Agglomeration Technology of Fine Manganese Concentrates with the

Application of Granulation

Volodymyr Krivenko

11

, Evhen Chuprinov

22

, Maryna Korenko

13

, Daria Kassim

14

and Inna Trus

25

1

State University of Economics and Technology, 5, Stepana Til`gi str., Kryvyi Rih, 50006, Ukraine

2

Igor Sikorsky Kyiv Polytechnic Institute, 37/4, Peremogy Avenu, Kyiv, 03056, Ukraine

Keywords: High-Intensity Magnetic Separation, Technology, Manganese Ore, Output Parameters, Sintering Process.

Abstract: The technology for processing the HIMS concentrate, including its partial regrinding and drying, mixing,

granulating and agglomeration in a high layer, has been developed. A technological scheme for the recon-

struction of the Bogdanovskaya sinter plant of the JSC "Pokrovskiy GZK" was developed. Studies have shown

that it is impossible to obtain strong, non-destructible (in the process of transportation) and handling granules

from this concentrate due to an insufficient amount (6-8 %) of fine particles with a particle size of -0,056 mm,

which mainly affect the lumpiness of raw materials. A new technology for the preparation and agglomeration

of fine concentrates, including preliminary granulation was developed.

1 INTRODUCTION AND

ANALYSIS OF PREVIOUS

STUDIES

The introduction of deeper and more advanced

enrichment schemes is one of the ways to increase the

manganese extraction during the manganese ores

enrichments in Ukraine in the situation of a constant

decline of the original ore qualities. It includes both

flotation and high-intensity magnetic separation

(HIMS) (Wu, 2015). As a result, it causes an increase

in the amount of fine particles and moisture in the

concentrates.

Deposits of manganese ores on the globe are

distributed very unevenly, just as uneven their

material composition, which is associated with the

genesis of ores (Kuleshov, 2011). A distinctive

feature of manganese ores from domestic deposits is

the relatively low manganese content and high

concentration of phosphorus and silica (Kutsin,

2012), which does not allow, unlike most foreign

1

https://orcid.org/0000-0001-7822-6358

2

https://orcid.org/0000-0001-8605-3434

3

https://orcid.org/0000-0002-4582-1756

4

https://orcid.org/0000-0002-1750-1237

5

https://orcid.org/0000-0001-6368-6933

ores, to use raw materials without prior enrichment

and storage.

A large number of works (You, 1999; Kwon,

2021; DeFerreira, 2021) are devoted to the study of

the manganese minerals recoverabilities, ores and

concentrates, while the work (DeFerreira, 2021) is

devoted to the study of Brazilian ores. However, the

data available in the literature are often ambiguous. It

is known that MnO2 and MnCO3 dissociate at

relatively low temperatures – 510 and 176 °C,

respectively.

In (Kutsin, 2012; Yuanbo, 2017; Singh, 2020) the

issues of mineralogical research of manganese ores of

sedimentary genesis are considered, the issues of

mineralogy and physicochemical properties of

manganese component of iron-manganese modules

are studied, as well as the method of thermochemical

determination of manganite in manganese ores and

the recommendation for Nikopol basin. In the article

(Kulik, 1996) the research of modern tendencies of

development of the manganese mining industry of the

world and Ukraine is executed, the ways of increase

of competitiveness of the domestic enterprises on

256

Krivenko, V., Chuprinov, E., Korenko, M., Kassim, D. and Trus, I.

Agglomeration Technology of Fine Manganese Concentrates with the Application of Granulation.

DOI: 10.5220/0011351500003350

In Proceedings of the 5th International Scientific Congress Society of Ambient Intelligence (ISC SAI 2022) - Sustainable Development and Global Climate Change, pages 256-264

ISBN: 978-989-758-600-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

increase of competitiveness of the domestic

enterprises on extraction of manganese ore depending

on a modern market situation are offered. The authors

of (Kulik, 1996) made an important conclusion that

the sources of relatively high-quality ores for

manganese and related components are man-made

deposits (sludge storages), the development of which

can be one of the most promising areas, which will

also solve current environmental problems.

In (Samal, 2021; Eom, 2016) the characteristics of

the mineral components of oxidative and carbonate

manganese ores are given. It is determined that the

nature of transformations during heat treatment

(agglomeration, firing of pellets and briquettes,

preheating) is largely determined by chemical,

mineralogical and particle size distribution, as well as

other properties of raw ore.

For the adequacy of raw material evaluation, it is

necessary to compare the quality indicators of

manganese concentrates produced in Ukraine and

abroad (Table 1).

Table 1: Technical requirements for the quality of manganese ores and concentrates for smelting ferroalloys

Component

Mass fraction, %

For

p

heromar

g

anese* For silicoman

g

anese *

Ukraine

I grade

Western

Europe

USA

grade «А»

Ukraine

II grade

Western

Europe

USA

grade «B»

I

g

rade

II

g

rade

I

g

rade

II

g

rade

Mn, no less 43,0 48,0 46,0 46,0 34,0 44,0 40,0 40,0

Fe, no more - - 7,5 8,0 - 9,0 12,0 16,0

SiO

2

, no more - 7,0 9,0 12,0 - 10,0 12,0 15,0

P, no more - 0,12 0,15 0,18 - 0,15 0,15 0,30

*the requirements to Nikopol oxide concentrates and ores and concentrates of foreign producers are specified

Table 2: Chemical composition of the studied samples of manganese ores

№

Producing

country

Mass fraction of components, %

Mn SiO

2

Al

2

O

3

CaO MgO Fe

2

O

3

P

2

O

5

Na

2

O K

2

O

Losses

during

calcination

1 Geor

g

ia 47,20 12,09 1,88 1,92 0,75 1,86 0,47 0,21 0,59 3,29

2 Brazil 47,60 9,30 1,20 1,03 1,34 9,30 0,14 0,23 1,15 2,29

3 Australia 47,00 13,05 1,63 2,67 0,98 8,94 0,07 0,12 0,03 3,88

4 Ghana-I 30,00 14,05 2,65 4,65 5,08 1,72 0,16 0,28 0,24 31,6

5 Ghana-II 39,79 19,30 4,20 0,40 0,12 7,10 0,32 0,19 0,63 5,02

6 Ghana-III 30,50 13,52 2,20 4,81 4,85 1,05 0,25 0,24 0,21 32,6

Table 3: The results of studies of the general physical properties of manganese ores

№

Producing

country

Mass

fraction of

moisture, %

Density, kg/m

3

Total

porosity, %

Strength (DSTU

3200-95) on

impact on

fraction more than

5 mm, %

bulk imaginary true

1 Georgia 4,0 1740 2400 3880 38,14 31,0

2 Brazil 8,4 2940 4210 4270 10,92 58,0

3 Australia 2,8 2110 3850 4020 4,23 75,6

4 Ghana-I* 1,6 2300 3240 3270 1,4 71,0

5 Ghana-II 7,2 2090 - 3670 - -

6 Ghana-III 1,6 2120 3190 3370 5,3 72,0

* manganese ore Ghana I and III - carbonate, Ghana II - oxide.

Agglomeration Technology of Fine Manganese Concentrates with the Application of Granulation

257

Table 4: Mineralogical composition of the studied samples of manganese ores

№

Producing

country

Distribution of man

g

anese b

y

mineral

p

hases, %

Ore phase Pyrolusite

Minerals of

the

psilomelan

group

Brownite Manganite

Manganese

carbonates

(rhodochrosite,

calcium

rhodochrosite

)

Mn M Mn M Mn M Mn M Mn M Mn M

1 Georgia 47,20 76,4 43,7 69,1 - - - - 3,2 6,1 0,3 1,2

2 Brazil 47,60 78,6 16,3 25,8 14,6 25,3 16,7 27,5 - - - -

3 Australia 47,00 77,2 2,5 3,9 3,2 5,4 40,5 66,0 - - 0,8 1,9

4 Ghana-I 30,00 78,5 1,1 1,7 - - 1,2 1,9 - - 27,7 74,9

5 Ghana-II 39,7 66,2 18,3 29,0 17,0 29,4 3,8 6,0 - - 0,6 1,8

6 Ghana-III 30,5 77,8 - - - - - - - - 30,5 77,8

М – the amount of manganese mineral in the ore part of the sample, %.

Samples of manganese ores of different chemical

and fractional compositions (Tables 2, 3, 4), which are

currently widely used in the production of manganese

ferroalloys at domestic enterprises, were studied.

These include samples of manganese ores from

deposits in Georgia, Brazil and Ghana (Grishenko,

2015).

Analyzing the studies results of the manganese

ores physical properties, given in table. 3, it should be

noted that the ores have low porosity, except for ores

from Georgia, and a higher actual density compared

to domestic manganese concentrates. Mechanical

strength (fraction more than 5 mm) of lump

manganese ores is low and inferior in strength to

manganese agglomerate made from domestic

concentrates. For fluxed and non-fluxed manganese

agglomerates of domestic production, the mechanical

strength is 76-80 % and the porosity is 8-22 %.

2 METHODOLOGY, PURPOSE

AND OBJECTIVES OF THE

STUDY

Analytical, laboratory and industrial methods were

used as research methods. A comparison of quality

indicators of manganese concentrates produced in

Ukraine and abroad was performed. Chemical and

mineralogical composition studies of the of dust and

sludge of JSC "Nikopol Ferroalloy Plant" was

conducted in the laboratory. The study of the

agglomeration process was carried out at the

experimental production facilities in the

Mechanobrchormet Institute.

Difficulties with the production of competitive

manganese alloys on domestic raw materials have

intensified in recent years, when, on the one hand,

domestic enterprises began to increase production of

low-phosphorus grades of silicomanganese and

ferromanganese, and on the other hand, increasing

energy costs acted before. This required the use of

imported manganese ores at Ukrainian ferroalloy

plants. Thus, the problem of complex studies of

physical and chemical properties and metallurgical

value of manganese raw materials with their

subsequent aggregation has become extremely

relevant for Ukrainian metallurgists.

The objectives of the article are to perform

comprehensive studies of physicochemical properties

and metallurgical value of manganese raw materials

of various deposits used in the production of

ferroalloys in high-capacity ore reduction furnaces, to

consider returning to the production of enrichment

products lumping is not possible. It is also necessary

to compare the requirements for the quality of

manganese ores and concentrates according to the

regulations of different countries.

3 RESULTS OF THE STUDY

Manganese concentrates sintering with increased

moisture capacity (12.0-26.5 %) and low bulk density

(1350-1750 kg/m

3

) results in high losses on ignition

(up to 10.5-25.5 %). To compare with the iron ores

agglomeration, there is a significant shrinkage of the

layer, and the specific yield of sintering products is

1.5-2.0 times lower.

Since the sintering of such raw materials requires

an increased mass fraction in the return charge as well

as coke breeze (by 1.5-2.0 times), an increase in the

proportion of thin and moisture-consuming

concentrates in the sinter charge makes the sintering

process even more difficult due to a decrease in the

gas permeability of the charge.

Foreign specialists at their sinter plants don’t have

any experience in sintering manganese charges that

ISC SAI 2022 - V International Scientific Congress SOCIETY OF AMBIENT INTELLIGENCE

258

include thin concentrates with high moisture capacity

either. Thin concentrates in various quantities are

added to gravity concentrates at domestic manganese

sintering plants. Such materials are supplied to the

sinter mixture in an unprepared form.

Laboratory and industrial studies have established

that the introduction of an unprepared HIMS

concentrate into the sinter charge in an amount of

more than 15% reduces the technological parameters

of the agglomeration process.

The urgency of the problem is confirmed by the

fact that the production volumes from thin

concentrates at the Pokrovskiy Ore Mining and

Processing Plant (JSC "Pokrovskiy GZK") will

increase to 300 thousand tons per year. The existing

capacities of the sinter plant will not be able to

process such a quantity.

The «Mekhanobrchermet Institute» specialists

with specialists from «State University of Economics

and Technology» and «Igor Sikorsky Kyiv

Polytechnic Institute» have developed a new

technology for the preparation and agglomeration of

fine concentrates, including preliminary granulation.

During the research manganese concentrates of

the current production of Pokrovskiy Ore Mining and

Processing Plant were used. Chemical and

granulometric composition of materials, as well as

their physical properties are presented in the table 5

and 6.

Table 5: Chemical composition of manganese concentrates from JSC "Pokrovskiy GZK"

Concentrate

Mass fraction of com

p

onents, %

Мn SiO

2

, А1

2

O

3

СаО МgО Fe

2

O

3

Na

2

O K

2

O P

2

O

5

СО

2

passing breeds

Oxide, gravity 36.30 22.68 1.98 2.12 1.18 3.40 0.60 1.20 0.40 1.94 0.20

Carbonate, gravity 28.00 14.75 4.08 8.38 1.70 3.85 0.62 1.40 0.47 19.56 25.50

HIMS 31.70 26.80 2.10 3.4 1.20 3.70 0.58 1.34 0.378 2.14 13.10

Table 6: Granulometric composition and physical properties of concentrates from JSC "Pokrovskiy GZK"

Material

Mass fraction, %, size classes, mm

Moisture

content, %

Specific

s

urface area

,

m

2

/kg

True

density,

kg/m

3

B

ulk density

,

kg/m

3

+ 10 10-5 5-3 3-1 1-0.5

0.5-

0.25

0.25-

0.16

0.16-

0.1

0.1-0

Oxide

gravity

concentrate

22.0 13.3 7.0 30.9 6.8 9.8 10.2 – – 17.5-22.5 – 3430 1600-1700

Carbonate

Gravity

concentrate

14.7 21.9 57.4 6.3 – – – – – 12.0-19.0 – 3230 1650-1750

Concentrate

HIMS

– – – – 23.8 11.7 10.6 23.6 24.1 6.2-21.5 88.0-98.0 3600 1350-1450

Gravitational oxide and carbonate concentrates

are mainly represented by a fraction of 1-10 mm. The

HIMS concentrate has a particle size of -1.0 mm and

a moisture content of 24-26 %. Studies have shown

that it is impossible to obtain strong, non-destructible

(in the process of transportation) and handling

granules from this concentrate due to an insufficient

amount (6-8 %) of fine particles with a particle size

of -0.056 mm, which mainly affect the lumpiness of

raw materials. It is possible to increase the proportion

of fine particles by grinding a part of the HIMS

concentrate in dry grinding mills with simultaneous

drying.

The refinement of the grinding technology was

carried out on a plant operating in a closed cycle with

an air-pass separator and equipped with a gas burner.

A batch of crushed product with a mass fraction of a

fraction of -0.056 mm equal to 70-75 % and a specific

surface area of 265-280 m

2

/kg was obtained at the

installation in the spent mode in order to conduct

research on its pelletizing into granules with a particle

size of 2-8 mm. Such granules absolutely meet the

requirements of the sintering process.

Agglomeration Technology of Fine Manganese Concentrates with the Application of Granulation

259

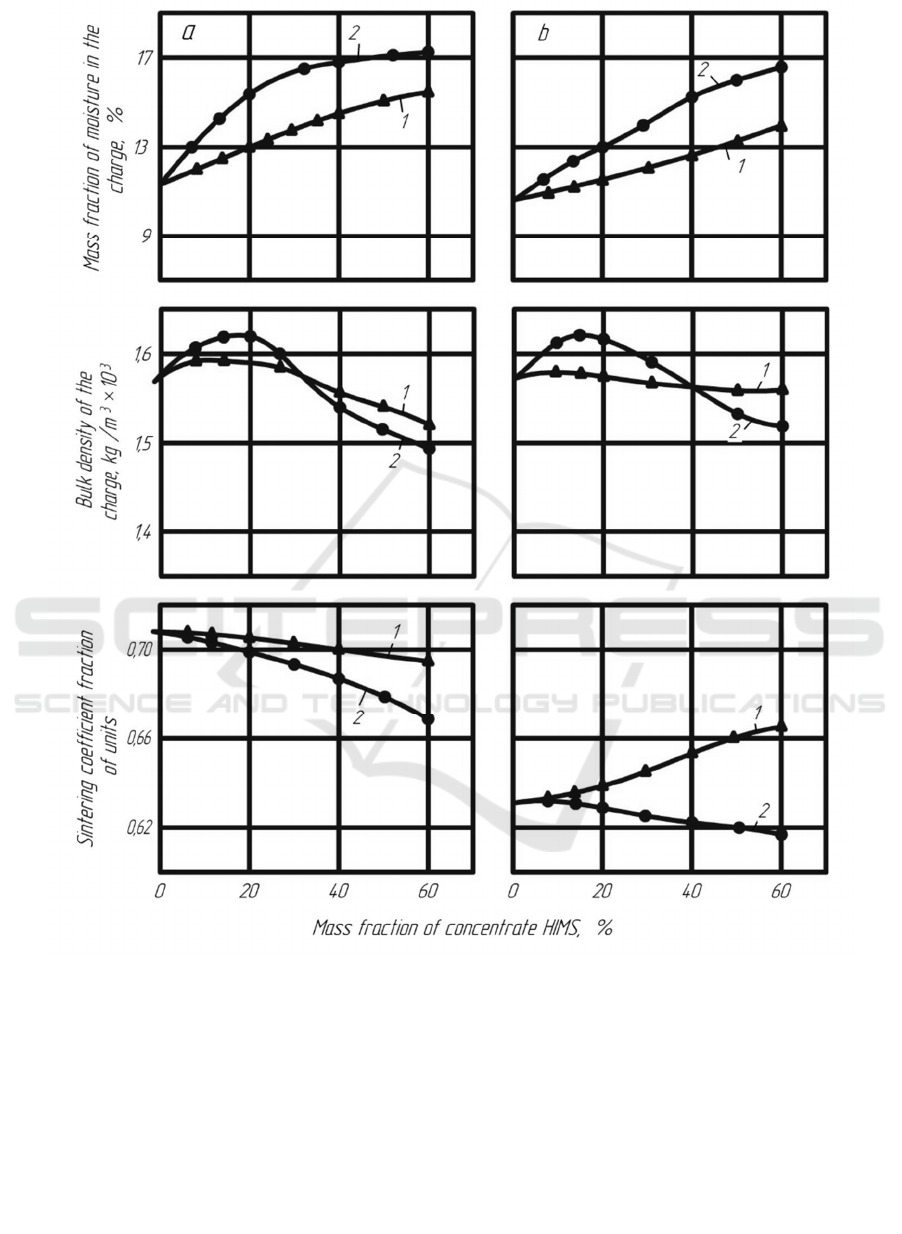

Figure 1: Dependence of the physical properties of the sinter charge and the sintering coefficient on the mass fraction of the

HIMS concentrate in the ore part of the charge during sintering of the agglomerate with oxide grade II (a) and carbonate (b)

gravity concentrates: 1 - concentrate of HIMS in the form of microgranules; 2 - HIMS concentrate in its original form

The crushed material in various amounts was

dosed to the original HIMS concentrate, mixed and

pelletized in a bowl pelletizer with the addition of

water. Strength tests of granules were carried out in

order to determine their resistance to destruction

during overloading and mixing with larger and more

abrasive components that make up the sinter charge,

as well as during intermediate storage in a hopper

under conditions close to industrial ones. The

research results are shown in the table 7.

ISC SAI 2022 - V International Scientific Congress SOCIETY OF AMBIENT INTELLIGENCE

260

Figure 2: Dependence of the technological parameters and the strength of the agglomerate on the mass fraction of the HIMS

concentrate in the ore part of the charge during sintering of the agglomerate with oxide grade II (a) and carbonate (b) gravity

concentrates:

1 - HIMS concentrate in the form of microgranules;

2 - HIMS concentrate in its original form.

The dependence of the physical properties of the

sinter charge and the sintering coefficient in the

production of manganese agglomerate on the mass

fraction of the HIMS concentrate in the initial and

prepared form is shown in Fig. 1. The dependence of

the technological parameters of the agglomeration

process on the mass fraction of the HIMS concentrate

is shown in Fig. 2.

An increase in the mass fraction of the HIMS

concentrate over 15-20 % leads to a deterioration in

the physical and gas-dynamic properties of the sinter

charge, which in turn reduces the technological

parameters of sintering and the quality of the sinter.

When the mass fraction of the HIMS concentrate in

an unprepared form in the sinter batch is equal to 40-

60%, the agglomeration process becomes unfeasible.

Agglomeration Technology of Fine Manganese Concentrates with the Application of Granulation

261

Due to the lower moisture capacity of the carbonate

gravity concentrate, the larger average particle size

and their greater roughness in comparison with the

oxide gravity concentrate of the II grade, the effect of

the addition of the HIMS concentrate to the charge

has a lesser effect on the deterioration of

technological parameters. When sintering carbonate

concentrate with additives of HIMS concentrate, due

to the high mass fraction of volatiles, the yield of

suitable agglomerate decreases and the rate of

filtration of exhaust gases. In combination with

thermal destruction of lump carbonate concentrate,

this causes to a significant increase in dust removal in

the process of sintering.

Table 7: Characteristics of the properties of the initial charge from the HIMS concentrate and granules obtained from it

Indicator

Ex

p

eriment o

p

tions

1 2 3 4 5

Moisture mass fraction in the HIMS concentrate before

mixin

g

, %:

in the original

16.0 16.0 25.0 25.0 25.0

in shredded

– 3.0 3.0 3.0 3.0

Mass fraction in the charge, %:

HIMS concentrate 100 80 60 40 20

crushed HIMS concentrate

– 20 40 60 80

Mass fraction -0,056 mm in the charge, %

6.2 25.9 37.3 48.7 60.1

Bulk density of granules.

1330 1350 1390 1430 1510

Mechanical strength of granules, after dropping twice

from a height of 2 m onto a metal plate (fraction yield

+2 mm

)

, %

32.4 68.7 86.8 96.9 96.4

When using HIMS concentrate in the sinter

charge in the form of granules, the characteristics of

the sintered layer are improved. Due to the increase

in the gas permeability of the charge, it is possible to

carry out the sintering process in a higher layer with

an unlimited amount of the proportion of granules in

the ore part of the sinter charge. With this technology,

rolling of solid fuel into granules is eliminated, which

reduces the specific consumption of coke breeze.

It has been established that the addition of HIMS

concentrate to the sinter charge in an unprepared form

in an amount of 15 to 30 % and of 30 to 50 % reduces

the specific productivity of the sinter plant by 25 and

50 % respectively, as well as the strength of the sinter

and increases the loss of the initial material.

The results of sintering class II oxide gravity

concentrate with the addition of HIMS concentrate in

the form of granules were processed on a computer

using the program of multiple correlation-regression

analysis. A mathematical model of the agglomeration

process has been created, which is described by the

regression equations connecting the output

parameters with the controlled ones:

Q = 2.7288 + 0.0471τ + 0.000799SV -

- 0.018642G - 0.014В - 0.15201С;

Р = 77.4465 + 1.06765τ - 0.0019413SV -

- 0.079485G - 0.0033346В + 0.21690С,

where Q - unit specific productivity, t/(m

2

·h); τ -

ignition time, min; SV - sintering vacuum, Pа; G -

mass fraction of granules of the HIMS concentrate (in

relation to the oxide gravitational concentrate of the

II class), %; В - mass fraction of return in the charge,

%; С - mass fraction of coke breeze in the charge, %;

Р - agglomerate impact strength, %.

The obtained regression equations were used to

optimize the sintering process. The optimization

problem consisted in determining such values of τ,

SV, G, B and C within the specified limits, at which

the specific productivity of the installation and the

mechanical strength of the agglomerate reached the

maximum values.

The conditions and results of optimization of the

sintering process are given in table 8.

The second method of pre-coating of fine

concentrates was investigated - the method of

briquetting, the feature of which was the absence of

binder and increasing the pressing pressure to 30

MPa. A batch of briquettes was obtained to conduct

research on sintering the sinter using a sinter batch of

raw briquettes measuring 15×15×20 mm.

Experiments on agglomeration have shown that with

a content of 30-40 % of briquettes in the charge, the

height of the sintered layer can be increased to 700-

900 mm.

In the process of processing the sludge formed

during the enrichment of oxidized manganese ores on

high-intensity magnetic separators, a concentrate

ISC SAI 2022 - V International Scientific Congress SOCIETY OF AMBIENT INTELLIGENCE

262

with a high specific surface area and high moisture

content was obtained. Concentrate of high-intensity

magnetic separation of manganese sludge contains,

%: 33,0 Mn; 24.8 SiO

2

; 2.9 Al

2

O

3

; 6.2 FeO; 0.435

P

2

O

5

and other components. The true density of the

concentrate is 3420 kg/m

3

, the specific surface area is

250 m

2

/kg; bulk density 1500 kg/m

3

, angle of natural

slope 43.5 degrees.

Table 8: Conditions and results of optimization of the sintering process

Parameters Parameter type

Symbol

Restrictions

Optimal value

Bottom

line

Upper

b

ounds

Specific

productivity,

t/

(

m

2

·h

)

Output Q 0.9 1.6 1.33

Agglomerate

im

p

act stren

g

th

P 74.0 81.0 79.2

Ignition time, min. Adjustable τ 3.0 5.5 5.0

Vacuum, Pa SV 5000 11000 6500

Mass fraction of

g

ranules, %

G 25.0 60.0 30.0

Mass fraction of

return, %

В 15.0 35.0 20.0

Mass fraction of

fines, %

С 7.0 9.5 9.0

The concentrate is characterized by high moisture

content - the moisture content in it after filtration is

30-40 %. The concentrate was pelleted in bowl

pelletizers with a diameter of 1 and 2 m to obtain raw

pellets of uniform particle size distribution (diameter

14-18 mm) without the use of reinforcing additives,

and then subjected to heat treatment. The optimal

parameters of heat treatment of pellets are given in

table. 9.

Table 9: Optimal parameters of heat treatment of pellets

Technological modes

Duration of heat

treatment, min

Temperature of the

heat carrie

r

, °С

Filtration speed,

m

3

/(m

2

·s)

Lquefaction,

×10

3

Pa

At the entrance At the exit

Heating the top

of the layer

90-120 200 30-40 0,3-0,5 2,00

Blow drying from below 12 350 80-90 1,2-1,4 5,00

Blow dr

y

in

g

on to

p

3-4 350 80-90 1,1-1,2 5,00

Heatin

g

6-7 700-900 200-350 1,1 5,00

Burnin

g

12-15 1150-1180 400-500 0,9-1,0 5,00

Recuperation 3 1000 500 0,9 5,00

Cooling 15-16 20-25 800-300 1,3-1,4 5,00

The introduction of 1.0-1.2 % of finely ground

solid fuel into the charge intensifies the firing process,

reduces the temperature interval between the horizons

of the fired layer, and increases the specific

productivity of the installation. The main average

quality indicators of pellets are as follows:

compressive strength,

kN

/

p

ellet

impact strength

(fr. +5 mm), %

specific

p

roductivity, t/(

m

2

·h)

without solid fuel 1,7 90 0,57

with the addition of 1% anthracite: 1,27 87 0,72

Agglomeration Technology of Fine Manganese Concentrates with the Application of Granulation

263

4 CONCLUSIONS

1. One of the ways to increase the rate of manganese

extraction in the enrichment of manganese ores in

Ukraine in a constantly declining quality of source

ore is the introduction of deeper and more advanced

enrichment schemes, including flotation and high-

intensity magnetic separation (HIMS), although this

leads to increased fine particles and moisture in

concentrates.

2. A comparative analysis of chemical,

mineralogical compositions and physical

characteristics of imported and domestic manganese

ores and concentrates, as well as the laws of

transformation of the phase composition in the

process of regenerative heat treatment. It is confirmed

that the main distinguishing feature of the studied

manganese raw materials from foreign producers is

the low value of the modulus of phosphorus (P/Mn <

0.0035) and silica (SiO

2

/Mn from 0.5 and below),

which allows to achieve high technical and economic

performance.

3. On the basis of the studies performed, it was

established that with the introduction of 30-50 % of

the HIMS concentrate into the sinter batch, the

productivity of the sinter plant decreases by 25-50 %,

the strength indicators of the agglomerate deteriorate,

and the removal of dust increases.

4. The technology for processing the HIMS

concentrate has been developed, including its partial

regrinding and drying, mixing, granulating and

agglomeration in a high layer. The optimal

parameters of agglomeration have been determined,

which make it possible to carry out the process

without reducing the technological parameters when

using 30-45 % HIMS concentrate in the sinter batch.

5. A technological scheme was developed for the

reconstruction of the Bogdanovskaya sinter plant of

the JSC "Pokrovskiy GZK". The technical and

economic assessment of the developed technology

that was carried out indicates its high efficiency.

REFERENCES

Wu, Y., Shi, B., Ge, W. et al. Magnetic Separation and

Magnetic Properties of Low-Grade Manganese

Carbonate Ore. JOM 67, 361–368 (2015).

https://doi.org/10.1007/s11837-014-1212-8

Kuleshov, V.N. Manganese deposits: Communication 1.

Genetic models of manganese ore formation. Lithol

Miner Resour 46, 473 (2011).

https://doi.org/10.1134/S0024490211050038

Kutsin, V.S., Gasik, M.I. Production of manganese

magnesia sinter using enriched Nikopol manganese ore

and magnesia-silicate slag from ferronickel production.

Steel Transl. 42, 48–55 (2012).

https://doi.org/10.3103/S0967091212010111

You, BD., Lee, BW. & Pak, JJ. Manganese loss during the

oxygen refining of high-carbon ferromanganese melts.

Metals and Materials 5, 497 (1999).

https://doi.org/10.1007/BF03026165

Kwon, EH., Lee, JA. & Han, JW. Modified Unreacted Core

Model for Reduction of Manganese Ore by CO Gas.

Met. Mater. Int. (2021).

https://doi.org/10.1007/s12540-021-01020-8

DeFerreira, T.H., Cabral, A.R. & Rios, F.J. Correction to:

Earthquake-induced clastic dyke and fluid inflow at the

Miguel Burnier manganese-ore deposit, Quadrilátero

Ferrífero of Minas Gerais, Brazil. SN Appl. Sci. 3, 546

(2021). https://doi.org/10.1007/s42452-021-04481-z

Yuanbo Zhang, Minghui Du, Bingbing Liu, Zijian Su,

Guanghui Li & Tao Jiang (2017) Separation and

recovery of iron and manganese from high-iron

manganese oxide ores by reduction roasting and

magnetic separation technique, Separation Science and

Technology, 52:7, 1321-1332, DOI:

10.1080/01496395.2017.1284864

Singh, V., Biswas, A. & Sahu, N. Development of a

Smelting Reduction Process for Low-Grade

Ferruginous Manganese Ores to Produce Valuable

Synthetic Manganese Ore and Pig Iron. Mining,

Metallurgy & Exploration 37, 1681–1692 (2020).

https://doi.org/10.1007/s42461-020-00271-0

Kulik, D.A., Chernovsky, M.I. Fractal properties of multi-

order folding as a tool for exploration of low-grade

banded iron ores in the Krivoy Rog basin (Ukraine).

Geol Rundsch 85, 3–11 (1996).

https://doi.org/10.1007/BF00192054

Samal, S.K., Mohanty, M.K., Mishra, B. et al. Thermal

Transformation of Oxide and Hydroxide Minerals in

Chromite and Manganese Ores. Mining, Metallurgy &

Exploration 38, 1125–1134 (2021).

https://doi.org/10.1007/s42461-021-00382-2

Eom, C.H., Min, D.J. Kinetics of the formation reaction of

manganese carbide under various gases. Met. Mater.

Int. 22, 129–135 (2016).

https://doi.org/10.1007/s12540-015-5419-1

Grishenko S.G., Krivenko V.V., Ovcharuk A.N.,

Olshansky V.I., Filippov I.Yu. The comprehensive

analysis of physical and chemical properties and

metallurgical value of foreign manganese raw materials

used during ferroalloy production. Proceeding of the

fourteenth international ferroalloys congress. Infacon

XIV Energy efficiency and environmental friendliness

are the future of the global Ferroalloy industry, Kiev,

2015, volume II, pp. 436-446.

ISC SAI 2022 - V International Scientific Congress SOCIETY OF AMBIENT INTELLIGENCE

264