Improved Method for Measuring the Pulse Wave Propagation

Velocity for Palpable Arteries

V. E. Antsiperov

a

, M. V. Danilychev, G. K. Mansurov and E. R. Pavlyukova

Kotelnikov Institute of Radioengineering and Electronics Russian Academy of Sciences, Moscow, Russian Federation

Keywords: Arterial Blood Pressure Sensor, Arterial Walls Stiffness, Pulse Wave Propagation Velocity.

Abstract: The results, regarding the development and testing of a quantitative method for diagnosing the condition of

the arterial walls, based on the application of a three-channel pneumatic sensor of an original design, are

presented. The possibility of using the data obtained by this device in combination with synchronous ECG

measurement to determine the velocity of pulse wave propagation between two cross sections of the selected

artery has been demonstrated. One of the key points of this technology is the selection of a specific pulse

wave element as a reference mark for tracking the signal transit time relative to the R-peak of the synchronous

ECG. After collecting measurement statistics, the average values of the wave propagation time between the

selected points of the artery, considering the variability of the front delay values, are used to directly calculate

the propagation velocity of the pulse wave in the investigated area of the artery. The value of the pulse wave

propagation velocity in return is an objective parameter that characterizes the degree of elasticity (or stiffness)

of the artery walls and their behaviour in different physiological situations.

1 INTRODUCTION

In previous articles (

Mansurov, 2019)

(

Antsiperov,

2020)

, the authors have developed and experimentally

investigated a line of unique sensors for recording the

blood pressure continuous dynamics.

Good results concerning the recording data

quality have been achieved with the development of

a three-channel pneumatic sensor for continuous non-

invasive blood pressure monitoring (

Mansurov, 2019)

.

Thanks to the addition to the sensor of a parallel

channel for synchronous recording of the ECG signal,

it became possible to for the combined device to

measure the absolute timing characteristics of the

pressure pulse waves, the main of which is the pulse

wave velocity (PWV). On the basis of the latter, it is

possible to assess the stiffness of the arterial walls,

which is directly related to the early manifestations of

symptoms of atherosclerosis.

Undoubtedly, the most important directions in the

fight against atherosclerosis are its prevention and

early diagnosis. In the early stages, even before the

appearance of obvious clinical signs, atherosclerosis

is characterized by an outwardly weak loss of the

main functions of the blood vessels. First, this is

a

https://orcid.org/0000-0002-6770-1317

manifested in the loss of elasticity by the vascular

walls. The process of increasing the stiffness of the

arterial walls leads to an increase in blood pressure

(BP), narrowing of the lumen of the arteries and a

deterioration in blood circulation in general. It has

long been established that one of the most adequate

methods for assessing arterial wall stiffness (gold

standard) is the measurement of pulse wave velocity

(PWV) value. Physically, PWV is the group velocity

of a pressure wave propagating along the elastic walls

of an artery because of the ejection of a mass of blood

from the left ventricle of the heart during systole.

Within the framework of the first order, linear

approximation, the theory of hydroelasticity gives the

following value for the velocity 𝑉 of an elastic wave

(Korteweg, 1878):

𝑉=

,

(1)

where E denotes the effective (tangential) Young's

modulus, parameters ℎ and 𝐷 are the wall thickness

and vessel diameter in rest, respectively, and 𝜌 is the

blood density in the vessel. It follows from (1), which

is known as Moens-Korteweg equation, that a growth

Antsiperov, V., Danilychev, M., Mansurov, G. and Pavlyukova, E.

Improved Method for Measuring the Pulse Wave Propagation Velocity for Palpable Arteries.

DOI: 10.5220/0010832100003123

In Proceedings of the 15th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2022) - Volume 1: BIODEVICES, pages 149-154

ISBN: 978-989-758-552-4; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

149

of the elasticity E of the vessel wall and a decrease in

its diameter 𝐷 lead to a increase in the value 𝑉 of

PWV.

The natural method of measuring the pulse wave

travel time (PWTT) between a pair of given points

located proximally on the arterial wall is a direct

method of measuring PWV. Direct measurement of

PWV requires a pair of sphygmometric sensors

located proximally above the superficial vessels

(arteries) and distal to the heart. Any of the pairs of

points located above the carotid, femoral, radial, and

other palpable arteries are suitable for this role. If the

distance 𝑑 between such pair of points is known and

the delay ∆𝑡 of pulse wave transition time between

these points is measured, then the PWV value is

obviously the ratio of the first of them to the second:

𝑉=

∆

=

,

(2)

where 𝑡

and 𝑡

are the time moments when the pulse

wave passes through the locations of the selected

points. How these moments are measured is not an

easy question. They can be measured by the event of

passing of a specific waveform-related label, which

can be the foot of the waveform, its maximum, the

maximum slope of the wavefront, etc. (Katsuura

, T. et

al, 2017

).

2 PWV ESTIMATION BASED ON

CONTINUOUS BLOOD

PRESSURE REGISTRATION

Earlier, we developed and tested a new three-channel

pneumatic sensor for continuous non-invasive blood

pressure monitoring (

Antsiperov, 2020). An obvious

advantage of the developed device is the possibility

of a continuous measurement of the dynamics of

blood pressure, which allows not only to determine

the current systolic / diastolic pressure, but also to

track the dynamics of blood pressure, both within the

cycle and at significant time intervals. At the same

time, it is not always possible to correctly calibrate

the measured value in pressure units. For correct

measurement of blood pressure in absolute units, a

certain position of the sensor above the artery is

required, as well as a rigid base below it, such as the

radial bone for the artery of the same name

(

Antsiperov, 2020). Only under the properly positioned

sensor the pressure in the working chamber of the

sensor could be considered equal to the blood

pressure in the artery (Figure. 1)

It was found experimentally that for arteries

whose location does not satisfy the above conditions,

it is possible to observe a pressure pulse wave signal,

the level and amplitude of which is noticeably

distorted by viscoelastic tissues lying both between

the sensor and the artery and beneath artery.

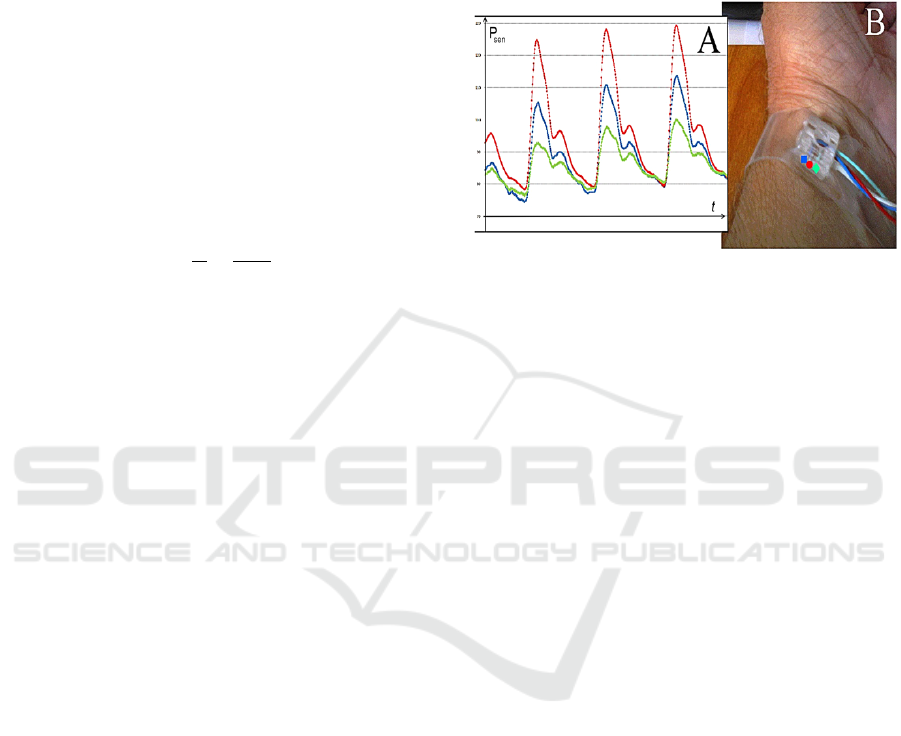

Figure 1: Three-channel pneumatic sensor for continuous

non-invasive arterial blood pressure monitoring (B). The

difference is the shape of the pulse wave signal from the

sensor (A), depending on the position of the sensor pads: ●

– pad is directly over the artery, ■. ♦ – pad is shifted to the

left and to the right respectively from the central projection

of the radial artery.

However, the general structure and corresponding

temporal characteristics of the signal are retained in

this case as well. This effect can be used to measure

the delay of signal front relative to the ECG reference

element. To solve the problem of the assessment of

pulse wave propagation velocity a unique way to use

pneumatic sensors was developed. The idea was the

following: if it is possible to take measurements for a

pair of points on the artery for a finite time with the

patient's condition unchanged, then you can try to do

it with the only one sensor. Evidently, the position of

the R-wave on the ECG can be used as a periodically

repeating reference "zero". For this purpose, an

additional channel for synchronous measurement of

the electrocardiographic (ECG) signal was integrated

into the pressure sensor configuration. In this case,

speaking in the language of radio engineering, this

channel acts as a kind of reference signal. The ECG

amplifier circuit was developed with the expectation

of using dry electrodes without a conductive gel and

without a neutral electrode, that required the

application of both analogue circuitry and digital

filters. The simplified scheme was selected to

minimize the inconvenience when applying and

removing the electrodes and is used so far at the

development stage only.

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

150

3 PWV BASED ON ABP/ECG

JOINT REGISTRATION

To solve this problem, we, together with

NEUROCOM LLC, have developed a new design

configuration of a portable sensor, which does not

require rigid attachment to the patient's body and

allows, with a certain skill, to take measurements in

many important positions (Figure 2). The three-

channel pneumatic sensor of a new configuration

(type) allows continuous measurements for several

minutes, even in some hard-to-reach places.

Figure 2: The version of the pressure sensor for measuring

short patterns of blood pressure with a built-in ECG channel

(two coloured button connectors).

Existing methods for assessing the stiffness of the

arterial walls by the pulse wave propagation velocity

are based, as a rule, on measuring the time of

propagation of the pulse wave along the radial artery

by the delay in the appearance of the wave on the

wrist relatively to the preceding R-peak of the

electrocardiogram. It was demonstrated (Kortekaas

,

2018

)

that the moment when the pulse wave appears

in the aorta does not coincide with the R-peak of the

ECG but has a certain time lag. The magnitude of this

lag differs for certain age groups and diseases, and it

varies relatively weakly within these categories. Even

this small variability has a significant impact on the

accuracy of pulse wave velocity (PWV)

measurements. The error in measuring the PWV

value mainly depends on the accuracy of measuring

the signal delay time, since the length of the section

of the artery under study can be measured quite

precisely. The distance from the aorta to the radial

artery in the area of the wrist joint in an adult man is

about 0.8 m, and the pulse wave propagation velocity

is about 7-14 m/s. Therefore, the signal delay can be

estimated to be on the order of 100 milliseconds. For

example, for a given measurement accuracy of 5%,

the error in measuring the delay should not be greater

than 5 ms.

It is not difficult to determine the moment of

"dynamic zero" from the "rather narrow" R-peak of

the ECG with such accuracy, but it is not so for a

pulse wave impulse. Quite often, many researchers,

being biologists or physicians by education and

scientific background, tend to use the position of the

minimum or, conversely, the maximum of the pulse

wave impulse as the required timestamps (

Kortekaas,

2018)

. However, it is well known from radiophysics

that various transient processes in the region of the

establishment of the pulse top or in the region of the

minimum significantly distort the main process and

interfere with fixing timestamps with the required

accuracy. As a solution, pulse technology uses

tracking of timestamps on the leading edge of the

pulse at the level of 0.1 and 0.9 of its amplitude

defining start and rise time. Taking into account these

considerations and having a portable pulse wave

sensor, a PWV measurement method was developed

based on determining the average difference in the

delay values from the R-peak on the ECG to the

sequential arrival of the pressure pulse front at

selected points on the artery under study.

4 EXPERIMENTAL RESULTS OF

PWV MEASURMENTS

In our experiments, the results of which are presented

in this section, a pulse wave was recorded at five

different points along the artery (Figure.3): on the

subclavian artery (1), on the brachial artery (2) by

0.35 m lower (just above the ulnar bend), on the radial

artery (3) by another 0.27 m lower, at the artery at the

base of the middle finger (4) lower by another 0.17 m

and at the artery in the pad of the same finger (5)

lower by another 0.06 m.

Figure 3: Locations of the points to measure PWV.

Improved Method for Measuring the Pulse Wave Propagation Velocity for Palpable Arteries

151

Figure 4 demonstrates the joint recording of the

pulse wave signal and the ECG, the numbers on the

graph correspond to the measurement points on the

patient's body (see Figure 3).

Figure 4: Five-point record of pulse wave and ECG signals.

When deciphering the readings, it should be

remembered that only for the radial artery, the pulse

wave parameters correspond to the actual blood

pressure. In other cases, there are various distortions

caused, for example, by the damping properties of the

surrounding soft tissues. Therefore, the amplitude and

constant component of the pulse wave in these areas

may differ rather significantly from the actual

pressure in the artery.

Since we are free of the tabular reference values

for the “pre-ejection period” (

Kortekaas, 2018)

, we

develop a criterion for the stabilization of the wave

propagation time, which is more reliable for pressure

wave signals. We will consider the beginning and end

of the leading edge of the signal, which we determine,

as it is customary in pulse technology, at levels 0.1

and 0.9 of the signal amplitudes (timestamps f01 and

f09, respectively). In our case, the levels of the

thresholds of the pulse wave fronts for each cycle are

updated, as demonstrated in Figure 5. Each positive

edge of the signal has "personal" marks of the

beginning and end of the edge. Of course, the

beginning of the front should be taken as the marks of

the passage of the wave, since the shape of the pulse

wave noticeably changes during the motion, as does

the duration of the front.

This algorithm was used first to indicate digital

value of R-f01 online. Value of R-f01 turned out to

be slightly varying from pulse to pulse and should be

averaged to use practically. Below, Figures 6-10

demonstrate the graphs of record fragments of pulse

wave and ECG signals at each of the five

measurement points and graphs of time parameters

for each successive pulse wave front.

Figure 5: Timestamps at the level of 0.1 and 0.9 of the

signal amplitudes for each wave front.

Legend: f01-09 – pulse wave rise time, R-R - time

intervals between successive R-peaks, f01-f01 -

intervals between successive edges of pulse waves,

R-f01 - delay time of pulse wave front relative to R-

peak.

Figure 6: Pulse wave and ECG recording and their temporal

characteristics for the subclavian artery (point 1 in Figure

3).

Figure 7: Pulse wave and ECG recording and their temporal

characteristics for the brachial artery (point 2).

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

152

Figure 8: Pulse wave and ECG recording and their temporal

characteristics for the radial artery (point 3).

Figure 9: Pulse wave and ECG recording and their temporal

characteristics for the digital artery (point 4).

Figure 10: Pulse wave and ECG recording and their

temporal characteristics for the digital artery (point 5 in

Figure 3).

It should be noted that these data were obtained

when measuring the indicators of cardiovascular

activity in a specific measuring environment and for

certain physiological conditions of the patient. But,

even under controlled experimental conditions, the

data may change due to the dependence of the

patient's reactions in a particular measurement

session on many uncontrolled factors. It is obvious

that even with a given physiological condition, all

time intervals are variable, and averaging is required

to correctly estimate the signal delay time. In this

case, the standard deviation did not exceed 1 ms.

The average delay time of the wave front relative

to the R-peak of the ECG was 60.5 milliseconds (ms)

for the subclavian artery, 109.5 ms for the brachial

artery, 130 ms for the radial artery, 140 ms at the base

of the finger and 177 ms at the fingertip for the digital

artery. Accordingly, the assessment of the

propagation velocity of the pulse wave in the section

1-2 from the subclavian to the brachial artery was

about 7.4 m/s, in the section 2-3 - 13.5 m/s, in the

section 3-4 - 17 m/s and in the section 4-5 about 2 m/s.

The increase in velocity in sites 1 - 4 can be explained

by a decrease in the diameter of the branching arteries

according Moens-Korteweg equation (1). The

decrease in speed in the last section, apparently, is due

to more complex reasons. Note that the duration of

the pulse wave front is not the same in different points

of the measurement sites: 94 ms on the subclavian, 65

ms on the brachial, 58 ms on the radial, 70 and 78 ms

on the digital arteries, respectively.

5 CONCLUSIONS

Thus, the variant of a three-channel pneumatic sensor

described in the paper, designed for measuring and

recording short-term blood pressure files, can be used

as a pulse wave sensor on all palpable arteries.

Experiments on measuring pressure in various

superficial arteries show that in the case of arteries

located above hard tissues (bones), both the shape of

the pulse wave and the actual value of blood pressure

can be recorded. This is true, for example, in the case

of the radial and femoral arteries. The presence in our

device of an additional ECG channel makes it

possible to uniformly measure the delay time of the

pulse wave at spaced points of the artery, that makes

it very easy to calculate the pulse wave propagation

velocity along the walls of the artery.

Obtaining and subsequent interpretation of data

on the dependence of the distribution of the pulse

wave velocity in the arterial system on various

internal and external factors is extremely interesting,

both for a general understanding of the processes

taking place in the human body and for the practical

diagnosis of the different diseases. It is important to

note that the claimed technology can significantly

improve the accuracy of measurements of the pulse

wave propagation velocity due to small size of

sensing pad.

Improved Method for Measuring the Pulse Wave Propagation Velocity for Palpable Arteries

153

REFERENCES

Antsiperov, V.; Mansurov, G.; Danilychev, M. and Bugaev

(2020) A. Non-Invasive Blood Pressure Monitoring

Based on Pulse Wave Recording with a New Three-

channel Pneumatic Sensor. Proc. of the 13th

International Joint Conference on Biomedical

Engineering Systems and Technologies (BIOSTEC

2020) – V. 1: BIODEVICES, P. 268-273. DOI:

10.5220/0009169902680273.

Katsuura, T. et al. (2017) Wearable pulse wave velocity

sensor using flexible piezoelectric film array. IEEE

Biomedical Circuits and Systems Conference

(BioCAS), P. 1-4.

Kortekaas, M.C., et. al. (2018) Small intra-individual

variability of the pre-ejection period. PLoS ONE, V.

13(10). DOI: 10.1371/journal.pone.0204105.

Korteweg D.J. (1878) Über die Fortpflanzungs-

geschwindigkeit des Schalles. In Elastischen Röhren

[About the speed of wave propagation in elastic tubes].

Ann Phys. V. 214, P.525-542.

Mansurov, G., Antsiperov, V., Danilychev, M. and

Churikov, D. (2019) Non-Invasive Blood Pressure

Monitoring with Positionable Three-chamber

Pneumatic Sensor. Proc. of the 12th International Joint

Conference on Biomedical Engineering Systems and

Technologies (BIOSTEC 2019) – V. 5: HEALTHINF,

P. 462-465. DOI: 10.5220/0007574904620465.

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

154