Maintenance Analysis of Boiler Feed Water Pump using

Quantitative Methods

Hendrik Elvian Gayuh Prasetya, Wilda Rahmania and Fifi Hesty Sholihah

Powerplant Engineering Department, Politeknik Elektronika Negeri Surabaya, Surabaya, Indonesia

Keywords: Steam Power Plant, BFP, Maintenance, Quantitative Methods, Reliability, MTTF.

Abstract: The boiler feedwater pump is a multistage pump driven by a boiler feed pump steam turbine on a steam power

p plant. A boiler feedwater pump has many failures, the example high temperature and vibration in bearing

and mechanical seal, leak in valve and line connection, etc. The failure in every component in the boiler

feedwater pump could be reduced by maintenance analysis. There are many methods for maintenance

analysis, one of that is quantitative analysis methods. Maintenance analysis with quantitative methods uses

downtime data on the BFP component as reference data. The downtime data is simulated using Weibull 6 ++

software to get the right distribution to determine the value of Reliability (R (t)), MTTF (Mean Time To

Failure), and failure rate. The result of maintenance analysis using quantitative methods is the reliability of

the Boiler Feed Water Pump components decreases over time, the result of the Mean Time To Failure

calculation is the value on the BFP component obtained the lowest MTTF value is the solenoid valve with the

MTTF value 408.62 and the highest MTTF value on the accumulator and regulator with MTTF value

57428.358. The maintenance recommendation on BFP components are the components that have CFR failure

rate characteristics the maintenance recommendations are corrective maintenance, and the maintenance

recommendation for components that have failure rate IFR and DFR are preventive maintenance.

1

INTRODUCTION

The development of coal production in 2009-2018

increased significantly with the production of 557

million tons in 2018. One of the factors which cause

the low realization of coal consumption is the operation

of the steam power plant in a 35,000 MW program is

not according to the plan and declining of the industry

activities. In 2018, power plant production reached

283,8 TWh which was derived from 56.4% coal,

20.2% gas, 6.3% fuel, and 17.1% NRE (New

Renewable Energy) ( Secretariat General National

Energy Council, 2019).

Steam Power Plant is a thermal power plant where

water is converted into steam high temperature to

rotate the steam turbine at a required rpm to generate

electricity. The Steam power plant has many critical

components there are boiler, low and high-pressure

turbine, condenser, feed water pump, etc (Ahmed and

Billah, 2012). Feedwater Pump or boiler feed water

pump (BFP) is the main pump of a steam power plant,

and it is the critical component of a steam power

plant.

The Boiler feedwater pump (BFP) is a pump

driven by a steam turbine boiler feed pump, the steam

of the turbine boiler feed pump is from the extraction

main steam turbin (PLTU 1 Jawa Tengah). The

function of this pump is to supply feed water to

boilers from the deaerator to the steam drum

bypassing the high-pressure heater (HPH). This is the

main pump in steam power plant so When this pump

is tripped, the steam power plant can not produce

electricity because this pump cannot be operated it

can affect the performance of the other components.

The failures on the boiler feedwater pump can be

resolved by maintenance.

Maintenance is a routine activity to keep a

particular machine at its normal condition so, it can

deliver the expected performance without causing any

looses and failure (Tadi and Ouali, 2011).

Maintenance has 3 types there are preventive

maintenance, corrective maintenance, and predictive

maintenance. The maintenance analysis method to

determine the reliability of the BFP component could

use quantitative methods (Dhilon, 2006).

Maintenance analysis with quantitative methods

uses downtime data on the BFP component as

reference data for quantitative analysis. The downtime

Prasetya, H., Rahmania, W. and Sholihah, F.

Maintenance Analysis of Boiler Feed Water Pump using Quantitative Methods.

DOI: 10.5220/0010968100003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1507-1514

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1507

data is simulated using Weibull 6 ++ software to get

the right distribution to determine the value of

Reliability (R (t)), MTTF (Mean Time To Failure),

and failure rate. the types of distributions used in

reliability calculations are lognormal distribution,

normal distribution, Weibull distribution, and

exponential distribution

The previous study entitled “A study of the

quantitative methods that support RCM operation”

this research discusses investigates the quantitative

methods to support the Reliability Centered

Maintenance (RCM) operation. The result of this

research is the quantitative method especially

probability theory is commonly used to the RCM

method to identify the maintenance analysis. the

probability theory in quantitative methods can

determine the distribution used to calculate reliability

and the Mean Time to Failure in the RCM method

(Mendes and Ribeiro, 2015).

The previous study entitles “Availability Analysis

of Heat Recovery Steam Generators Used in Thermal

Power Plants” discusses the method for reliability and

availability evaluation in HRSG, especially two

HRSG in 500 MW combines-cycle power plant. The

first step is knowing the generator functional tree and

FMEA analysis, the second step involves reliability

and availability based on the time to failure data after

that it could be obtained the availability value for each

HRSG components. After that, the maintenance

analysis will be improved through the use of reliability

centered maintenance (RCM) concepts (Carazas and

Salazar, 2011 ).

1.1 Maintenance on Boiler Feed Pump

Turbine

A.

Boiler Feed Water Pump

The boiler feed Water Pump (BFP) is one of the

critical rotating machinery on steam power plants

(Yoshikawa, 2016).

The Boiler feedwater pump is the

application of large- sized centrifugal pumps in the

steam power plant. The Boiler feedwater pump serves

to control and supply water from the water tank (feed

water tank) to the boiler with certain pressure

specifications.

Figure 1: Boiler Feedwater Pump.

The boiler feedwater pump is driven by a small

turbine, turbine boiler feed pump driven by steam from

extraction in the main turbine. The workings of the

boiler feedwater pump (BFP) are a shaft from the

turbine boiler feed pump coupled with the boiler feed

pump turbine shaft so the pump can be driven. When

the BFP’s shaft rotated, the impeller attached to the

shaft also rotated, and then the water can enter through

the suction pump.

Figure 2: Components of the boiler feedwater pump.

The components of the boiler feed pump water pump

are coupling, bearing, turning gear, mechanical seal,

selenoid valve, sensor LCV, control valve,

transmitter, regulator, etc (Dhilon, 2006). These

components mutually affect the performance of this

boiler feed water pump, when one of the components

has a failure then the performance of the BFP will

decrease or this BFP will be trip.

B.

Maintenance

The definition of maintenance is the technical and

managerial action taken during component or asset

usage period to maintain and restore the function

(Shin and Jun, 20015).

Maintenance has a function

or influence on components, i.e (Patton and Joseph,

1995) :

1.

Every component has a useful life and in the

future could have many failures.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1508

2.

To find out precisely the equipment will be has

a failure

3.

To increase the lifetime of an operating unit.

Maintenance applications can be divided into several

types, among others :

a.

Corrective Maintenance

Corrective maintenance is maintenance

activities are carried out on machines that fail

and cannot function properly (Dhilon, 2006). The

characteristic of corrective maintenance is

replacing parts that are failing and the failure will

affect the performance of other components or

units.

b.

Preventive Maintenance

Preventive maintenance is maintenance that is

scheduled and periodically (Dhilon, 2006).

Preventive maintenance aims to expedite the

production process and reduce the possibility of

failures that will occur in the operating unit.

Preventive maintenance can also determine the

maintenance schedule so it can maintain the

performance of equipment and prevent

equipment from failing (MathWorks,2019).

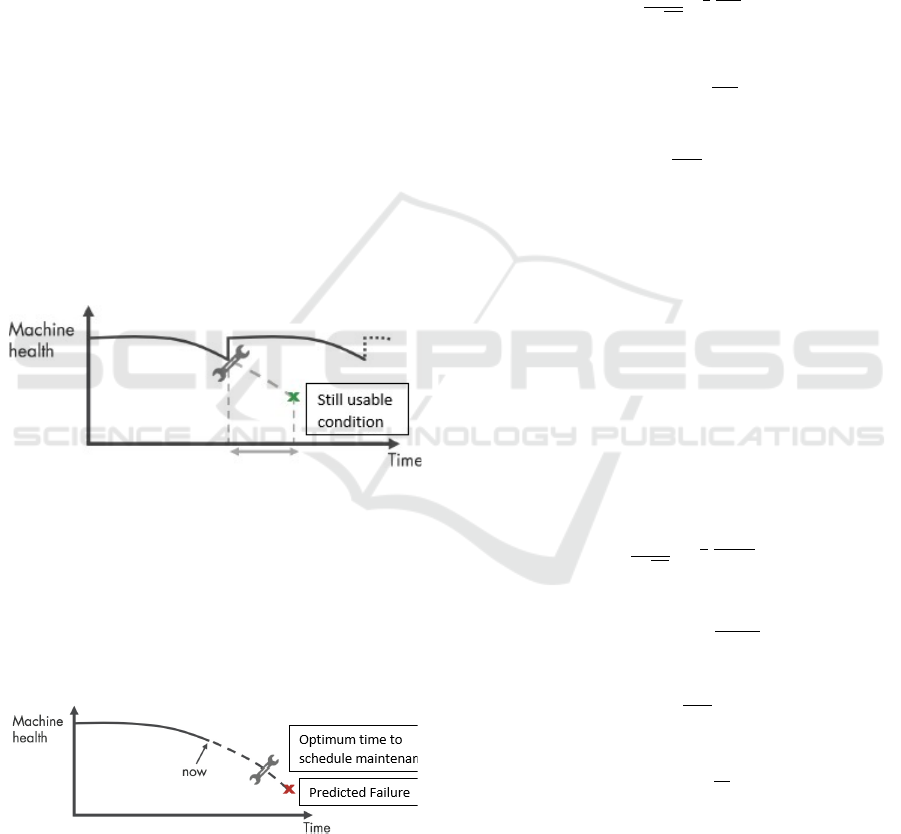

Figure 3: Preventive Maintenance.

c.

Predictive Maintenance

Predictive maintenance is a method that can predict

the lifetime of a component, based on inspection

or diagnosis so that the component's lifetime can

be known (Dhilon, 2006). Knowing the predicted

failure time will help to find the optimum time to

schedule maintenance for the equipment.

Figure 4: Predictive Maintenance.

C.

Quantitative Analysis Method

The quantitative analysis method is a numerical

method that can be used to determine the level of

reliability of equipment by using mathematical

calculations based on the distribution formula

(Ebelling,1997).

1.

Normal Distribution

A normal distribution is used to model the

phenomenon of wear and tear of the equipment or

operating unit. The parameter used is μ (middle

value) σ (standard deviation).

The reliability function is:

- Failure Distribution Function:

𝑓

(

𝑡

)

=

√

𝑒

[

(

)

]

(1)

- Reliability Function:

𝑅

(

𝑡

)

= 1 − 𝜙

(2)

- Failure Rate Function :

𝜆

(

𝑡

)

=

𝑓(𝑡) (3)

𝑅(𝑡)

- Mean Time to Failure :

𝑀𝑇𝑇𝐹 = 𝜇 (4)

t : Failure Time

𝜇 : Mean

𝜙 : Normal Distribution Table

𝜎 : Standard Deviation

2.

Lognormal Distribution

The lognormal distribution uses two parameters,

namely (μ) (shape parameter) and (σ) (location

parameter) which is the middle value of a failure

distribution. The reliability function is:

-

Failure Distribution Function :

𝑓

(

𝑡

)

=

√

𝑒

[

(

)

]

(5)

- Reliability Function :

𝑅

(

𝑡

)

= 1 − 𝜙 (

)

(6)

- Failure Rate Function :

𝜆

(

𝑡

)

=

()

()

(7)

- Mean Time to Failure:

𝑀𝑇𝑇𝐹 = 𝑒

(𝜇+

)

(8)

t : Failure Time

µ : Mean

σ : standard Deviation

Ф : normal distribution table

3.

Exponential Distribution

An exponential distribution is used to calculate

reliability which has a constant failure rate. The

Maintenance Analysis of Boiler Feed Water Pump using Quantitative Methods

1509

parameter used in the exponential distribution is λ

which indicates the average failure on the

component. The reliability function is0:

-

Failure Distribution Function :

𝑓

(

𝑡

)

= 𝜆𝑒

−𝜆𝑡

(9)

-

Reliability Function:

𝑅

(

𝑡

)

= 𝑒

−𝜆𝑡

(10)

-

Failure Rate Function:

𝜆

(

𝑡

)

=

𝜆

(11)

-

Mean Time to Failure:

𝑀𝑇𝑇𝐹 =

λ

(12)

t : Failure time

λ: lambda

4.

Weibull Distribution

Weibull distribution is the most widely used

distribution, this distribution is used for increasing

failure rates and decreasing failure rates. In this

Weibull distribution, there are 2 types, Weibull 2

parameter distribution, and Weibull 3 parameter

distribution. The reliability Weibull 2 parameter

distribution function is:

-

Failure Distribution Function:

𝑓

(

𝑡

)

=

(

)

𝑒

(

)

(13)

-

Reliability Function:

𝑅

(

𝑡

)

= 𝑒

(

)

(14)

-

Failure Rate Function:

𝜆

(

𝑡

)

=

(

)

(15)

β : beta

t : failure time

θ : teta

In addition to calculating reliability, the quantitative

analysis also analyzes the availability, availability is

the probability that a component carries out its

function within a certain period of time when used

during operating conditions (Dhilon, 2006).

𝐴

(

𝑖

)

=

(16)

MTBF : Mean time between failure

MTTF : Mean time to failure

MTTR : Mean time to repair

The availability value can change with time, it can be

written in the equation (Dhilon, 2006).

𝐴

(

𝑡

)

= 1 − [

− (

)𝑒

[

(

)

]

]

(17)

2

RESEARCH METHOD

The objective of this study is to determine the

reliability, Mean Time to Failure, type of maintenance,

and preventive maintenance scheduling on a boiler

feedwater pump by using quantitative methods. the

steps carried out in this study can be explained by this

flowcharts.

Figure 5: Flowchart Research.

This research to know the probability distribution and

the parameter by using ReliaSoft Weibull 6++

software. ReliaSoft Weibull6++ software is a data

analysis tool that performs utilizing lifetime

distribution, warranty, and degradation data analysis

geared toward reliability engineering.

The data input ReliaSoft Weibull 6++ software is

the time to failure (TTF) and time to repair (TTR) data

obtained form the industry. TTF and TTR data are

obtained from the length of time to repair and

vulnerable time between one failure and subsequent

failure.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1510

2.1 Procedure

There are several processes in simulating this Weibull

6 ++ software, i.e. Calculate the value of the TTF and

TTR from the downtime data on the BFP components.

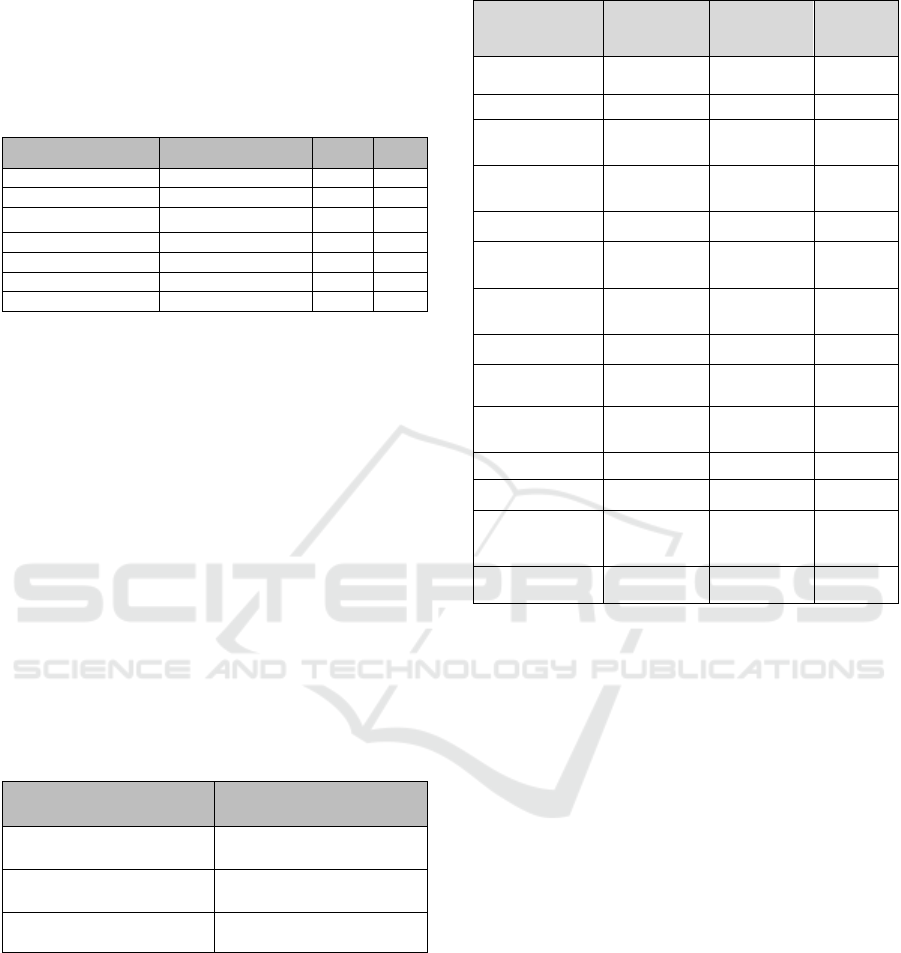

Table 1: Transmitter downtime data.

Actual Start Actual Finish TTF TTR

3/9/12 9.00 AM 3/9/12 3.00 PM 0 6

5/16/12 10.26 AM 5/21/12 1.22 PM 1627 123

10/9/12 4.42 PM 10/9/12 5.42 PM 3365 1

4/8/16 7.24 AM 4/8/16 7.24 PM 4358 0

4/8/16 9.00 AM 4/8/16 5.00 PM 4347 8

12/20/16 9.00 AM 12/20/16 3.00 PM 6120 6

4/5/18 8.00 AM 4/5/18 1.00 PM 11313 5

Simulate the TTF data or TTR data on ReliaSoft

Weibull 6++ software, after simulating the Weibull

6

++ software, then we will find out the exact distribution

used in the calculation of reliability in accordance with

the TTF data owned. in addition to the known types of

probability distributions that are also known parameter

values according to the type of distribution,

Transmitter

Weibull 2

parameter

b

eta (β) = 1,5789

Eta (θ) = 7108,98

2.2 Maintenance Recommendation

Maintenance recommendations for each BFP

component can be determined based on the type of

failure rate for each component. every component

has a maintenance technique to reduce the chance

of failure.

Table 2: Maintenance Recommendation.

Failure Rate Characteristic

Maintenance

Recommendation

DFR

(Decreasing Failure Rate)

Preventive maintenance

CFR

(Constant Failure Rate)

Corrective maintenance

IFR

(Increasing Failure Rate)

Preventive maintenance

3

RESULT AND ANALYSIS

Maintenance analysis with quantitative methods to

determine the reliability value of a component through

calculations using a probability distribution. the

results of the reliability calculation and the meantime

to failure on the BFP components

Table 3: Quantitative Analysis Result.

Components

Type of

Distribution

The time is

taken when R

(t) = 80%

MTTF

Turning Gear

Exponential 740 jam 3333,33

Bearing Lognormal 340 jam 2946,6

Mechanical Seal Weibull 2

parameter

30 jam 2121,71

Solenoid Valve

Weibull 2

parameter

167 jam 408,62

Sensor Exponential 90 jam 1666,67

LCV

Weibull 2

parameter

370 jam 2398,76

Control Valve

Weibull 2

parameter

26000 jam 40445,168

Relief Valve Exponential 1100 jam 5000

Frame Pump and

turbine

Lognormal 1200 jam 8509,22

Transmitter

Weibull 2

parameter

2700 jam 6382,11

Accumulator Exponential 12800 jam 57428,358

Regulator Exponential 12800 jam 57428,358

Indicator Gauge

(pressure and

Temperature)

Weibull 2

parameter

945 jam 3137,15

Line dan Valve Exponential 6450 jam 28964,518

The results of quantitative analysis that has been done

by calculating the reliability and MTTF on each BFP

component. Form fig 6 can be seen that the value of

reliability decreases with time due to lifetime and

components that have decreased component function

over time. In the calculation of the Mean Time to

Failure value in the BFP component, the higher the

MTTF value indicates that the component rarely have

fails and the lower MTTF value indicates that the

component often has failed. this is because when the

MTTF value decreases the distance between failures

is very close so it can be concluded that the

component most often has a failure.

From table 3 it can be concluded that the

component has most frequently failed is the solenoid

valve with an MTTF value of 408.62. Failure that

often happened in the solenoid valve is the solenoid

coil broken because of the poor quality of electronic

components so that failure often occurs. The highest

MTTF value is the accumulator and regulator with an

MTTF value of 57428,358, this indicates that the

accumulator and regulator are the most often

components have failure and the time interval

between failures is quite long. the highest the MTTF

value, it shows that the components more

Maintenance Analysis of Boiler Feed Water Pump using Quantitative Methods

1511

Figure 6: Reliability Graphic on BFP component.

often have a failure, and the smallest MTTF value

indicates the component is most often has a failure.

Form the distribution parameter it can calculate the

failure rate on every component of BFP. There are

three kinds of failure, increasing failure rate,

decreasing failure rate, and constant failure.

Figure 7: Constant failure rate graphic.

Figure 8: Decreasing Failure Rate.

Figure 9: Increasing Failure Rate.

The constant failure rate graph above shows the

components are in a constant condition. the failure rate

characteristic with the constant graph above is

Constant Failure Rate (CFR), it means that this

equipment is in the useful life phase or the equipment

is in a condition where there is not increasing or

decreasing in failure and the failure that occurs on this

CFR phase is mostly caused by human error. The

graph with the CFR (Constant Failure Rate)

characteristic is also caused by the lambda parameter

value (λ) on the exponential distribution (Dhilon,

2006).

The second failure rate graph above shows that

there is a decreasing in the failure rate over time, the

failure rate characteristic with the decreasing graph is

the Decreasing Failure Rate (DFR), it means that this

equipment is in the burn-in phase and the failure in the

components that have DFR graph is caused due to

defects in the production of manufacturing

(Ebelling,1997). The graph with the DFR (Decreasing

Failure Rate) characteristic is also by the results of the

2-parameter Weibull distribution where the value of

the shape parameter (β) is less than 0 (Dhilon, 2006).

The third failure rate graph above shows that there

is an increase in the failure rate over time, the

characteristics of the failure rate with the graph

increase as above are Increasing Failure Rate (IFR),

it means that this equipment is in the wear-out phase

or long use and the failure caused is due to fatigue,

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1512

corrosion, aging and many more (Ebelling,1997). To

reduce these failures, preventive maintenance is

required to reduce the failure rate. The graph with the

IFR (Increasing Failure Rate) characteristic is also

caused by the results of the 2 parameters Weibull

distribution with the value of the shape parameter (β)

is more than 2 (Dhilon, 2006).

Each BFP components have their failure rate

graph, the failure rate graph can also determine the

appropriate maintenance recommendations for each

component. The following table shows the

characteristics of the failure rate and maintenance

recommendations for each component of the boiler

feedwater pump.

Table 4: Failure Rate Characteristics and Maintenance

Recommendation.

No Equipment

Failure Rate

Characteristics

Maintenance

Recommendation

1 Turning Gear

CFR

(Constan

t

Failure Rate)

Corrective

maintenance

2 Bearing

DFR

(

Decreasing Fai lure Rate

)

Preventive

maintenance

3 Solenoid Valve

DFR

(

Decreasing Fail ure Rat e

)

Preventive

maintenance

4 Mechanical Seal

DFR

(

Decreasing Failure Rate

)

Preventive

maintenance

5 LCV

DFR

(

Decreasing Failure Rate

)

Preventive

maintenance

6 Sensor

CFR

(Constant Failure Rate)

Corrective

maintenance

7 Control Valve

IFR

(Increasing Failure Rate)

Preventive

maintenance

8 Relief Valve

CFR

(Constan

t

Failure Rate)

Corrective

maintenance

9 Frame Pump dan

turbine

DFR

(

Decreasing Failure Rate

)

Preventive

maintenance

10 Transmitter

IFR

(Increasing Failure Rate)

Preventive

maintenance

11 Accumulator

CFR

(Constan

t

Failure Rate)

Corrective

maintenance

12 Regulator

CFR

(Constant Failure Rate)

Corrective

maintenance

13 Indicator Gauge

(pressure and

Temperature)

IFR

(Increasing Failure Rate)

Preventive

maintenance

14 Line dan Valve

CFR

(Constan

t

Failure Rate)

Corrective

maintenance

The components that have a CFR (Constant

Failure Rate) failure rate indicates that maintenance

recommendation is corrective maintenance, this is

because when the component is in the CFR phase it

indicates that the component is in the useful life phase

or the component is in a condition to operating

properly according to its function, and for

components with CFR failure rates that occur due to

human errors. To reduce this failure in the

components that are in the CFR phase, corrective

maintenance can be carried out by replacing damaged

or decreased performance components with new

components so that they can run properly.

Components that have the characteristics of the

IFR lure rate (Increasing Failure Rate) and DFR

creasing Failure Rate) recommended maintenance

preventive maintenance because the components at

have IFR failure rate characteristics are in wear- ut

condition. Failures that often occur in components

with IFR failure rates are fatigue, corrosion, aging

(lifetime), etc. So to avoid this failure, it is necessary

to periodically check the conditions so the

performance of the BFPT components is well

maintained and components have a DFR (Decreasing

Failure Rate) failure rate are also recommended for

preventive maintenance because the components at

the DFR failure rate are in burn-condition or the

component has just been operated and has failed.

Failures that occur are due to manufacturing defects

that reduce the performance of the components when

used, so preventive maintenance is needed so that the

defect does not cause excessive failure to a

component, and the performance of the boiler

feedwater pump is well maintained.

4

CONCLUSION

The emphasis of this research is the use of quantitative

analysis methods to determine the maintenance of the

Boiler Feed Water Pump. From the results are, it can

be concluded that the Boiler Feed Water Pump is a

critical component that often has fails. The results of

the analysis using quantitative methods are calculating

reliability, MTTF, and failure rate using probability

distribution that the reliability of the Boiler Feed

Water Pump components decreases over time, the

decrease in reliability is due to age or lifetime, thus

affecting the BFP's components performance. The

result of the Mean Time To Failure calculation is the

value on the BFP component obtained the lowest

MTTF value is the solenoid valve and the highest

MTTF value on the accumulator and regulator. This

MTTF value shows how often the BFP component has

failed, the smaller the MTTF value indicates that the

component often has failed and the highest the MTTF

value means that the component rarely has failed.

Determination of maintenance recommendations for

BFP components based on the failure rate

characteristics of each component, components that

have CFR failure rate characteristics, maintenance

Maintenance Analysis of Boiler Feed Water Pump using Quantitative Methods

1513

recommendations are corrective maintenance, and the

maintenance recommendation for components that

have failure rate IFR and DFR are preventive

maintenance.

REFERENCES

Secretariat

General National Energy

Council, (2019).

Indonesia Energy Outlook 2019. ISSN 2527-3000,

Jakarta.

R. Ahmed, M. Billah, and M. M. Hossain. (2012).

Increasing the efficiency of steam power plant with

the help of solar energy. 2nd International Conference

on the

Developments in Renewable Energy

Technology

(ICDRET 2012). Dhaka. pp. 1-3.

PLTU 1 JAWA TENGAH 2X (300-400) MW COAL

FIRED POWER PLANT. Turbine Manual Operation.

L. Tadj, M. S. Ouali, S. Yacout, D. Ait-kadi. (2011).

Replacement Models with Minimal Repair. London:

Springer-Verlag.

B. S. Dhilon. (2006). Maintainability, Maintenance, and

Reliability for Engineers. United States of America:

Taylor & Francis Group.

A. A. Mendes and J. L. D. Ribeiro. (2015). A study of

the quantitative methods that support RCM operation.

Proc. - Annu. Reliab. Maintainab. Symp., vol. 2015-

May,

no.

May.

doi:

10.1109/RAMS.2015.7105162.

F. J. G. Carazas, C. H. Salazar, and G. F. M. Souza.

(2011). Availability analysis of heat recovery steam

generators used in thermal power plants. Energy, vol.

36, no. 6, pp. 3855–3870.

S. Yoshikawa. (2016). Boiler Feed Pump. Ebara

Engineering Review No. 251 (2016-4).

J.-H. Shin and H.-B. Jun. (2015). On condition based

maintenance policy, J. Comput. Des. Eng., vol. 2, no. 2,

pp. 119–127.

Patton, Jr., and Joseph, D. (1995). Preventive

Maintenance. The International Society for

Measurement and Control. United States.

B.S. Dhillon. (2006). Maintainability, Maintenance, and

Reliability for Engineers. New York: Taylor & Francis

Group, LLC.

MathWorks. (2019). Introduction to Predictive

Maintenance with MATLAB. pp. 1–17.

C. E. Ebeling. (1997). Intro to Reliability &

Maintainability Engineering.pdf.. p. 486.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1514