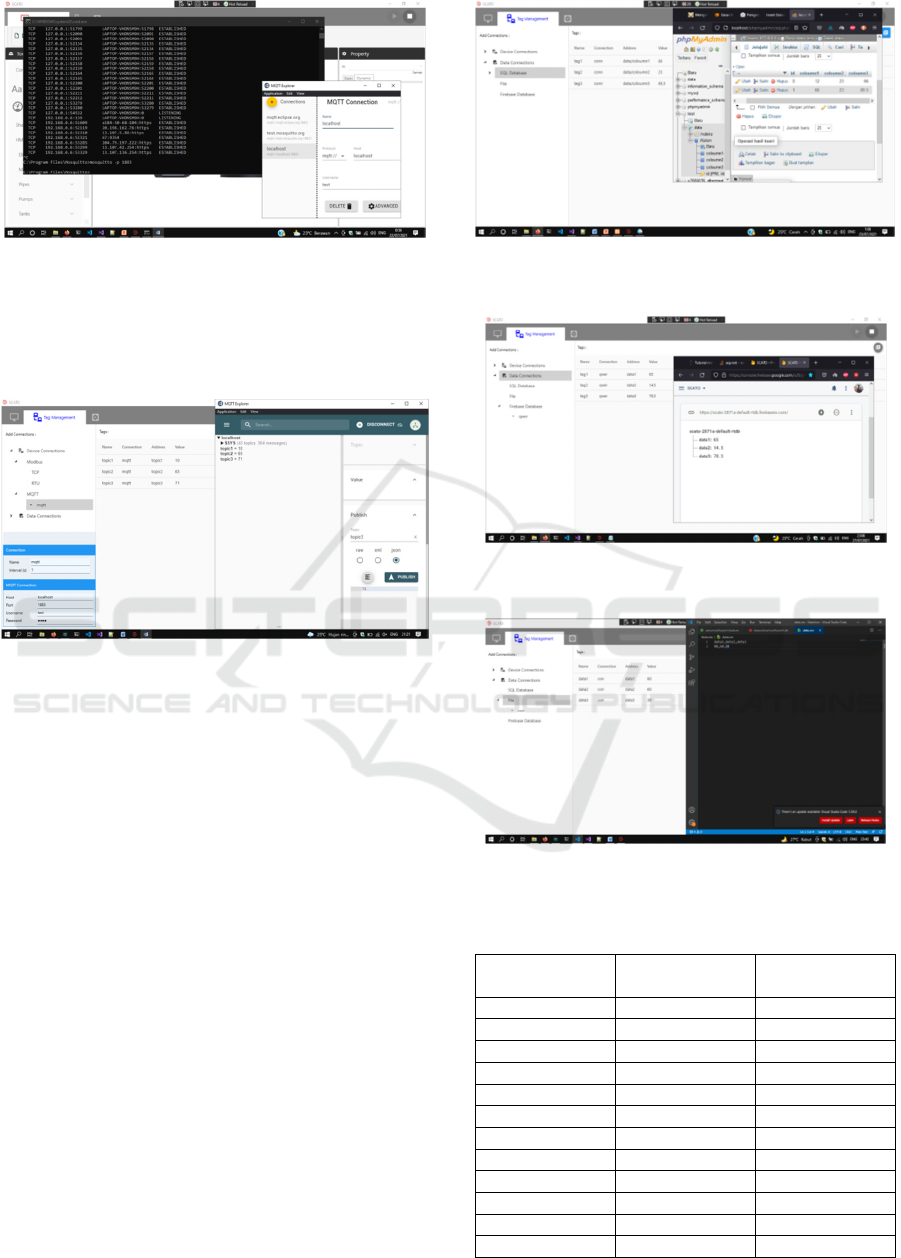

3.1 Modbus Protocol Communications

SCATO dynamic applications use several Modbus

communications protocols, including Modbus TCP/IP

and Modbus RTU interface. In order to communicate

with each other, data is organized using a registry

number for each Modbus communication. Every

device or device that is connected to each other using

Modbus requires Modbus access as a communication

protocol that corresponds to each registry number on

Modbus access. on Modbus TCP, the parameters used

are IP Address, and also on another side, the

parameters of Modbus RTU that have been used are

serial port and baud rate. The successful connection

that has been made using Modbus protocol

communications can be seen in Figure 7.

Figure 7: Modbus Protocol.

3.2 MQTT Protocol Communications

The MQTT work system uses the Publish and

Subscribe data method. In its application, the SCATO

software will connect to a broker and have a certain

topic, which in this case study the broker used is

’mosquitto’ with local configurations and the help of

the MQTT Explorer application as an interface.

Figure 8 shows MQTT Explorer.

SCADA Dynamic Application Design Equipped with Multi Connections

1041

Figure 8: Mosquitto and MQTT Explorer.

After setting up the configurations of MQTT, the data

received will be automatically separated and

described based on the subscribed topic. How to set

up the configuration can be shown in figure 9

.

Figure 9: MQTT Protocol.

3.3 Database Management System

Some of the databases supported by SCATO include

MySQL, Firebase, and CSV files with int, float,

double, and Boolean data types. The data will be

received and parsed based on each column in the

database table automatically. Communication with

the database can be made with the help of a connector

in the form of a library framework such as SQL

Connections and Fire sharp which are available in the

NuGet Library Package. The explanation of Database

Connection Protocol is shown in Figures 10,11 and

12 sequentially.

3.4 Connection Test Established of

SCATO and Controller

In the following communication test, SCATO uses

variables to test the connection between the hardware

and the SCATO application. In this Communication

Test to prove the success of the connection that has

been made where the results can be seen in Tables 1,

2, and 3 sequentially.

Figure 10: Database Connection Between SCATO and

phpmysql.

Figure 11: Database Connection Between SCATO and

Firebase.

Figure 12: Database Connection Between SCATO and

CSV.

Table 1:

Modbus TCP Communication Test.

Variable

Input Data

SCATO

READING

Data1 28 28

Data2 60 60

Data3

0 0

Data1 28 28

Data2 60 60

Data3

0 0

Data1 29 29

Data2 60 60

Data3

1 1

Data1 28 28

Data2 59 59

Data3

1 1

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1042

Table 2:

MQTT Communication Test.

Variable

Input Data

SCATO

READING

Topic1

28 28

Topic2

60 60

Topic3

0 0

Topic1

28 28

Topic2

60 60

Topic3

0 0

Topic1

29 29

Topic2

59 59

Topic3

0 0

Topic1

27 27

Topic2

59 59

Topic3

0 0

Topic1

29 29

Topic2

60 60

Topic3

0 0

Table 3:

Mysql Connection Test.

Variable Input Data

SCATO

READING

Ta

g

1 67 67

Ta

g

2 22 22

Ta

g

3 96,5 96,5

Ta

g

1 12 12

Ta

g

2 76 76

Ta

g

3 33,8 33,8

Ta

g

1 60 60

Ta

g

2 12 12

Ta

g

3 32,1 32,1

Ta

g

1 88 88

Ta

g

2 87 87

Ta

g

3 66,5 66,5

Ta

g

1 24 24

Ta

g

2 55 55

Ta

g

3 11,8 11,8

3.5 Connection Test Established of

SCATO and Database

The speed of data reading is very influential on

application performance where monitoring

applications must display data in real-time. the

smaller the latency or delay, the better for the

application to display data automatically. The results

of the reading test can be seen in Tables 4,5, 6 and 7.

Table 4:

Modbus TCP/RTU Read Speed Data.

TCP Rea

d

Variable Data Readin

g

Speed(s)

Data1 0,52

Data2 0,61

Data3 0,51

RTU Rea

d

Data1 0,61

Data2 0,58

Data3 0,64

Table 5:

MQTT Read Speed Data.

Variable Data Readin

g

Speed(s)

Topic1 0,56

Topic2 0,64

Topic3 0,47

Table 6:

Mysql Read Speed Data.

Variable Data Readin

g

Speed(s)

Ta

g

1 0,48

Ta

g

2 0,48

Ta

g

3 0,56

Table 7: Firebase/CSV Read Speed Data.

Firebase Rea

d

Variable Data Readin

g

Speed(s)

Data1 0,56

Data2 0,56

Data3 0,40

CSV Rea

d

Data1 0,42

Data2 0,56

Data3 0,62

4 CONCLUSIONS

Based on testing and system analysis that has been

done, the result of this research can be concluded that

1. Communication between Modbus TCP-IP and

Modbus RTU with the SCATO application

runs with a data reading accuracy rate of 100.

2. Communication between MQTT and the

SCATO application runs with a data reading

accuracy rate of 100.

3. Communication between MySQL, Firebase,

and CSV databases can run with a data reading

accuracy rate of 100

SCADA Dynamic Application Design Equipped with Multi Connections

1043

REFERENCES

Atmoko, R. A. & Yang, D., 2018. Online Monitoring &

Controlling Industrial Arm Robot Using MQTT

Protocol. Bandung, Indonesia, 2018 IEEE International

Conference on Robotics, Biomimetics, and Intelligent

Computational Systems (Robionetics ).

Chandra, S. D., 2016. Desain Dan Implementasi Protokol

Modbus Untuk Sistem Antrian Terintegrasi Pada

Pelayanan Surat Izin Mengemudi (SIM) Di Kepolisian

Resort. Undergraduate. Surabaya: Institut Teknologi

Sepuluh Nopember.

Fahmi, M., 2013. ntegrasi Sistem SCADA Web – DCS

Berbasis Networking PLC Dilengkapi Sistem Auto

Recovery Dan Auto Redundant Dengan Menggunakan

Multiple Communication Devices. Surabaya,

Proceeding Seminar Nasional Pendidikan Teknik

Elektro.

Gorskis, H., 2018. SQL query construction from database

concepts. Riga, Latvia, 2018 59th International

Scientific Conference on Information Technology and

Management Science of Riga Technical University

(ITMS).

Karacay, G., 2018. Talent Development for Industry 4.0.

s.l.:s.n.

Kelong Wang, D. P. L. S., 2014. Implementation of Modbus

Communication Protocol based on ARM Coretx-M0.

Shanghai, China, 2014 IEEE International Conference

on System Science and Engineering (ICSSE).

Subiyanto, L., 2015. MODUL AJAR KODE: A

PRAKTIKUM PROGRAMMABLE LOGIC

CONTROLLER. Surabaya: Politeknik Perkapalan

Negeri Surabaya.

Wenzhu You, H. G., 2019. Design and Implementation of

Modbus Protocol for Intelligent Building Security.

Xi'an, China, 2019 IEEE 19th International Conference

on Communication Technology (ICCT).

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1044