Semantic Integration Patterns for Industry 4.0

Felix Strohmeier

1a

, Georg Güntner

1b

, Dietmar Glachs

1c

and Reinhard Mayr

2

1

Salzburg Research Forschungsgesellschaft mbH, Jakob-Haringer-Straße 5/3, A-5020, Salzburg

2

Ing. Punzenberger COPA-DATA GmbH, Karolingerstrasse 7b, A-5020, Salzburg

Keywords: Asset Management, Semantic Interoperability, Digital Twin, Middleware, Asset Administration Shell.

Abstract: In the manufacturing industry, digital twins have emerged as a key technological concept for the creation and

use of digital representations of assets and their associated processes. In emerging networked manufacturing

systems, digital twins of machines or components do not reside within one specific application, platform or

edge node, but they ideally consume and deliver information (e.g. sensor data, master data) to all connected

applications in the operational systems. This results in complex integration requirements for both, the assets

and the applications. Starting from an overview of industrial information models, the paper describes a recent

research approach towards semantic interoperability concepts for data-driven digital twin in

manufacturing systems. It gives an architectural overview of a platform for the integration of operational

management systems and connected assets based on semantic integration patterns. The paper describes

the initial concepts of the underlying research project “i-Twin”.

1 INTRODUCTION

Digitalization is currently one of the main drivers for

improvements in productivity and resource efficiency

within industrial manufacturing. Initiatives started in

the last decade, such as the “Plattform Industrie 4.0”

(https://bit.ly/3J4zxfT) and the “Industry IoT

Consortium” (https://bit.ly/2yvG9U7), turned almost

every newly designed machine into a smart,

connected asset. This shaped the ecosystem on shop

floors from classical hierarchical production-line

processes based on the “automation pyramid”

(Åkerman, 2018) to flexible connected production

networks. These networks induce communication and

interoperability requirements related to the

production assets.

To address this challenge, industrial data models

for engineering and operation have been developed,

partly independently by manufactures and partly in

standardization organisations. Compatibility between

these models is still limited, as industry standards

emerge slowly and are often shaped for special

branches or domains. Interoperability concepts

therefore tend to use domain-specific, proprietary,

closed approaches for creating, transforming,

a

https://orcid.org/0000-0001-8842-4139

b

https://orcid.org/0000-0001-7258-7320

c

https://orcid.org/0000-0001-5314-249X

importing, exporting, and synchronizing data sets and

messages.

Recently, digital twins - digital replica of physical

assets - emerged as a key technological concept for

machines and infrastructure components in the

manufacturing industry. Information models for data-

driven digital twins aim to describe:

the master data of the manufacturing plant and

equipment,

the configuration parameters for operating the

plant and its components, and

the dynamic sensor data acquired from plant

equipment, which are then used for a variety of

accompanying processes such as monitoring,

analytics, forecasting, and optimization (e.g. KPI

determination, maintenance planning, increase of

equipment availability).

Digital twins ideally consume and deliver

information to all connected applications in the

operational manufacturing systems. Therefore, digital

twins and related information models find themselves

naturally in the centre of interoperability

considerations, and solutions to provide open,

standard-based, self-describing (semantic) interfaces

between the participants of a manufacturing eco-

Strohmeier, F., Güntner, G., Glachs, D. and Mayr, R.

Semantic Integration Patterns for Industry 4.0.

DOI: 10.5220/0011550100003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 197-205

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

197

system bear a high potential to reduce integration

efforts.

This is where a research project entitled “i-Twin”

(https://srfg.at/i-twin) enters the scene: Starting in

2022, the project investigates interoperability

concepts for data-driven digital twins in the

manufacturing industry. The project propagates an

open-source middleware for the integration of

operational management systems and connected

assets based on a concept called “semantic integration

patterns”. It aims at reducing the integration effort

and allowing secure and reliable exchange of master

data and operational data in manufacturing networks.

In our paper, we describe the architectural

concepts forming the foundation of the semantic

integration patterns for Industry 4.0, which are by

design rooted in the RAMI4.0/AAS (DIN SPEC

91345, 2016) information model and apply the model

not only to connected assets, but also to (software)

applications in the manufacturing system.

The remainder of the paper is organized as

follows: Section 2 gives an overview of the state of

the art in industrial information modelling and

highlights the relationship of digital twins with

models in the digital factory. Section 3 describes the

architectural approach towards semantic integration

patterns in the digital factory. Finally, section 4 shows

the potential of the chosen approach for semantic

integration of operational systems and assets in the

manufacturing industry, followed by an example for

the industrial uptake and exploitation and an outlook

of the future work.

2 INDUSTRIAL INFORMATION

MODELS

In this section, we give an overview of industrial

information models (digital twins, assets, digital

factory) with a focus on models supporting machine-

readable semantic modelling schemes. The overview

of the state of the art in this area also includes a survey

and known challenges in the field of middleware for

manufacturing software integration.

2.1 Digital Twins and the Digital

Factory

Introducing the concept of Digital Twins (Kritzinger,

Karner, Traar, Henjes, & Sihn, 2018) as a digital

replica of physical assets is widely adopted approach

to self-describe the physical properties of assets and

provide digital communication interfaces to the

outside world. The currently developed “Digital Twin

Framework for Manufacturing” (ISO/DIS 23247-1,

2021) is a standardisation approach towards a

context-dependent implementation and the promotion

of reusability and composability of digital twins (Lu,

Liu, Wang, Huang, & Xu, 2020). Further

standardization activities w.r.t Digital Twins

(ISO/IEC AWI 30172, 2020; ISO/IEC AWI 30173,

2020) have just been started. The recently released

standard series “Digital Factory Framework” (IEC

62832-1, 2020) goes one step further and connects

digital twins of multiple assets into a “Digital

Factory”. The recent foundation of the “Industrial

Digital Twin Association” (IDTA,

https://industrialdigitaltwin.org/) reflects und

underlines the importance and necessity of

standardization of information models for digital

twins in the industry.

2.2 RAMI4.0 and the Asset

Administration Shell

To address compatibility issues in industrial

horizontal and vertical integration scenarios, the

“Reference Architecture Model Industrie 4.0

(RAMI4.0)” (DIN SPEC 91345, 2016) includes a

meta-model standard for the digital description of

physical assets (with properties and capabilities)

called “Asset Administration Shell (AAS)”. AAS

integrates multiple underlying semantic standards for

cross-domain aspects, such as security, identification,

configuration, and domain-specific aspects, e.g. for

manufacturing or food & beverage.

The term Asset Administration Shell (AAS) was

coined in combination with its functional counterpart,

the “I4.0 component”, which need to be (1) uniquely

identifiable, and (2) able to communicate with other

I4.0 components. The current specification provides

comprehensive information on the structure of the

AAS (AAS Part 1, 2022), and the specification of the

interoperability at runtime (AAS Part 2, 2021) for

I4.0 components. This specification now provides full

understanding on how to implement and use the AAS

and provides mappings to XML, JSON, RDF, OPC

UA (IEC 62541, 2020), and AutomationML (IEC

62714, 2022) as well as a package file format for AAS

(AASX) to share I4.0-compliant information.

Furthermore, an AAS supports data

interoperability based on semantic integration by

providing references to standardized and corporate

ontologies as a fundamental part of the AAS data

model.

As shown in Section 3, AAS and its information

model form the basis for the implementation of the

semantic integration patterns.

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

198

2.3 Semantic Information Models and

Domain Knowledge

According to the World Wide Web Consortium,

RDF, RDF Schema (RDFS) and OWL are base

technologies for expressing knowledge (W3C, 2022).

While RDF represents the formal language for

describing structured information, RDFS contributes

the data-modelling vocabulary for RDF data. As an

extension of RDF, it provides mechanisms for

describing groups of related resources and the

relationship between them. In addition, the Web

Ontology Language (OWL) allows for representing

rich and complex knowledge about things. The

Simple Knowledge Organisation System (SKOS)

finally is used for defining classification schemes or

taxonomies.

A recent European study underlined the impact of

semantic technologies and semantic enrichment on

improved data quality (EC DIGIT, 2019). In the

manufacturing domain, the representation of self-

contained knowledge about assets is supported by the

RDF data model for the Asset Administration Shell.

The digital exchange format IEC 61360 (CDD,

2017) for commonly shared concepts represents the

industrial counterpart of the semantic web technology

for vocabularies and is an integral part of the AAS. It

allows for the definition of hierarchical concept

classes, their properties and unit of measures. It also

supports the assignment of predefined value lists to

properties in a general manner or when used in

combination with distinct concept classes.

ECLASS (https://eclass.eu/) is a well-known

“common data dictionary” based on the mentioned

IEC 61360 format and provides a cross-sector

standard for classification of products and services.

Using such standardized reference data is a key when

exchanging data with other companies, or with other

business domains. The thirty-nine subject areas

covered by ECLASS include electrical engineering,

construction, logistics, food, medicine optics,

automotive and others.

The Industrial Ontologies Foundry (IOF, 2021)

provides reference ontologies to support

manufacturing and industry needs. The work is

conducted in different working groups, addressing

topics such as maintenance, supply chain, production

planning.

With OPC UA, the OPC Foundation developed an

open standard for the exchange of machine

information via internet protocols (TCP/IP, HTTP).

In addition to the transport of measured and

controlled variables from and to the machines, OPC

UA supports sector-specific extensions (“Profiles”)

of the information models based on companion

specifications (CS). Notable among others are OPC

UA for Machinery, Robotics and Machine Vision

(OPC UA Information Models, 2021). Well-

established standards in specific manufacturing

domains, such as ISA-95, Weihenstephan Standards

(WS, 2022) and EUROMAP (EUROMAP, 2021), are

currently mapped into OPC UA companion

specifications. Based on OPC UA, “universal

machine technology interface” (UMATI, 2021)

currently develops a CS for machine tools. In 2019,

semantic descriptions of OPC UA information

models (“OPC UA NodeSet ontologies”) were

proposed to represent semantic digital twins of

manufacturing resources (Perzylo, Profanter, Rickert,

& Knoll, 2019).

2.4 Middleware for Manufacturing

Software Integration

To our current knowledge, there are no ongoing

activities or a roadmap for standardisation of

interfaces for the rising number of factory software

applications in Digital Factories, such as CMMS

(computerized maintenance management system),

MES (machine execution system) or ERP (enterprise

resource planning) systems, to foster their

interoperability. The European research project

PERFoRM (H2020) identified the architecture

requirements for an industrial manufacturing

middleware (Gosewehr, Wermann, Borsych, &

Colombo, 2017). However, the project was only few

years too early to fully integrate the emerging

Industry 4.0 standards (e.g. RAMI4.0).

On a high level, the architectural approach to

interoperability and data integration issues, as

suggested by the stakeholders in the design and

development of the emerging approaches for

European data ecosystems (e.g. GAIA-X,

International Data Space), is clearly relying on

semantic interoperability and interface descriptions.

Especially with the rise of the Industry 4.0 paradigm,

this led to the definition of a new series of standards

(e.g. RAMI4.0/AAS, OPC UA CS, and frameworks

for digital twins and digital factories) that are just

starting to get industrial adoption. These new

standards have enormous potential for application

integration in the industry.

Available commercial solutions of OT software

platforms, such as Forcam MES, zenon, PS7, PI Asset

Framework, and even larger approaches, such as

Siemens MindSphere or SAP AIN) preferably build

on existing OT and IT information models. Moreover,

interoperability between the manufacturing

applications is usually accomplished by proprietary

interfaces. On the one hand, this is due to the lack of

existing interoperability standards at the time when

these systems were developed; on the other hand, the

Semantic Integration Patterns for Industry 4.0

199

use of proprietary interfaces creates a strong bond

between manufacturers and their IT system providers

and integrators (“vendor lock-in”).

With the strong digitalization trend in the

manufacturing industry and the emerging Industry 4.0

standards integrating semantic interoperability

concepts by design (e.g. RAMI 4.0, OPC UA CS, and

Digital Factory), we see a good chance for claiming a

solution for a semantic interoperability middleware

for the small and medium sized companies (SMEs) in

the European manufacturing and IT industry.

However, for SMEs, these standards bear another

difficulty: Since they usually do not have the

resources necessary to build a customized data

ecosystem for their operational systems, and since

extensive commercial solutions are not available for

them at an affordable price, they often rely on the

availability of a middleware solution supported by

their system providers.

Therefore, we propose the semantic integration of

those solutions with the semantic descriptions for the

assets by also using the concept of the AAS. This

approach is based on an idea of a highly influencing

IEEE article, where AASs were added also to logical

components that are managing physical assets on

higher layers, such as for OPC UA gateways and web

applications (Ye & Hong, 2019). They come up with

the recommendation that “practitioners should use

standard technologies to implement AASs because

unification and standardization can expedite the

convergence of heterogeneous technical, syntactic,

and semantic specifications existing in the market. In

this way, proprietary I4.0 Components will be

interoperable and available to the public in future I4.0

networks.”

3 SEMANTIC INTEGRATION

PATTERNS

As pointed out in the previous section, the RAMI4.0

set an architectural standard for the digitally

connected industry. Subsequently a set of standards

provided the conceptual framework for a new

generation of IT systems and opened the floor for

semantic interoperability in the “Digital Factory”.

Yet, apart from solutions designed for the large

and very large industry, there is a lack in a

middleware layer for semantic interoperability that

fits the requirements (and the budget) of SMEs. On

the other hand, developers of the IT systems for such

manufacturers are urgently looking for lightweight

interfaces for the exchange of (semantically enriched)

data between machines and the applications or

between different operational applications.

Typical scenarios exemplifying these

interoperability problems are:

Different IT systems managing asset information

(e.g. ERP, CMMS, edge nodes) want to make sure

they are “talking” about the same machine and at

the same time avoid duplicate and outdated

information.

An edge controller requests the recent

maintenance history of a specific asset in order to

inform operating staff about recent maintenance

activities.

A management dashboard requests the reasons for

downtimes in order to calculate the overall

equipment efficiency (OEE).

An analytics service wants to use selected

machine data to develop machine-learning models

depending on the material used at production

time. Regular updates of the trained models to

edge nodes for real-time analysis is required.

To master this communication requirements and

to overcome the mentioned integration hurdles, we

propose to activate not only the production

environment as I4.0 components. All applications

required in a manufacturing environment can be

equipped with an AAS in order to establish the

runtime connectivity for other participants.

Furthermore, we propose the definition and

implementation of semantic integration patterns for

assets on the one hand, and for manufacturing

applications on the other hand. For this, the Asset

Administration Shell (defined in RAMI4.0) serves as

the basic concept for the development of semantic

integration patterns.

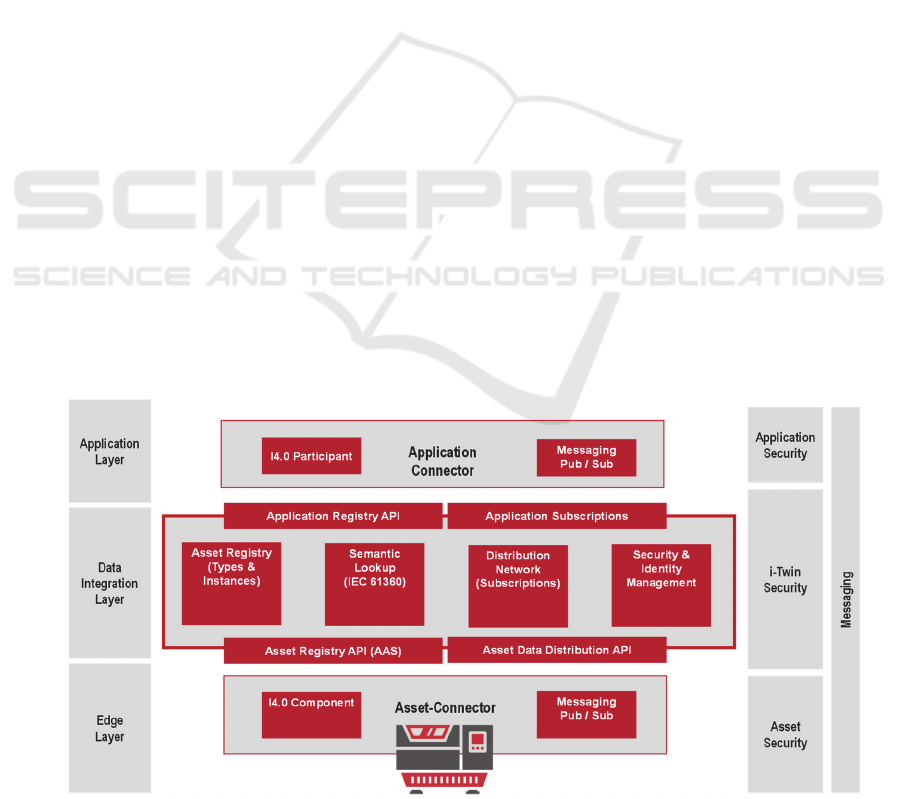

outlines the functional aspects in a networked

manufacturing environment in which IT systems

(“application layer”) receive information from the

production equipment (“edge layer”) but also

exchange (higher level) information between each

other. The proposed data integration layer a) acts as

the abstraction layer between the connected

applications, b) provides the data distribution

mechanisms for data producers and data consumers

and c) distributes security settings across the system

and finally d) connects with active I4.0 components,

e.g., activated AAS instances. The active I4.0

component finally serves as the runtime environment

for the proposed semantic integration efforts.

3.1 Innovative Architectural Design for

the Digital Factory

The data integration layer including generic

connectors is the enabler of the proposed semantic

interoperability between manufacturing applications

and

assets in an operational environment. The

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

200

Figure 1: Semantic interoperability middleware – functional aspects.

solution is based on the following design principles:

Digital Factory: The IEC 62832 standard defines

as set of model elements and rules for modelling

production systems.

Semantic Integration Patterns (for details see

section 3.2) for minimally invasive integration of

manufacturing applications (e.g. CMMS) and OT

software platforms, as well as for analytics

services based on available standards for the

exchange of machine learning and KI models.

A messaging system for semantically described

data streams.

A security and identity management service to

protect data processed in the middleware.

From a technological perspective, the proposed

solution builds on the following design criteria:

Canonical meta-data format: The use of Asset

Administration Shell (AAS) as a meta-model for

describing assets, their properties and capabilities

in a consistent format, and subsequently allows

the use of semantic markup.

Semantic markup: The IEC 61360 (CDD)

standard is applied for semantic enrichment of

asset properties. ECLASS already provides a data

set of approx. 46.000 concepts for products and

services from different application areas. In

addition, the administration and provision of

corporate and domain specific concepts (e.g. a

maintenance ontology) must be supported.

Identity management: A central identity and

rights management based on state of the art

security mechanisms ensures that data packages

are accessible only for authorized participants and

applications with valid access tokens.

Figure 2 gives an overview of the building blocks

of our three-tier approach for a semantically enriched

middleware and connected I4.0 components. This

approach also contains the asset connectors and

application connectors. We refer to both types of

connectors as “semantic connectors” and describe the

underlying design principles in the subsequent

section 3.2.

The application layer provides connectors for

factory applications (e.g., analytics service, ERP

system) according to semantic integration patterns.

On the edge layer, asset connectors realize the

integration of assets and their related asset data, again

based on semantic integration patterns. Connectors

expose the applications or the assets data and

functionality in standardized interfaces to the I4.0

world, hiding the proprietary details of the

applications or assets, but adhering to security

settings. They connect with the semantic integration

middleware consisting of the following basic

components. For better understanding, we also

provide some implementation options of them:

Asset Repository: Manages the static information

(“master data”) required for data exchange from the

applications and assets involved. This can be

separate, but also based on existing asset information

systems in the companies, if available.

Distribution Network: Allows loose coupling of

factory applications, represents the data hub enabling

applications to access real time asset data by means

of stream processing. Instead of direct updates in a

central database, generated events ("management/

control information") are exchanged between

applications, or sensor data ("real-time data") are

exchanged between machines and applications. It

integrates message brokers such as Apache Kafka or

MQTT implementations into the system. Main

Semantic Integration Patterns for Industry 4.0

201

advantages of the stream processing approach are

higher read/write performance, scalability, flexibility,

agility and traceability in case of errors.

Semantic Lookup: Extends the elements and

properties used in the Asset Repository with global

and corporate classification schemes, dictionaries

according to formats like IEC 61360 (e.g. ECLASS),

and RDF/OWL.

Security & Identity Management: Manages

security mechanisms such as encryption, user & role

management, authentication and access control (e.g.

implemented using OAuth2 mechanisms,

https://oauth.net/2/). Security is applied to the data

integration layer as well as the connectors

(application/edge layer).

3.2 Semantic Connectors

Asset Connectors expose a standard compliant I4.0

interface, providing secure access to real-time data

but also accepting method invocation requests.

Internally, they interact directly with the asset’s

control device or facilitate OPC UA or similar

methods to obtain the asset’s details, for example to

obtain or update the value of a property or to invoke

a control command. Likewise, Application

Connectors expose a standard compliant interface in

the exactly same way as asset connectors. Effectively,

they transform both the applications methods and the

exchanged data into the standardized I4.0 world. The

aim is to enable method invocation requests to the

standardized I4.0 world, of course by applying

security settings.

Both types of connectors require an AAS

determining the runtime API (AAS Part 2, 2021) and

more important, the structure of the exchanged data

(AAS Part 1, 2022). An asset or application exposing

its information in this way is referred to as an active

I4.0 component, providing standardized access and

data. The AAS specification provides the model

elements for describing properties of an asset and its

communication capabilities.

Our proposed approach to go beyond the state of

the art of current enterprise integration patterns (EIP,

https://www.enterpriseintegrationpatterns.com/) for

software is the design of Semantic Integration

Patterns extending the traditional EIP concepts by

making the exchanged operational data or message

payload explicitly known to all of the participants

finally participating in a communication. As an

example, active I4.0 components representing an

asset want to retrieve its maintenance history from a

CMMS. For a successful management of this request,

the I4.0 needs to know a) how to interact with the

CMMS, b) the exact method name including required

request parameters and c) the structure of the

maintenance history records returned by the CMMS.

In a traditional way, this results in massive integration

efforts for each required functionality. Moreover,

whenever a connected application changes, the

integration effort must be repeated.

To reduce this integration hurdles, a semantic

integration pattern may be seen as a potential

communication between two participants. First, the

AAS meta model is used to define the commonly used

functionality provided by application types. As

indicated in the example, the provision of the

maintenance history may be considered as a

functionality provided by most (or all) CMMS. When

modelling the application type for CMMS, it is

obvious to foresee this method. By using model

inheritance with AAS meta-model, the generic

definitions are redefined and finally instantiated by a

Figure 2: Building blocks of the semantically enriched middleware and connected I4.0 components.

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

202

concrete CMMS.This holds for both, the AAS model

elements and the linked semantic information model.

Hence, the following design principles apply to

the semantic integration patterns:

Extensive use of model inheritance

Extensive use of type/instance relationships

Mandatory use of semantic references to

semantic information models

As a result, the I4.0 component simply needs to

know the semantic identifier of the requested method.

It may ask the Asset Repository whether the method

is enabled, e.g., a concrete CMMS system is

integrated with the system and offers this requested

method. In case a CMMS is present, the I4.0

component receives the full details of the methods

request parameters and also the response data

structures. It is then possible to create and invoke the

request by means of the Asset Repository component.

The I4.0 component does not need to know which

CMMS system is in use or where it can be reached.

Due to the semantic definition of each exchanged data

object, the structure of the method’s response is also

available in a standardized, I4.0 compliant structure.

The semantic connector finally transforms exchanged

data into application specific, type safe data objects.

Application connectors bring semantic

integration patterns to life. They take the structural

settings obtained from the Asset Repository and

instantiate the respective AAS models. Application

Connectors use the semantic identifiers obtained in

the instantiated AAS model structure and facilitate

the Semantic Lookup to gain insights into the

requested data structures in order to validate the data

and to transform the data from/to proprietary

interfaces. This transparent exchange of structural

data definitions works for method invocations and

asynchronous data streams. Thus, the following

design principles w.r.t to networking are met:

Applicability in networked manufacturing

environments

Compliance with existing and emerging industry

standards (esp. RAMI4.0), w.r.t data exchange.

Support for data-driven digital twins integrating

distributed data sources (“micro data ecosystem”

for assets)

4 CONCLUSIONS

In this paper, we presented a conceptual approach

towards the development of a semantic

interoperability middleware platform acting as

mediation layer between manufacturing applications

in the office floor (IT) and industrial assets in the shop

floor (OT). We introduced the concept of semantic

integration patterns as a means to provide

semantically enriched and secure exchange of

information between the participants of a

manufacturing IT eco-system. In the concluding

section, we describe the potential of the proposed

solution, provide an example for the industrial

exploitation and give an outlook of the future work in

the underlying i-Twin project.

4.1 Potential of the Chosen Approach

As key beneficiaries of the proposed semantic

integration middleware layer, we identified

manufacturers (including equipment manufacturers),

application developers, system integrators, service

providers, and edge developers. Subsequently we

describe the potential and the benefits for these

stakeholder groups:

Manufacturers and equipment manufacturers

benefit from:

Transparency of data produced and consumed by

assets and applications;

Secure access to and distribution of data between

manufacturing applications;

Availability of searchable asset libraries in a

vendor independent standardised format;

Established workflows for the integration of

analytics services with established secure data

provision in the training phase;

Integration of asset descriptions from equipment

manufacturers in a standardized format with

semantically described data points.

Generally semantic data integration is a driver for

acceleration, automation and cost optimization of

production processes.

Application developers, system integrators and

service providers benefit from:

Reduction of integration effort of own system

with other systems by semantic integration

patterns for application types (access to type-

based application profiles);

Reduction of integration effort for asset data with

own system by semantic integration patterns for

asset types (access to type/instance-based asset

libraries);

Automated data modelling and data-exchange

from edge to application.

Edge developers benefit from:

Availability of a library of semantic integration

patterns for applications and assets for speeding

up the commissioning phase;

Speeding up of the integration design phase (data

point engineering, asset master data) through

methodological support.

Semantic Integration Patterns for Industry 4.0

203

4.2 Industrial Exploitation by Example

As an example of how the developed concepts will be

applied and drive the product and process innovation

at an Austrian OT software development company,

we highlight some of the strategic potentials

identified by their head of research.

The semantic integration patterns will expand the

existing competence in the field of OT data modelling

and data analytics towards semantic integration of OT

systems with manufacturing IT systems (e.g.

computer-based maintenance management systems).

Especially on edge components or services a certain

level of semantic information enrichment for existing

software solutions will be necessary. It will be a

mandatory “feature” to properly prepare the data

locally before the data exchange to “higher level”

application scenarios for example predictive analytics

can be executed.

Actual architecture concepts will be extended or

validated against the conceptual design of the

semantic interoperability middleware. This concerns

especially the area of abstract model descriptions and

the necessary secure data exchange over different

operational levels. Existing platform solutions, which

are actually solely handling industrial data, will be

enriched with new services and especially

connectivity capabilities. These connectivity add-ons

will not only handle the raw (secure) data

transmission but also if necessary a semantic

transformation between different standardized

models of the various Industries.

Typical processes in relevant customer segments

(process industry, pharmaceutical, critical

infrastructure and food & beverage) will be validated

against the challenges of modern Industry 4.0

applications. Industry independent solutions, which

are targeting all these industries, must show a high

flexibility in terms of semantic data modelling, as we

already see today that each Industry are striving to

develop their specific standards. This further on will

lead to the generation of new services and which will

allow for designing generic rules for transformation

of semantic information between the different

standards.

4.3 Outlook

The underlying project, in which the concepts

presented here are developed (i-Twin), continues to

provide a conceptual system design of the semantic

interoperability platform (parts of the ongoing work

in this field were described in the previous sections).

Such a platform will allow the implementation of

data-driven digital twins integrating distributed data

sources (e.g. a micro data ecosystem for industrial

assets).

Based on the architectural design, a proof-of-

concept implementation of a cloud-based, secure,

multi-tenant, and multi-sided platform will be

developed, characterized by open interfaces and open

source permissive license.

Further research will be dedicated to the design

and publication of semantic integration patterns for

assets, applications, and analytic services, covering

the support of type/instance relationships; the

applicability in networked manufacturing

environments, and the compliance with existing and

emerging domain standards (esp. RAMI4.0/AAS).

A validation process in an industrial asset

management scenario and in a lab environment will

accompany the research.

ACKNOWLEDGEMENTS

The research presented has been conducted in the

i-Twin project (title: “Semantic Integration Patterns

for Data-driven Digital Twins in the Manufacturing

Industry”), which is funded by the Austrian Federal

Ministry for Climate Action, Environment, Energy,

Mobility, Innovation and Technology (BMK) and the

Austrian Research Promotion Agency (FFG) within

the research programme "ICT of the Future". The

project has a duration of 27 months and will end in

March 2024.

REFERENCES

AAS Part 1 (2022). “Details of the Asset Administration

Shell - Part 1”, https://www.plattform-i40.de/IP

/Redaktion/EN/Downloads/Publikation/Details_of_the

_Asset_Administration_Shell_Part1_V3.html

AAS Part 2 (2021). “Details of the Asset Administration

Shell - Part 2”, https://www.plattform-i40.de/IP/

Redaktion/EN/Downloads/Publikation/Details_of_the

_Asset_Administration_Shell_Part2_V1.html

Åkerman, M. (2018). “Implementing Shop Floor IT for

Industry 4.0”, Doctoral Thesis - https://www.

researchgate.net/publication/326224890_Implementin

g_Shop_Floor_IT_for_Industry_40

CCD (2017). “IEC61360 Common Data Dictionary

(CDD)” https://en.wikipedia.org/wiki/IEC_61360

DIN SPEC 91345 (2016). “Reference Architecture Model

Industrie 4.0”, (RAMI4.0)”: https://www.beuth.de/de/

technische-regel/din-spec-91345/250940128

EC DIGIT (2019). „European Commission: Data Quality

Management“, https://joinup.ec.europa.eu/sites/default

/files/document/2019-09/SEMIC%20Study%20on%

20data%20quality%20management.pdf

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

204

EUROMAP (2021). “EUROMAP-OPC UA interfaces for

plastics and rubber machinery”, https://www.euromap

.org/opcua_platform/

Gosewehr, F., Wermann J., Borsych W., Colombo A.W.

(2017). „Specification and Design of an Industrial

Manufacturing Middleware”, IEEE 15th International

Conference on Industrial Informatics (INDIN), pp.

1160-1166, doi: 10.1109/INDIN.2017.8104937.

https://www.horizon2020-perform.eu/files/documents

/INDIN%C2%B417_Specification%20and%20design

%20of%20an%20industrial%20manufacturing%20mi

ddleware.pdf

IEC 62541 (2020). “OPC Unified Architecture, Parts 1-14”,

https://opcfoundation.org/developer-

tools/specifications-unified-architecture

IEC 62714 (2022). “AutomationML (Automation Markup

Language)”, https://www.automationml.org/

IEC 62832-(1-3), (2020). “Industrial-process measurement,

control and automation - Digital factory framework”

https://webstore.iec.ch/publication/65858

IOF (2021). “Industrial Ontologies Foundry”,

http://industrialontologies.org

ISO/DIS 23247-1 (2021). “Automation systems and

integration - Digital Twin framework for

manufacturing Part 1: Overview and general

principles”, https://www.iso.org/standard/75066.html

Kritzinger, W., Karner, M., Traar, G., Henjes, J., Sihn, W.

(2018). „Digital Twin in manufacturing: A categorical

literature review and classification“, IFAC-

PapersOnLine, Volume 51, Issue 11, ISSN 2405-8963,

https://doi.org/10.1016/j.ifacol.2018.08.474.

Lu, Y., Liu C., Wang, K.I.-K., Huang, H., Xu, X. (2020).

“Digital Twin-driven smart manufacturing:

Connotation, reference model, applications and

research issues”. Robotics and Computer-Integrated

Manufacturing, Volume 61, 101837, ISSN 0736-5845,

https://doi.org/10.1016/j.rcim.2019.101837.

OPC UA Information Models (2021). „OPC Unified

Architecture Information Models”, https://

opcfoundation.org/developer-tools/specifications-opc-

ua-information-models/

Perzylo, A., Profanter, S., Rickert, M., Knoll, A. (2019).

„OPC UA NodeSet Ontologies as a Pillar of

Representing Semantic Digital Twins of Manufacturing

Resources”, doi: 10.1109/ETFA.2019.8868954.

https://www.researchgate.net/publication/334646317_

OPC_UA_NodeSet_Ontologies_as_a_Pillar_of_Repre

senting_Semantic_Digital_Twins_of_Manufacturing_

Resources

UMATI (2021). “umati”, https://umati.org/

W3C (2022). “World Wide Web Consortium”,

https://www.w3.org/

WS (2022). Weihenstephan Standards - The

communication interface for your machines,

https://www.weihenstephan-standards.com/en/

Ye, X. and Hong, S. H. (2019). “Toward Industry 4.0

Components: Insights Into and Implementation of

Asset Administration Shells”, in IEEE Industrial

Electronics Magazine, vol. 13, no. 1, pp. 13-25, March

2019, doi: 10.1109/MIE.2019.2893397. https://

ieeexplore.ieee.org/document/8673850

Semantic Integration Patterns for Industry 4.0

205