Characteristics of Flow Rate on the Performance of Pico Hydro

Turbine System as an Alternative Powerplant

Rusman

1

and Khairuddin Karim

2

1

Mechanical Engineering Department, Politeknik Negeri Samarinda, Samarinda Indonesia

2

Electrical Engineering Department, Politeknik Negeri Samarinda, Samarinda, Indonesia

Keywords: Turbine, Green Energy, Environmentally Friendly, Characteristic, Flow Rate.

Abstract: The essential functional boundaries of a streamlined pico-hydropower framework with an arrangement for

water reusing were explored. Five worked on the turbine of sprinter measurements 0.45, 0.40, 0.35, 0.30, and

0.25 m were planned, privately manufactured, and tried related to five PVC lines of measurements 0.0762,

0.0635, 0.0508, 0.0445, and 0.0381 m as penstocks. Five straight forward spouts of region proportions 1.0,

0.8, 0.6, 0.4 and 0.2 were created for every penstock width. The turbines were progressively mounted at the

foot of an overhead supply to such an extent that the powerful upward range from the power source of the

supply to the plane of the turbine shaft was 6.95 m. A 0,125 kW electric siphon was utilized to reuse the water

downstream of the turbine back to the overhead supply. The mean most extreme, what's more, least rotational

velocities of the shaft of every turbine were estimated for every penstock distance across and spout region

proportion, and the volumes of water dislodged in the repositories were too checked. This deliberate

information was utilized to process shaft force and framework volumetric stream rate for every activity.

Dimensionless stream, head and force coefficients, and explicit speed were registered, and functional

attributes were created. This standard technique by and large utilized for the examination of mathematically

comparable water-driven machines have been applied to this framework, and the outcomes got will be

priceless being developed of the framework into a straightforward, harmless to the ecosystem and tiny

decentralized force age framework that might contribute absolutely to the energy blend in Indonesian. The

chance of scaling the framework to oblige giant turbine and penstock measurements, and thus higher limit

alternators exist and is an objective for future turns of events.

1 INTRODUCTION

Although energy plays a significant role in a country's

economic development, access to power is minimal

in many developing countries due to a mix of factors

(Yah, 2017). Many functional energy supply systems

operate below-installed capacity in Indonesia and are

often vulnerable to limitations due to human and

natural causes. In addition, many of the designs are

large, centralized, and utilize energy resources that

have few adverse impacts on the environment. In

addition, some of the energy sources used are

depleting, so their sustainability is not guaranteed

(Edomah, 2016). Exploring and transporting new

deposits also adds to adverse environmental effects

such as oil spills while increasing friction in the host

community (Olusegum, 2010).

As a result, there is increasing interest and

demand for renewable energy sources and more

intelligent, smaller, and more decentralized energy

systems that will make more efficient use of these

renewable and conventional sources. This system

gives end users more control, which creates a greater

sense of responsibility regarding system maintenance

and security, especially with saboteur activities

common to various motivations (Bala, 2013). Also,

developing systems that generate the required power

at or close to the point of application can reduce

attacks on supply structures, especially with

increasing regional unrest in a developing country

like Indonesia. Such a system does not require

maintenance and protection of the supply structure.

Hydroelectric power plants have many advantages

over renewable energy sources from solar power

(Ribal, 2017).

Rusman, . and Karim, K.

Characteristics of Flow Rate on the Performance of Pico Hydro Turbine System as an Alternative Powerplant.

DOI: 10.5220/0010960100003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1097-1102

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1097

2 MATERIAL AND METHOD

PVC pressure lines of breadths 0.0762, 0.0635,

0.0508, 0.0445 and 0.0381 m were chosen as

penstocks. As indicated by (Kunwor, 2012) and

(ESHA.Small Hydropower, 2018 ). PVC is lighter,

has better grating qualities, and is less expensive than

steel, separated from the abstract factor of being all

the more promptly accessible in the necessary sizes.

Their pressing factor qualities are comparable. The

related frictional misfortunes were assessed utilizing

the conditions proposed by (Muchira, 2011) for lines

of breadth more noteworthy than 5 cm and stream

speed under three m/s. A normal worth of C = 137.5

was utilized in this examination since it lies between

135 furthermore, 140 for plastic lines. The choppiness

misfortunes (Ht) were assessed with values for the

coefficients K for pipe section, door valve, and 90º

elbow got from (Yan, 2012) as 0.5, 0.25, and 0.9

individually. For the change in penstock

measurements, K qualities were gotten utilizing the

condition given by (Muchira, 2011). The K qualities

for the decrease of penstock from 0.0762 to 0.0635 m,

0.0635 to 0.0508 m, 0.0508 to 0.0445 m, and 0.0445

to 0.0381 m were then registered. Ht esteems were

then figured with just the valve, elbow, and section

coefficients applied to the biggest measurement

penstock. The compression coefficients were then

progressively added as the penstock sizes were

diminished. The net head accessible was then

processed. The planning technique for a solitary spout

Pelton turbine looking like a propeller turbine was

taken on. This is because a propeller turbine takes into

consideration the generators to be straightforwardly

determined consequently staying away from

transmissions and the chaperon misfortunes.

Likewise, the sprinters had a somewhat lower number

of fixed cutting edges, in this manner improving the

fabricating cycle and lessening the potential for

conflicting sharp edge development and direction.

Besides, the Pelton turbine can be mounted upward or

evenly (Ingram, 2009). An abasic Angular shape

sharp edge with about 60º included point was taken

on. The methodology introduced was utilized in this

work to acquire the base turbine sprinter widths

which were then, at that point scaled upwards to

improve manufacturability, what's more, application

for the investigation. The upsides of the framework

stream rate processed were subbed into the

articulations for the turbine boundaries given by

RETScreen. The particular speed of the turbine was

processed utilizing several spouts = 1 (for

straightforwardness and simplicity of fabricating).

This was utilized to process the turbine sprinter

measurement, DT in meters. Five (5) various upsides

of DT were gotten relating to the five penstock sizes

chose which were then scaled upwards. The scaled

upsides of DT utilized for this work were 0.25,

0.30,0.35, 0.40, and 0.45 m. The center point distance

across and subsequently, edge tallness or cup length

was found utilizing an articulation given by

(ESHA.Small Hydropower, 2018 ). Just as the edge

stature. The number of edges was chosen from a

diagram of boundaries for measuring turbines by

(Bala, 2013) to be 6. The center point and cups were

projected from acrylic in the wake of doing the actual

starter tests, what're more, arrangements to the sizes

acquired. The cups were entirely welded to the center

point utilizing gas welding. Two roundabout spines

made of a 2 mm steel sheet to work with the coupling

of a steel shaft of 20 mm distance across the center

are welded to the post in the wake of going the beam

through an opening in it. The spine has arrangements

for three (3) M14 screws and nuts that are equitably

situated along an advantageous circumferential plane

so the center point with the cups is clasped opposite

the shaft. An average proportion of spine breadth (Df)

to center measurement (Dh) of 0.75 was utilized for

the five turbines. Fig. 1 shows the gathered turbine

sprinter. The gathered turbine was mounted in a

packaging made of 4 mm sheet steel and remotely

built up having an annulus or stream region (A),

which fulfills the base condition for freedom of about

0.03 m. Figure 2 shows a gathered turbine. Proper

orientation and seals were chosen to mount the

turbine with free turn and forestall spillages. The

packaging cover was gotten in position utilizing M13

and M14 fasteners and nuts. The help of the turbine

was made of a blend of 5 mm youchannel and 4 mm

point iron with arrangements for four M20

establishment bolts. The leave conduit was

rectangular cross-area and tightened to a 76.2 mm

measurement inside the strung barrel-shaped

connector. The line was advantageously skewed in

request to improve the release of water from the

turbine. Fig. 1 shows a detonated perspective on the

turbine. The spouts were created utilizing a 1 mm

thick steel sheet. The advancement of each was cut

out of the sheet metal which was then, at that point,

suitably collapsed and welded utilizing gas welding

on account of the light check of the metal. The spouts

had a mean stature of 50 cm. Figure 2 shows every

one of the spouts utilized for the examination, each

set of 5 including taps of region proportions 1.0 to 0.2.

Fig. 1 shows the complete setup for the study, while

Fig. 2 shows a broadened perspective on the parts on

the ground. It has two repositories, one mounted

overhead, and the other underground. The course of

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1098

action was to such an extent that the overhead supply

conveys water to the turbine through the penstock.

Five spouts of the comparable length of around 50 cm

were created for every penstock measurement with

region proportions of 1.0, 0.8, 0.6, 0.4, and 0.2 to

work with stream speed increase at the exit of the

penstock. Water from the spouts encroaches on the

turbine's sharp edges when the outlet valve of the

overhead supply is opened. The entire turbine

gathering is mounted on a level plane with the water

outlet port advantageously slanted with the end goal

that streams from the turbine packaging are

improved. The turbine releases water to the ground

supply. The water is then re-flowed to the overhead

Supply by a 0,125 kW Touch Model electric siphon.

The siphon has an evaluated stream pace of 3.0 –

10.8m3/h (0.833 – 3.0 x 10-3 m3 /s) with the most

outstanding and least heads of 29 m and 17 m

separately Furthermore, 220 – 240V, 7.1A. For this

examination, the head, H ≈ 6.95 m. The test

framework release was then, at that point still up in

the air for every penstock size by timing the release

of water from the overhead supply. The rotational

speed of the shaft of the turbine (N) was estimated

utilizing the DT-2268 and DT- 2858 Contact Type

Advanced Tachometer for each Penstock distance

across and spout setup. The tachometers had a 5-digit,

10 mm LCD show With an estimation scope of 2.5 –

99,999 Rpm. The goal is 1 Rpm more than 1000 Rpm

with the precision of ± 0.05% + 1 Rpm and

photograph Distinguishing distance of up to 300 mm.

The tachometers have the memory ability to appear

the last worth, most extreme price, and least Esteem,

and a regular examining season of 1 second. The

estimations were completed without coupling the

alternator to the turbine (no-heap Tests). The rotor of

the tachometer was squeezed daintily into a visually

impaired opening on the turning shaft in Request to

gauge the rotational speed. This was rehashed a few

times relying upon the term for a specific estimation

which was restricted by the water level in the supply

on the Ground. During this period, the most extreme

and least rotational speed was noticed and Recorded.

An average length of about 4.24 minutes/estimation

was utilized all through with the base and most

extreme qualities being 1.73Also, 6.75 minutes. The

entire method was Completed for every one of the

five turbines. The qualities of N were djusted for

misfortunes forced by the arrangement for releasing

water into the repository on the ground by applying a

factor of Hd/H, where Hd = the stature of the

conveyance port above The plain of the turbine shaft

and H = head. For the four more modest penstock

measurements, the qualities of N were additionally

adjusted because the conveyance of the line to the

ground repository was not decreased to Match their

more modest measures. A factor of Dp/Dd, where Dd

= size of the conveyance line and Dp = width of the

penstock. The water levels in the two repositories

were checked while utilizing a plunge stick alongside

an estimating tape, and They were used to acquire the

volume of water released. The volumetric stream

rates were then figured. The liquid force (Pf)

accessible for every activity was calculated utilizing

the relationship given by (Yan, 2012) and (Muchira,

2011). The shaft force, Ps, and effectiveness of the

framework were figured from the first standards

utilizing conditions given by something similar

creator.

Figure1: A Turbine Runner Assembly For The System.

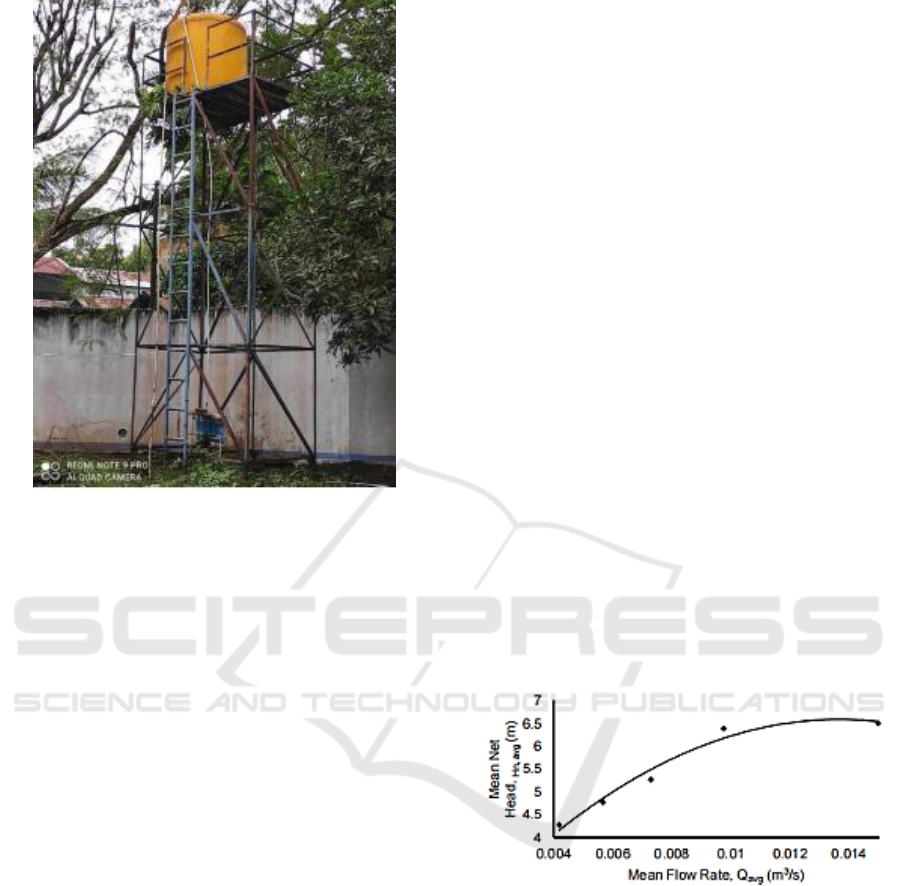

For this study, the mean values of flow rate and

net head for the no-load test, as presented in Table 1,

are plotted in Fig. 3. The characteristic curve is

parabolic, with an R

2

value of 0.9697. The trend is as

obtained in a previous study (Ramos, 2012). It has the

following expression given in equation 1:

H

n,avg

= - 27132Q

avg

2

+ 740.6Q

avg

+ 1.5363 (1)

where H

n,avg

= mean system net head (m) and Q

avg

=

mean system flow rate (m

3

/ s). This expression can be

instrumental in obtaining an initial design for

increasing the flow rate for further system

development for a given value of H

n, avg

.

Based on the dimensional analysis results of the

hydraulic turbine parameters, four coefficients were

calculated to summarize and generalize its

performance. The coefficients are the coefficients of

the head, flow, and power as well as specific speed.

Characteristics of Flow Rate on the Performance of Pico Hydro Turbine System as an Alternative Powerplant

1099

Figure 2: The Pico-Hydropower System.

They are calculated using equations 2 to 5. This

formulation will be beneficial, especially regarding

upgrading the system to produce higher power

(Ingram, 2009). They will be invaluable for the initial

design data and are the essential hope for reaching

this system in its final application form.

They can be calculated using the expressions given

below.

Flow coefficient, K

Q

= Q/ND

3

(2)

Head coefficient, K

H

= gH/N

2

D

2

(3)

Power coefficient, K

P

= P/ρN

3

D

5

(4)

Specific speed, K

S

= K

P

1/2

/K

H

5/4

(5)

3 RESULTS AND DISCUSSION

For this examination, the mean upsides of the stream

rate and the net head for the no-heap tests as

introduced in Table 1 were plotted in Fig. 3. The

trademark bend was illustrative, with R2 worth of

0.9697. The pattern is as-is reachable in past

investigations (Yan, 2012). It has the accompanying

articulation given in condition 8:

Hn,avg = - 27132Qavg2 + 740.6Qavg + 1.5363 (6)

where Hn,avg = mean framework net head (m) and

Qavg = mean framework stream rate (m3/s). This

articulation can be extremely helpful in getting an

underlying plan for increasing stream rate for

additional improvements of the framework for given

upsides of Hn,avg (Yan, 2012). Four coefficients

were processed, to sum up, and sum up their

exhibition, given aftereffects of dimensionless

examination of water-powered turbine boundaries.

The coefficients were ahead, stream, and force

coefficients just as the particular speed. They were

figured utilizing Conditions 4 to 7. These details will

be precious, particularly regarding likely

arrangements to increase the framework to produce

higher force (Muchira,2011). They will be priceless

for starting plan information and are critical to

accomplishing this framework in its possible

application structure. The processed upsides of the

coefficients are displayed in Table 1. Fig. 3 relates the

mean head coefficient (KH) to the mean stream

coefficient (KQ). The trademark bend is illustrative

for this work, with R2 worth 0.9939, and the

articulation is given in condition 6.

KH = 1765.2KQ2 – 1.6098KQ + 0.0027 (7)

Fig. 3 shows the comparing bend for the connection

between the mean force coefficient and the stream

coefficient, which has an illustrative pattern with R2

worth of 0.9982. The articulation got is displayed in

condition 7.

KP = 3.4689KQ2 – 0.0019KQ + 1 x 10-6 (8)

Figure 3: Mean Net Head and Flow Rate Characteristic for

The System.

The coefficients establish many execution qualities

addressing the entire group of five turbines created

for this work. They are indistinguishable for all of

them as long as boundaries; for example, Mach

number, Reynolds' number, and relative surface

unpleasantness of the line dividers are very similar or

can be expected to be consistent. This supposition

holds for this work. Applying comparability laws and

given the presumptions over, these coefficients can be

utilized to anticipate the presentation of one more

comparable turbine with a more modest or bigger

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1100

Table 1: Dimensionless coefficients for turbines with

penstocks of diameter 0,0508 m.

sprinter distance across running at a given speed

(Muchira, 2011). As indicated by (Muchira, 2011)

and (Yan, 2012), the particular speed (Ks ) can be

gotten from condition seven by controlling KQ, KH,

and KP. The mean upsides of the figured KS from

exploratory information for every one of the groups

of five turbines are displayed in Table 1. They all

exist in the reach 1.7 < KS < 3.0. However, these

qualities are tiny contrasted with the scope of 10 to 35

revealed by (Ingram, 2009) and (ESHA.Small

Hydropower, 2018 ) for one-stream Pelton turbines,

they are near one another, fortifying a previous idea

during the time spent the bigger extent of the

examination that the distinction between the sprinter

measurements was not huge enough to affect upon

their exhibitions fundamentally.

4 CONCLUSION

Up until now, the discoveries in this work on the

streamlined pico-hydro framework show that it likely

exists for it to contribute emphatically towards

improving the energy mash in Indonesia and other

agricultural nations as a unit that will work without

reliance on abnormal environmental conditions,

without antagonistic impacts on the climate and

which surrenders control to the end client. Further

advancement is anyway essential to completely

understand this potential. Its boundaries should be

appropriately controlled to accomplish a self-running

status before it can turn out to be economically

helpful. The proposals for this work are issues for the

following phase(s). Given the current discoveries and

the first desires of this examination, further

subsidizing will be looked for so the accompanying

viewpoints could be researched: (1) The conveyance

pipe from the siphon will be altered to make the

proportion of conveyance release from the supply to

be more good for framework execution; (2) The

framework will be tried with the overhead repository

situated above 7.0 m to exploit more noteworthy

head; (3) a close financial examination of this

framework with an independent sun oriented force

framework and a petroleum product fueled

framework will likewise be attempted.

REFERENCES

Yah, N.F., A.N. Oumer, and M.S. Idris, Small scale hydro-

power as a source of renewable energy in Malaysia: A

review. Renewable and Sustainable Energy

Reviews,2017. 72: p. 228-239.

Edomah N. On the path to sustainability: Key issues On

Nigeria’s sustainable energy development, Energy

Reports. 2016;2:28- 34.

Olusegun HD, Adekunle AS, Ohijeagbon IO, Oladosu

OA,Ajimotokan HA. Retrofitting a hydro-power

turbine for he generation of clean electrical power.

USEP: Journal of Research Informationin Civil

Engineering.2010;7(2):61-69.

Bala EJ. Achieving renewable energy potential in Africa,

Joint WEC, AUC and APUA Workshop, Addis Ababa,

Ethiopia;2013.

Ribal A, Amir AK, Toaha S, Kusuma J,Khaeruddin K.Tidal

current energy resource assessment Around Buton

Island, Southeast Sulawesi, Indonesia. International

Journal of Renewable Energy Research. 2017;7(2).

Kunwor A. Technical specifications of micro-

hydrosystems design and its implementation:

Feasibility analysis and a sign of Lamaya Khola micro-

hydropower plant. BSc. Thesis, Arcada

Polytechnic;2012.

ESHA.Small Hydropower energy efficiency Campaign

action (SHERPA) -strategic study for the development

of small dro power (SHP) in the European Union.

European Small Hydropower Association 2008.

Available:http://www.esha.be/

Muchira MJ. Performance of a modified vehicle Drive

system in generating hydropower. A Thesis submitted

for MSc. Renewable Energy Technology, Kenyatta

University, Kenya. 2011;44.

Ho-Yan B. Design of a low head Pico hydro turbine For

rural electrification in Cameroon. Thesis Presented

toThe University of Guelph, Canada; 2012.Available

https://dspace.lib.uoguelph.ca/xMaui/handle/10214/35

52

Nozzle area Turbin Runner Head Power Coeff Flow Coeff Spesific

ratio

Dia., D

T ( m)

Coeff Kp x 10 -4

K

Q

x 10-4

speed

A1/A2

K

H x 10-3

Ks

1,0 4,20 3,43 8,28 1,77

0,8 3,83 2,68 6,90 1,68

0,6 0,45 3,11 1,74 5,97 1,82

0,4 2,89 1,31 4,33 1,71

0,2 2,71 0,69 2,97 1,57

1,0 3,45 2,78 9,02 2,20

0,8 2,78 1,87 8,00 2,31

0,6 0,40 2,54 1,65 7,07 2,30

0,4 2,35 1,07 5,60 2,05

0,2 2,09 0,82 3,51 1,80

1,0 4,55 6,57 11.59 2,15

0,8 3,97 5,43 9,81 2,19

0,6 0,35 3,43 3,66 8,25 2,33

0,4 2,25 2,52 4,52 2,21

0,2 2,00 1,08 4,05 2,11

1,0 3,57 4,77 14,99 2,70

0,8 3,07 3,09 13,55 3,20

0,6 0,30 2,86 2,13 12,89 3,41

0,4 2,54 1,64 9,23 3,01

0,2 2,08 1,23 7,65 2,70

1,0 3,86 8,79 22,12 3,04

0,8 3,23 7,82 20,67 3,05

0,6 0,25 3,19 6,45 18,76 3,20

0,4 3,13 4,75 15,21 2,91

0,2 3,02 3,01 10,54 2,48

Characteristics of Flow Rate on the Performance of Pico Hydro Turbine System as an Alternative Powerplant

1101

Ingram G. Basic concepts in Turbomachinery, Grant

Ingram and VentusPublishing ApS. 2009;17:88-

91.Available:www.bookboon.com

Ramos HM, Kenova KN, Pillet B. Stormwater storage pond

configuration for hydropower Solutions: Adaptation

and optimization.J. of Sustainable Development.

2012;5(8):27–42

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1102