Real-time Monitoring Method for Carbon Dioxide and Residual

Oxygen in Medical Package

Xin Chen

1,2,1st

, Chunhong Zhang

3,1st

, Yuanlan Huang

3,1st

and Dan Li

3,*

1

Jinan Guoke Medical Technology Development Co., Ltd, Jinan, 250001, China

2

Shandong Engineering Technology Research Laboratory, Suzhou Institute of Biomedical Engineering and Technology,

Chinese Academy of Sciences, Suzhou, 215163, China

3

PLA Naval Medical Center, China

1st: Joint author

*

Corresponding author

Keywords: Vials, Medicine Packaging, Inert Gas Packaging, Nitrogen-Filled Packaging, Modified Packaging, Carbon

Dioxide Content, Residue Oxygen Content.

Abstract: Objective inert gas in vial is commonly used form of packaging which to prevent the drug deterioration.

Oxygen and carbon dioxide were remained in vial bottle is an important factor for medicine quality which be

strengthened monitoring. Methods The residue amount of carbon dioxide and oxygen were tested in different

kinds of vials, respectively. The test method of gas content in pharmaceutical packaging was introduced, and

the results were compared and analyzed. Results The results of experiment show that 1# gas contents in sample

is consistent with air, 2# and 3# samples are nitrogen-filled packaging, and oxygen and carbon dioxide content

in 3# sample changed little after a month. Therefore, 3# sample has the best preservation effect. Conclusion

The method with high test efficiency, can quickly and effectively reflect the gas component in samples.

According to the changes of gas component along with time in the packaging, preservation effect of 3# sample

is the best one in three kinds medicine samples.

1 INTRODUCTION

Most pharmaceutical products are sensitive to oxygen

and are easy to be oxidized causing deterioration,

discoloration, peculiar smell and the like, which not

only affects the curative effect of the products, but

also causes toxic and harmful substances generated

by oxidation to even endanger life, and drugs

containing hydroxide, calcium salt and other

components are easy to absorb carbon dioxide to

generate carbonate (Zhou, Mei 2011, Ma 2011, Zhou

2008). In order to reduce the amount of oxygen and

carbon dioxide contacted by drugs, oxygen and

carbon dioxide sensitive drugs are usually packaged

in the form of vacuum pumping, inert gas (generally

nitrogen) filling and the like.

As common medical packaging, vials are

mainly divided into soda-lime glass, borosilicate

glass, neutral borosilicate glass, plastic and other

material types, which can be used for packaging

powder injection, vaccine, lyophilized agent,

biological preparation and other drugs, most of

which adopt nitrogen-filled packaging form, and

are sealed with rubber, metal and plastic combined

cover (Huang, Zhu, Chen 2013, WANG, ZHAO

2007). Due to the limitation of inflation equipment

and process, the contents of nitrogen, oxygen and

carbon dioxide in the finished package of vials may

be different from expectations. In addition, under

the influence of packaging barrier and sealing (Fan

2014), the gases inside and outside the package

may exchange slowly, resulting in the changes of

the contents of the above gases with the extension

of storage time. Therefore, the timely detection and

dynamic monitoring of the gas composition in the

nitrogen-filled vials have certain guiding role in

preventing the deterioration of drugs and

determining the appropriate shelf life.

At present, many enterprises only rely on using

barrier packaging materials to hinder gas infiltration

/exudation of packaging materials, and cannot

eliminate the existing oxygen and other gases in the

Chen, X., Zhang, C., Huang, Y. and Li, D.

Real-time Monitoring Method for Carbon Dioxide and Residual Oxygen in Medical Package.

DOI: 10.5220/0011244800003444

In Proceedings of the 2nd Conference on Artificial Intelligence and Healthcare (CAIH 2021), pages 209-213

ISBN: 978-989-758-594-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

209

packaging, and also lack real-time monitoring of the

internal gas composition. Instead, the monitoring of

the gas composition in the packaging should cover

any circulation link of the product, including just

completed packaging, storage process, transportation

process, sales process, expiration of the shelf life and

so on. The actual test results will also be used as

strong evidence for judging the quality of the goods.

(FAN 2012, WU, LIANG 2011) At present, GB/T

6285-2003 Determination of Trace Oxygen in

Gases—Electrochemical Method (Fan 2014) is the

standard for the test of oxygen content in gas, and no

method standard for the test of gas composition

content in packaging has been issued. In this paper,

according to the general testing methods and testing

experience in the industry, the oxygen and carbon

dioxide contents in several different packaging forms

of vials were tracked and tested.

2 TEST PRINCIPLE

Insert the sampler into the inside of the package to be

tested and collect enough sample gas from the top of

the package. The sample gas is introduced into the gas

analysis sensor, and the test data are recorded after a

certain test time interval or the gas concentration

output value of the gas analysis sensor is stable.

The corresponding gas analysis sensors are

needed for the test of different gas contents. When

testing the oxygen content in the sample gas, the

sample gas needs to be introduced into the oxygen

analysis sensor; when testing the carbon dioxide

content in the sample gas, the sample gas needs to be

introduced into the carbon dioxide analysis sensor.

For known packages filled with high purity nitrogen

inside, the nitrogen content in the packaging can be

obtained by subtracting oxygen content, carbon

dioxide content and other known gas content from the

total gas content.

3 DETECTION EQUIPMENT AND

METHOD

3.1 Test Instruments and Samples

3.1.1 Instruments and Their Performance

The test equipment used in this test is HGA-02

Headspace Gas Analyzer independently developed

and produced by Jinan Labthink Electromechanical

Technology Co., Ltd., which meets the requirements

of GB/T 6285 and is equipped with high-precision

oxygen and carbon dioxide sensors, a sliding test

head capable of testing samples at any height and a

high precision sampling device capable of absorbing

small volume gases (Fig.1), and is suitable for rapid

and accurate detection and analysis of the content and

mixing ratio of oxygen and carbon dioxide in flexible

plastic packaging bags and containers in production

sites, warehouses, laboratories and other occasions.

When the oxygen content is 0~2%, the test accuracy

is ±0.3% (absolute value), and ±0.5% (relative value)

when the oxygen content is 2~100%; the test range of

carbon dioxide is 0~100%, and the test accuracy is

±0.5%.

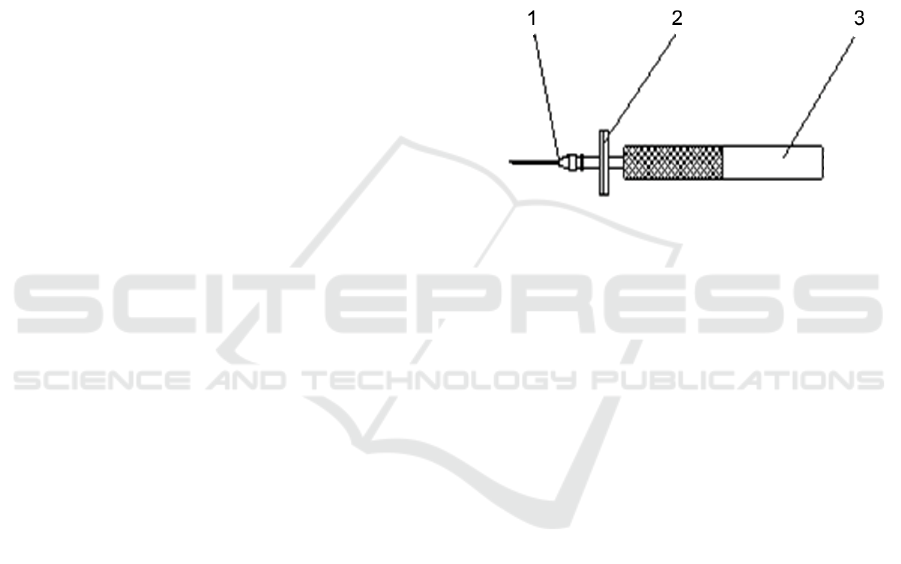

1. Sampling needle, 2. Filter, 3. Handle

Figure 1: Diagram of the Structure of High Precision

Sampling Device.

3.1.2 Samples

In this test, three kinds of vial powder injection

samples were used, numbered 1#, 2# and 3#

respectively, one of which was in ordinary air

packaging, and the other two were in nitrogen-filled

packaging. The number of samples for each kind of

sample should be sufficient to complete the entire

test, at least five, and take the average test as the test

result. The samples should be placed in the dryer for

more than 48 h under the sample condition

adjustment and standard environment specified in GB

/ T 2918.

3.2 Test Method

(1) Determine the appropriate test parameters

according to different equipments before verification.

The main factors affecting the stability and reliability

of the test results are sample gas extraction and

sample gas flow through the sensor. When the sample

gas extraction speed and the sample gas flow rate in

the instrument are constant, the sample gas extraction

and the sample gas flow through the sensor are related

to the sample gas extraction time and the sample gas

analysis time respectively. Therefore, it is necessary

to determine the optimal sample gas extraction time

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

210

and sample gas analysis time to prevent its impact on

the test results. Set the sampling time, analysis time

and other test parameters on the control panel of

Headspace Gas Analyzer, and the sampling time and

analysis time of this test are set to 12 s.

(2) Place the finished packing sample of vial in

the gas collection device, carefully remove the

stopper of the vial, and the gas in the bottle will be

collected in the gas collection device. Stably place the

sample, then insert the sampling needle into the inside

of the package through the middle part of the sealing

gasket. The puncturing force shall be appropriate to

prevent the sampling needle from sticking into the

contents of the package, causing the needle to become

blocked or broken.

(3) Carefully insert the sampling needle into the

gas collection device (Fig.2). Click the test button to

start the test. The sampling needle shall not be pulled

out from the gas collection device. The sample gas to

be tested in the sampler shall be introduced into the

detection device through the sample injection port.

The sample gas will enter the gas analysis sensor

through the sample injection port and pipeline. The

instrument collects the sample gas in the gas

collection device and analyzes it. After the test, the

test results, i.e. oxygen content and carbon dioxide

gas content, are automatically displayed. Five

specimens of each sample were tested in parallel.

1. Samples, 2. Sealing gasket

Figure 2: Schematic diagram of gas sampling with gas

collection device.

4 RESULTS AND DISCUSSION

4.1 Gas Sampling Time

The analysis time of sample gas is fixed at 12 s. The

optimum time of gas sampling time is determined by

measuring the gas content in three kinds of samples

with the sampling time changed in the range of 4s -

12s. The test results are shown in Table 1.

The data in Table 1 show that when the sampling

time is 8 s - 12 s, the oxygen content test results of the

three samples are stable and independent of the

sampling time, with the maximum error <2% and

standard deviation RSD <0.5%. Therefore, the

sampling time of this equipment is fixed at 12 s to

ensure that sufficient sample gas is drawn.

4.2 Gas Analysis Time

The gas sampling time is fixed at 12 s. The optimal

analysis time of sample gas is obtained by testing the

gas content in three kinds of samples with the gas

analysis time varied within the time range of 8 s - 18

s. The test results are shown in Table 2.

The data in Table 2 show that when the analysis

time of the three kinds of sample gases exceeds 11 s,

the oxygen content test results are stable regardless of

the change of analysis time, with maximum error

<3% and standard deviation RSD <0.5%. In order to

ensure the stability of the test results and reduce the

test time, the preferred gas analysis time of this

equipment is set to be 12 s.

4.3 Sample Testing and Analysis

In this test, the oxygen and carbon dioxide contents

of the three samples before and after the interval of 1

month are tested respectively. The test results are

shown in Table 3.

Table 1: Gas Content Analysis Results for Different Gas Sampling Times

Sampling time (s) Sample 4 5 6 7 8 9 10 11 12

Oxygen content (%)

1# 19.31 19.57 21.17 20.49 20.36 20.47 20.35 20.38 20.41

2# 1.83 1.96 1.81 1.92 2.09 2.11 2.09 2.10 2.12

3# 0.85 0.92 1.09 0.95 1.19 1.19 1.20 1.18 1.20

Carbon dioxide

content (%)

1# 0.02 0.02 0.03 0.02 0.02 0.02 0.02 0.03 0.02

2# 0.01 0.00 0.01 0.02 0.01 0.00 0.00 0.01 0.01

3# 0.00 0.01 0.00 0.01 0.00 0.00 0.00 0.01 0.00

Real-time Monitoring Method for Carbon Dioxide and Residual Oxygen in Medical Package

211

Table 2: Gas Content Analysis Results for Different Gas Analysis Times.

Sampling time

(s)

Sample 8 9 10 11 12 13 14 15 16 17 18

Oxygen

content (%)

1# 19.05 21.00 20.46 20.53 20.49 20.39 20.46 20.37 20.41 20.50 20.47

2# 1.73 1.80 1.91 2.07 2.09 2.09 2.11 2.10 2.12 2.10 2.09

3# 1.05 1.12 1.07 1.20 1.19 1.17 1.19 1.21 1.18 1.20 1.20

Carbon

dioxide

content (%)

1# 0.03 0.02 0.03 0.03 0.02 0.02 0.02 0.02 0.03 0.02 0.02

2# 0.01 0.01 0.02 0.00 0.00 0.01 0.00 0.00 0.01 0.00 0.00

3# 0.01 0.00 0.01 0.00 0.00 0.00 0.00 0.01 0.00 0.01 0.00

Table 3: Test results of oxygen and carbon dioxide content in three samples.

Gas content/%

1# sample 2# sample 3# sample

Before 1

month

After 1

month

Before 1

month

After 1

month

Before 1

month

After 1

month

Oxygen

content

1 20.31 20.76 2.16 16.31 1.26 2.99

2 20.56 20.23 2.03 16.49 1.18 3.04

3 19.70 20.31 2.07 16.08 1.20 3.09

4 20.64 20.51 2.11 15.94 1.21 3.13

5 20.11 20.57 2.17 16.18 1.17 3.06

Average 20.26 20.48 2.11 16.20 1.20 3.06

Standard

deviation

0.38 0.21 0.059 0.21 0.035 0.052

Carbon

dioxide

content

1 0.03 0.02 0.01 0.01 0.00 0.00

2 0.02 0.02 0.01 0.02 0.00 0.01

3 0.03 0.03 0.00 0.02 0.00 0.01

4 0.02 0.02 0.02 0.02 0.00 0.00

5 0.02 0.02 0.00 0.01 0.00 0.00

Average 0.02 0.02 0.01 0.02 0.00 0.004

Standard

deviation

0.0055 0.0045 0.0084 0.0055 0.00 0.0055

As can be seen from Table 1, the standard

deviation of the 12 groups of data is low, indicating

that the dispersion degree between the test data of

each group is small, and the test method for testing

the oxygen and carbon dioxide content in the package

adopted in this paper has good stability and

repeatability.

The detection data of the three samples before one

month showed that the contents of oxygen and carbon

dioxide in 1# sample bottle were high, which were

basically the same as those in air, indicating that the

gas in 1# sample was ordinary air. The contents of

oxygen and carbon dioxide in 2#and 3# samples are

obviously lower than those in 1# sample, which are

nitrogen-filled packaging, and the contents of oxygen

and carbon dioxide in 3# sample are the lowest. The

difference of oxygen and carbon dioxide content in

the nitrogen-filled packaging is related to the nitrogen

filling process and the purity of the filled nitrogen. In

order to ensure the quality guarantee effect of the

nitrogen-filled packaging, the content of nitrogen in

the package should be increased, and the contents of

oxygen and carbon dioxide in contact with the

medicine should be reduced. Therefore, the air in the

package should be removed as far as possible before

nitrogen filling, the volume of residual gas should be

reduced, and the purity of the filled nitrogen should

be ensured.

After a comprehensive analysis of the test data of

the three samples before and after one month's

interval, the oxygen and carbon dioxide contents in

1# sample did not change significantly; the content of

both gases in the 2# sample increased after being

placed for one month, and the oxygen content

increased by about 7 times; the oxygen and carbon

dioxide contents of 3# sample only increased slightly.

This shows that among the three samples, 3# sample

has good barrier property and sealing property, which

can effectively prevent the gas exchange inside and

outside the bottle; 2# sample has poor barrier

property or sealing property, and the gas in the

environment permeates into the sample at a high

speed, while 1# sample is ordinary air, so it is

impossible to infer the barrier property or sealing

effect from the change of oxygen and carbon dioxide

content. From the point of view of the preservation

effect of the sample on the internal gas, if the same

drug is packaged, the quality guarantee effect of 3#

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

212

sample on the packaged drug is better, and the quality

guarantee period can be relatively prolonged.

5 CONCLUSIONS

The content of oxygen and carbon dioxide in

packaging is an important factor affecting the quality

of pharmaceuticals, and the residual oxygen is one of

the basic requirements of GMP for inert gas

packaging of sterile drugs. In this paper, the contents

of oxygen and carbon dioxide in three kinds of vial

powder injection samples were measured by

Headspace Gas Analyzer, and the contents of residual

oxygen and carbon dioxide in 3# sample were the

lowest and the gas preservation effect was the best.

From the test process, the test method used in this

paper is simple, short-time, high-efficiency, and can

quickly and effectively reflect the gas content in the

samples, also reduce the number of defective

products with unqualified internal gas composition in

the production line, effectively control the proportion

of oxygen and carbon dioxide in the gas-modulated

packaging of drugs, promote the overall quality of

domestic packaging products to pursue the goal of

high standards and high quality, and accelerate the

large-scale use of innovative and convenient modern

test equipment in domestic drugs and other industries.

At present, the testing technology both at home

and abroad have no uniform standard test methods,

but the test principle, test structure, test indicators and

other specific content has been initially formed. Due

to the lack of standard support, versatility and data

comparability are not high. Therefore, there is an

urgent need for the development and publication of

relevant standards in the industry, and only with

testing standard specification can this method and

quantitative indicators be effective in product

standards.

REFERENCES

FAN Jun. The Relation between Headspace Gas Analysis

and Shelf Life of Package[J]. Packaging Engineering,

2012,33(5):146.

Fan Y. (2014) Air Tightness Inspection of Vial Container

[J]. Heilongjiang Medicine Journal, (3): 593-595.

GB/T 6285-2003, Determination of Trace Oxygen in Gases

- Electrochemical Method [S]. Fan Y. (2014) Air

Tightness Inspection of Vial Container [J].

Heilongjiang Medicine Journal, (3): 593-595.

Huang W.C., Zhu L., Chen Z., et al. (2013) The Application

of Neutral Borosilicate Vial in Freeze-Dried Hepatitis

A Vaccine Production [J]. International Journal of

Epidemiology and Infectious Disease, 40(2): 139-140.

Ma C.L. (2011) Discussion on the Deterioration of Chinese

Herbal Medicine and its and Prevention [J]. Chinese

and Foreign Medical Research, 23 (9): 147-148.

WANG Xing-dong, ZHAO Jiang. Packing Efficiency and

Correlation detection of Nitrogen[J]. Packaging

Engineering, 2007, 28(9):213-214.

WU Shu-yi, LIANG Yi. Observation and Discussion of the

Latest In-line Headspace Oxygen Monitoring[J].

Mechanical and Electrical Information,2011, (32):42-

44.

Zhou J.Q., Mei D. (2011) Effects of Drug Packaging

Materials on Drug Quality and Safety [J]. Adverse

Drug Reactions, 13(1): 27-31.

Zhou Y. (2008) Discussion on Factors of Drug

Deterioration and its Control Measures [J]. Chinese

Journal of Modern Drug Application, 10 (2): 116-117.

Real-time Monitoring Method for Carbon Dioxide and Residual Oxygen in Medical Package

213