The Utilization Fly Ash as Material Substituon for Filler Asphalt

Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal

Density (PRD) Method

Archenita, Marzah, Liliwarti and Aqilah

Civil Engineering Department, Padang State Polytechnic, PNP Padang, Indonesia

Keywords: Asphalt Concrete Wearing Coarse (AC-WC), Filler, Fly Ash, Marshall Method, Optimum Asphalt Content

(OAC), Percentage Refusal Density (PRD) Method.

Abstract: Asphalt Concrete Wearing Coarse (AC-WC) consists of asphalt and aggregate mixed, that largest composition

is aggregate (90% from the total weight of mixture). The availability of mixed-forming materials is very

important in ensuring smooth implementation in the field, apart from the quality of the material. In some

areas, the availability of filler is considered quite difficult because the filler usually comes from rock ash, so

it takes a replacement material that has the same specifications as the filler from rock ash. The possible

material is fly ash which is waste in coal mines and has not been utilized to the fullest. This research will

analyze the performance of AC-WC coarse that make use of filler substitution material using fly ash with

variation FA-0%, FA-5%, and FA-10%. The samples made by Marshall Method will give the Optimum

Asphalt Content (OAC) value on each mix variation. While the performance of these AC-WC mixtures on

secondary compaction by traffic was carried out using the Percentage Refusal Density (PRD) Method. The

analysis result shows that the OAC value at 0% fly ash variation is 5.95%, at 5% fly ash variation is 6.25%,

and at 10% fly ash variation is 6.32%. While the performance of AC-WC mixture indicated by the PRD value

meets the specifications, namely the PRD test gives a minimum VIM value of 2%. Based on the results of the

study, it can be seen that with the addition of fly ash there is an increase in the asphalt content used but the

increasing is not too big. So the fly ash can recomended to use as substitution filler on AC-WC mixture.

1 INTRODUCTION

Asphalt Concrete Wearing Coarse (AC-WC) is one

type of coating on flexible pavement. Similar to other

flexible pavement layers, AC-WC is also composed

of a mixture of asphalt and aggregate. As a material

with the largest percentage amount (about 90% -

95%), aggregate is divided into coarse aggregate, fine

aggregate, and filler. The quality of the material

forming the road pavement layer, AC-WC mixture, is

one of the determining factors for the performance of

road pavement layers (AASHTO, 1993), especially

the aggregate, considering that the percentage of

aggregate in the pavement mixture can reach 75-85%

of the total volume of the mixture or around 90% of

the total weight of the mixture. In addition to material

quality, the availability of mixed-hforming materials

is also very important in ensuring smooth

implementation in the field. Filler is one part of the

aggregate and is quite difficult to obtain because

usually, the filler used comes from rock ash. In some

locations, the availability of such a filler is felt to be

very difficult, so it is necessary to replace material

that has the same specifications as the filler from the

rock ash. One possible material is fly ash. Fly ash is a

waste material in coal mines, the availability of which

is quite a lot and has not been utilized and is found in

the West Sumatra area, precisely in the Sijantang

area, Sijunjung Regency.

The performance of the AC-WC layer using filler

material substitution using fly ash with variations in

the substitution of 0% fly ash (FA-0%) or without fly

ash, 5% fly ash (FA-5%), and 10% fly ash (FA-10%)

will be known in this research. This percentage will

be mixed later in the asphalt mixture (test object) at a

temperature of 150oC. This specimen is compacted in

a mold measuring 152-153 mm (6 inches) by

Marshall compaction 2x75 impact. Furthermore, to

see the performance of this AC-WC layer after the

mixture was secondarily compacted by traffic during

the design life, without undergoing any plastic

Archenita, ., Marzah, ., Liliwarti, . and Aqilah, .

The Utilization Fly Ash as Material Substituon for Filler Asphalt Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal Density (PRD) Method.

DOI: 10.5220/0010960200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1103-1111

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1103

deformation, a test was carried out using a field

condition approach using the Percentage Refusal

Density (PRD) Method. In the PRD method,

compaction of the mixture is carried out manually

with a number of 2x400 collisions, which is

equivalent to compaction using an electric vibrating

compactor (BS 598 Part 104 1989). The test object

used is a test object with asphalt content which gives

a Marshall VIM value of 6% (VIM6%), and 0.5%

above and below the asphalt content. While the

asphalt used is asphalt PEN 60/70 that produced by

Pertamina.

2 RESEARCH METHOD

The research was carried out in two laboratories, the

material testing laboratory Civil Engineering

Department-Padang State Polytechnic and the road

laboratory of Public Work Department. The material

for forming the AC-WC mixture is aggregate

obtained from the quarry in the Padang area, while fly

ash as a filler replacement material is obtained from

the Sijantang area, Sijunjung Regency. Another

material that also forms the AC-WC mixture, namely

asphalt, is used from Pertamina's production with

PEN 60/70 specification.

2.1 The Aggregate Properties Testing

This test is carried out in the Material Testing

Laboratory of Civil Department - Padang State

Polytechnic. The aggregates referred to here whose

properties are tested are coarse aggregate, fine

aggregate, and filler including fly ash. The properties

testing of aggregates consists of:

‒ Specific gravity and absorption of coarse

aggregate, fine aggregate, filler and fly ash.

‒ Aggregate Impact Value (coarse aggregate)

‒ Aggregate Crushing Value (coarse aggregate)

‒ Aggregate Abrasion Value By Los Angeles

Machine

‒ Flakiness And Elongation Index

‒ Soundness Test By Sodium Sulfat/

Magnesium Sulfat

Specification of coarse aggregate and fine

aggregate according to 2018 specifications are shown

in Table 1 and Table 2.

Table 1: Coarse Aggregate Specification.

Testing Method Value

Soundness by natrium

sulfat/magnesium sulfat

solven

t

SNI 3407: 2008

Max 12%

/ max 18%

Abrasion by Los Angeles

Machine

SNI 2417: 2008 Max 40%

Aggregate adhesiveness

to asphal

t

SNI 2439: 2011 Min 95%

Aggregate rupture field SNI 7619: 2012 95/90

**

Flakiness and Elongation

particles

ASTM D4791-1 0

Ratio 1:5

Max 10%

Material passes sieve

No.200

SNI ASTM C117:

2012

Max 1%

**

95/90 indicates that indicates that 95% of the coarse aggregate has a fracture area of

1 or more and 90% of the coarse aggregate has a fracture area of 2 or more

Source : General Specifications 2018

Table 2: Fine Aggregate Specification.

Testing Method Value

Sand equivalent value SNI 03-4428-1997 Min 50%

Void level test without

campaction

SNI 03-6877-2002 Min 45

Lump of clay and fragile

grains in the aggregate

SNI 03-4141-1996 Max 1%

Aggregate passes sieve

No.200

SNI ASTM C117:

2012

Max 10%

Source : General Specifications 2018

2.2 The Asphalt Properties Testing

This test is carried out in the Road Testing Laboratory

of Public Work Department. The properties testing of

asphalt consists of:

‒ Specific gravity of Asphalt

‒ Penetration Test

‒ Ductility Test

‒ Softening Point Test

‒ Flashing And Burning Point Test

‒ Weight Loss Test

‒ Viscosity Test

‒ Stripping Test

Specification of asphalt are shown in Table 3.

Table 3: asphalt Specification.

Testing Method Value

Penetration at 25

0

C (0.1 mm) SNI 2456: 2011 60 - 70

Kinematic Viscosity 135

0

C (cSt) ASTM D2170-10 ≥ 300

Softening Point (

0

C) SNI 2434 : 2011 ≥ 48

Ductility at 25

0

C , (cm) SNI 2432 : 2011 ≥ 100

Flash Point (

0

C) SNI 2433 : 2011 ≥ 232

Solubility in Trichloroethylene (%) AASHTO T44-14 ≥ 99

Specific Gravity SNI 2441 : 2011 ≥ 1

Source : General Specifications 2018

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1104

2.3 Mixture Design

The mixtures make by Marshall Method. The

procedure design of this method is:

‒ Determine gradation, based on specifications

of Bina Marga 2018. Mix design has taken into

account the substitution of fly ash as a filler.

The gradation used is shown in Table 4 and

Figure 1.

Table 4: Gradation of asphalt concrete wearing coarse.

Sieve Size % of Weight Passed

ASTM Mm

Specification Gradation Design

¾” 19 100 100

½” 12.5 90 – 100 95

3/8” 9.5 77 – 90 83.5

No.4 4.75 53 – 69 61

No.8 2.36 33 – 53 43

No.16 1.18 21 – 40 30.5

No.30 0.600 14 – 30 22

No.50 0.300 9 – 22 15.5

No.100 0.150 6 – 15 10.5

No.200 0.075 4 – 9 6.5

Source : General Specifications 2018

Figure 1: Asphalt Concrete-Wearing Coarse Mixture

Gradation Chart.

The modification of the AC-WC mixture with using

of fly ash as a filler so the composition of the mixture

gradation in Table IV becomes as in Table 5.

‒ Determine middle asphalt content as

approximate asphalt content. Middle asphalt

content depend on gradation of mixture, and

calculated by formula;

Pb = 0.035*%CA + 0.045*%FA + 0.18*%FF + K (1)

Where,

CA = coarse aggregate

FA = fine aggregate

FF = fine filler

K = constant, used 1

Table 5: Gradation of asphalt concrete-wearing coarse

mixture by substitution fly ash as filler.

Sieve Size

Asphalt Concrete-Wearing Coarse

Gradation with

%Pas

sed

%Bat

ed

Mixed Weight (gr)

ASTM mm

0%F

A

5%F

A

10%

FA

¾” 19 100 0 0 0 0

½” 12.5 95 5 60 60 60

3/8” 9.5 83.5 11.5 138 138 138

No.4 4.75 61 22.5 270 270 270

No.8 2.36 43 18 216 216 216

No.16 1.18 30.5 12.5 150 150 150

No.30 0.600 22 8.5 102 102 102

No.50 0.300 15.5 6.5 78 78 78

No.100 0.150 10.5 5 60 60 60

No.200 0.075 6.5 4 48 48 48

Filler 6.5 78 74.1 70.2

Fly ash 3.9 7.8

Total 1200 1200 1200

The middle asphalt content is the basis for

determining other asphalt content in the manufacture

of mixtures. Percentage of coarse aggregate is obtain

from the total percentage of aggregate retained up to

sieve No.4.75 (Table V) i.e 39%.

While the percentage of fine aggregate is obtained

from the percentage of aggregate that passes the

No.4.75 sieve and is retained by the No.200 sieve

(Table V) i.e 54.5%. Percentage of filler is 6.5%. The

asphalt content to be used in making of samples is Pb,

0.5% and 1% above, and also 0.5% and 1% below the

Pb value. So variation of asphalt content that used is

5 variation.

Make a sample of Marshall test with variation 0%

fly ash, 5% fly ash, and 10% fly ash as filler

substitution. Each sample is made with 5 variations of

asphalt content and for each asphalt content 3 samples

are made. So the number of samples for one variation

of the mixture is 15 pieces. With 3 mixed variations

0

10

20

30

40

50

60

70

80

90

100

0,01 0,1 1 10 100

the weight passes the sieve (%)

Aggregate Grain Size (mm)

Bottom limit

Top limit

Gradation design

The Utilization Fly Ash as Material Substituon for Filler Asphalt Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal

Density (PRD) Method

1105

(0%FA, 5%FA, and 10%) then the total for all of

samples is 45 pieces.

2.4 Mixture Analysis

A mixed analysis is carried out after sample making

is complete. The analysis carried out on the Marshall

sample includes volumetric analysis and stability

analysis. A volumetric analysis will get the

dimensions and weight of the sample, density, VIM

(Void in Mix), VMA (Void in Mineral Aggregate),

and VFA/VFB (Void Filled Asphalt/Void Filled

Bitumen). Volumetric analysis calculations use the

formula;

• Bulk Specific Gravity of Combined Aggregate

n

n

n

sb

G

P

G

P

G

P

PPP

G

+++

+++

=

.....

.....

2

2

1

1

21

(2)

Where;

G

sb

= Total bulk specific gravity of

aggregate

P

1

,…,P

n

= Percentage of each aggregate

fraction

G

1

,…,G

n

= Bulk Specific Gravity of each

aggregate fraction

• Effective Specific Gravity of Combined

Aggregate

b

b

mm

b

se

G

P

G

P

G

−

−

=

100

100

(3)

Where;

G

se

= Total effective specific gravity of

aggregate

G

mm

= Mixed maximum specific

gravity, zero void (AASHTO T-

209.90)

P

b

= Asphalt content in percent of the

total weight of the mixture

G

b

= Asphalt specific gravity

• The theoretical maximum Specific Gravity of

asphalt mix

b

b

se

s

mm

G

P

G

P

G

+

=

100

(4)

Where;

P

s

= Aggregate content, percent of the

total weight of the mixture

• Void in Mineral Aggregate (VMA)

s

sb

mb

P

G

G

VMA

x−= 100

(5)

Where;

G

mb

= Bulk specific gravity of solid mix

• Void in Mix (VIM)

mm

mbmm

G

GG

VIM

−

=

(6)

• Void Filled Asphalt (VFA)

VMA

VIMVMA

VFA

x )(100 −

=

(7)

• Asphalt Absorption (P

ba

)

()

b

sbse

sbse

G

GG

GG

P x

x

x

ba

)(100 −

=

(8)

Where;

P

ba

= Asphalt absorption, percent of

total aggregate

• Effective Asphalt Content (P

be

)

s

ba

bbe P

P

PP x

100

−=

(9)

Where;

P

be

= Effective Asphalt content,

percent of total mix

While at the stability analysis will get the value of

stability and flow of the mixture. Both analysis will

give the optimum asphalt content value. The analysis

was carried out using a graph of the relationship

between asphalt content with VIM, VMA, VFA,

Stability, Flow, and MQ.

2.5 Percentage Refusal Density (PRD)

Method

Percentage Refusal Density (PRD) is a ratio of

laboratory test density to refusal density in percent.

Absolute density is an approximation to field

conditions after the asphalt mixture has been

secondarily compacted by traffic for several years of

the design life, without undergoing any plastic

deformation. Procedure test of PRD method is;

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1106

‒ Mixture Design; PRD test samples were made

with mixed variations of 0% fly ash, 5% fly

ash, and 10% fly ash, as filler substitution.

Asphalt content used in the manufacture of

samples is asphalt content at 6% VIM

conditions. The other two percentages of

asphalt content that will be used in making the

sample are 0.5% above and 0.5% below of the

asphalt content value at the 6% VIM

condition. PRD sample compaction was

carried out manually with a total of 400

collisions on both sides of the sample used a

4-inch diameter mold.

‒ Mixture Analysis; The point analyzed in the

PRD test is the VIM value, which is known as

the VIM refusal. Refusal VIM value according

to 2018 specification is a minimum 2%.

3 RESULT AND DISCUSSION

The test results on the material forming the AC-WC

mixture i.e. aggregate properties test and asphalt

properties test show on Table 6 and Table 7. The

tables show that the results of testing the properties of

aggregate and asphalt generally meet the

specifications. therefore these materials can be used

for the manufacture of the AC-WC mixtures.

Table 6: The result of aggregate properties test.

No.

Aggregate

Characteristics

The Test

Result

Specification

A. Coarse Aggregate

1.

Bulk specific gr

avity

2.68

Min 2.5

Surface Saturated

Dry (SSD) specific

gravity

2.60

Apparent specific

gravity

2.72

Min 2.5

Effective specific

gravity

2.70

2.

Soundness by

natrium

sulfat/magnesium

sulfat solven

t

3.

Abrasion by Los

Angeles Machine

33.36% Max 40%

4.

Aggregate

adhesiveness to

asphal

t

5.

Aggregate rupture

field

6.

Flakiness and

Elongation particles

7.

Material passes

sieve No.200

No.

Aggregate

Characteristics

The Test

Result

Specification

B. Fine Aggregate

1. Bulk specific gravity 2.66

Min 2.5

Surface Saturated Dry

(SSD) specific gravity

2.60

Apparent specific

gravity

2.70

Effective specific

gravity

2.68

2. Absorption 2.37% < 3%

3. Sand equivalent value

C. Filler

1.

Specific gravity of

stone ash

2.5

Min 2.5

2.

Specific gravity of fly

ash

2.4

Table 7: The result of asphalt properties test.

No.

Asphalt

Characteristics

The Test

Result

Specification

1.

Penetration at 25

0

C

(0.1 mm)

67.3 60 - 70

2.

Kinematic Viscosity

135

0

C (cSt)

463 ≥ 300

3. Softening Point (

0

C) 55.5 ≥ 48

4. Ductility at 25

0

C , (cm) 142 ≥ 100

5. Flash Point (

0

C) 320 ≥ 232

6.

Solubility in

Trichloroethylene (%)

92.723 ≥ 99

7. Specific Garvity 1.047 ≥ 1

The result of kinematic viscosity shows on Table

8 whereas the Saybolt Furol graph shows on Fig.2.

Table 8: The result of kinematic viscosity test.

Temperature (

0

C) Waktu Alir (detik) Sentistokes (cSt)

120 326 656

140 158 338

160 72 150

Figure 2: Saybolt Furol Graph.

10

100

1000

110 120 130 140 150 160 170 180 190

Viskositas Kinematik (Cst)

Temperatur (

O

C)

Relationship Temperature - Viscosity

Mixing

Compaction

280

170

144

158

The Utilization Fly Ash as Material Substituon for Filler Asphalt Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal

Density (PRD) Method

1107

The kinematic viscosity value is used to obtain the

mixing temperature and compaction temperature. The

result of kinematic viscosity is plotted on the Saybolt

Furol graph so that the mixing temperature and

compaction temperature are obtained.

Based on the Saybolt Furol graph shows that the

mixing temperature is 158

0

C and the compaction

temperature is 144

0

C.

3.1 Mixture Analysis by Marshall

Method

By using equation (1) obtained the value of the

middle asphalt content is 6%. Thus the asphalt

content used in making the sample is 5%, 5.5%, 6%,

6.5%, and 7%. Volumetric analysis on the Marshall

Method will produce VIM, VMA, VFA values using

equation (2) until (9). The results of calculations

using these equations are shown in Table 9.

Table 9: Test results marshall Asphalt Concrete-Wearing Coarse mixture without fly ash.

Bulk Specific Gravity of Aggregate

(Gsb)

= 2.655

Effective Specific Gravity of

Aggregate (Gse)

= 2.729

Specific Gravity of Asphalt (Gb)

= 1.047

Sample

Code

Sample

Height

Asphlat

Content

(Pb)

Aggregate

Content

(Pb)

Sample Weight

Sample

Volume

Specific Gravity

of Mix

Density

Void in

Mix

Void in

Mineral

Aggregate

Void

Filled

Asphalt

Dry

Saturated

Surface

Dry (SSD)

In

water

Bulk

G

mb

Max

G

mm

3 – 5 ≥ 15 ≥ 65

mm % % gram gram gram cc % % %

A-1 67.41 5 95 1240.1 1243.7 707.5 536.2 2.313 2.526 2.313 8.45 17.24 50.96

A-2 65.43 5 95 1248.3 1248.9 723.2 525.7 2.375 2.526 2.375 6.01 15.03 60.02

A-3 66.15 5 95 1236.3 1242.6 711.8 530.8 2.329 2.526 2.329 7.80 16.65 53.13

B-1 67.33 5.5 94.5 1250.3 1252.0 723.1 528.9 2.364 2.508 2.364 5.73 15.85 63.84

B-2 68.10 5.5 94.5 1254.4 1256.3 721.9 534.4 2.347 2.508 2.347 6.39 16.44 61.11

B-3 66.50 5.5 94.5 1246.0 1246.4 723.5 522.9 2.383 2.508 2.383 4.98 15.18 67.21

C-1 68.98 6 94 1259.2 1261.3 723.3 538.0 2.341 2.489 2.341 5.98 17.12 65.10

C-2 65.66 6 94 1249.4 1249.5 727.8 521.7 2.395 2.489 2.395 3.79 15.20 75.04

C-3 67.34 6 94 1254.9 1255.6 723.5 532.1 2.358 2.489 2.358 5.26 16.49 68.11

D-1 66.08 6.5 93.5 1254.4 1255.0 726.8 528.2 2.375 2.471 2.375 3.90 16.36 76.17

D-2 67.84 6.5 93.5 1263.6 1264.0 729.0 535.0 2.362 2.471 2.362 4.42 16.81 73.69

D-3 66.25 6.5 93.5 1261.6 1261.2 732.5 528.7 2.386 2.471 2.386 3.44 15.96 78.45

E-1 67.67 7 93 1254.5 1255.2 725.7 529.5 2.369 2.453 2.369 3.43 17.00 79.83

E-2 67.93 7 93 126.05 1265.9 728.9 537.0 2.356 2.453 2.356 3.98 17.48 77.22

E-3 66.40 7 93 1261.6 1261.9 728.3 533.6 2.364 2.453 2.364 3.63 17.17 78.87

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1108

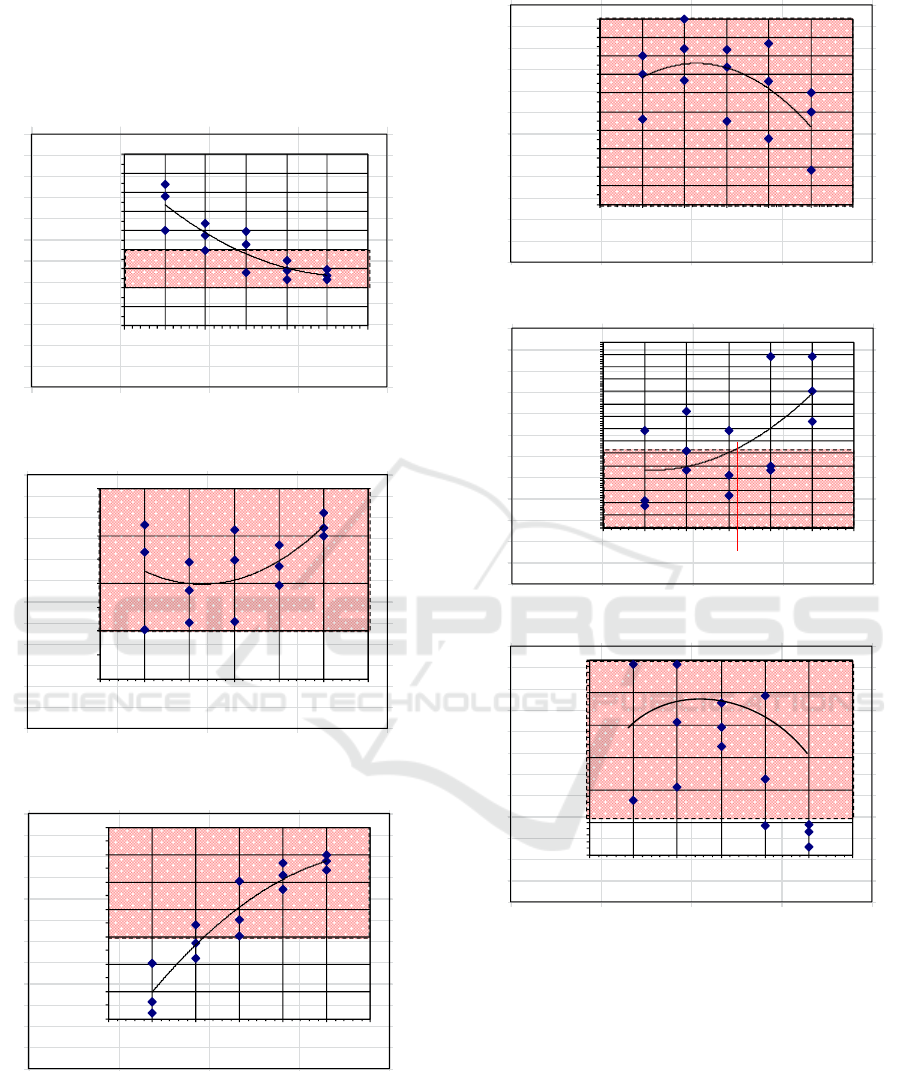

The results of the Marshall test on the AC-WC

mixture shown in Table IX, were analyzed

graphically the asphalt content for the value of VIM,

VMA, VFA, Stability, and flowas shown in Fig.3

until Fig.8.

Figure 3: Graphic Analysis Asphalt Content – Void in

Mix.

Figure 4: Graphic Analysis Asphalt Content – Void in

Mineral Aggregate.

Figure 5: Graphic Analysis Asphalt Content – Void in

Filled Asphalt.

Figure 6: Graphic Analysis Asphalt Content – Stability.

Figure 7: Graphic Analysis Asphalt Content – Flow.

Figure 8: Graphic Analysis Asphalt Content – Marshall

Question.

Based on the graph, it can be seen that the asphalt

content range meets the specifications (shaded part).

The optimum asphalt content is obtained by taking

the median value of the asphalt content range that

meets all specifications that show in Fig.9.

1,00

2,00

3,00

4,00

5,00

6,00

7,00

8,00

9,00

10,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V I M (%)

Asphalt Content (%)

14,00

15,00

16,00

17,00

18,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V M A (%)

Asphalt Content (%)

50,00

55,00

60,00

65,00

70,00

75,00

80,00

85,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V F A (%)

Asphalt Content (%)

800,00

900,00

1000,00

1100,00

1200,00

1300,00

1400,00

1500,00

1600,00

1700,00

1800,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

Stability (kg)

Asphalt Content (%)

2,50

2,75

3,00

3,25

3,50

3,75

4,00

4,25

4,50

4,75

5,00

5,25

5,50

5,75

6,00

6,25

4,50 5,00 5,50 6,00 6,50 7,00 7,50

Flow (mm)

Asphalt Content (%)

200,00

250,00

300,00

350,00

400,00

450,00

500,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

M Q ( kg/ mm)

Asphalt Content (%)

The Utilization Fly Ash as Material Substituon for Filler Asphalt Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal

Density (PRD) Method

1109

Figure 9: Graphical Analysis for Optimum Asphalt

Content value on Asphalt Concrete-Wearing Coarse

mixture 0% fly ash.

In the same way, calculations and analyzes were

also carried out for the AC-WC mixture with the

substitution of 5% and 10% fly ash as filler. So the

Optimum Asphalt Content (OAC) on the AC-WC

mixture with 5% fly ash is 6.25%, while for the AC-

WC mixture with 10% fly ash is 6.32%.

Based on this results show that the addition of fly

ash substitution will increase the value of the

optimum asphalt content.

3.2 Mixture Analysis by Percentage

Refusal Density Method

The PRD samples were made with asphalt content at

6% VIM conditions obtained on the chart of

Marshall analysis results, which are shown in

Fig. 10.

Figure 10: The marshall analysis chart to determine the

middle asphalt content of the PRD sample on Asphalt

Concrete-Wearing Coarse mixture 0% fly ash.

In the same way is also done for the AC-WC

mixture with the substitution of 5% and 10% fly ash

as filler. Thus the value of PRD Asphalt content in

the AC-WC mixture with 5% fly ash is 5.35%, while

for the AC-WC mixture with 10% fly ash it is 5.4%.

The tests carried out on the PRD samples were

only volumetric tests/analyses, which are shown in

Table 10.

Table 10: the test percentage refusal density (prd) results on Asphalt Concrete-Wearing Coarse mixture without fly ash.

Bulk Specific Gravity of Aggregate

(Gsb)

= 2.655

Effective Specific Gravity of

Aggregate (Gse)

= 2.729

Specific Gravity of Asphalt (Gb)

= 1.047

Sample

Code

Sample

Height

Asphlat

Content

(Pb)

Aggregate

Content

(Pb)

Sample Weight

Sample

Volume

Specific Gravity

of Mix

Density

Void in

Mix

Void in

Mineral

Aggregate

Void

Filled

Asphalt

Dry

Saturated

Surface

Dry (SSD)

In

water

Bulk

G

mb

Max

G

mm

Min 2

mm % % gram gram gram cc % % %

A-1 67.17 5.5 94.5 1234.2 1235.8 713.7 522.1 2.364 2.526 2.364 6.43 15.41 58.28

A-2 65.63 5 95 1241.3 1243.1 724.1 519.0 2.392 2.508 2.392 4.62 14.86 68.89

A-3 65.13 6 94 1241.0 1241.9 724.4 517.5 2.398 2.489 2.398 3.66 15.09 75.70

The Ma r shall OA C

V

oid In Mix

V

oid in M inera l A

gg

re

g

ate

V

oid Filled A s

p

hal

t

St abilit

y

Ke lele han

Marshall

Q

uotien

t

7,05,0 5,5 6,0 6,5

=

5,95

5,80 6,10

1,00

2,00

3,00

4,00

5,00

6,00

7,00

8,00

9,00

10,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V I M (%)

Asphalt Content (%)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1110

The Void in Mix (VIM) values are plotted on the

Marshall analysis VIM graph so that a refusal VIM

graph is obtained, that shows on Fig.11 for AC-WC

mixture without fly ash (0% FA), Fig.12 for AC-WC

mixture with 5% fly ash (5% FA), Fig.13 for AC-WC

mixture with 10% fly ash (10% FA).

Figure 11: Void In Mix (VIM) refusal on Asphalt Concrete-

Wearing Coarse mixture 0% fly ash.

Figure 12: Void In Mix (VIM) refusal on Asphalt Concrete-

Wearing Coarse mixture 5% fly ash.

Figure 13: Void In Mix (VIM) refusal on Asphalt Concrete-

Wearing Coarse mixture 10% fly ash.

Based on graphical analysis for the refusal VIM

value in all variations of the AC-WC mixture (Fig.11

until Fig.13), it meets the required value of at least 2%.

4 CONCLUSION

According to the result of the utilization fly ash as

material substitution for filler in Asphalt Concrete-

Wearing Course (AC-WC) mixed with Percentage

refusal density (PRD) method can conclude that: The

Optimum Asphalt Content (OAC) increases with the

increase in the percentage of use of fly ash as a filler

substitution and the voids found in all variations of

the AC-WC mixture meet the required specifications

(Percentage Refusal Density Method test result). The

increase in OAC value due to filler substitution in the

mixture is not too large, so use of fly ash as a filler

substitution in the AC-WC mixture is recommended.

ACKNOWLEDGEMENTS

This reseach are fully funded by DIPA Politeknik

Negeri Padang.

REFERENCES

AASHTO, “Standart Specifications for Transportation

Materials and Methods of Sampling and Testing,”, Part

II Tests, 1998, pp. 52-204.

ASTM, “Test Method for Indirect Tension Test for

Resilient Modulus for Bituminous Mixtures,”, D 4123-

82 (1995), Annual Books of ASTM Standards, 1997.

Daniyanto, E., "Pengaruh Campuran Fly Ash Terhadap

Laston Perkerasan Jalan," 2019. https://riset.unisma.

ac.id/index.php/ft/article/download/1776/1673.pdf

Gunawan, G. and Nono, “Potensi Pemanfaatan Bahan

Limbah Fly Ash Dan Bottom Ash Untuk Lapisan

Fondasi Jalan Semen [Journal],” 2017, accessed via

http://repository.its.ac.id/2952/7/3115040616-Undergr

aduate-Theses.pdf.

Kartikasari, D., and Hartantyo, S.D., "Penggantian Filler

Dengan Fly Ash Dan Serbuk Batu Bata Pada Campuran

Aspal (AC-WC)," UkaRsT VOL.1, NO.1 TAHUN

2017 ; p ISSN 2579-4620 ; e ISSN 2581-0855.

Kementerian Pekerjaan Umum dan Perumahan Rakyat,

"Spesifikasi Umum 2018 Untuk Pekerjaan Konstruksi

Jalan dan Jembatan," Seksi 6.4, 2018.

Munir, Misbachul, "Pemanfaatan Abu Batubara untuk

Hollow Block yang Bermutu dan Aman Bagi

Lingkungan," Program Studi Ilmu Lingkungan,

Program Pascasarjana, Universitas Diponegoro,

Semarang, Indonesia, 2008.

SNI No. : 06-2489-1991, "Metoda Marshall," 1991.

The Asphalt Institute, "Principles of Construction of Hot

Mix Asphalt Pavements," Manual Series No.22, The

Asphalt Institute, 1983, pp 9-83.

Yuri, Novebrian, "Pengaruh Penambahan Abu Batubara

(Fly Ash Dan Bottom Ash) Terhadap Karakteristik

Aspal Penetrasi 60/70," [Skripsi] Universitas Andalas

Padang accessed via http://scholar.unand.ac.id/12592/

1,00

2,00

3,00

4,00

5,00

6,00

7,00

8,00

9,00

10,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V I M (%)

Asphalt Content (%)

2,00

2,50

3,00

3,50

4,00

4,50

5,00

5,50

6,00

6,50

7,00

7,50

8,00

8,50

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V I M (%)

Kadar aspal (%)

1,00

2,00

3,00

4,00

5,00

6,00

7,00

8,00

9,00

10,00

4,50 5,00 5,50 6,00 6,50 7,00 7,50

V I M (%)

Kadar aspal (%)

The Utilization Fly Ash as Material Substituon for Filler Asphalt Concrete Wearing Coarse (AC-WC) Mixed with Percentage Refusal

Density (PRD) Method

1111