Synthesis and Characterization of Chitosan-Ssodium Alginate

Composite Membrance for Direct Methanol Fuel Cell (DMFC)

Application

Rif’ah Amalia, Firmansyah Adi Nugroho and Ivan Susanto

Department of Mechanical and Energy Engineering, Politeknik Elektronika Negeri Surabaya, Surabaya, Indonesia

Keywords:

Sysnthesis, Characterization, Methanol, Composite Membrane, Direct Methanol Fuel Cell.

Abstract:

Direct methanol fuel cell is one type of direct alcohol fuel cell, where methanol in liquid form

enters the

anode cell without going through reforming process. Methanol has the advantage of

being relatively

cheap and has high electrochemical activity. However, direct methanol fuel cells

have several

disadvantages, namely low efficiency (about 60%), slow methanol oxidation reaction

rate, the occurrence

of methanol cross over and also the price of the membrane used as an

electrolyte membrane in direct

methanol fuel cells. The procedure in this research are composite

membrane fabrication; characterization

and performance composite membrane are membrane

functional group analysis; morphology of

membrane analysis; density of membrane measurement;

methanol permeability measurement; swelling

membrane. The result from this research are based

on FTIR analysis, The entire membrane has amino and

carboxylic acid groups that are bonded to

each other and have hydrogen bonds; based on SEM analysis,

chitosan: sodium alginate membrane

has good pore performance; the density of the membrane increases as

the composition of sodium

alginate increases. The highest of membrane density is 1.3676 g/mL at 5:2

w/w; there is no

methanol crossover so that the membrane can answer the problems of conventional

Nafion®

membranes; Swelling methanol at 5:1 and 5:2 w/w have the same swelling value, which is 10;

Composite membrane from chitosan – sodium alginate can be used as as a substitute for the nafion

membrane

in DMFC.

1

INTRODUCTION

The increase in population and industrial growth

contributes to the increasing demand and demand for

energy. On the other hand, the availability of energy

sourced from fossil fuels such as coal, oil and natural

gas used in conventional power plants is decreasing

from time to time. This is an important challenge and

problem that will be faced by the world. New

renewable energy sources will answer energy

challenges and problems in order to meet future

energy needs. New renewable energy sources that can

be developed include wind, geothermal, biomass,

solar, tidal, hydropower, waves, hydrogen and fuel

cell energy.

Fuel cell is one of the promising power plants

because it has high efficiency, clean energy and low

environmental impact. The fuel cell system is

designed to consume hydrogen and oxygen directly

and produce products in the form of water, heat and

electricity. There is without fuel combustion from a

furnace or boiler turned to electrical energy, so it

cleanest and potential energy.

Fuel cell is an electrochemical cell that converts

the chemical energy in hydrogen and oxygen fuels

into electrical energy directly through a redox

reaction. Fuel cell have two electrodes, anode as

negative electrode and cathode as positive electrode.

Fuel such as hydrogen is placed at the anode cell and

oxygen at the cathode cell. The catalyst in the anode

cell releases hydrogen molecules into protons and

electrons. Electrons pass through an external circuit

to generate electricity, while protons migrate through

the electrolyte to the cathode, where protons react

with oxygen and electrons, producing heat and water.

The overall reaction have been done in the fuel cell in

following:

Anode

: H

2

→ 2H

+

+ 2e

-

Cathode

: O

2

+ 4H

+

+ 4e

-

→2H

2

O

1054

Amalia, R., Nugroho, F. and Susanto, I.

Synthesis and Characterization of Chitosan-Ssodium Alginate Composite Membrance for Direct Methanol Fuel Cell (DMFC) Application.

DOI: 10.5220/0010958900003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1054-1062

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

General reaction : 2H

2

+ O

2

→ 2H

2

O

Fuel cells can be applied portable in consumer

electronics, battery chargers, miniature toys, kits, and

gadgets; transportation application on auxiliary

power units, marine propulsion, stationary

application in distributed power generation,

combined heat and power, combined cooling, heat

and power, back up power supply, remote area power

supply.

Fuel cells can be classified based on operating

conditions, such as pressure, temperature, type of

electrode, catalyst, interconnection, and type of

electrolyte used. Based on the type of electrolyte, fuel

cells can be classified as follows (1) solid oxide fuel

cell with ceramic electrolyte; (2) carbonate fuel cell;

(3) proton exchange membrane fuel cell with its

electrolyte consisting of proton membrane; (4)

phosphoric acid fuel cell; (5) alkaline fuel cell with

alkaline electrolyte solution such as potassium

hydroxide, sodium hydroxide. The following details

the differences types of fuel cell:

Table 1: Types of Fuel Cell.

Different PEMF

C

AFC PAFC MCF

C

SOF

C

Electroly Hydrat Mobiliz Immobi Immo Perov

te

ed ed or lized bilize skites

Polyme Immobi Liquid d (Cera

ric Ion lized Phosph Liqui mics)

Exchan Potassi oric d

ge um Acid in Molte

Membr Hydrox SiC n

anes

ide in Carb

asbesto onate

s in

matrix

LiAl

O

2

Electrode

s

Carbon Transiti

on

metals

Carbon Nicke

l and

Nicke

l

Oxid

e

Perov

skite

and

perov

skite /

metal

cerme

t

Catalyst

Platinu

m

Platinu

m

Platinu

m

Electr

ode

mater

ial

Electr

ode

mater

ial

Interconn

ect

Carbon

or

metal

Metal Graphit

e

Stainl

ess

steel

or

Nicke

l,

ceram

Nicke

l

ic, or

steel

Operatin 40 – 80 65°C – 205 °C 650 600-

g °C 220 °C °C 1000

Temperat

°C

ure

Charge

Carrier

H

+

OH

-

H

+

CO

-

3

O

-

External

Reformer

for

hydrocar

bon

fuels

Yes Yes Yes

No,

for

some

fuels

No,

for

some

fuels

and

cell

desig

ns

External

shift

conversio

n

of CO to

hydrogen

Yes,

plus

purifica

tion to

remove

trace

CO

Yes,

plus

purifica

tion to

remove

CO

and

CO

2

Yes No No

Prime

Cell

Compone

nts

Carbon

-based

Carbon

-based

Graphit

e-based

Stainl

ess-

based

Cera

mic

Product

Water

Manage

ment

Evapor

ative

Evapor

ative

Evapor

ative

Gase

ous

Produ

ct

Gase

ous

Produ

ct

Product

Heat

Manage

ment

Process

Gas +

Liquid

Coolin

g

Mediu

m

Process

Gas +

Electrol

yte

Circula

tion

Process

Gas +

Liquid

cooling

mediu

m or

steam

generat

ion

Intern

al

Refor

ming

+

Proce

ss

Gas

Intern

al

Refor

ming

+

Proce

ss

Gas

Based on the type of electrolyte dan operation

temperature, fuel cell can be classified as follow : at

the high temperature fuell cell are molten carbonate

fuel cell and solid oxide fuel cell, and at the low

temperature are phosphoric acid fuel cell, polymer

electrolyte membrane fuel cell, alkaline fuel cell and

Synthesis and Characterization of Chitosan-Ssodium Alginate Composite Membrance for Direct Methanol Fuel Cell (DMFC) Application

1055

direct methanol fuel cell.

Direct methanol fuel cell is one type of direct

alcohol

fuel cell, where methanol in liquid form

enters the anode cell without going through

reforming process.

Direct methanol fuel cells are

widely applied in cell

phones, vehicles, laptops,

cameras, home appliances.

Methanol has the

advantage of being relatively cheap

and has high

electrochemical activity. However,

direct methanol

fuel cells have several disadvantages,

namely low

efficiency (about 60%), slow methanol

oxidation

reaction rate, the occurrence of methanol

cross

over and also the price of the membrane used as

an

electrolyte membrane in direct methanol fuel cells.

Nafion is a membrane that has a high proton

conductivity value, strong chemical stability and has

high mechanical strength. However, the Nafion

membrane can cause methanol cross over in direct

methanol fuel cells and cause environmental

pollution.

Nur Rokhati fabricated a chitosan – alginate

composite membrane for use in DMFC. The

fabricated membrane was then characterized. The

film characterization carried out included tests of:

permeability, degree of swelling, mechanics,

morphology (by SEM), and surface chemical

structure (by FTIR). The results showed that the

alginate film had a higher permeability and swelling

degree than the chitosan film. Both chitosan and

alginate give the phenomenon that the greater the

concentration of the solution, the smaller the

permeability value and the degree of swelling, with

the degree of swelling to water being the largest

followed by technical methanol (± 95%) and the

smallest being methanol PA (> 99, 9%). The

mechanical strength of chitosan film is greater than

that of alginate film. The alginate/chitosan composite

film made by layer by layer method provides better

characteristics than the composite film made by

mixing alginate solution and chitosan solution.

Romadhoni Anto conducted research on chitosan

and

sodium alginate composites. Composite

membranes

were produced with various

concentrations of

chitosan-sodium alginate. The

composites were

characterized by scanning electron

microscopy

(SEM), Fourier transform infrared

spectrophotometer

(FTIR). The FTIR spectrum

shows the NH3C group

at 1637.29 cm

-1

and the

COO group is symmetrical at 1253.68 cm

-1

which

shows the interaction between

chitosan and sodium

alginate. SEM micrographs

showed that the

composite membrane was non-

porous. The 3:5

chitosan-sodium alginate composite

membrane has

the highest proton conductivity is 9.594 × 10

-7

S/cm.

Based on the results of this study,

the chitosan-

sodium alginate composite membrane

can be

applied properly in the Direct Methanol Fuel

Cell

system.

Riki Siswanto conducted a research by

making a

chitosan-alginate composite membrane.

The results showed that there was an effect of

adding more

chitosan composition to the

membrane

characteristics. In physical properties,

the more

addition of chitosan composition causes

the

formation of smaller pore sizes. While the

mechanical

properties resulted in increased tensile

strength and

elongation values. The results of the

filtration test

resulted in a decrease in the flux value

to urea and an

increase in membrane rejection.

Chitosan alginate 4:1

(v/v) membrane has optimal

results and is better to be

used as a membrane

candidate in hemodialysis

applications. The pore

size formed is in the range of 29.14 – 105.1 nm.

Tensile value of chitosan:alginate membrane 4:1

(v/v) is 31.23 N/mm

2

and % elongation is 13.27%.

Then the value of the flux to urea is 0.03 ml.cm

-2

.menit

-1

and a membrane rejection is 60.87%.

(Eldin, 2017) conducted research on chitosan by

chemically cross linked it by activation with an

alginate biopolymer which has a low molecular

weight with various molar ratios. The results show

that the covalently cross linked CS/Alg-GA

membrane has low permeability with range methanol

2.179×10

-9

until 2.5×10

-10

cm

2

/s compared to nafion

membrane (1.14×10 cm

2

/s).

So, in this paper, the focus is on the use of low

cost, low methanol cross over and environmental

friendly membranes to overcome the weaknesses of

the Nafion membrane, but in terms of characteristics

and performance it has the same advantages and even

exceeds the Nafion membrane. The types of

membrane used in this study were chitosan and

alginate.

2

EXPERIMENTAL

2.1 Materials

Chitosan, sodium alginate, acetic acid glacial

(CH

3

COOH), tchloric acid, aquadest, methanol,

black platinum powder, platinum-ruthenium powder,

carbon paper, acrylic, syringe, oxygen cylinder,

printer hose, acrylic 3 and 5 mm.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1056

2.2 Method

2.2.1 Composite Membrane Fabrication

In this study, the variation of chitosan: sodium

alginate of 5:1, 5:2 (w/w). The process of making

chitosan – sodium alginate composite membrane

includes the following steps:

1.

Mixing chitosan: sodium alginate according

to

variation (5:1, 5:2 (w/w)) with 1% glacial

acetic

acid.

2.

Stirring using a hot plate magnetic stirrer for

30

minutes so that the solution becomes

homogeneous.

3.

Each homogeneous solution was allowed to

stand

for 1 night to wait for the entire reaction

to

become even.

4.

The solution that has been allowed to stand is

then

each added with 32% hydrochloric acid

(HCl)

with a volume of 1 mL HCl for every

100 mL of

solution volume, then stirred until

homogeneous.

After that, the two solutions

were mixed and

stirred for 1 hour using a hot

plate magnetic stirrer

and then stirred until

homogeneous. After that, the

two solutions

were mixed and stirred for 1 hour

using a hot

plate magnetic stirrer and then filtered

using

filter paper, so that the residue of the

mixture

could be eliminated.

5.

The homogeneous solution mixture was left for

1

night to remove air bubbles contained during

the

mixing process. The solution mixture is

placed in

the refrigerator so as not to spoil.

6.

The mixture that has been free of bubbles is

then

printed on the surface of the glass whose

edges

have been given foam double-sided

tape as a 2

mm thick mold barrier. Ensure that

the solution is

evenly distributed, so that the

resulting membrane

has an even thickness.

The membrane printing

process is carried out

in a room with good air

circulation without

conditioning the room

temperature and left to

dry evenly. If the

environmental conditions

support the drying

process, then the drying

can take place only in 1

night. After the mold

is dry, the membrane is

slowly removed from

the mold.

2.2.2 Characterization and Performance

Composite Membrane

a.

Membrane Functional Group Analysis.

Membrane functional groups analysis

using

Fourier transform infrared (FTIR)

spectroscopy.

b. Morphology of Membrane Analysis.

Surface

and cross-sectional morphology

transverse films

were observed using a

scanning electron

microscopy (SEM) with

10000X magnification.

c. Density of Membrane

1.

The steps for testing the density of composite

membranes can be broken down into the

following points:

2.

Cut the composite membrane with a uniform

size, which is 2 x 7 cm.

3.

Measure the empty weight of the pycnometer,

which is then recorded as W

0

.

4.

Measure the weight of the pycnometer with a

piece of composite membrane sample, which

is then recorded as W

1

.

5.

Measure the weight of the pycnometer filled

with water, and then record it as W

3

.

6.

Insert the composite membrane sample piece

into the pycnometer which has been filled with

water. In this measurement, you must first

make sure that there are no air bubbles in the

pycnometer. Then weigh the pycnometer

filled with water and the membrane which has

been confirmed that there are no air bubbles in

it

and the results are recorded as W

2

.

7.

For density data from air (ρa), take the

reference density, i.e 1.2 kg/m

3

, atau 0.0012

g/mL.

8.

Collecting water density data (ρ1) by utilizing

data on W

3

and W

0

, with the following

equation:

d.

Methanol Permeability

In this analysis, a vessel with a barrier is

required,

where a chitosan-sodium alginate

composite

membrane acts as a barrier. The

methodology is

described as follows:

1.

Prepare test vessels and samples of

fabricated chitosan – alginate composite

membranes that have been cut according

to

the size of the bulkhead of the vessel.

2.

Clamp the chitosan-alginate composite

membrane between the two sides of the

vessel and ensure that it is tight so that

no

methanol seeps out of the vessel

through the

gaps between the vessel and

the membrane

that may exist.

3.

One side of the vessel is filled with 50 mL

of

methanol, while the other side is left

Synthesis and Characterization of Chitosan-Ssodium Alginate Composite Membrance for Direct Methanol Fuel Cell (DMFC) Application

1057

empty.

After that, the vessel was

positioned upright,

with the composite

membrane as the base

from the side of

the methanol vessel.

4.

This test is carried out for one hour.

5.

Checking whether there is methanol

seeping

e.

Swelling Membrane

The swelling test requires an oven to dry the

fabricated composite membrane sample, a

balance to weigh the sample weight, a vessel as

a container to soak the sample in methanol, and

methanol. The testing methodology can be

described as follows:

1.

Each membrane is cut to the size of 5 x 2

cm.

2.

Put the sample into the oven and dried at

a

temperature of 125°C for 24 hours so that

the

water content evaporates.

3.

After the membrane is dry, weigh the

membrane using a balance to determine its

dry

weight (D).

4.

Soak the sample in methanol for 48 hours.

5.

After the immersion process is complete,

then

the surface of the sample is dried

using a

highly absorbent cloth or tissue so

that there is

no methanol remaining on the

surface of the

membrane.Setelah

permukaannya kering,

membran ditimbang

untuk mengetahui bobot

basahnya (W).

6.

The wet and dry weight data are then used

to

find the percentage of methanol

absorption

through the equation:

3

RESULT AND DISCUSSION

Membrane Functional Group Analysis

FTIR analysis was carried out to determine the

functional groups contained in the fabricated chitosan

– sodium alginate composite membrane. The FTIR

results are in the form of a spectrum that states the

functional groups contained in the sample which are

expressed by wave numbers. The classification of

specific functional groups based on the wave range

can be seen in table 2 below:

Table 2: Specific groups and wavelength ranges of FTIR.

Compound Functional

Group

Absorption Area (cm

-1

)

Alkana C-H 2850-2960, 1350-

1470

Alkena C-H 3020-3080, 675-870

C=C 1640-1680

Alkuna C-H 3300

Aromatik C-H 3000-3100, 675-870

C=C 1500-1600

Alcohol,

eter,

carboxylic

acid, eter

C-O 1080-1300

Aldehida,

keton,

C=O 1690-1760

carboxylic

acid, ester

Alcohol,

phenol

(monomer)

O-H 3610-3640

Alcohol,

phenol (bond

of H)

O-H 2000-3600 (length)

Carboxyl

ic acid

O-H 3000-3600 (length)

Amine N-H 3310-3500

C-N 1180-1360

Nitro

NO

2

1515-1560, 1345-

1386

The FTIR spectrum on the chitosan – sodium

alginate composite membrane with a variation of

the ratio 5/1 (w/w), based on Fig.1 which refers to

table 2 shows the C – N functional group (amino

acids) at wave numbers 1739.39 cm

-1

(x

1

) and group

C – O – O (carboxylic acid) on wave number

1216.77 cm

-1

(x

2

). The two spectra indicate that

there is an electrostatic interaction of the

carboxylate group of sodium alginate with the

protonated amino group of chitosan which indicates

that the composite membrane produced is

homogeneously mixed. At wavenumber 3442.52

cm

-1

, there is an OH group (x3). The presence of the

OH group is expected to increase the strength of the

intermolecular interactions of the fabricated

composite membrane, for example hydrogen bonds

between chitosan and sodium alginate.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1058

Figure 1: FTIR spectrum of chitosan - sodium alginate

composite membrane 5/1 (b/b).

The FTIR spectrum on the chitosan – sodium algia

composite membrane with a variation of the ratio 5/2

(w/w), based on Fig.2 which refers to table 2 shows

the C – N functional group (amino acids) at wave

numbers 1739.25 cm

-1

(x

1

) and group C – O – O

(carboxylic acid) on wavenumber 1216.77 cm

-1

(x

2

).

The two spectra indicate that there is an electrostatic

interaction of the carboxylate group of sodium

alginate with the protonated amino group of chitosan

which indicates that the composite membrane

produced is homogeneously mixed. At wavenumber

3396.74 cm

-1

, there is an OH group (x

2

). The presence

of this OH group produces a more drastic peak than

the 5/1 variation, so it is expected to increase the

strength of intermolecular interactions of the

fabricated composite membrane, for example

hydrogen bonds between chitosan and sodium

alginate.

Figure 2: FTIR spectrum of chitosan - sodium alginate

composite membrane 5/2 (b/b).

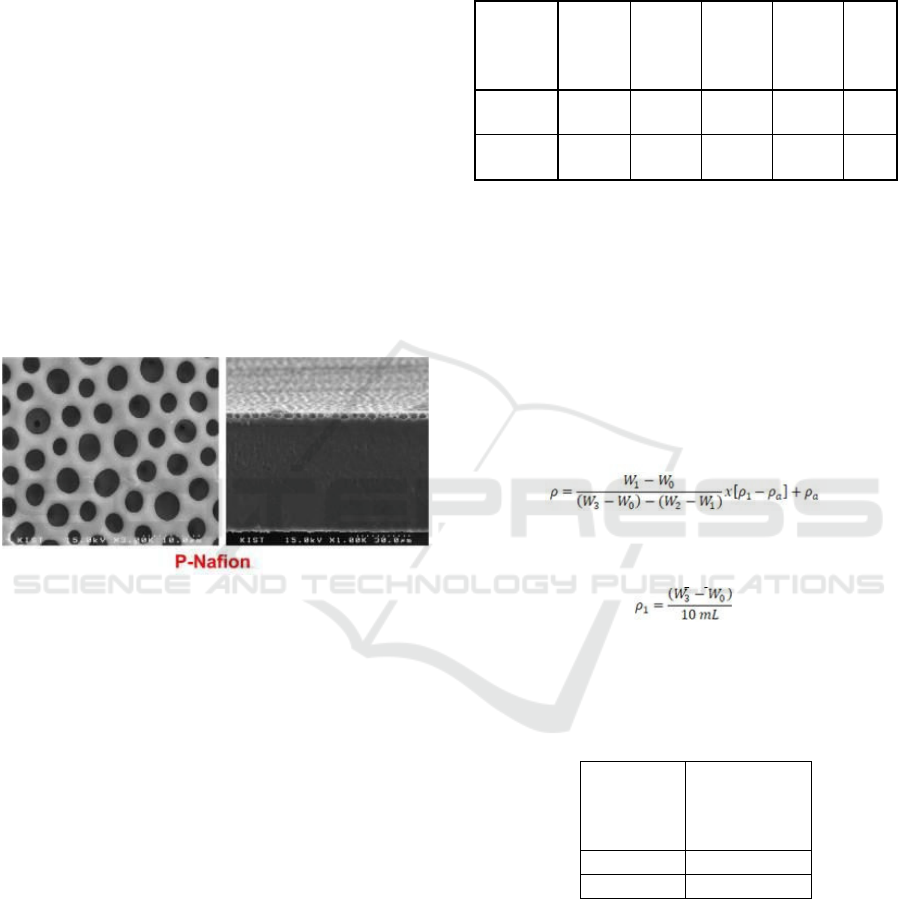

Morphology of Membrane

SEM characterization was carried out with a

magnification of 2000 times, where the results for

each variation showed a tendency for the chitosan –

sodium alginate composite membrane to have no

pores (non-porous).

Figure 3: SEM morphology on composite membrane

samples with a ratio of 5/1 (w/w) with a

magnification of

2000x.

In the variation of chitosan – sodium alginate

5/1

(w/w), it was found that there were quite a

number of pores formed on the surface of the

chitosan – sodium alginate composite membrane.

However, even though there are pores formed, the

number is not too large, so the membranes produced

from the variation in the ratio of 5/1 tend to have no

pores. This indicates that the solution of chitosan

and sodium alginate has been homogeneous. From

the morphological results, the chitosan – sodium

alginate composite membrane with a variation of

5/1 (w/w) has good potential to be applied in

DMFC.

Figure 4: SEM morphology on composite membrane

samples with a ratio of 5/2 (w/w) with a

magnification of

2000x.

The results of SEM morphology on the chitosan –

sodium alginate composite membrane variation 5/2

(w/w) showed that the number of pores formed was

decreasing. The decrease in the pores formed on the

composite membrane is due to the increased

Synthesis and Characterization of Chitosan-Ssodium Alginate Composite Membrance for Direct Methanol Fuel Cell (DMFC) Application

1059

composition of sodium alginate, thus closing the

pores that may be formed from chitosan. The decrease

in the pores formed also indicates that the chitosan

and sodium alginate solutions are mixed until

homogeneous.

From the results of the SEM analysis of the chitosan

– sodium alginate 5/2 (w/w) composite membrane, it

shows that the membrane has the potential to be used

as a replacement composite membrane in DMFC

applications, because the tendency of the presence of

pores on the membrane is only slightly.

Figs 1 and 2 show that the entire composite

membrane fabricated has the potential to be applied

to the DMFC and become an alternative choice for

the Nafion® membrane. The absence of pores formed

allows the chitosan – sodium alginate composite

membrane to be more resistant to methanol, so that

methanol crossover can be minimized.

For comparison, the SEM morphology results from

Nafion® (Dang, 2014) are listed below.

Figure 5: Nafion® membrane morphology with 1000x.

magnification.

From the morphology, it can be seen that Nafion®

211 has pores all over its surface. These pores cause

Nafion® 211 to easily undergo methanol crossover,

which has an impact on decreasing DMFC

performance because Nafion® 211 has pores that can

be occupied by methanol, and can even be passed as

a transport medium for methanol across from the

anode to the cathode.

Density of Membrane

From the results of density testing using a

pycnometer, the results are shown in table 3 below:

Table 3: Data on the weight of the pycnometer (W

0

), the

empty pycnometer and the membrane sample (W

1

), the

weight of the sample in a pycnometer filled with water

(W

2

), the weight of the pycnometer with water (W

3

) and

the density of water (ρ1).

Chitosan:

Sodium

Alginate

(w/w)

W

0

(g)

W

1

(g)

W

2

(g)

W

3

(g)

ρ

1

(g/m

L)

5:1 10,99 11,07 21,22 21,21

1,02

2

5:2 10,95 11,07 21,24 21,21

1,02

6

Where:

W

0

= Weight of the pycnometer (grams)

W

1

= Weight of pycnometer and sample (grams)

W

2

= Weight of pycnometer and sample filled with

water (grams)

W

3

= Weight of the pycnometer filled with water

(grams)

ρ

1

= Density of water (gram/mL)

The membrane density in each variation was

evaluated through the following equation:

The value of water density (ρ1) is obtained through

the following equation:

And the results of the evaluation of these

equations

can be seen in table 4. below:

Table 4: The results of the

calculation of the sample

density for each variation.

Chitosan:

Sodium

Alginate

(w/w)

ρ (g/mL)

5:1 1,167829

5:2 1,3676

The density value obtained can be seen through

the graph in Fig.6 below:

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1060

Figure 6: Comparison of the density of the chitosan –

sodium

alginate composite membrane fabricated for each

variation.

The addition of sodium alginate will improve

the

cross-linked structure of the chitosan in the gel so

that

it becomes stiffer and the gel will be stronger.

Because sodium alginate has the property of

absorbing water, the addition of sodium alginate will

decrease the breaking point of the gel, which means

that the strength of the gel will increase. The

increasing gel strength of this membrane has an

impact on increasing the density of the chitosan-

alginate composite membrane.

Because the strength of the membrane

increases,

then when viewed from the calculation

results, the

membrane density from the smallest to

the largest is

a variation of 5:1 with the result

1.167829 g/mL; 5:2

with the result 1.3676 g/mL.

Permeability of Membrane

From the membrane permeability test, the following

results were obtained:

Table 5: Membrane permeability analysis.

Chitosan:

Sodium

Alginate

(w/w)

Membrane permeability

5:1 No

5:2 No

From the test results, there is no methanol

crossover, namely the crossing of methanol to the side

of an empty vessel through or through the membrane.

The sides of the membrane in empty vessels in all

variations remained dry when wiped with a tissue,

after each test was carried out for 1 hour. This is an

indication that the chitosan – alginate composite

membrane can be used as an alternative proton

transfer membrane to replace Nafion® in DMFC,

because it is able to hold methanol, so it can solve the

problem of methanol cross over.

Methanol crossover is the event of

displacement of methanol particles from the anode

(high methanol concentration) to the cathode (low to

zero methanol concentration) and is caused because

the proton transfer membrane is unable to hold

methanol. The methanol crossover event will reduce

the performance of the DMFC because the resulting

potential difference will decrease. The underlying

reason for the methanol crossover is that there are

differences in the concentration of methanol on the

anode and cathode sides, where on the anode side the

concentration of methanol is high, and there is no

concentration of methanol at the anode. high

concentration towards the other side of lower

concentration.

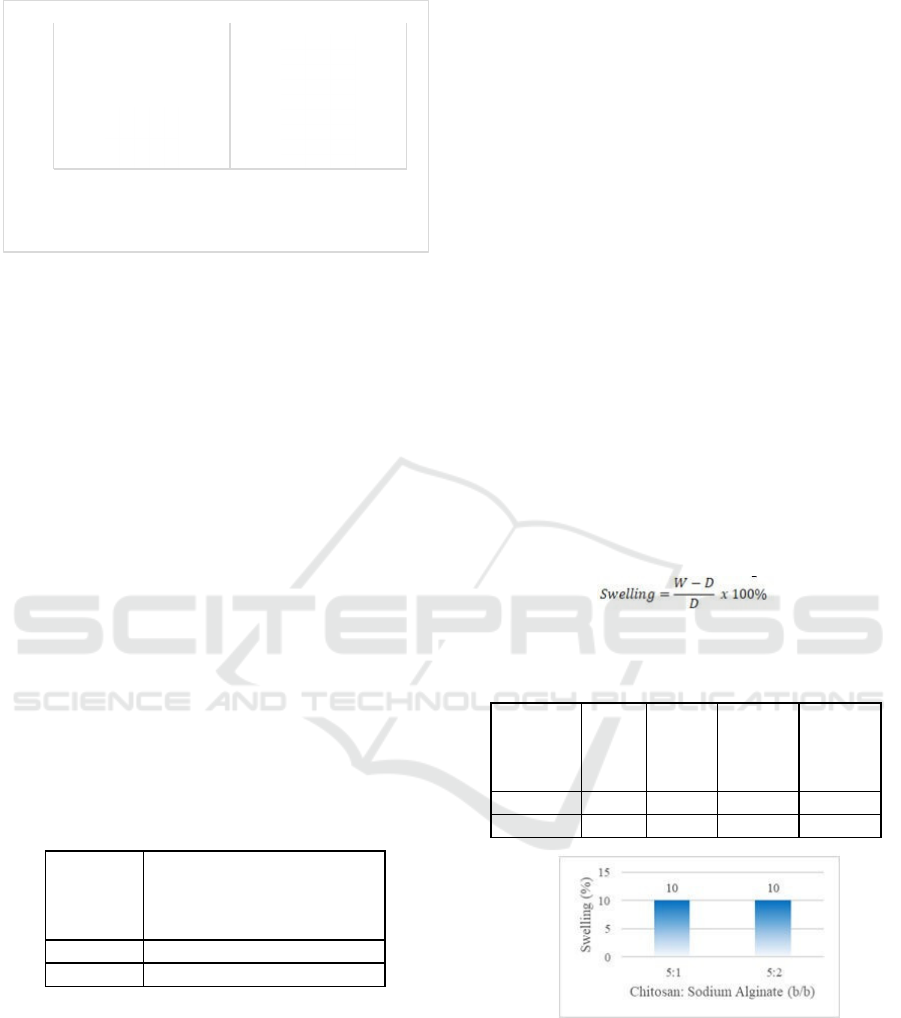

Composite Membrane Swelling Analysis

The swelling test requires uniform sample pieces

for

each variation, container, digital balance, oven,

and methanol. The dry weight of the membrane was

obtained after the sample was oven-baked for 24

hours at a temperature of 125°C. Then, the wet weight

was obtained after the membrane was soaked in

methanol for 48 hours. Swelling of methanol is

obtained through the following equation:

The results obtained can be seen in table 6 below:

Table 6: dDy sample data (D) and wet sample (W).

Chitosan:

Sodium

Alginate

(w/w)

D (g) W (g) swelling %

swelling

5:1 0,1 0,11 0,1 10

5:2 0,1 0,11 0,1 10

Figure 7: Swelling of fabricated chitosan-sodium alginate

composite membrane.

From the test results, it was found that the addition

of alginate concentration could increase the

membrane's ability to adsorb methanol. This is due to

the nature of sodium alginate which only has anionic

groups (hydroxyl and carboxyl) which causes the

molecular bonds between polymer chains to be less

dense, so that there is a larger space for liquid to

1,3676

1,167829

5:1 5:2

Chitosan : Sodium Alginate (w/w)

ρ

(

gram/mL

)

Synthesis and Characterization of Chitosan-Ssodium Alginate Composite Membrance for Direct Methanol Fuel Cell (DMFC) Application

1061

occupy which makes the membrane absorption large.

While the nature of chitosan, besides having a

cationic group that can form a strong and tight film, it

also has an acetyl group which is hydrophobic (does

not absorb water). So that the absorption of chitosan

is smaller than alginate.

Thus, in this paper, data were obtained that the

more concentration of sodium alginate in the

composition of a membrane, the higher the absorption

of methanol, which is because sodium alginate has a

higher absorption capacity than chitosan.

4

CONCLUSIONS

1. Based on FTIR analysis, The entire membrane

has

amino and carboxylic acid groups that are

bonded

to each other and have hydrogen bonds.

2. Based on SEM analysis, chitosan: sodium

alginate

membrane has good pore performance.

3. The density of the membrane increases as

the

composition of sodium alginate

increases.The

highest of membrane density is

1.3676 g/mL at

5:2 w/w.

4. There is no methanol crossover so that the

membrane can answer the problems of

conventional Nafion® membranes.

5. Swelling methanol at 5:1 and 5:2 w/w have

the

same swelling value, which is 10.

6. Composite biomembrane from chitosan –

sodium

alginate can be used as as a

substitute for the

nafion membrane in DMFC.

ACKNOWLEDGEMENTS

I am sincerely thankful to local research funding from

politeknik elektronika negeri surabaya for give me

funding to do this research.

REFERENCES

EG&G Technical Services, Inc, “Fuel Cell Handbook”,

Seventh Edition, U.S. Department of Energy Office of

Fossil Energy National Energy Technology Laboratory,

November 2004.

Peighambardoust, Seyed Jamaleddin & Rowshanzamir,

Soosan & Amjadi, M.. (2010). Review of the proton

exchange membranes for fuel cell applications.

International Journal of Hydrogen Energy. 35. 9349-

9384. 10.1016/j.ijhydene.2010.05.017.

Omar Z. Sharaf, Mehmet F. Orhan, An overview of fuel cell

technology: Fundamentals and applications,

Renewable and Sustainable Energy Reviews, Volume

32, 2014, Pages 810-853,ISSN 1364-0321,

https://doi.org/10.1016/j.rser.2014.01.012.

Shaari, Norazuwana & Kamarudin, S.K.. (2017).

Characterization studies of sodium alginate/sulfonated

graphene oxide based polymer electrolyte membrane

for direct methanol fuel cell. Malaysian Journal of

Analytical Science. 21. 113-118. 10.17576/mjas-2017-

2101-13.

N. Shaari, S.K. Kamarudin, Sodium alginate/alumina

composite biomembrane preparation and performance

in DMFC application, Polymer Testing, Volume 81,

2020, 106183,

ISSN

0142-9418,

https://doi.org/10.1016/j.polymertesting.2019.106183.

B.C. Ong, S.K. Kamarudin, S. Basri, Direct liquid fuel

cells: A review, International Journal of Hydrogen

Energy, Volume 42, Issue 15, 2017, Pages 10142-

10157, ISSN 0360-

3199, https://doi.org/10.1016/j.ijhydene.2017.01.117.

N. Rokhati, B. Pramudono, N. Widiasa, and H. Susanto,

"KARAKTERISASI FILM KOMPOSIT ALGINAT

DAN KITOSAN," Reaktor, vol. 14, no. 2, pp. 158-164,

Oct. 2012. https://doi.org/10.14710/reaktor.14.2.158-

164

Romadhoni Anto, Membran Komposit Kitosan-Natrium

Alginat untuk Aplikasi Direct Methanol Fuel Cell.

Bogor : Institut Pertanian Bogor, 2013.

Riki Siswanto, Jan Ady, Djoni Izak R., Sintesis dan

Karakterisasi Biokomposit Kitosan-Alginat Sebagai

Kandidat Membran pada Aplikasi Hemodialisa,

Surabaya : Universitas Airlangga.

Mohy Eldin, Mohamed & Hashem, A. & Tamer, Tamer &

Omer, Ahmed & Youssef, Mohamed Elsayed & Sabet,

Maysa. (2017). Development of Cross linked

Chitosan/Alginate Polyelectrolyte Proton Exchanger

Membranes for Fuel Cell Applications. International

journal of electrochemical science. 12. 3840 – 3858.

Dang, Q. K., Henkensmeier, D., Krishnan, N. N., Jang, J.

H., Kim, H. J., Nam, S. W., & Lim, T. H. (2014). Nafion

membranes with a porous surface. Journal of membrane

science, 460, 199-205.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1062