Automatic Feature Extraction for Bearings’ Degradation Assessment

using Minimally Pre-processed Time series and Multi-modal Feature

Learning

Antonio L. Alfeo

1,2

, Mario G. C. A. Cimino

1,2

and Guido Gagliardi

1,3,4,∗

1

Department of Information Engineering, University of Pisa, Pisa, Italy

2

Bioengineering and Robotics Research Center E. Piaggio, University of Pisa, Pisa, Italy

3

Department of Information Engineering (DINFO), University of Florence, Florence, Italy

4

Department of Electrical Engineering, KU Leuven, Leuven, Belgium

Keywords:

Feature Learning, Data Fusion, Deep Learning, Multimodal Autoencoder, Contrastive Learning, Predictive

Maintenance, Smart Manufacturing.

Abstract:

Maintenance activities can be better planned by employing machine learning technologies to monitor an asset’s

health conditions. However, the variety of observable measures (e.g. temperature, vibration) and behaviours

characterizing the health degradation process results in time-consuming manual feature extraction to ensure

accurate degradation stage recognitions. Indeed, approaches able to provide automatic feature extraction from

multiple and heterogeneous sources are more and more required in the field of predictive maintenance. This is-

sue can be addressed in a data-driven fashion by using feature learning technology, enabling the transformation

of minimally processed time series into informative features. Given its capability of discovering meaningful

patterns in data while enabling data fusion, many feature learning approaches are based on deep learning

technology (e.g. autoencoders). In this work, an architecture based on autoencoders is used to automatically

extract degradation-representative features from minimally preprocessed time series of vibration and temper-

ature data. Different autoencoder architectures are implemented to compare different data fusion strategies.

The proposed approach is tested considering both the recognition performances and the quality of the learned

features with a publicly available real-world dataset about bearings’ progressive degradation. The proposed

approach is also compared against manual feature extraction and the state-of-the-art technology in feature

learning.

1 INTRODUCTION

The paradigm known as Industry 4.0 recommends

the integration of machine learning in industrial pro-

cesses to improve them (Alfeo et al., 2021) and avoid

production inefficiencies (Alfeo et al., 2020). Re-

garding the maintenance procedures, such technolo-

gies are enabling the so-called Predictive Mainte-

nance (PdM) (Jimenez et al., 2020). PdM aims at

driving the maintenance operations to execute them

just before the breaking point rather than after a fail-

ure or according to some regular schedule. This al-

lows avoiding the costs due to a failure while still ex-

ploiting the whole remaining useful life (RUL) of an

asset’s component (Wan et al., 2017).

∗

Corresponding author

RUL predictions are often unreliable since they

are greatly affected by the usage of the assets while

in an unhealthy stage (Lei et al., 2018). For this rea-

son, many real-world applications provide degrada-

tion stage estimations rather than RUL predictions.

The number of stages characterizing the degra-

dation process results from a trade-off between the

interpretability of the prediction and the complex-

ity of the degradation process. The more the asset’s

degradation process is consistent and progressive, the

more it can be effectively modeled with a few easy-

to-interpret stages. Most of the research works (Lei

et al., 2018) divide the degradation process into three

(Vinh et al., 2009), others into four (Scanlon et al.,

2012), or even five stages (Kimotho et al., 2013).

However, due to the many possible measures to

monitor an asset’s health condition, and the diversity

94

Alfeo, A., Cimino, M. and Gagliardi, G.

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature Learning.

DOI: 10.5220/0011548000003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 94-103

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

of the degradation processes across industries and ma-

chines, it is difficult to provide a high-quality feature

extraction process that is also generalizable among

different PdM applications (Ran et al., 2019). More-

over, both too many redundant features and a few less

informative ones (i.e. that do not ease the distinction

between the behaviors under analysis), may degrade

the performance of algorithms using them (Lorena

et al., 2019). This results in a time-consuming collab-

oration between data scientists and maintenance ana-

lysts to manually transform raw signals into informa-

tive features for application-specific PdM approaches.

In this context, a less manual feature extraction pro-

cess is more and more needed (Yan and Yu, 2015),

and this can be achieved by employing feature learn-

ing approaches (Bengio et al., 2013). Contrary to

manual knowledge-driven feature extraction (Parola

et al., 2022), feature learning is an integrated learn-

ing process in which algorithms learn to automatically

transform minimally processed data into informative

features able to simplify a classification task (Vincent

et al., 2010). Feature learning does not necessarily

require prior domain knowledge, e.g. which features

to select and which to eliminate, and it can be done

by explicitly maximizing the relationship between the

learned features and the target classes.

In this context, the capability of automatically ex-

tracting informative features from multiple and het-

erogeneous sources is more and more required in the

field of predictive maintenance (Lei et al., 2018). The

convenience of multi-modal ML approaches for PdM

is indeed emphasized in different recent surveys such

as (Merkt, 2019). This type of data is coming from

multiple sensors, which normally would require a

specific preprocessing and feature extraction for each

one of them. The use of a feature learning approach

can therefore be a valid solution to handle this kind of

data effectively.

Many recent multi-modal feature learning ap-

proaches are based on deep learning technology

(Zhong et al., 2019), and especially on deep autoen-

coders (AE) (Ran et al., 2019). Indeed, by being char-

acterized by hierarchically stacked nonlinear mod-

ules, deep learning enables the simultaneous process-

ing of data from different sources or modalities while

providing a higher-level representation of the inputs

that can be used as features in a classification prob-

lem. This study aims to compare the complexity

and accuracy of different AE architectures for mul-

timodal feature learning and to exploit those with a

well-known PdM benchmark dataset. For instance,

concatenating the features obtained by training one

AE for each modality may result in a longer training

time whereas concatenating the modalities results in

a more complex AE architecture. The contribution of

this work can be summarized as:

• an architecture to learn degradation-representative

features by providing a deep autoencoder-based

with minimally preprocessed time series of vibra-

tion and temperature data;

• a comparison of different variations of the autoen-

coder architecture to implement different data fu-

sion strategies;

• an assessment of the quality of the learned fea-

tures and recognition performances with respect

to the classic feature extraction and the state of

the art technology in feature learning;

The proposed approach has been tested on 3 real-

world cases study characterizing the degradation of

industrial bearings via their temperature and vibra-

tion. The paper is structured as follows. In section

2, the literature review is presented. Section 3 details

the proposed approach. The case study and the ex-

perimental setup are presented in sections 4. Finally,

section 5 and 6 discuss the obtained results and the

conclusions, respectively.

2 RELATED WORKS

In this section, a survey of the state of the art is

presented. It addresses deep learning-based feature

learning with a focus on approaches based on multi-

modal feature learning. Deep learning approaches

have proven to be effective at providing a non-linear

combination of the input data to distill higher-level in-

formation, i.e. automatically learning features (Tang

et al., 2019).

A deep learning architecture is built by stacking

layers of artificial neurons (Gao et al., 2020). The

inputs provided to the architecture are processed by

each layer, thus each layer produces the features for

the next one. This processing is guided by a loss func-

tion that minimizes a target error. Thus, is intrinsi-

cally a feature learning approach, although depend-

ing on the loss used, features may be more or less

useful for feature extraction. For instance, the most

used deep learning architecture for feature-learning is

the so-called autoencoder (AE), which has proven its

convenience in learning latent feature representation

in many application domains (Deng, 2014).

AE is made of two main components: the en-

coder produces a compact representation of the in-

puts, whereas the decoder reconstructs the input data

from such a compact representation. The AE net-

work is then trained through a loss function that max-

imizes the similarity between its input and output, re-

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature

Learning

95

sulting in a completely unsupervised approach. Once

trained the compact representation provided by the

encoder can be used as a feature for classification

tasks. Specifically designed to be fed by different in-

puts, the so-called multimodal autoencoder can fuse

multi-sensory data while performing feature learning

(Yan et al., 2020).

When based on autoencoders, it is possible to pro-

vide a feature learning approach with a data fusion

mechanism in 3 different ways (Gao et al., 2020):

• Data-level Fusion: these approaches learn a

multi-modal feature representation by processing

the concatenation of the original input data for

each modality (Gecgel et al., 2022).

• Architecture-level Fusion: these approaches learn

a multi-modal feature representation by process-

ing each modality independently, up to the last

layers of the neural network architecture that are

shared among the different modalities (Shin et al.,

2021).

• Representation-level Fusion: these approaches

learn a multi-modal feature representation by pro-

cessing independently each modality and concate-

nating the representation learned from each one of

them (Alfeo et al., 2022).

As an example, in (Ngiam et al., 2011) many

AE deep learning approaches for handling multi-

modal audio-video features are proposed and dis-

cussed. In particular, the so-called shared modality

AEs which take concatenated multi-modal features as

input and reconstruct them (data-level Fusion), and

multi-Modal AEs which are multi-input-multi-output

networks (Architecture-level Fusion), in which one

modality is provided at each input level and processed

by the network together with the others and then re-

constructed separately at each output level.

Alternatively, to feature learning approaches

based on AE, a neural network can directly learn

a new set of features by employing specifically de-

signed loss functions. An example of this is the

multi-similarity loss provided by Tensorflow Simi-

larity (Elie Bursztein, 2021) which represents the

state-of-the-art learning features for similarity rank-

ing problems. This approach is based on learning

a representation in the latent space that clusters the

samples belonging to the same class while maximiz-

ing the distance between samples belonging to dif-

ferent classes. This results in a fully supervised fea-

ture learning approach. The main difference between

these two approaches is that AE tries to learn a new set

of features that is informatively identical to the origi-

nal one so that it can be reconstructed correctly, simi-

larity encoder instead learns a new set of features that

maximize their separability in correspondence with

the target classes.

3 DESIGN

In this section, the design of the proposed approach is

detailed. It consists of three functional modules, i.e.

data preparation, feature extraction, and degradation

stage recognition.

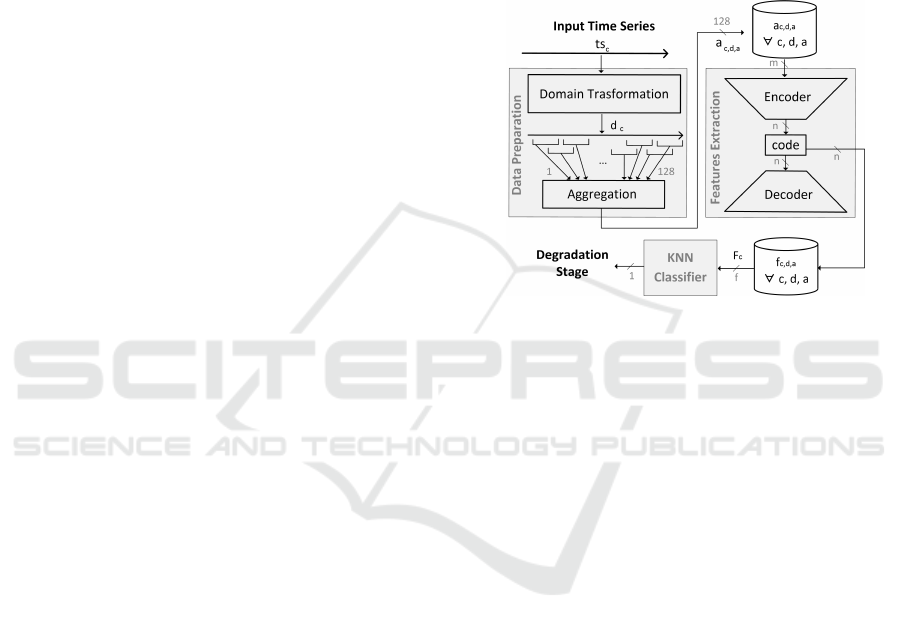

Figure 1: Architecture of the proposed approach.

The data preparation module provides the mini-

mal preprocessing needed to use them as inputs for

the feature extraction module. The vibration and

temperature time series are segmented using semi-

overlapping time windows with a duration of 30 sec-

onds. Each segment ts

c

is associated with a degra-

dation stage (c is for the time windows count). If

an analysis in the time domain can be sufficient with

non-fluctuating time series such as the temperature,

the vibration time series are often analyzed in the fre-

quency domain (Pandarakone et al., 2018). Thus, the

vibration time series are transformed via the discrete

Fourier transform by the data preparation module, ob-

taining d

c

(d is for domain transformation, if any).

Both the arrays obtained via the discrete Fourier trans-

form of the vibration segment and the temperature

segment are split into 128 semi-overlapped parts. Fi-

nally, each part is aggregated via its mean or standard

deviation and rescaled between 0 and 1 via a min-

max procedure, obtaining a

c,d,a

. As the results of the

data preparation, each 30 seconds observation results

in four a

c,d,a

arrays of 128 elements: 2 are obtained

via the discrete Fourier transform of the vibration sig-

nal and 2 via the temperature one. Overall, the data

preparation module provides an array a

c,d,a

for each

time windows c, domain transformation d (discrete

Fourier transform for the vibration and none for the

temperature), and aggregation operator a (mean and

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

96

standard deviation).

The feature extraction module processes the data

provided by the data preparation module and learn

degradation-representative features F

c

to be used in

a classification task. To do so, this module employs a

deep autoencoder.

As introduced in Section 2, there are different data

fusion strategies that can be realized via autoencoders.

Specifically:

• the data-level fusion via the so-called shared-

input autoencoder (SAE), Fig. 2.a; with this ap-

proach, the modalities fusion is obtained by con-

catenating the data derived from each modality,

and then processing them via an autoencoder to

learn a multimodal representation

• the architecture-level fusion using a multimodal

autoencoder (MMAE), in which each modality

feeds a distinct part of the neural network of

which the autoencoder is made; thanks to some

shared layers of neurons these modalities are then

recombined to learn a multimodal representation

that allows the reconstruction of both modalities

(Fig. 2.b)

• the representation-level fusion by processing the

data for each modality via different autoencoders;

the codes obtained via each modality are then

concatenated to build a shared representation be-

tween the two modalities. This feature learning

approach is referred as partition-based autoen-

coder (PAE), Fig. 2.c.

The above described multi-modal feature learning

strategies are depicted in Fig. 2. This Figure shows

two generic modalities from which a multimodal rep-

resentation is going to be learned. The parts of the au-

toencoders working with one modality are colored in

blue (for the first modality) or orange (for the second

one). In purple are the parts working in a multimodal

fashion. The dashed box highlights the modalities fu-

sion phase.

Once the feature extraction module is properly

trained, the learned multimodal representation (i.e.

the code, or their concatenation) can be used as a fea-

ture for the degradation stage recognition.

As specified in Section 1, a proper feature extrac-

tion approach should help as much as possible to dis-

tinguish the categories investigated (e.g., the degra-

dation stages) and thus simplify their recognition. If

that occurs, the assessment of new instances with un-

known degradation stages can even be based on a sim-

ple measure of distance from instances with known

degradation stages, since the new instance would be

in proximity to instances characterized by the same

degradation stage and far from the others.

Figure 2: Autoencoder-based multimodal feature learning

approaches, i.e. shared-input autoencoder (a), multi-modal

autoencoder (b), and partition-based autoencoder (c). In

blue and orange are the parts of the autoencoder that work

with one single modality. The dashed box highlights the

modalities fusion phase.

To test this capability, the proposed approach

uses a K-Nearest-Neighbors Classifier, as provided by

the well-known Python library sci − kitlearn (Nelli,

2018). Rather than associating instances to classes via

a mathematical model, K-Nearest-Neighbors Classi-

fier stores the instances of the training data and clas-

sifies new instances according to the most frequent

class within its K nearest neighbors. In the proposed

implementation K is set equal to one, that is, new in-

stances are assigned the class of the nearest instance

of the training data. This choice is made precisely to

shift the burden of an effective recognition to high-

quality feature extraction.

4 EXPERIMENTAL SETUP

In this section, the experimental dataset and the exper-

imental setup are described. This is used for the eval-

uation of the effectiveness of the proposed approach.

The dataset used in this study is publicly available

at (Nectoux et al., 2012). The data are obtained via the

experimental platform Pronostia, collecting the tem-

perature (10 Hz) and vibration (25.6 kHz) time se-

ries during the progressive degradation of industrial

bearings under different operative conditions. The

three complete case studies provided in the dataset

are named B11, B12, and B21 as in (Nectoux et al.,

2012).

These run-to-failure time series are segmented

into partially overlapping time windows with a dura-

tion of 30 seconds. Each segment is associated with

a degradation stage of the bearing. In this study, 3

degradation stages are considered: regular, degraded,

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature

Learning

97

Figure 3: The Pronostia plaform.

and critical. The degradation label for each segment

is obtained by analyzing the behavior of the vibra-

tion signal. In short, the transition between regular

and degraded health stages is detected as the instant

in which the vibration results consistently equal to or

greater than 1 g (Alfeo et al., 2022). On the other

hand, the transition from the degraded to the critical

health stage is determined by looking for a sudden in-

crease in the Root Mean Square (Mao et al., 2019).

More details about this labeling procedure are pro-

vided in (Alfeo et al., 2022). As a result, each case

study results in a number of instances per degradation

stage as detailed in Table 1.

Table 1: Instances per class and case study.

Degradation stage B11 B12 B21

Regular 1871 748 753

Degraded 1665 319 371

Critical 181 73 74

Regarding the experimental setup, the autoen-

coders are characterized by a symmetric decoder and

encoder. The encoder features 4 layers made of 128,

64, 32, and 16 artificial neurons respectively. The

multimodal encoder features the same number of lay-

ers and neurons for each modality, except for the most

internal one (i.e. with 16 neurons) that is replaced

with 3 layers (made of 64, 32, and 16 neurons) shared

among the modalities. According to the current fea-

ture extraction module, the input layer of the encoder

(as well as the output layer of the decoder) varies

to fit the input length. This results in a comparable

number of trainable parameters for each autoencoder-

based feature extraction module. All of them use

mean absolute error as training loss, 128 as batch size,

Relu as activation function, and Adam as an optimiza-

tion algorithm. To provide a baseline of the recog-

nition performances, a classic feature extraction ap-

proach can be implemented, i.e. by employing a set

of largely used ”heuristic-based” features for indus-

trial assets’ degradation analysis (Hamadache et al.,

2019). Specifically:

• 90th, 75th, 50th, and 25th percentile of the time

series

• maximum, median, mean absolute deviation,

skewness of the time series

• the difference between the global (i.e. of the

whole run to failure time series) and local (i.e. of

the current time window) mean absolute deviation

• the difference between the global and local me-

dian (Alfeo et al., 2020)

• number of continuous time-intervals with values

greater than 90th, 75th, 50th, and 25th percentile

of the time series (Alfeo et al., 2020), only for the

temperature

• number of samples greater than 50% and 25%

of the maximum of the time series (Alfeo et al.,

2020), only with temperature data

• root mean square, crest factor, impulse factor,

peak to peak, entropy, kurtosis of the time series

(Hamadache et al., 2019), only for the vibration

In addition to a performance baseline, the experi-

mental comparison employs a state-of-the-art feature

learning approach, namely contrastive learning tech-

nology, as mentioned in Section 2. Its implementation

has been released by Google and made available in

September 2021 and known as Tensorflow similarity.

Tensorflow Similarity makes available a Multi-

Similarity Loss function which measures the similar-

ity, e.g. inverse of the euclidean distance, between

the representation of 3 data points in the embedding

space i.e. the anchor, the positive, and the negative.

The anchor is similar to the positive, i.e. belongs to

the same class, and is dissimilar to the negative, i.e.

another class. To achieve these results the framework

trains the network in a way that the distance between

the anchor sample and the negative sample represen-

tations is greater (and bigger than a margin m) than the

distance between the anchor and positive representa-

tions. Regarding the performance evaluation, the ex-

perimental results are presented as a 95% confidence

interval (CI) obtained via a 10-repetitions stratified

Monte Carlo cross fold validation, featuring 90% of

the data as training set and 10% as testing set. The

hardware platform used for the experiments employs

an CPU Intel Core i5-3337U@1.80GHZ, RAM 6 GB

DDR3, and an GPU Invidia GeForce GT 630M.

The considered classification problem is unbal-

anced, since the regular stage lasts longer than the

critical one and this results in less instances of the

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

98

more severe degradation stage. For this reason the

classification performance is measured in terms of

F1-score (Nguyen, 2019), i.e. the harmonic mean of

precision and recall, where the precision is the num-

ber of true positives divided by the number of all pos-

itives, and the recall is the number of true positives

divided by the number of all samples that should have

been identified as positive (Eq. 1). The highest possi-

ble value of an F-score is 1.0, indicating perfect pre-

cision, I.e., there are no false positives (e.g. a critical

stage recognized as a regular one), and perfect recall,

i.e. There are no false negatives (e.g. a regular stage

recognized as a critical one), the lowest possible value

for the F1-score is 0 if either the precision or the re-

call is zero, I.e., there are no true positives (e.g. a

correctly recognized regular stage).The highest possi-

ble value of an F-score is 1.0, indicating perfect pre-

cision, I.e., there are no false positives (e.g. a critical

stage recognized as a regular one), and perfect recall,

i.e. There are no false negatives (e.g. a regular stage

recognized as a critical one), the lowest possible value

for the F1-score is 0 if either the precision or the recall

is zero, I.e., there are no true positives (e.g. a correctly

recognized regular stage).For the sake of readability,

the F1-score is multiplied by 100, so that the values

would be bounded between 0 (worst case) and 100

(best case).Since the classification problem features

more than 2 classes, we consider the average of the

F1-scores for each class as the global F1-score.

F1 =

2 ∗ Precision ∗ Recall

Precision + Recall

=

2 ∗ T P

2 ∗ T P + FP + FN

(1)

A feature can be considered informative, if it ease

the separation of the instances among classes (Lorena

et al., 2019). In this regard, class separability metrics

may correlate with classification accuracy (Skrypnyk,

2011), (Cano, 2013). The class separability metrics

allows measuring how well the learned features space

helps separating different classes. In this context, the

so called L1 measure quantifies whether the classes

can be linearly separated in the feature spaces (Lorena

et al., 2019). Specifically, the L1 measure is com-

puted as the sum of the distances of incorrectly clas-

sified examples to a linear boundary used in their clas-

sification. If the value of L1 is zero, then the problem

is linearly separable and can be considered simpler

than a problem for which a non-linear boundary is re-

quired. Lower values for L1 (bounded between 0 and

1) indicate that the problem is close to being linearly

separable, thus simpler. For the sake of readability,

1 − L1 is employed as class separability metric, and

multiply it by 100, so that the values reported in this

work would be bounded between 0 (worst case) and

100 (best case). A qualitative evaluation of the class

separability is presented via a visualization of the in-

stances in the learned feature space. By being mul-

tidimensional, such feature space is almost impossi-

ble to represent graphically. Thus, the feature space

is represented via a projections over its two principal

components’ directions. Of course, such projection

is a valid tool for visualization purposes and qualita-

tive analysis, but it may not exhaustively represent the

proximity between the instances in the feature space

(Liu et al., 2021).

5 RESULTS

In the following, the different feature extraction ap-

proaches are shortened as follows: heuristic-based

features (HB), partition-based autoencoder (PAE),

shared-input autoencoder (SAE), multi-modal au-

toencoder (MMAE), similarity-based encoder (SE).

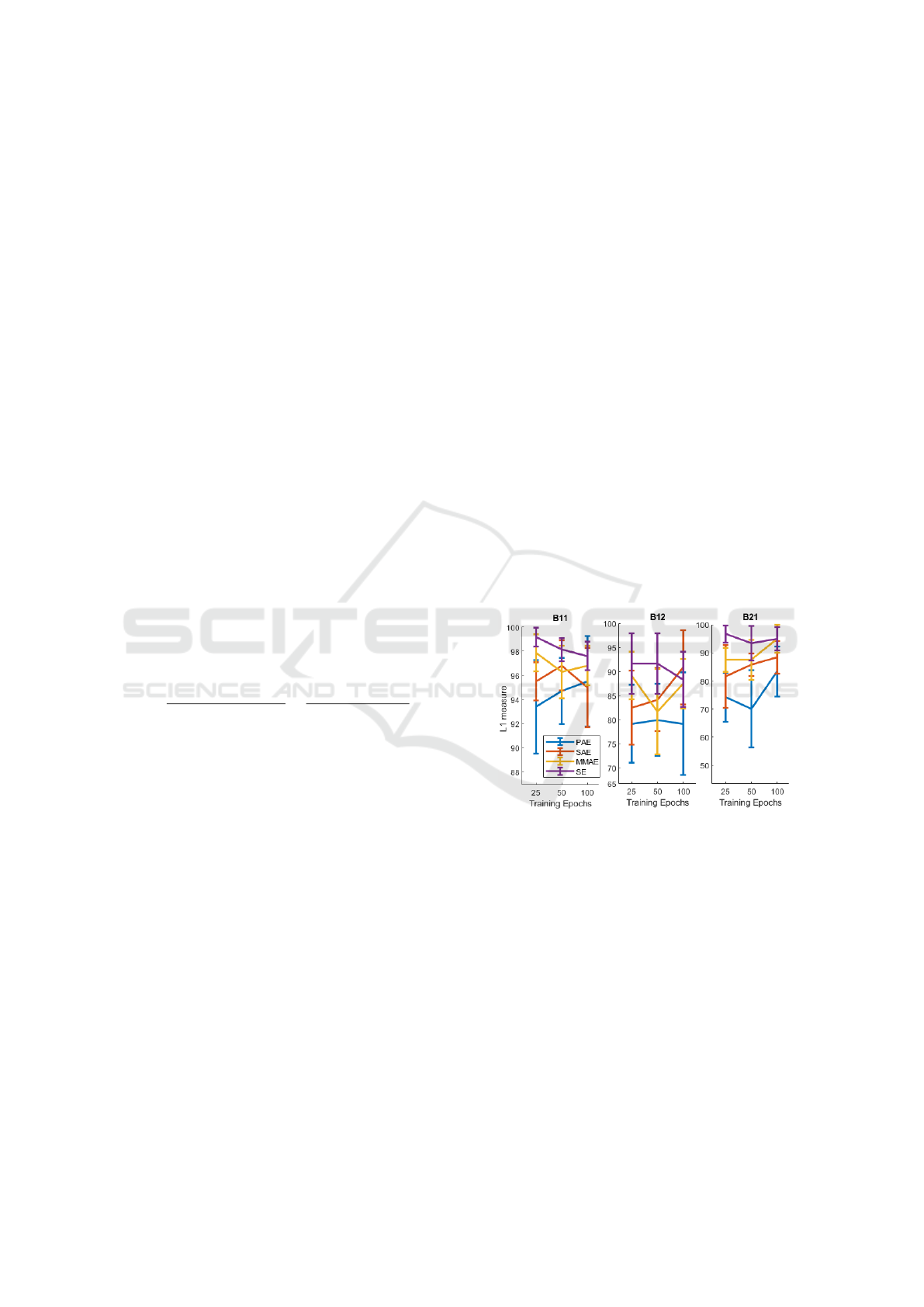

First, it is tested how training epochs impact on

the quality of features learned, which is measured in

terms of class separability with the L1 measure. Fig.

4 shows such quality as training epochs increase (i.e.,

25, 50 and 100 epochs) for each feature learning ap-

proach considered.

Figure 4: L1 measure by changing the number of training

epochs and feature extraction approach. Average and 95%

confidence interval.

The trend observed in the results is a non-

consistent and almost negligible improvement in the

class separability metric. This is also confirmed by

considering the results in terms classification perfor-

mance which are slightly better or comparable despite

the number of training epochs used. Indeed, the great-

est increase in classification performance is obtained

with SAE and the B21 case study: here increasing the

number of training epochs from 25 to 100 results in a

F1-score increase of 4.01%. By considering just the

average separability metrics, PAE seems to results in

features with the worst average class separability with

2 cases study over 3, whereas SE results in features

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature

Learning

99

with the best average class separability with 2 cases

study over 3.

Next, it is tested if the class separability obtained

with the features provided by the different Feature Ex-

traction (FE) approaches is correlated to their classi-

fication performance. Table 2 reports the the L1 mea-

sures obtained with the features provided by each FE

approach, with 100 training epochs. Moreover, Table

3 reports the F1-scores obtained with the KNN classi-

fier by using the features obtained with each Feature

Extraction (FE) approach, and 100 training epochs.

The best average performances for each case study is

highlighted in bold.

Table 2: L1 measure using 100 training epochs for each

Feature Extraction (FE) approach. Average ± 95% confi-

dence interval. 3 degradation stages. In italic the AE-based

approaches.

FE B11 B12 B21

PAE 95.79±3.79 79.17±10.61 83.33±8.89

SAE 95.26±3.30 90.83±7.67 88.33±5.76

MMAE 97.11±1.65 87.50±5.07 95.0 ± 5.03

HB 90.0 ± 4.7 67.50±23.92 80.0 ±14.11

SE 97.89±1.19 88.33±5.76 95.0 ± 4.17

Table 3: F1-score using KNN (k=1) and 100 training epochs

for each Feature Extraction (FE) approach. Average ± 95%

confidence interval. 3 degradation stages. In italic the AE-

based approaches.

FE B11 B12 B21

PAE 97.79±0.32 88.04±2.52 90.47±2.08

SAE 98.85±0.22 93.25±1.26 96.76±0.96

MMAE 98.88±0.27 91.99±1.74 96.43±0.68

HB 94.44±1.91 74.61 ± 5.2 79.31±3.81

SE 98.59±0.29 91.90±1.99 94.62 ±1.7

As shown in Table 3, all feature learning ap-

proaches offer better degradation stage recogni-

tion performance than the heuristic-based features.

Among all the variations of the feature learning mod-

ule, PAE offers the worst performance, in accordance

with the results obtained with the separability met-

rics in 2. The performances offered by the other ap-

proaches are similar. Moreover, there is a clear cor-

relation between the average separability metric ob-

tained in a given case study and the corresponding

average classification performance. For example, the

average separability metrics in case B11 are all be-

tween 90 and 97.11, and the average F1 score is be-

tween 94.44 and 98.88. In the case of B21 the average

separability metrics are clearly lower and the average

F1 score do not exceed 93.25. It is interesting to note

that SE has comparable or worse performance than

other unsupervised approaches, despite being a super-

vised approach specifically designed to separate fea-

tures of different classes in the latent space. To do so,

SE employs a much more complex training process,

resulting in way longer training time, as confirmed by

the training times of the various feature learning mod-

ules(Table 4). Besides SE, PAE has a longer training

time because it has to be trained for each modality,

whereas SAE and MMAE require only one training

procedure. The further difference between MMAE

and SAE can be motivated by considering that, with

a fully connected neural network, an input twice as

long corresponds to a neural network input layer fea-

turing twice as many connections between neurons,

that are the actual parameters to train in a neural net-

work. Considering the number of input sensors ( i.e.

the number of modalities ) as a variable for the train-

ing time computation it can be seen that SAE, MMAE

and SE need a single training phase to handle all the

modalities at the same time, PAE instead needs to

train one AE for each modality resulting in bigger

compressive training time as table 4 shows.

Table 4: Training time [s] of each trainable Feature Extrac-

tion (FE) module. Average ± 95% confidence interval. 3

degradation stages. In italic the AE-based approaches.

FE B11 B12 B21

PAE 82.27±1.77 51.60±1.79 54.07±1.84

SAE 42.95±3.08 28.90±5.64 28.71±1.98

MMAE 42.76±4.11 22.01±0.43 22.10±1.32

SE 652.62±90.7 582.66±19.7 585.64±12.2

The results suggest that both the feature learning

module based on MMAE and SAE are the most con-

venient for the proposed 3-stages classification prob-

lem. The goodness of the proposed approach is also

tested with a more complex classification problem,

e.g., with a higher number of degradation stages to

consider. For this experimentation different degrada-

tion stages are considered, i.e. the time intervals in

which the bearing is in degradation stages ”regular”

and ”degraded” are splitted (in half) into new degra-

dation stages. The resulting problem is a five-stages

bearing degradation recognition. Table 5 reports the

classification performance obtained with each varia-

tion of the proposed approach, as well as the ones ob-

tained with the heuristic-based feature.

The classification performance obtained by using

the heuristic-based features are dramatically lower

compared to the ones obtained with 3 degradation

stages. This may be not only due to the higher com-

plexity of the classification task but also due to the

fact that both the split among the 3 degradation stages

and the heuristic-based features are specifically de-

signed to represent some physical characteristics of

the degradation phenomenon. Instead, the degrada-

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

100

Table 5: F1-score with KNN (k=1) and 100 training epochs

for each Feature Extraction (FE) approach. Average ± 95%

confidence interval. 5 degradation stages. In italic the AE-

based approaches.

FE B11 B12 B21

PAE 92.93±1.06 80.81±4.06 80.06±2.51

SAE 97.06 ± 0.5 88.53±1.56 88.97±2.27

MMAE 97.10±0.74 87.90±1.48 90.11±1.07

HB 50.59±3.62 37.11±4.75 39.66±6.87

SE 95.89±0.98 86.08±1.88 86.24±2.89

tion stages of the 5-stages classification problem are

partially arbitrary. All the approaches based on fea-

ture learning provide average classification perfor-

mances greater than 90 with case study B11, and

greater than 80 with the others. Also in this case

the classification performance of PAE is the worst

among all the feature learning approaches. On the

contrary, MMAE and SAE provide the best classifica-

tion performances in all 3 case studies, despite provid-

ing lower performances that the ones obtained with

the 3-stages classification problem.

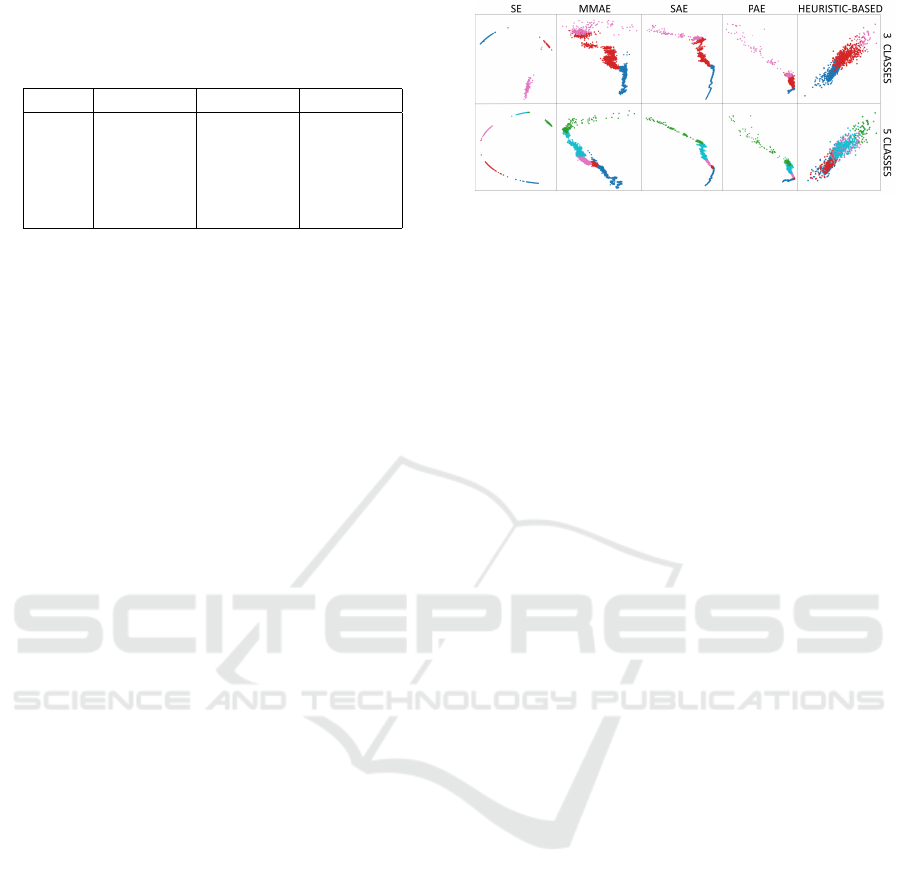

Fig. 5 provides a qualitative assessment of how

easily the classes can be distinguished by projecting

the obtained features onto their 2 principal compo-

nents. In this regard, even if the samples correspond-

ing to more severe degradation stages are arranged

progressively, with the heuristic-based features the

samples of different classes seems to be projected

pretty close with each others. This partially explain

the poor classification performances, especially in the

5-stages classification problem. On the other hand,

feature learning approaches result in clearly separa-

ble and adjacent group of samples corresponding to

more severe degradation stages. This simplifies the

classification task even when performed with really

simple approaches like KNN with 1 neighbor. Inter-

estingly, this property seems to be maintained even in

the 5-stages classification problem, and thus support

the good recognition performance obtained in such a

classification task.

The obtained results confirm how those feature

learning approaches succeed in capturing the progres-

sion of the degradation phenomenon, despite being

trained in an unsupervised manner, and regardless of

the number of degradation stages, as well as their ar-

rangement over time.

6 CONCLUSION

This work proposes an architecture based on au-

toencoders to automatically extract degradation-

representative features from minimally preprocessed

Figure 5: Features learned with the B11 test samples and

projected over two Principal Components. The degradation

stages ranges from regular (blue) to critical (pink with 3

classes, green with 5 classes).

time series of vibration and temperature of indus-

trial bearing. By using a publicly available real-world

dataset about bearings’ progressive degradation to test

the proposed approach against manual feature ex-

traction and the state-of-the-art technology in feature

learning. According to the obtained results, the au-

toencoders featuring a data fusion mechanism at data-

and architecture-level (i.e. SAE and MMAE) result

in features characterized by greater quality. Indeed,

those provide easily separable classes in the space of

learned features, and thus are able to simplify the clas-

sification task even if performed via simple classifica-

tion approaches, i.e. via a KNN classifier considering

just one neighbor.

Compared with manually extracted features, the

proposed approach results an increase of the classifi-

cation performances up to 19%. At the same time, by

being data-driven, the proposed approach does not re-

quire any effort to choose and design the features to

be extracted from the input data. In this work, a min-

imalist preprocessing procedure is proposed; it con-

sists of a frequency domain transformation for only

the vibration time series, and a subsequent window

aggregation of the resulting vectors. This input for-

mat, passed to each of the feature learning approaches

tested, produced features that allow clear separation

of classes, as qualitatively confirmed by the projec-

tions of the samples onto the principal components of

the feature space.

Interestingly, the multimodal autoencoder results

in recognition performances that are comparable with

the ones obtained via state-of-the-art approaches (i.e.

based on contrastive learning) despite being trained in

an unsupervised manner, and regardless of the num-

ber of degradation stages considered.

The promising results provided in this study leave

room for more intensive experimentation as the num-

ber and type of input modalities vary. As future

works, more recent datasets and better-performing

methods than KNN can be used to further test the

proposed approach and improve recognition perfor-

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature

Learning

101

mance. Moreover, assets’ degradation can be mon-

itored with measures such as acoustic noise, power

consumption, torque and many more. By including

all these modalities, it would be possible to test the ca-

pacity of the proposed approach to be data-agnostic,

that is, valid regardless of the measure used to assess

the current degradation stage.

ACKNOWLEDGEMENTS

Work partially supported by (i) the Tuscany Region

in the framework of the SecureB2C project, POR

FESR 2014-2020, Project number 7429 31.05.2017,

(ii) the Italian Ministry of University and Research

(MUR), in the framework of the ”Reasoning” project,

PRIN 2020 LS Programme, Project number 2493 04-

11-2021, and (iii) the Italian Ministry of Education

and Research (MIUR) in the framework of the Cross-

Lab project (Departments of Excellence). The authors

thank Mario Alberto Gherardi for his work on the sub-

ject during his master thesis.

REFERENCES

Alfeo, A. L., Cimino, M. G., Manco, G., Ritacco, E., and

Vaglini, G. (2020). Using an autoencoder in the de-

sign of an anomaly detector for smart manufacturing.

Pattern Recognition Letters, 136:272–278.

Alfeo, A. L., Cimino, M. G., and Vaglini, G. (2021). Tech-

nological troubleshooting based on sentence embed-

ding with deep transformers. Journal of Intelligent

Manufacturing, 32(6):1699–1710.

Alfeo, A. L., Cimino, M. G., and Vaglini, G. (2022). Degra-

dation stage classification via interpretable feature

learning. Journal of Manufacturing Systems, 62:972–

983.

Bengio, Y., Courville, A., and Vincent, P. (2013). Represen-

tation learning: A review and new perspectives. IEEE

transactions on pattern analysis and machine intelli-

gence, 35:1798–1828.

Cano, J.-R. (2013). Analysis of data complexity measures

for classification. Expert systems with applications,

40(12):4820–4831.

Deng, L. (2014). A tutorial survey of architectures, algo-

rithms, and applications for deep learning. APSIPA

transactions on Signal and Information Processing, 3.

Elie Bursztein, James Long, S. L. O. V. F. C. (2021). Ten-

sorflow similarity: A usable, high-performance metric

learning library. Fixme.

Gao, J., Li, P., Chen, Z., and Zhang, J. (2020). A survey

on deep learning for multimodal data fusion. Neural

Computation, 32(5):829–864.

Gecgel, O., Ekwaro-Osire, S., Gulbulak, U., and Morais,

T. S. (2022). Deep convolutional neural network

framework for diagnostics of planetary gearboxes un-

der dynamic loading with feature-level data fusion.

Journal of Vibration and Acoustics, 144(3).

Hamadache, M., Jung, J. H., Park, J., and Youn,

B. D. (2019). A comprehensive review of artifi-

cial intelligence-based approaches for rolling element

bearing phm: shallow and deep learning. JMST Ad-

vances, 1(1):125–151.

Jimenez, J. J. M., Schwartz, S., Vingerhoeds, R., Grabot,

B., and Sala

¨

un, M. (2020). Towards multi-model ap-

proaches to predictive maintenance: A systematic lit-

erature survey on diagnostics and prognostics. Journal

of Manufacturing Systems, 56:539–557.

Kimotho, J. K., Sondermann-W

¨

olke, C., Meyer, T., and

Sextro, W. (2013). Machinery prognostic method

based on multi-class support vector machines and hy-

brid differential evolution–particle swarm optimiza-

tion. Chemical Engineering Transactions, 33.

Lei, Y., Li, N., Guo, L., Li, N., Yan, T., and Lin, J. (2018).

Machinery health prognostics: A systematic review

from data acquisition to rul prediction. Mechanical

systems and signal processing, 104:799–834.

Liu, Y., Hu, Z., and Zhang, Y. (2021). Bearing feature

extraction using multi-structure locally linear embed-

ding. Neurocomputing, 428:280–290.

Lorena, A. C., Garcia, L. P., Lehmann, J., Souto, M. C., and

Ho, T. K. (2019). How complex is your classification

problem? a survey on measuring classification com-

plexity. ACM Computing Surveys (CSUR), 52(5):1–

34.

Mao, W., He, J., and Zuo, M. J. (2019). Predicting re-

maining useful life of rolling bearings based on deep

feature representation and transfer learning. IEEE

Transactions on Instrumentation and Measurement,

69(4):1594–1608.

Merkt, O. (2019). Predictive models for maintenance opti-

mization: an analytical literature survey of industrial

maintenance strategies. Information Technology for

Management: Current Research and Future Direc-

tions, pages 135–154.

Nectoux, P., Gouriveau, R., Medjaher, K., Ramasso, E.,

Chebel-Morello, B., Zerhouni, N., and Varnier, C.

(2012). Pronostia: An experimental platform for bear-

ings accelerated degradation tests. In IEEE Interna-

tional Conference on Prognostics and Health Man-

agement, PHM’12., pages 1–8. IEEE Catalog Num-

ber: CPF12PHM-CDR.

Nelli, F. (2018). Machine learning with scikit-learn. In

Python Data Analytics, pages 313–347. Springer.

Ngiam, J., Khosla, A., Kim, M., Nam, J., Lee, H., and Ng,

A. Y. (2011). Multimodal deep learning. In ICML.

Nguyen, M. H. (2019). Impacts of unbalanced test data

on the evaluation of classification methods. Recall,

100:90–00.

Pandarakone, S. E., Masuko, M., Mizuno, Y., and Naka-

mura, H. (2018). Deep neural network based bearing

fault diagnosis of induction motor using fast fourier

transform analysis. In 2018 IEEE energy conversion

congress and exposition (ECCE), pages 3214–3221.

IEEE.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

102

Parola, M., Galatolo, F. A., Torzoni, M., Cimino, M., and

Vaglini, G. (2022). Structural damage localization via

deep learning and iot enabled digital twin. In Proc.

of third International Conf. on Deep Learning Theory

and Applications, July 2022, Lisbon, Portugal.

Ran, Y., Zhou, X., Lin, P., Wen, Y., and Deng, R. (2019). A

survey of predictive maintenance: Systems, purposes

and approaches. arXiv preprint arXiv:1912.07383.

Scanlon, P., Kavanagh, D. F., and Boland, F. M. (2012).

Residual life prediction of rotating machines using

acoustic noise signals. IEEE Transactions on Instru-

mentation and Measurement, 62:95–108.

Shin, B., Lee, J., Han, S., and Park, C.-S. (2021). A study

of anomaly detection for ict infrastructure using con-

ditional multimodal autoencoder. Journal of Intelli-

gence and Information Systems, 27(3):57–73.

Skrypnyk, I. (2011). Irrelevant features, class separability,

and complexity of classification problems. In 2011

IEEE 23rd International Conference on Tools with Ar-

tificial Intelligence, pages 998–1003. IEEE.

Tang, S., Yuan, S., and Zhu, Y. (2019). Deep learning-

based intelligent fault diagnosis methods toward ro-

tating machinery. Ieee Access, 8:9335–9346.

Vincent, P., Larochelle, H., Lajoie, I., Bengio, Y., Man-

zagol, P.-A., and Bottou, L. (2010). Stacked denois-

ing autoencoders: Learning useful representations in a

deep network with a local denoising criterion. Journal

of machine learning research, 11.

Vinh, N. X., Epps, J., and Bailey, J. (2009). Information the-

oretic measures for clusterings comparison: is a cor-

rection for chance necessary? pages 1073–1080.

Wan, J., Tang, S., Li, D., Wang, S., Liu, C., Abbas, H., and

Vasilakos, A. V. (2017). A manufacturing big data so-

lution for active preventive maintenance. IEEE Trans-

actions on Industrial Informatics, 13:2039–2047.

Yan, W. and Yu, L. (2015). On accurate and reliable

anomaly detection for gas turbine combustors: A deep

learning approach. In Annual Conference of the PHM

Society, volume 7.

Yan, X., Liu, Y., and Jia, M. (2020). Health condition

identification for rolling bearing using a multi-domain

indicator-based optimized stacked denoising autoen-

coder. Structural Health Monitoring, 19:1602–1626.

Zhong, G., Ling, X., and Wang, L.-N. (2019). From shal-

low feature learning to deep learning: Benefits from

the width and depth of deep architectures. Wiley In-

terdisciplinary Reviews: Data Mining and Knowledge

Discovery, 9:e1255.

Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature

Learning

103