TMRobot Series Toolbox: Interfacing Collaborative Robots with

MATLAB

João Lobato Pereira

1,2 a

, Mauro Queirós

1,2 b

, Nuno M. C. da Costa

2c

, S. Marcelino

6

,

José Meireles

3d

, Jaime C. Fonseca

2e

, António H. J. Moreira

4,5 f

and João Borges

2,5 g

1

University of Minho, Guimarães, Portugal

2

Algoritmi Center, University of Minho Guimarães, Portugal

3

MEtRICs Research Center, University of Minho, Guimarães, Portugal

4

2Ai – School of Technology, IPCA, Barcelos, Portugal

5

Polytechnic Institute of Cávado and Ave, Barcelos, Portugal

6

DIB4T, Marinha Grande, Portugal

Keywords: TMRobot, TM5_700, MATLAB, Individual Function, Class_TMRobot, Modbus TCP, Socket TCP/IP.

Abstract: As collaborative robots rise in popularity in industrial and domestic environments, TECHMAN Robot

developed the TMRobot series, a wide variety of smart, safe, and straightforward collaborative robots. This

paper presents the TMRobot Series Toolbox, which contains functions and methods to interface with the

TMRobot series cobots from an external device using MATLAB. By using these, the users have access to

connection, kinematic, point motion, set, get, and simulation functionalities which run on a remote computer

connected to the TMRobot controller via TCP/IP protocols. The toolbox is then validated with some

application examples.

1 INTRODUCTION

1.1 Motivation and Related Work

One of the significant changes that accompany the

implementation of the new concept of Industry 4.0 is

the use of collaborative robots (Poor & Basl, n.d.).

The most common industrial robots are large, heavy,

strong, and robust devices that work on very specific

tasks. Sensors, signals, and safety nets are installed

for safety reasons. According to relatively complex

programs, they are used to complete human tasks

while operating in a restricted area (Poór et al., 2019).

A collaborative robot or cobot is also an industrial

robot designed to cooperate with the human operator

to create value. These robots can perform different

tasks, such as picking up and inserting objects,

a

https://orcid.org/0000-0002-1053-7405

b

https://orcid.org/0000-0001-5896-7423

c

https://orcid.org/0000-0002-8425-3501

d

https://orcid.org/0000-0003-0881-2348

e

https://orcid.org/0000-0001-6703-3278

f

https://orcid.org/0000-0002-2148-9146

g

https://orcid.org/0000-0002-5880-033X

delivering parts to the operator, among others (Broum

& Šimon, n.d.).

In order to control a TM5_700 (TMRobot series),

one needs to have an external toolkit for

communication and control. TMRobot, unlike Kuka

(Safeea & Neto, 2019), Puma (Gil et al., 2015), and

Universal Robotics (Vivas & Sabater, 2021), does not

have one. As such, our motivation for this project was

to create ways to command and monitor this robot.

To support this project development Peter

Corke’s Robotics Toolbox is used, one of the most

popular MATLAB toolboxes in the field of robotics.

Peter Corke’s Toolbox includes functionalities for

robotic manipulators, such as homogeneous

transformations, direct and inverse kinematics, direct

and inverse dynamics, and trajectory generation

(Corke, 2017). Also, it is essential to mention the

Kuka Sunrise Toolbox (KST) project, where the

46

Pereira, J., Queirós, M., C. da Costa, N., Marcelino, S., Meireles, J., Fonseca, J., Moreira, A. and Borges, J.

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB.

DOI: 10.5220/0011526000003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 46-55

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

authors, similarly to this project, developed more than

50 functions divided into six categories to interface

with the KUKA LBR iiwa manipulators—creating

the first Toolbox to interface with the KUKA

Sunrise.OS with functionalities like networking, real-

time control, point-to-point motion, setters, getters,

and physical interaction (Safeea & Neto, 2019).

1.1 Project Goals

The main goal of this project is to develop an easy-to-

use toolkit capable of interfacing with the TM5_700

collaborative robot. Since this specific robot shares

the same software and communication protocols with

the rest of the TM series cobots, the methods

developed can be used for every TMRobot, which is

already a significant advantage of the TMRobot

Series Toolbox. Other advantages are:

1) It takes the user away from having to learn a

new software associated with this robot’s

controller TMFlow;

2) Easy and fast interaction between the robot

and an external computer;

3) External sensors/devices are integrated into

the computer, and data are transmitted to/from

the robot via TCP/IP;

4) Complex applications can be included in the

external device allowing for more advanced

robot manipulation (i.e. machine learning,

vision);

5) Supplementing the robot’s system

functionalities with simulation capabilities.

The functions and methods within the package,

much like the KST toolbox, are divided into different

categories depending on their role: connection, setters,

getters, point motion, simulation, and gripper. A deep

study of the TMRobot manuals was required to define

which types of communication with external devices

were most suitable for the different functions

(Software Manual TMflow_ Software Version:

1.68_Document Version: 1.01 i Software Manual

TMflow Original Instruction Software Version: 1.68,

n.d.). With that, for the acquisition and manipulation

of robot parameters like joint values, end-effector

position, IO connectors, and others, the Modbus TCP

protocol was picked since, by extensive testing, it

turned out to be simpler and provide more

information. For the motion control of the robotic arm,

the socket TCP/IP transport protocol was used

alongside the robot’s external script protocol, which

defines the specific command exchange format

(Expression Editor and Listen Node Software Version:

1.80 Expression Editor and Listen Node, n.d.).

2 SYSTEM ARCHITECTURE

This project is composed of two main subsystems: the

operational subsystem, which incorporates the

TMRobot and its controller; and the control and

monitoring subsystem defined by the external device

and its properties. Figure 1 shows how these two

components interact. After deliberation and research

on projects with similar goals, we choose MATLAB

as the software to associate with the external device.

This is a tool that is in constant improvement. It is

flexible, versatile, and supports a variety of

communication protocols which represent an

essential requirement for this development.

MATLAB has been commonly used on a big scale in

the academic environment, so its high-level

programming structure is well-known, allowing users

with minimal experience to easily understand and

utilize this work.

Figure 1: System architecture and communication scheme.

2.1 Operational Subsystem: Robot

Controller

This subsystem is mainly responsible for interpreting

the commands and requests coming from the external

device, following the instructions on those

communication messages, moving the robotic arm to

the requested poses, sharing and setting different

parameters in the controller, and even confirming

connections and states of movements. For this to be

possible, some steps must be performed on the side of

the robot’s software TMFlow. As the scheme in

Figure 1 shows, to control the real robot to the extent

required, both Modbus TCP and SocketTCPListenner

servers need to be set up. To start the Modbus TCP

server, the user only needs to login into the TMFlow

software, open the settings menu, go to connection,

open the Modbus slave tab, select the communication

type, TCP, and enable the service.

To run the Socket server, it is required to create a

new project in the project tab and place the Listen

Node after the start block. Ensure the timeouts are set

to zero in the node properties and run that project.

Figure 2 shows this simple setup.

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB

47

Figure 2: Setting SocketTCPListenner server.

2.2 Control and Monitoring

Subsystem: External Device

This subsystem is where the user executes all the

developed functions according to his tasks needs or

desired actions. The commands and requests

developed inside these functions were coded

according to the specific protocol format of the

TMRobot so that the user could control not only the

TM5_700 collaborative robot but also other TM

series robots. To create both Modbus TCP and Socket

clients, specific MATLAB toolboxes are required

(Modbus Communication - MATLAB & Simulink,

n.d.), (TCP/IP Communication - MATLAB &

Simulink, n.d.). Moreover, users must add to their

software the Industrial communication, the

Instrument control, the Optimization, and Peter

Corke’s Robotics toolboxes (Access MATLAB Add-

On Toolboxes - MATLAB & Simulink, n.d.).

This way it is possible to make the TMRobots

more accessible to a wide variety of people from

different backgrounds and open the door of

collaborative robotics for academic and educational

applications. This toolbox was made publicly

available (GitHub - Joaolobatopereira117/TMRobot-

Series-Toolbox, n.d.).

3 TOOLBOX FUNCTIONS

This section is divided into two parts that represent

different levels of the TMRobot Series Toolbox

usage. The individual function library is more

suitable for quick and simple tasks requiring a single

robot to accomplish the end goal. In contrast, the

Class_TMRobot, with its aggregated structure,

allows for a more complex task design with the

integration of several TMRobots controlled from the

same platform, which will be represented as different

class objects, each one with its organized properties

and methods. This structured approach is where this

toolbox differentiates from the KST toolbox.

3.1 Individual Function Library

In this section, implementation examples of some

functions are given so that the user can follow and

understand their functionalities better. For clearer

understanding, the functions are divided into eight

different categories:

1) Connection - Connection with the robot

controller;

2) Setters – Set parameters in the robot controller

(digital output, referential base);

3) Getters – Get parameters from the robot

controller (end-effector position and

orientation, joint angles, digital input and

output);

4) Point Motion – Point to point motion in joint

and cartesian space;

5) Gripper – Gripper control;

6) Kinematics – Forward and inverse kinematics;

7) Simulation – Manipulation and visualization

of the virtual model;

8) Test arm configuration – Test specific robot

poses in joint and cartesian space;

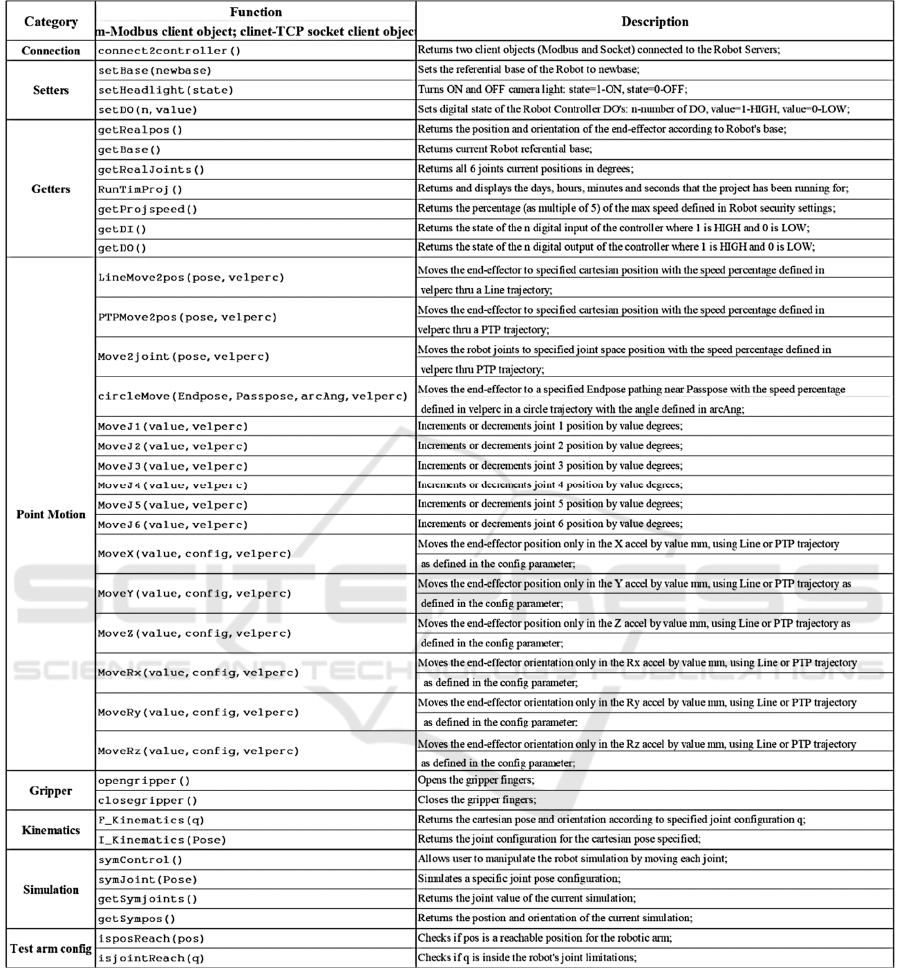

Table 1 aggregates all the individual functions

within each category and represents all the work done

in the first part of this section.

Connection:

In order to start controlling the robot, both the

external device and the controller must be physically

connected with the RJ45 ethernet cable in their

specific ports and the IP addresses in the same

network frame. With these conditions assured, the

user is ready to establish the connection using the

function

connect2controller(ip,socketport,modbusport),

where ip is a string with the IP address of the robot

and ports are the socket and Modbus communication

port, that by default are 502 and 5890, respectively.

The example below illustrates a connection.

>>ip=”192.168.0.111”;

>>socketport=5890;

>>modbusport=502;

>>[socketclient,modbusclient]=connect2c

ontroller(ip,socketport,modbusport);

This function returns both Modbus and socket

clients, which are meant to be used in the rest of the

library functions.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

48

Table 1: List of all functions in the individual function library in TMRobot Series Toolbox.

Setters:

This category includes functions to set different

referential bases for the Robot base and to control

LED and digital output states. For example, to set a

new base:

>>newbase=[300 300 300 180 0 90];

>>setBase(socketclient,newbase);

To set the digital output five to a HIGH state:

>>setDO(modbusclient,5,1);

Getters:

These functions will allow users to monitor all kinds

of robot parameters, from the input-output (IO) states

to joint and cartesian positions. To illustrate the

acquisition of the current base and end-effector

position according to this new base:

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB

49

>>getBase(modbusclient);

ans

300 300 300 180 0 90

>>getRealpos(modbusclient);

Both these functions return a 1x6 cell array with

the [X Y Z Rx Ry Rz] values.

To get the state of digital input 2:

>>getDI(modbusclient,2);

ans

0

Point Motion:

This category allows users to move the robotic arm

from the current configuration/position to a final pose

through different types of trajectories (PTP, line, and

circle) with the desired speed percentage. In addition

to this, the user can move the end-effector through a

single axis or even actuate over one specific joint.

This next example moves the robot to the user

defined finalpos with 75% of the speed defined for

the project.

>>finalpos=[400 50 350 180 0 90];

>>vel_percent=75;

>>LineMove2pos(socketclient,finalpos,ve

l_percent);

To individually move the first joint plus 10

degrees with 100% speed, use the moveJ1 function

with the following parameters:

>>MoveJ1(socketclientmodbusclient,10,10

0)

Gripper:

The functions developed in this category are specific

to the 2FG7 Omron gripper, and some additional

blocks have to be added to the project in the TMFlow.

If the user has the same gripper properly installed, the

complete project folder is also available on the Github

page with the name ToolboxProj, so it is required to

download it, import it to the robot operational system

and run it. After that, the system is ready to interpret

both open and close actions:

>>opengripper(modbusclient,socketclient

);

>>closegripper(modbusclient,socketclien

t);

Kinematics:

By relying on the Peter Corke robotic toolbox for all

the virtual model related work, kinematic functions

are already defined and associated with the serial link

object, created with the portion of code bellow,

sym_model - virtual representation of the TMRobot to

control according to its Denavit Hartenberg

parameters Figure 3. So, it was just a matter of

shaping their inputs and outputs to the format that

suited this work.

Figure 3: TM5_700 Denavit Hartenberg parameters.

Users are free to use these functions, however

their purpose is to support other functions to test

specific pose configurations and to allow switching

between joint and Cartesian space, and vice-versa.

In the forward kinematic function, the user

defines a set of 6 joint values in degrees as a 1x6 array

Links Θº αº a mm d mm Offset

1 Θ

1

-90º 0 145.1 0º

2 Θ

2

0º 329 0 -90º

3 Θ

3

0º 311.5 0 0º

4 Θ

4

90º 0 -122.2 90º

5 Θ

5

90º 0 106 0º

6 Θ

6

0º 0 114.4 0º

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

50

cell and will be answered with the position and

orientation of the end-effector, [X Y Z Rx Ry Rz] in

mm and degrees. For the inverse kinematic, it is the

exact opposite:

>>F_Kinematics(sym_model,[0 0 0 0 0 0]);

>>I_Kinematics(sym_model,[0 -236.6

891.6 90 0 0]);

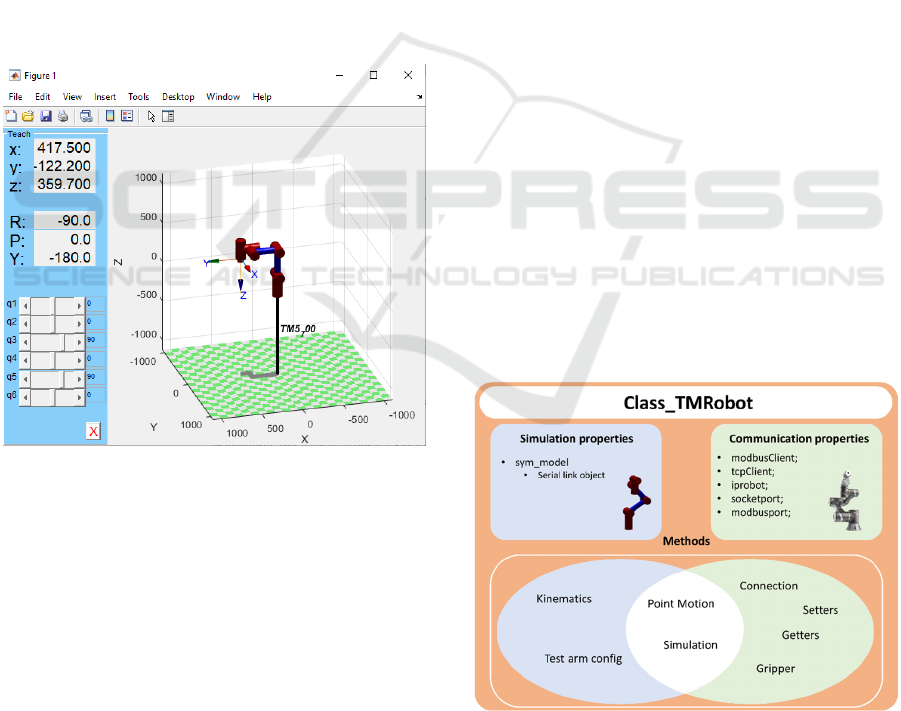

Simulation:

The functions in this category are meant to help users

visualize specific robot pose configurations, before

sending any definitive commands to the real robot.

The symControl(sym_model,q) function, based on

a method from the serial link class, allows for direct

manipulation of the virtual model. Moreover, when

users run this method, an interactive plot opens,

where they can change joint values and watch the

robot motion, as shown in Figure 4:

>>symControl(sym_model,[0 0 90 0 90 0]);

Figure 4: Interactive plot.

The user can then call getSympos() to obtain the

coordinates and orientation of the pose defined in the

plot:

>>getSympos(sym_model);

Test Arm Config:

Much like the kinematic methods, the two functions

in this category will support other functions, ensuring

the robot does not receive invalid joint target poses

and unreachable cartesian positions.

The isjointReach(sym_model,q) returns logical

value 1 if the joint values on the input q are inside the

joint limits defined on the model. The same happens

if the input position on isposReach(sym_model,pos)

obtains a successful output from the inverse

kinematics function used inside this method.

>>isjointReach(sym_model,[0 0 90 0 90

0]);

>>isposReach(sym_model,[300 10 50 0 0

0]);

3.2 Class_TMRobot

As mentioned before, this class originates not only

from the need to integrate both real and virtual

systems but also from the fact that many of the

functions developed before needed access to common

data. So, to optimize the TMRobot Series Toolbox,

we aggregate these functions into an organized

structure where their common inputs become its

properties, and all these functions are rearranged into

its methods.

Merging the system communication attributes

with the simulation model of the robot into the

Class_TMRobot creates advantages in integrating

different categories like Kinematics and Test arm

config with Point Motion methods. Access to all this

new information makes for improvements in some of

the old functions, mainly those responsible for arm

movement. Also, it enables access to functions that

allow the user to test the capacity of the robot to reach

certain arm positions, making sure the user cannot

send wrong target coordinates or joint poses to the

controller. Figure 5 demonstrates the composition and

organization of the whole class relating the method

categories with the type of property they require for

processing.

Figure 5: Class_TMRobot.

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB

51

Class Properties:

As illustrated above, these are divided into two types:

1) Simulation properties – sym_model, object from

serial link class;

2) Communication properties – modbusClient and

tcpClient are private properties that are only set

in the connect and disconnect methods, so users

cannot access them. The rest of the properties are

public and meant to be defined by users for their

specific robot, iprobot, socketport, and

modbusport.

Class Methods:

In this topic, implementation examples of the

constructor will be demonstrated since the rest of the

methods in the class come from the functions

developed before and are similar in usage and achieve

the same action within the physical world.

Constructor:

Before using all these methods, the user must be able

to represent his own robot as an object of this class.

For that, the object constructor

Class_TMRobot(varargin) is used. This function can

be called in many different ways:

>>TM5_700=Class_TMRobot();

In this example, the object created, TM5_700 has

its properties defined by default, where the

sym_model property is a serial link object created

based on the Denavit Hartenberg parameters of a

TM5_700 cobot. The iprobot, modbusport, and

socketport are defined as “192.168.0.111”, 502, and

5890, respectively.

>>TM5_700=Class_TMRobot(‘iprobot’,’192.

168.0.1’);

In this case, the object is created with the IP

“192.168.0.1,” and the rest of the properties remain

defined by default. It is advised to use this constructor

if the user is trying to control a TM5_700 because the

virtual model is already set. If, for example, the user

is using a TM12 or other type of TMRobot, just create

a serial link object with the correct DH parameters

and specify all the properties within the constructor:

>>TM5_700=Class_TMRobot(‘sym_model’,TM1

2Model,’iprobot’,’192.168.0.2’,’modbusp

ort’,503,’socketport’,5891);

Table 2 aggregates all the class methods within

each of their respective categories.

Table 2: List of all CLASS_TMROBOT Methods.

4 APPLICATION EXAMPLES

This section demonstrates some application examples

and different uses of the TMRobot Series Toolbox to

validate all the developed work.

1) Example 1: Development of a graphical user

interface called ControllerInterface, making

use of many setters, getters, gripper, and point

motion methods;

2) Example 2: Pick and Place task using both

individual function library and the

Class_TMRobot;

Connection

connect 2cont r ol l er _C( )

F_Ki nemat i cs_C( q)

I _Ki nemat i cs_C( Pose)

set Base_C( newbase)

set Headl i ght _C( st at e)

set DO_C( n, val ue)

get Real pos_C( )

get Base_C( )

getRealJoints_C()

RunTi mPr oj _C( )

get Pr oj speed_C( )

getDI_C()

get DO_C( )

Li neMove2pos_C( pose, vel per c)

PTPMove2pos_C( pose, vel per c)

Move2j oi nt _C( pose, vel per c)

ci r cl eMove_C( Endpose, Passpose, ar cAng, vel per c)

MoveJ1_C( val ue, vel per c)

MoveJ2_C( val ue, vel per c)

MoveJ3_C( val ue, vel per c)

MoveJ4_C( val ue, vel per c)

MoveJ5_C( val ue, vel per c)

MoveJ6_C( val ue, vel per c)

MoveX_C( val ue, conf i g, vel per c)

MoveY_C( val ue, conf i g, vel per c)

MoveZ_C( val ue, conf i g, vel per c)

MoveRx_C( val ue, conf i g, vel per c)

MoveRy_C( val ue, conf i g, vel per c)

MoveRz_C( val ue, conf i g, vel per c)

symCont r ol _C( )

symJoi nt _C( Pose)

get Symjoints_C()

get Sympos_C( )

opengr i pper _C( )

cl osegr i pper _C( )

i sposReach_C( pos)

i sj oi nt Reach_C( q)

Kinematics

Simulation

Test arm config

Class methods

Setters

Getters

Point Motion

Gripper

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

52

Figure 6: Different Robot states.

Figure 6 b) shows another robot state where the

button is not being pressed, joint five is set to 90

degrees, and the gripper is opened. Figure 9 shows the

app manipulation required to get to state b).

4.1 Example 1: Controller Interface

The goal with this example was to create a MATLAB

App that would support the user in designing different

tasks, in the way that he could manipulate the robot

with the simple click of a button and immediately

have at its disposal the positions, orientations and

joint configurations to then include these points on

the final motion process. Since the app required the

use of many methods, it turned out to be an excellent

way to validate the Class_TMRobot and its methods

interacting with each other. This example is included

in the TMRobot Series Toolbox repository with the

name ControllerInterface as shown in Figure 7.

Figure 7: GUI Controller Interface.

To establish a successful connection, one needs to

check if the project is running in the TMFlow and

proceed to define the robot’s IP address and set the

connect button ON. If users try to open the gripper,

move the robot, and others without establishing a

connection, the message “Not connected to robot”

will appear (Figure 7).

Figure 8: Interface connected to TM5-700.

Successfully connected to the controller in Figure 8,

we have all the parameter sections, Digital Input (DI),

Cartesian space, and Joint space, being updated in

real-time. The DI7 is activated since the button

connected to this pin is being pressed, joint five is set

to 60 degrees, and the gripper is closed (Figure 6 a).

Figure 9: Interface associated with Robot state b).

4.2 Example 2: Pick and Place Task

In this example, the goal was to build a pick and place

task only using the functions and methods from this

Toolbox.

For the test conditions of this example, we have

the components (pick site) on the left side of the table

and the PCB board on the right side (place site). The

goal is to fill the PCB with three of these components.

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB

53

This simple task will be accomplished using both

the individual function library and the

Class_TMRobot, so the differences and similarities

can be highlighted.

The first process of finding the pick and place

positions is the same across both implementations.

The following portions of code illustrate the

differences between the two approaches when

developing a motion sequence.

Since the test performed is a simple task with only

one robot, the individual function library would be

suitable. However, if the goal was to control a real

assembly line with many robots working

simultaneously, the class becomes a more suitable

approach due to its structure and organization.

Even though the way these functions and methods

are implemented is different, their effect in the

physical world is exactly the same, and it makes for

the fact that the methods in the Class_TMRobot

integrate the individual functions. To finally validate

the proper behaviour of both approaches, the

movements have been recorded and illustrated in

Figure 10 where the PCB gets fully assembled.

Figure 10: PCB assembling.

5 CONCLUSION

In this article, we introduced the TMRobot Series

Toolbox to interface with the controller that equips

the collaborative TMRobot series, which have been

rising in popularity. These robots are being applied to

processes in assembling notebook computers and

servers and on automobile and flat panel display

production lines that many thought robots would have

a difficult time handling.

This Toolbox runs on an external computer

connected to the TMRobot controller via TCP/IP. We

presented features concerning connection, point

motion, setters and getters, gripper control, and

simulation functions. These features were extensively

tested and demonstrated reliability, versatility,

stability, and ease of use.

The TMRobot Series Toolbox is useful, not only

in teaching, since it allows for students to interact

with real collaborative robots through a familiar tool

that is MATLAB, but also in industrial environments

as it enables the integration of other hardware devices

as well as other methodologies and process control

techniques such as machine learning, data analysis

and artificial intelligence (AI). The performance of

the Toolbox was tested through two successful

application examples.

The future work basically relates to the

development of higher-level functions that allow for

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

54

more complex control for example, the integration of

machine learning methods for close loop control

maintaining the highest level of precision and

incorporation of the designed system into a Simulink

model.

ACKNOWLEDGEMENT

This work is co-funded by the European Regional

Development Fund (ERDF) through the Operational

Competitiveness and Internationalization Programme

(COMPETE 2020) of the Portugal 2020 Program

[Project No. 45070, " FlexASComp”; Funding

Reference: POCI-01-0247-FEDER-045070].

REFERENCES

Access MATLAB Add-On Toolboxes - MATLAB &

Simulink. (n.d.). Retrieved March 27, 2022, from

https://www.mathworks.com/help/thingspeak/matlab-

toolbox-access.html

Broum, T., & Šimon, M. (n.d.). Preparation of

Collaborative Robot Implementation in the Czech

Republic.

Corke, P. (2017). Robotics, Vision and Control -

Fundamental Algorithms In MATLAB® Second,

Completely Revised, Extended And Updated Edition.

Annals of Mathematics and Artificial Intelligence,

75(1–2), 693. https://www.springer.com/gp/book/9783

319544120

Expression Editor and Listen Node Software Version: 1.80

Expression Editor and Listen Node. (n.d.).

Gil, A., Reinoso, O., Marin, J. M., Paya, L., & Ruiz, J.

(2015). Development and deployment of a new robotics

toolbox for education. Computer Applications in

Engineering Education, 23(3), 443–454.

https://doi.org/10.1002/CAE.21615

GitHub - joaolobatopereira117/TMRobot-Series-Toolbox.

(n.d.). Retrieved April 13, 2022, from https://github.

com/joaolobatopereira117/TMRobot-Series-Toolbox

Modbus Communication - MATLAB & Simulink. (n.d.).

Retrieved March 24, 2022, from https://www.math

works.com/help/icomm/modbus.html?s_tid=CRUX_lf

tnav

Poor, P., & Basl, J. (n.d.). 29th Daaam International

Symposium On Intelligent Manufacturing And

Automation Czech Republic And Processes Of Industry

4.0 Implementation. 454–0459. https://doi.org/10.2507/

29th.daaam.proceedings.067

Poór, P., Broum, T., & Basl, J. (2019). Role of

Collaborative Robots in Industry 4.0 with Target on

Education in Industrial Engineering; Role of

Collaborative Robots in Industry 4.0 with Target on

Education in Industrial Engineering. https://doi.org/

10.1109/CRC.2019.00018

Safeea, M., & Neto, P. (2019). KUKA Sunrise Toolbox:

Interfacing Collaborative Robots With MATLAB;

KUKA Sunrise Toolbox: Interfacing Collaborative

Robots With MATLAB. https://doi.org/10.1109/MRA.

2018.2877776

Software Manual TMflow_ Software version:

1.68_Document version: 1.01 i Software Manual

TMflow Original Instruction Software Version: 1.68.

(n.d.).

TCP/IP Communication - MATLAB & Simulink. (n.d.).

Retrieved March 24, 2022, from https://www.math

works.com/help/matlab/tcpip-communication.html

Vivas, A., & Sabater, J. M. (2021). UR5 Robot

Manipulation using Matlab/Simulink and ROS. 2021

IEEE International Conference on Mechatronics and

Automation, ICMA 2021, 338–343. https://doi.org/

10.1109/ICMA52036.2021.9512650

TMRobot Series Toolbox: Interfacing Collaborative Robots with MATLAB

55