Research on Standard Digitization Technology based on Knowledge

Graph and Semantic Data Dictionary

Chengcheng Wang and Chunxi Wang

Instrument Technology and Economy Research Institution, Guanganmenwai 397A, Beijing, China

Keywords: Standard Digitization, Semantics, Knowledge Graph, Data Dictionary, Interoperation.

Abstract: Standard digitization is the inevitable trend of standard development. IEC, ISO and other international

standardization organizations have laid out their layout in the field of standard digitization and built a

hierarchical model of machine-readable standards. National standards in the field of industrial process

automation can be divided into basic standards (terms and definitions, symbols, classification, etc.), the

method of standard (test, procedures, guidelines and interface, etc.) and product standard (product, function,

service, data, etc.), digital requirements also exist in application scenarios such as guidance, testing, and

certification. Based on the analysis of key technologies such as machine-readable, knowledge graph, semantic

information model, semantic interoperation and semantic data dictionary, a standard correlation model with

pressure meter as the core is preliminarily constructed in this paper, which provides technical support for the

subsequent standard digital transformation.

1 INTRODUCTION

As a new round of technological revolution and

industrial revolution worldwide, digital

transformation drives production mode, life style and

the way of governance profound changes, and a

comprehensive, profound and revolutionary impact

on economic growth, standardization as a guide and

standardize the key elements of the national economy

development in our country, plays an important role

in the wave of the digital transformation. Although

the object and scope of standardization are different,

there is a demand for digital transformation.

At present, the three major international

standardization organizations (ISO, IEC, ITU),

European Standardization Organization

(CEN/CENELEC), as well as the United States,

Germany, Russia and so on have started the process

of standard digital transformation. IEC's MSB

(Marketing Strategy Committee) white paper

“semantic Interoperability: Challenges in the Digital

Transformation” has been published; SMB/SG12

(Digital Transformation Strategy Group) was set up

to work on digital work, machine-readable standards,

semantic interoperability, systems approach, etc. The

database type standard platform has been established,

which can formulate, publish, maintain and download

IEC international standards online. In industrial

process automation, electric power and other fields,

the establishment of machine-readable standards has

been carried out

(Wang, 2021, Wang, 2021, Cao,

2016, Li, 2020, Lu, 2020).

In 2018, ISO established the SAG/MRS (Machine

Readable Standards Strategy Advisory Group),

published the machine-readable Standards

implementation Roadmap, which was incorporated

into the ISO 2030 Strategy. It has also established an

ISO international standard online browsing platform,

which can retrieve symbols, codes, terms, definitions,

etc (Chen, 2021,

Huang, 2021, Chen, 2020, Kou,

2019).

2 THE PROGRESS AND

SIGNIFICANCE OF STANDARD

DIGITIZATION

Based on the significance of digital transformation of

standards, ISO, IEC and regional and national

standards organizations have carried out active

research on this topic. IEC and ISO have agreed on

a hierarchical model for machine-readable standards

(see Table 1).

394

Wang, C. and Wang, C.

Research on Standard Digitization Technology based on Knowledge Graph and Semantic Data Dictionary.

DOI: 10.5220/0011180000003440

In Proceedings of the International Conference on Big Data Economy and Digital Management (BDEDM 2022), pages 394-399

ISBN: 978-989-758-593-7

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: Machine readable standard classification model,

Classific

ation

Level 0

Leve

l 1

Level 2 Level 3 Level 4

Name Paper

Ope

n

digit

al

For

mat

Machi

ne

readabl

e

docum

ent

Machi

ne

readabl

e and

execut

able

conten

t

Machine

interpret

able

content

Icon

Format

Paper,

TXT

PDF XML - -

Concept

Traditi

onal

text

format

Disp

lay

and

searc

h

relat

ed

cont

ent.

Contai

ns

standar

d text-

structu

red

content

, with

softwa

re that

recogn

izes

file

structu

re and

perfor

ms

basic

operati

ons.

Standa

rd

content

with

semant

ics can

be

selecti

vely

access

ed

depend

ing on

the

applica

tion

scenari

o, and

applica

tion

progra

m

interfa

ces

(API)

can be

used to

perfor

m

more

comple

x

operati

ons on

standar

d

content

.

Machine

s can

perform

or parse

standard

content

in more

complex

ways.

The

standard

contains

an

informat

ion

model

represen

ting the

standard

content

and the

relations

hip

between

the

elements

, which

can

achieve

breakpoi

nt-free

and

unambig

uous

data

flow.

ISO's SAG-MRS also recommends the unified

definition of level 3 and Level 4 Standards as ISO

SMART (Standards Machine Applicable, Readable

and Transferable), that is, the machine can be

available, readable and resolvable without the

participation of personnel (Sabbir, 2020, James,

2020). Therefore, based on the classification of IEC

and ISO for standard digitization, we can regard

standard digitization as the primary stage of "human

readable" and the advanced stage of "machine

readable".

Primary stage (0 and 1) is mainly the realization

of digital reading and retrieval of standard, namely

through the analysis of demand for standard in digital

environment, help users to timely, accurately and

quickly find relevant standards, solve the problem

which hard to find the standard. At present, several

standard resource retrieval platforms have been

developed in China, which can basically meet the

query and retrieval of keywords. However, most of

the technical content of the standard is read in the way

of documents, without a complete analysis. The main

reasons include:

Data protection and copyright ownership of

source documents;

The technical level of standard content

analysis is insufficient;

The mutual application of standards and the

timeliness of version update iteration.

Therefore, the digital transformation of standards

must be jointly participated by standardization

engineers and data engineers, otherwise the digital

standard intelligence stays in the stage of circulation

and storage, unable to play the role of application on

the level of "human readable", more difficult to

achieve the function of "machine readable".

The advanced stages (levels 2 to 4) focus on

implementing the digital application of the standard.

We analyse the digital application scenarios of

standards from the types of standards. Generally,

standards in China can be divided into basic standards

(terms, definitions, symbols, classification, etc.),

method standards (tests, procedures, guidelines,

interfaces, etc.) and product standards (products,

functions, services, data, etc.). Compared with basic

standards, it is more meaningful to transform method

standards and product standards into machine-

readable standards. The main application scenarios of

the two standards vary with different application

industries and can be generally summarized as

guidance, testing and certification.

2.1 Guidance

Which mainly refers to the process in which digital

standards guide and standardize activities within the

scope of application. Take the manufacturing

industry as an example, digital standards can provide

standardized design guidance, manufacturing

requirements and development methods in the

process of product design, manufacturing and

development, and cooperate with the development of

intelligent manufacturing to realize the intelligent

Research on Standard Digitization Technology based on Knowledge Graph and Semantic Data Dictionary

395

design, manufacturing and development process,

such as the self-organization of equipment functions.

2.2 Test

Which include the test from enterprise, as well as the

third party, digital standard can support the rapid test

plan formulation, the rapid generation of test data,

test results of quick judgment and rapid formation of

test report, most of all, eliminate the inconformity of

understanding of standard terms in the process of test,

ensure the consistency of different main body to carry

out the test results. Under the cooperation of

information tools, the openness and transparency of

the testing process will be improved to the maximum

extent to enhance the effect of the implementation of

standards.

2.3 Certification

As a transmission process of trust, in this paper not

only refers to the certification activities of products,

systems and capabilities carried out by third-party

certification bodies, but also includes enterprises'

self-evaluation of their standards compliance. On the

basis of the standard digital, can pass, the technical

requirement of the standard quantitative into different

indicators, enterprise control system related indexes,

the submission and upload data and supporting

materials, the system through the data model and

standard algorithm, the input of product data, such as

enterprise information necessary parameters for the

item scores and comprehensive scores. Only to the

enterprise system to upload the material authenticity

review unit manual audit, again according to the

system automatically score, form the comprehensive

score of jitc or standard products conform to the

degree of hierarchy, rather than simply to meet and

do not conform to the evaluation conclusion, on the

other hand, also can be realized based on the standard

digital traceability of the products or services.

3 REQUIREMENTS ANALYSIS

OF STANDARD DIGITAL

Among the standard types with digital requirements,

product standard, protocol/interface standard, test and

evaluation method standard, operation and

installation method and other standards account for

more than 80%.

The digitization of product standard can support

the retrieval and judgment of standard applicability,

reference relationship between standards and

correlation analysis between technical content.

The digitalization of protocol/interface standards

can greatly reduce the workload of communication

protocol development and support the rapid testing of

protocol consistency and interoperability.

The digitalization of test standards can clarify the

applicability of standards, and realize the guidance of

test evaluation and validity verification.

Although the requirement for digitalization of

different types of standards are different, the

significance is clear. From the perspective of

technology path, XML language is one of the optional

technology paths from level 2 to level 4 to realize

standard digital transformation. However, XML

language is essentially a standard for data storage,

exchange and expression, which is used to mark data

and define data types. The semantics of data still need

to be defined in the process of digitalization. Based

on the above analysis, the semantics of the data can

be used "standard model" or "product model", the so-

called "standard model" in standard elements as the

core, such as product standards for technical

requirements, test methods, inspection rules, in order

to establish the semantic model structure, the type test

evaluation standard to test process, test requirements,

test methods and results analysis in order to establish

the semantic model structure, The definition and

update of the "standard Model" are quick and simple,

and the relationship between them is clear. However,

the "standard model" developed for one standard is

difficult to be applicable to all standards. "Product

model" is a semantic model with product elements as

the core and product structure, function and

requirements as the structure. The definition and

correlation of this model are relatively complex, but

it can be applied to various types of standards at the

same time.

Different standardization areas can adopt the

"standard model" or develop compatible

"middleware" models, but from the perspective of the

standard digital transformation roadmap published by

IEC and ISO, the "product model" is also chosen as

the semantic modeling approach. For example, IEC

61360 series standards put forward the concept of

common data dictionary (CDD), hoping to establish

cross-domain knowledge base for all equipment and

services in the field of electrical technology. The

knowledge base/database is maintained by the IEC

SC3D (Product Attributes, Categories and

Identification) and the TC (Technical Committee) or

SC (sub-technical Committee) of each related

technical area. And IEC/TC65 is developing IEC

BDEDM 2022 - The International Conference on Big Data Economy and Digital Management

396

61987 series standards, according to different product

types into a number of parts.

4 KEY TECHNOLOGY OF

STANDARD DIGITIZATION

According to the above analysis, standard digitization

in a broad sense is to realize standard representation

digitization, content digitization and application

digitization through semantic technology and

information technology. And machine readable is the

core form of standard digitization, refers to the

machine without manual operation available,

readable, transferable process. To realize machine

readable, we must first ensure the interaction between

the machine and the real world. The basis of the

interaction is the reception of language (the process

of converting human language into program,

including speech recognition, image recognition,

natural language processing, expert system, etc.) and

semantic recognition (which can be understood as

program dictionary and rule base).

According to the definition given by IEC,

semantics are concepts and are represented as data

structures through classes and their attributes. Data

structures have rules or models, and the model is an

information model, that is, a declarative model that

accurately describes the machine ontology and its

interactions and can be recognized by other

machines. In real life, semantics are difficult to

cover or fully define, but information models can.

Through the standardization of semantic information

model, the mapping or fusion between information

models can be realized, and the knowledge base built

on this basis can be shared through the information

model.

Semantic interoperability refers to multiple assets

(such as facilities, machines and systems, etc.)

between right exchange and the ability to understand

each other data, which means "to understand each

other data can be implemented by the transformation

of the information model and the meaning of" right

"refers to the assets without using artificial

intervention or additional programming, information

model conversion can be realized. Therefore,

semantic interoperability is based on language

reception and automatic transformation of semantic

information models, corresponding to level 3 or level

4 of standard digitization.

Common Data dictionary is a evolving database

containing all the necessary information for

describing objects (equipment, products, services,

etc.) in the form of categories and lists of Properties

(LOP), these include administrative property list

(ALOP), operational property list (OLOP), device

property list (DLOP), and Business property list

(CLOP). Therefore, a common data dictionary is a

collection of semantics and a resource base for

building semantic information models, so it is also

called semantic data dictionary. The information

system based on data dictionary can realize the

interconnection among equipment layer, enterprise

layer and industry layer, thus realizing the function of

"machine readable".

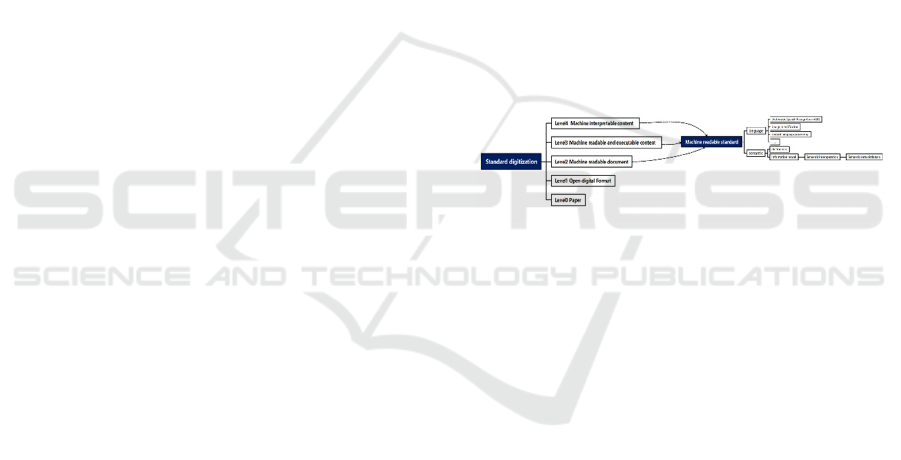

The relationship of the above core concepts is

shown in Figure 1. It can be seen that semantic data

dictionary is the core technology to realize standard

digitization, and the key to establishing semantic data

dictionary lies in the construction of data dictionary

architecture and knowledge association modelling.

Especially in the immature stage of standard

digitization research, knowledge association lacks

training sets and it is difficult to realize automatic

extraction and association of knowledge.

Figure 1: Standard digitization core concept relationship.

5 CASE ANALYSIS OF

STANDARD DIGITIZATION

5.1 The Establishment of Knowledge

Graph Model

This paper takes the national standard of industrial

process automation as the analysis object, and takes

pressure instrument as the core to build a partial

knowledge graph model, which provides guidance for

the construction of semantic data dictionary. The

knowledge graph model includes the following

models:

5.1.1 Class

A collection of individual objects , for grouping

individual objects that have something in common,

for example:

Class(ID(Person)),

Classassertion( :Person :Mary).

Research on Standard Digitization Technology based on Knowledge Graph and Semantic Data Dictionary

397

5.1.2 Object Attributes

Object attributes are used to represent an association

between two entities, for example:

ObjectProperty(IS(hasWife)),

ObjectPropertyAssertion( :hasWife :John :Mary).

5.1.3 Data Attributes

Data attributes are used to associate entities with data

values such as Integer and String, for example:

DatatypeProperty(ID(hasAge)),

DataPropertyAssertion( :has Age :John

“51”^^xsd:integer).

5.1.4 Definition Domain and Range Domain

The knowledge graph model supports the declaration

of domain and range for attributes and implicit

additional information for attributes. The range of a

data attribute is a data type, and the range of an object

attribute is an entity.

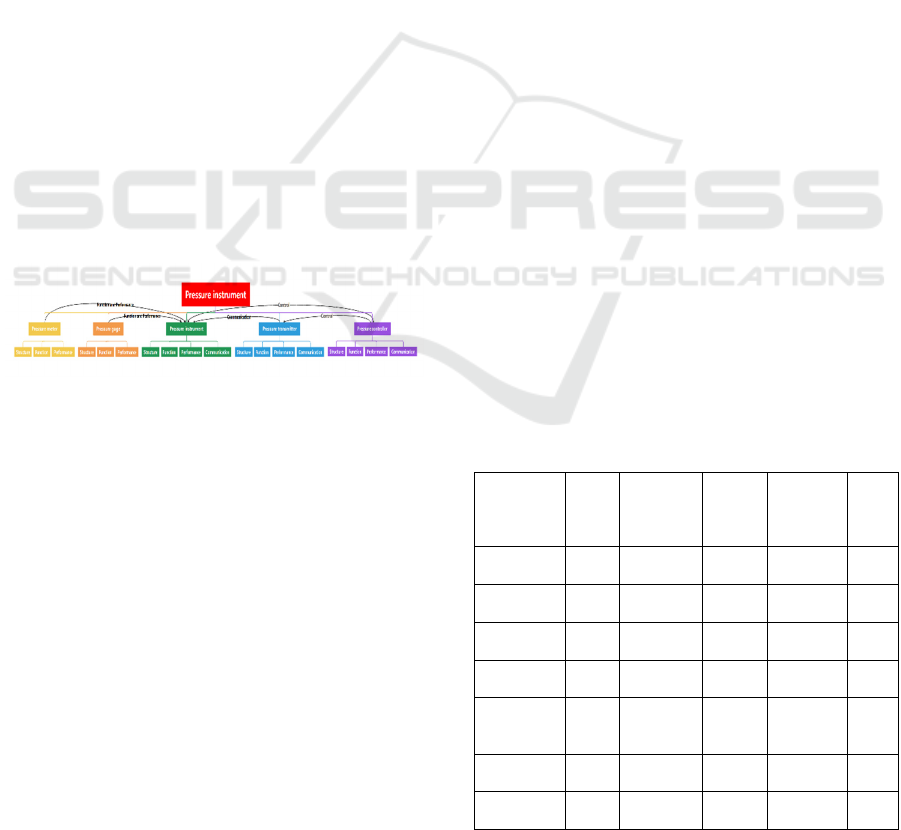

According to the above research, the model of

"product model" is adopted to realize modeling.

According to the technical standards related to

pressure instruments in the field of industrial process

automation, pressure instruments are divided into

pressure gauge, pressure gauge, pressure instrument,

pressure transmitter and pressure controller, as shown

in Figure 2.

Figure 2: Product model of pressure instrument.

5.2 The Establishment of Knowledge

Graph Model Transformation

between Standard CDD and

Knowledge Graph Model

A standard knowledge graph model in the field of

product and industrial process automation can be

established. MySQL is used as the modelling tool of

the standard data dictionary. The transformation

relationship between the pattern information and the

ontology elements of the knowledge graph is as

follows:

The entity table (ET) in the data dictionary

(CDD) is mapped to OWL class, which is

named after the data table, namely:

∀𝐸𝑇 ∈ 𝐶𝐷𝐷 → 𝐶𝑙𝑎𝑠𝑠𝐼𝐷𝐸𝑇

(1)

For the column (C) in the data table, the non-

foreign key column is mapped to an OWL

data attribute, which is named after the

column. The domain of the attribute is the

class mapped from the current table, and the

value field is the data type of the column,

namely:

∀∈ 𝑎𝑡𝑡𝑟

𝐸𝑇

∩𝐼𝑠𝑁𝑜𝑡𝐹𝑜𝑟𝑒𝑖𝑔𝑛𝐾𝑒𝑦

𝐶,𝐸𝑇

→ 𝐷𝑎𝑡𝑎𝑡𝑦𝑝𝑒𝑃𝑟𝑜𝑝𝑒𝑟𝑡𝑦𝐼𝐷

𝑐

,𝑑𝑜𝑚𝑎𝑖𝑛𝐼𝐷

𝐸𝑇

, 𝑟𝑎𝑛𝑔𝑒𝑑𝑎𝑡𝑎𝑡𝑦𝑝𝑒𝐶

(2)

For the two data tables T and R, T is

associated with R conventionally through its

foreign key column FK, which is mapped to

an OWL object attribute named after this

column. namely:

∀𝐹𝐾

∈ 𝑎𝑡𝑡𝑟

𝑇

∩𝐼𝑠𝑁𝑜𝑡𝐹𝑜𝑟𝑒𝑖𝑔𝑛𝐾𝑒𝑦

𝐹𝐾, 𝑇

∩𝑅𝑒𝑙𝑎𝑡𝑖𝑜𝑛𝐹𝐾,𝑇,𝑅

→ 𝑂𝑏𝑗𝑒𝑐𝑡𝑃𝑟𝑜𝑝𝑒𝑟𝑡𝑦𝐼𝐷

𝐹𝐾

,

𝑑𝑜𝑚𝑎𝑖𝑛

𝐼𝐷

𝑇

, 𝑟𝑎𝑛𝑔𝑒𝐼𝐷𝑅

(3)

Based on the above rules, automatic mapping of

data dictionary schema information to OWL ontology

classes, data attributes, object attributes and other

elements can be encoded.

5.3 The Establishment of Standard

Semantic Data Dictionary

According to the analysis of the standard content, the

semantic data dictionary of the standard includes

general semantics and special semantics, among

which the general semantics is the general technical

content of the standard, and the special semantics of

the standard is related to the type and content of the

standard, as shown in Table 2:

Table 2: List of standard semantic relationships

Generic

standard

semantics

Abb.

Special

standard

semantic

s

Abb.

semantic

relation

Abb

.

Foreword FOR

Summar

y

SUM

Coordin

ation

CO

O

Introducti

on

INT

Overvie

w

OVE

Comple

mentary

CO

M

Scope SCO Gen GEN

Subordin

ate

SU

B

Normative

reference

NO

R

Met MET Contains

CO

N

Terms and

Definition

s

TER

Performa

nce

PRO

Exclusio

n

EX

C

Abbreviati

ons

AB

B

Function FUN

Relevan

ce

RE

L

Symbol

SY

M

Require

ments

REU

BDEDM 2022 - The International Conference on Big Data Economy and Digital Management

398

Generic

standard

semantics

Abb.

Special

standard

semantic

s

Abb.

semantic

relation

Abb

.

Bibliograp

hy

BIB

This paper establishes mutual relations from the

aspects of classification, structure, function and

performance, and test methods, including reference,

inclusion, mutual exclusion, and supplement, as

shown in FIG. 3.

Figure 3: Standard knowledge graph model for pressure

instrument

6 CONCLUSIONS

Through the understanding and analysis of the

concept of standard digitization, this paper

establishes the standard digitization model of typical

products of industrial process automation, which

provides the method of thinking for the establishment

of semantic data dictionary. The main viewpoints

include:

Standard digitalization can be divided into

"primary stage" and "advanced stage". Not

all standards need to be "machine-readable",

but "machine-readable" standards are

necessarily related to application scenarios.

In addition to industry differences, the main

application scenarios are guidance, testing

and certification.

Semantic interoperability is the key in

standard digitization. In order to achieve

semantic interoperability, a standardized

semantic data dictionary is needed.

The construction of semantic data dictionary

includes two approaches with "product

model" and "standard Model" as the core,

which is recommended in this paper.

Different standard scopes mean different

modelling paths, but the business path at the

core is recommended.

The following deficiencies still exist in the

research process of this paper, which need to be

further strengthened and improved in the subsequent

research process:

The analysis of standard digitization is not

in-depth enough, the analysis level only

stays in the name, scope and structure, the

analysis of function, performance, test

methods and other content is insufficient, the

most critical is that the general path and

method of standard digitization has not been

established.

The analysis of standard digitization is not

comprehensive enough, mainly confined to

the field of industrial process measurement

control and automation, and there is not

enough research on relevant supporting

technical standards in other fields. As a

modelling method, there is also a lack of

guidance for the digitalization of standards

in other fields.

This paper is supported by the national key

research and development program "NQI" machine

readable standard generic technology and

international standards in key fields

(2021YFF0601400).

REFERENCES

Cao yongsheng. (2016). Construction and implementation

of standard digital system[J]. Standardization in China.

Chen jin. (2020). The application of standard digitization

and quantization[J]. Management informatization in

China.

Chen xiaorong, Huang jianmin. (2021). Exploration of

standard index retrieval method based on semantic

technology[J]. Standard Science, 2021(08).

Kou jie. (2019). Exploration and research on standard

application mode in digital environment[J]. Aviation

standardization and quality, 2019(06).

Li jun, Lu Hongwei. (2020). Research on enterprise

standard digitization thinking based on artificial

intelligence[J]. value engineering.

Sabbir M. Rashid1, James P. McCusker1. (2020). The

Semantic Data Dictionary – An Approach for

Describing and Annotating Data[J]. Data Intelligence.

Wang chunxi, wang shuo. (2021) Research on machine

readable standards in industrial automation[J].

Standardization in China.

Research on Standard Digitization Technology based on Knowledge Graph and Semantic Data Dictionary

399