Condition based Maintenance on Data Streams in Industry 4.0

Nadeem Iftikhar

a

and Adrian Mihai Dohot

Department of Computer Science, University College of Northern Denmark, Sofiendalsvej 60, Aalborg, Denmark

Keywords:

Predictive Maintenance, Condition Monitoring, Smart Manufacturing, Sensor Data, Unlabeled Data,

Unsupervised Machine Learning.

Abstract:

An asset failure is costly for the manufacturing industry as it causes unplanned downtime. Unplanned down-

time halts production lines, and can lead to productivity loss. One of the widely used methods to reduce

downtime is to make use of condition based maintenance. The goal of condition based maintenance is to mon-

itor as well as detect present and/or upcoming asset failures and thus reduce unplanned downtime. A newly

emerged phenomena is to monitor the asset condition at real-time. Thus, this paper presents the techniques

to process data-in-motion in order to monitor the health and condition of industrial assets in real-time. The

techniques presented in this paper require no historical and/or labeled data and work well on streaming data.

1 INTRODUCTION

The most common cause of unplanned downtime is

a breakdown of an asset. Asset failures cost around

$1 trillion USD per year, globally. Further, accord-

ing to Alexander Hill, chief global strategist at Sens-

eye

1

“unplanned downtime is the curse of the in-

dustrial sector.”

2

In order to minimize unplanned

downtime and unscheduled maintenance, many large

enterprises set condition based maintenance as their

strategic objective. On the other hand, small and

medium sized enterprises (SMEs) are lagging be-

hind. SMEs lagged behind due to lack of manage-

ment commitment, shortfall of skills and financial re-

sources, restraint from adopting Industry 4.0 and so

on. Hence, manageable and feasible approaches to

condition based maintenance are required for SMEs.

In order to monitor the health and condition of

an asset the following four terms/strategies are com-

monly used: (1) condition monitoring (CM); (2) con-

dition based monitoring (CBM); (3) predictive main-

tenance (PdM); and (4) condition based maintenance

(CbM). These terms are often used interchangeably

and without clarity. CM and CBM are identical and

focus on real-time/current health and condition of an

asset, while PdM focuses on predicting the upcom-

ing defects, such as remaining useful life (RUL) or

a

https://orcid.org/0000-0003-4872-8546

1

https://www.senseye.io

2

https://www.assemblymag.com/articles/96518-

equipment-failure-is-costly-for-manufacturers

time-to-failure (TTF) of an asset. CbM is the um-

brella term. CbM could be CM/CBM-based or PdM-

based. CbM may use CM-based thresholds to avoid

immediate (current) asset failures and/or PdM-based

predictions to avoid upcoming (future) asset failures.

Traditional machine learning (ML) based predic-

tive maintenance techniques require historical and/or

labeled data for training purposes in order to identify

patterns to forecast upcoming machine failures. In

spite of that, new streaming ML approaches that do

not need historical and/or labeled data for PdM are

emerging, instead they can use streaming data for on-

line model training and predictions. The online model

will be trained/retrained in real-time after adequate

data has been collected. This will constantly refine

predictions as the data volume grows. Moreover, due

to the lack of historical and/or labeled data, CM/CBM

also seems a feasible solution that allows monitoring

and diagnostics of assets, consequently diverting un-

planned shutdowns.

To summarize, the main contributions in this pa-

per are as follows: (1) presenting a scalable and

streaming data pipeline to handle ingestion; process-

ing and analysis; (2) presenting monitoring tech-

niques to focus on the real-time condition of assets

to avoid costly production line disruptions; and (3)

building predictive capabilities for early detection of

asset failures solely using streaming and unlabeled

data.

The paper is structured as follows. Section 2

presents the related work. Section 3 presents the

Iftikhar, N. and Dohot, A.

Condition based Maintenance on Data Streams in Industry 4.0.

DOI: 10.5220/0011553500003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 137-144

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

137

streaming data pipeline architecture. Section 4

presents the condition based maintenance techniques.

Section 5 concludes the paper and points out the fu-

ture research directions.

2 RELATED WORK

This section mainly concentrates on the previous

work done in relation to CbM, CM and PdM in In-

dustry 4.0. A comprehensive review by (Butler et al.,

2022) outlined the techniques that recent research

presents for CM, diagnostics and prognostics. A work

by (Dinardo et al., 2018) proposed a prognostic ap-

proach to detect faults in rotating machines. The

approach is based on continuous vibration monitor-

ing using statistical methods. Deep learning based

methods have been used for CM by (Serin et al.,

2020). ML architecture for PdM based on random

forest is proposed by (Paolanti et al., 2018). Simi-

larly, various supervised ML algorithms such as, lo-

gistic regression, neural networks, support vector ma-

chines, decision trees and k-nearest neighbors were

applied to predict costly production line disruptions

(Iftikhar et al., 2019). The accuracy of the proposed

ML models were tested on a real-world data set with

promising results. Further, supervised machine learn-

ing based anomaly detection is presented by (Pittino

et al., 2020). Outlier detection in sensor data us-

ing ensemble learning is presented by (Iftikhar et al.,

2020). An online anomaly detection using periodic

auto-regression model based on lambda architecture

is introduced by (Liu et al., 2016). (Boniol et al.,

2021) proposed a novel unsupervised online method

for sub-sequence anomaly detection in streaming se-

quences. The proposed method has the ability to iden-

tify single and recurrent anomalies without any prior

knowledge of the anomaly characteristics. An unsu-

pervised real-time anomaly detection algorithm con-

sisting of long short-term memory (LSTM) autoen-

coder is proposed by (Hsieh et al., 2019). Further, a

novel unsupervised approach for online outlier detec-

tion in streaming data is presented by (Guo and Shen,

2022). The approach performs well on real-time out-

lier detection with no need for historical/labeled data.

Furthermore, problems and future directions with

respect to CM in Industry 4.0 are highlighted by (Pi-

menov et al., 2022). The most significant issues pre-

sented in their work that needs further research and

attention are: small data-sets, unlabeled instances and

tuning of ML model without the assistance of experts

(in other words ML models should be easy-to-use

and easy-to-maintain). Similarly, a survey by (Chat-

terjee and Ahmed, 2022), pointed out that an online

anomaly detection approach that can achieve detec-

tion accuracy comparable to that of supervised ap-

proaches is desirable.

The focus of the previous works is on various

aspects and recent advancements of CbM, CM and

PdM. Most of these works focus on the use of CM

and PdM in medium and large enterprises as they

are somewhat difficult to implement and/or maintain.

On the other hand, the work presented in this paper

emphasises on the realistic, easy-to-use and easy-to-

maintain CM and PdM techniques in SMEs. In addi-

tion, this paper answers most of the challenges with

respect to unlabeled data, streaming data and lack of

historical data.

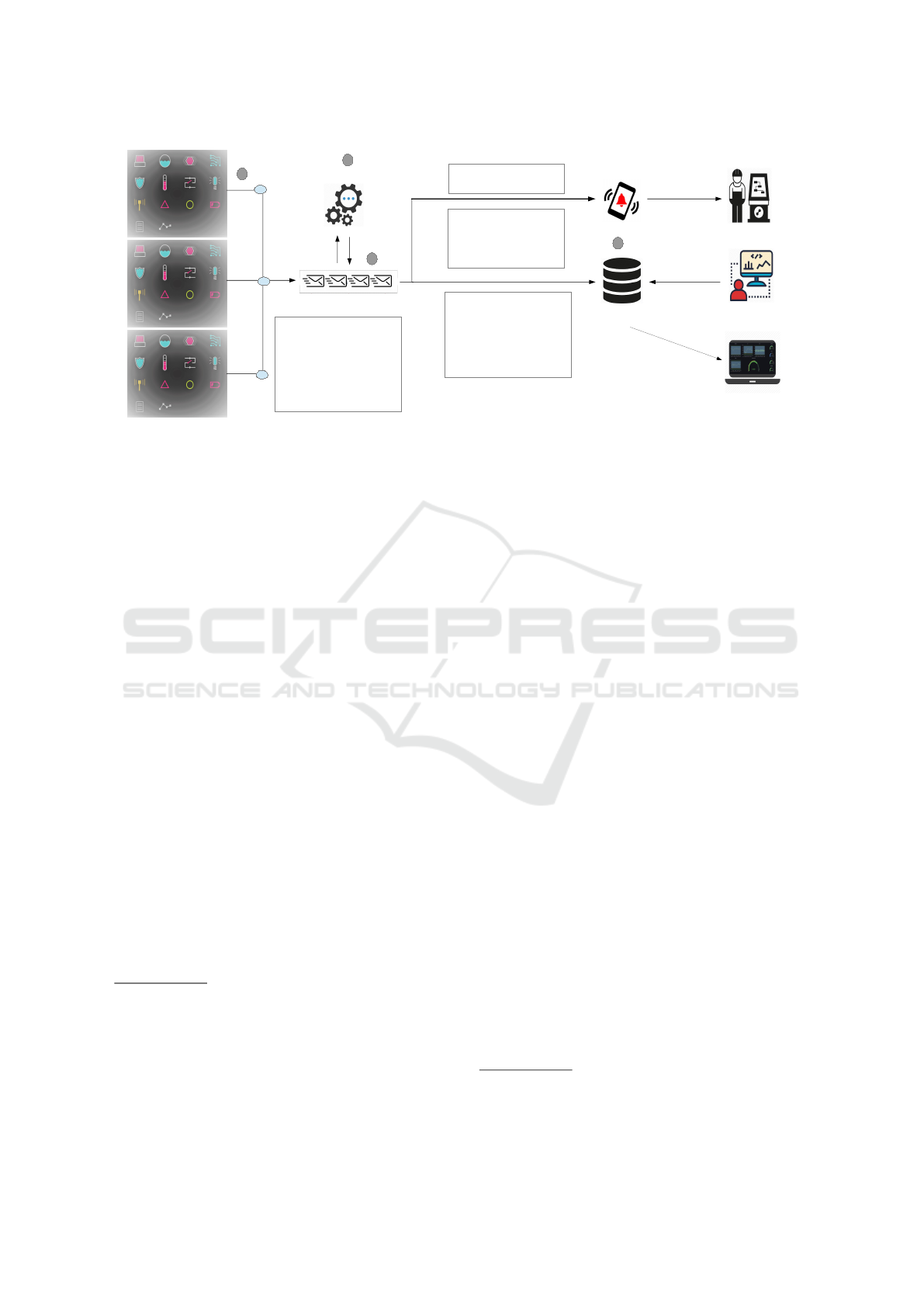

3 STREAMING DATA PIPELINE

ARCHITECTURE

This section provides insight into the approach taken

to build a complete scalable pipeline of relevant tools

and techniques to analyze and visualize streaming

data. In order to build a stream processing pipeline,

there are two well known architectures lambda archi-

tecture (Marz and Warren, 2015) and kappa architec-

ture (Lin, 2017). Lambda architecture has the abil-

ity to handle real-time and batch data processing re-

quirements. It consists of three layers speed, batch

and serving. Lambda architecture captures as well

as persists data before feeding it to the batch and

stream processing layers in parallel. In lambda archi-

tecture a copy of the raw input data is retained perma-

nently and unchanged (master storage). The main is-

sue with lambda architecture is maintenance. For the

reason that data processing and data transformation

logic and code are duplicated at two different layers

(speed and batch) and these layers normally use dif-

ferent tools/technologies. Kappa architecture on the

other hand, captures data (events in Kappa terminol-

ogy) into an unified log (scalable queue) and fed to the

stream processing layer only. The log is immutable

and append-only. There is no batch layer in kappa ar-

chitecture, hence only one layer has to be maintained,

which is responsible for both real-time and batch pro-

cessing with a single set of tools/technologies. In this

paper, kappa has been used as a scalable streaming

data pipeline architecture. The kappa architecture and

data flow is presented in Fig. 1. The architecture con-

sists of four main modules: (1) IoT sensor network;

(2) persistence and append only message bus for stor-

ing event streaming data for long periods of time; (3)

stream processing to process the latest streaming data

in real time and update the serving layer (analysis

ready data store); and (4) analysis ready data store

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

138

Stream Processing

Persistent Messaging Bus

Sensors

Real-time Operational

Dashboard

Stream Processing Jobs

All data is stored in the messaging

bus, which is immutable and

ordered. When reprocessing

of the data is required, a new

processing job can be initiated in

parallel that re-reads the entire

dataset or data of interest from the

messaging bus and stores the

processed data in the data store.

How Does it Work?

Sensors collect data which can then

be sent over the network to the

messaging bus for immutable,

append-only storage. Stream

processing jobs are run on the data,

while the data is still in motion. The

processed data is further sent to

a data store for visualization or

querying purposes and/or consumed

by other applications.

Analysis Ready Data

Store (ARDS)

Alert Notification

Analysis Ready Data

Store (ARDS)

Real-time and historical

insights are stored in ARDS to

broadcast to the operational

dashboard and to perform further

analysis.

Alert Notification

Alerts could be triggered for

critical anomalous conditions.

Sensors

Query

Notify to Operator

Machine

Operator

Business

Analytics

M

o

n

i

t

o

r

i

n

g

1

2

3

4

Figure 1: Overall scalable streaming data pipeline - kappa architecture.

(serving layer) to store the real-time and historical in-

sights. The kappa architecture is scalable and flexible

in the sense that it can accomplish a wide range of

processing tasks (both real-time and batch) in paral-

lel.

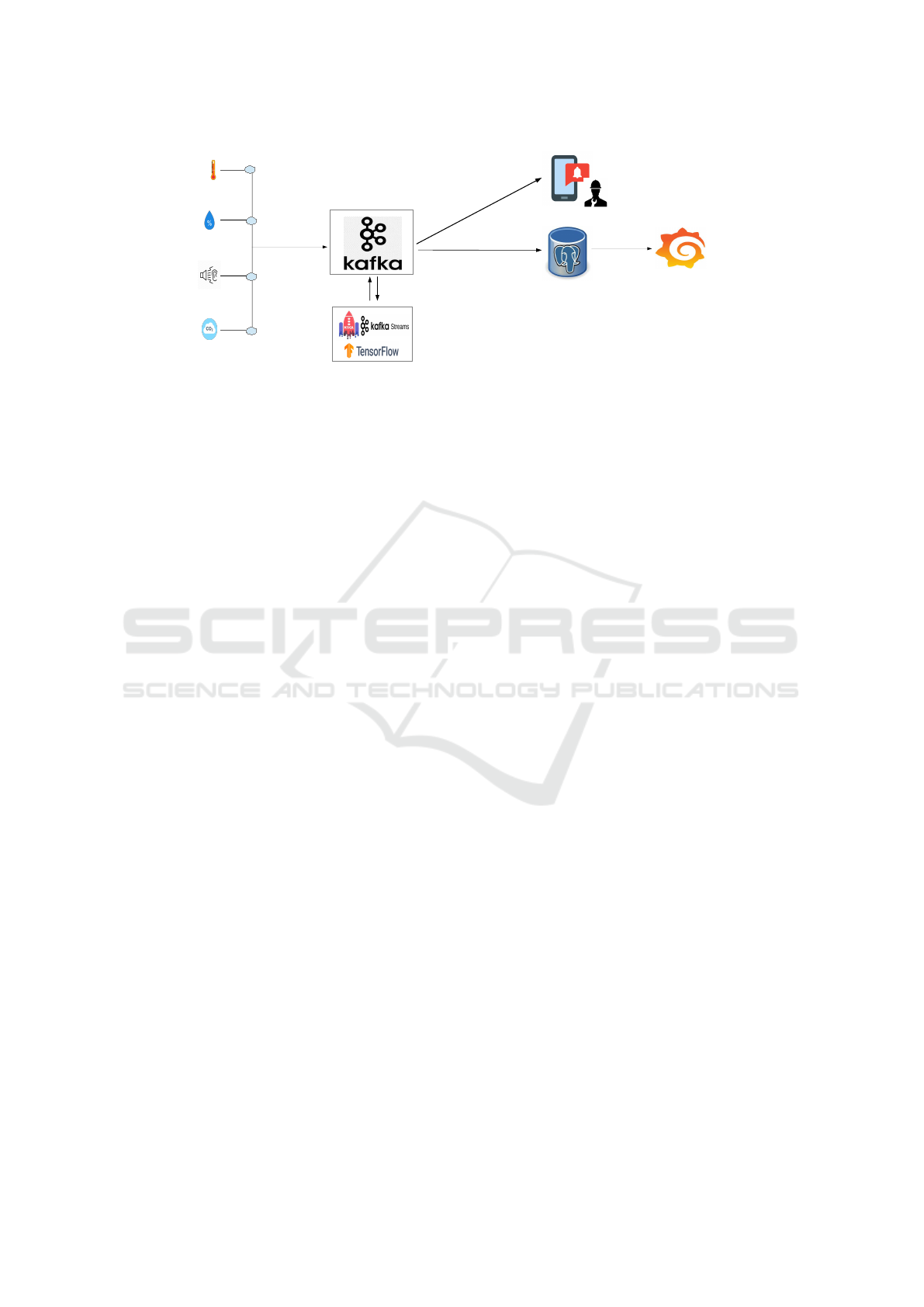

Moreover, a concrete kappa architecture with cho-

sen software platforms is presented in Fig. 2. The

sensor network consists of indoor climate meters (IC-

Meter)

3

deployed in class rooms/public buildings in

Denmark for demonstration purposes to measure in-

door climate data such as, temperature, humidity,

CO

2

and noise. IC-Meter has implemented a pub-

lic REST API

4

to retrieve data from the IC-Meter

server. Data transmitted by the IC-Meter REST API is

streamed into Kafka

5

(a light weight distributed data

stream processing framework) through Kafka Con-

nect. Kafka Connect is the data integration frame-

work for Kafka. It connects data sinks and sources to

Kafka Streams

6

. Kafka Streams is a library for build-

ing streaming applications. Other streaming frame-

works could also be used, such as Storm

7

, Spark

Streaming

8

, Flink

9

and so on. Deployment of an on-

line model in the streaming application for real-time

predictions is also possible. The processed streaming

data is then pushed into the Kafka Connect data sink

(PostgresSQL/TimescaleDB in the given case). The

processed streaming data can then be visualized in a

dashboard, for example Grafana

10

. In addition, an

alert notification may also be sent to the attached con-

3

https://www.ic-meter.com/dk

4

https://app.ic-meter.com/icm-mobile2

5

https://kafka.apache.org

6

https://kafka.apache.org/documentation/streams

7

https://storm.apache.org

8

https://spark.apache.org/streaming

9

https://flink.apache.org

10

https://grafana.co

sumer (mobile app) depending on the severity of the

alarm.

4 CONDITION BASED

MAINTENANCE

This section presents several practical CM and PdM

techniques. Some of these techniques are also demon-

strated by using the stream processing capabilities

of Kafka Streams. Due to its ease-of-use, KSQL

11

is used as a stream processing framework. KSQL

is built on Kafka Streams. In KSQL it is possible

to write real-time streaming applications by using a

SQL-like query language. First, a practical technique

using stateless CM is introduced. In stateless opera-

tions there is no need to keep the previous state and

each data-point in the stream is evaluated individu-

ally. Further, several easy-to-use, easy-to-maintain

and realistic stateful CM and PdM techniques are also

presented. In stateful operations, data-points from a

single/multiple streams are aggregated, correlated or

joined. Even though, indoor air quality has been cho-

sen as a case study for this paper, however the CM and

PdM techniques presented in this paper are generic.

As a matter of fact, poor indoor air quality in indus-

trial buildings is a serious concern. A team of engi-

neers at Purdue University in Indiana

12

have studied

the relationship between indoor climate and produc-

tivity and found out that poor indoor climate results

in lower productivity.

11

https://www.confluent.io/product/ksqldb

12

https://bgridsolutions.com/poor-indoor-climate-leads-

to-lower-productivity

Condition based Maintenance on Data Streams in Industry 4.0

139

K

a

f

k

a

C

o

n

s

u

m

e

r

Kafka Connect (Sink)

PostgreSQL/

Timescale DB

Garafana Dashboard

Real-time Monitoring

Mobile App

Stream processing

Real-time Insights

Kafka Connect

(Source)

Figure 2: Concrete kappa architecture with software platform.

4.1 Condition Monitoring

Condition monitoring is the process of monitoring an

asset’s (room’s in this paper) condition based on one

or several parameters and look for changing trends

or signs that reveals that an abnormal condition or a

fault is approaching. For example, if CO

2

levels are

the same as usual, the rooms indoor air quality most

probably is stable (under an acceptable level), and no

further actions are required. Whereas, if CO

2

levels

increase and exceed a certain threshold, the building

caretaker should intervene and inspect the ventilation

system in order to identify the root cause. If a prob-

lem is identified, in that case a technical person should

monitor the ventilation system more closely while a

repair is scheduled to avoid any further damage.

-----------------------

IC-Meter data snapshot:

-----------------------

{"indoor_Measurements_Toftevangschool":

[{"unit":4,

"time": "2022-07-23T15:00:00Z",

"temperature": 17.00,

"humidity": 29.82,

"co2": 1220.0,

"noise": 32.1},

{"unit":4,

"time": "2022-07-23T15:05:00Z",

"temperature": 18.87,

"humidity": 31.01,

"co2": 1050.0,

"noise": 31.9},

{"unit":4,

"time": "2022-07-23T15:10:00Z",

"temperature": 20.4,

"humidity": 33.01,

"co2": 700.0,

"noise": 31.5},...]}

The above mentioned IC-Meter data snapshot pro-

vides a quick overview of the sensor data that is being

used in the rest of the paper. The IC-Meter is used

for the measurement of indoor climate and ventilation

condition. The IC-Meter data (JSON format) contains

six attributes. The data has 5 minutes granularity. The

rows in the snapshot read as follows. Unit, represents

the room in the given building. Timestamp, represents

the date and time of the sensor data acquisition. In-

door temperature normal range is between 17-25

◦

C.

While, the normal range of humidity is 25-70 %. The

CO

2

and noise levels should be < 1000 ppm and 80

dB(A), respectively.

4.1.1 Threshold Events

It is a stateless CM technique, while the rest of the

techniques presented in this paper are stateful. First, a

topic and a new stream with the specified columns and

properties is created. Afterwards, Kafka Connect im-

ports streaming events into a Kafka topic. In KSQL,

streams can be created from topics as well as of query

results from other streams.

CREATE STREAM indoor_climate (

building VARCHAR, unit INT, timestamp

VARCHAR, temperature DOUBLE, humidity

DOUBLE, co2 DOUBLE, noise DOUBLE)

WITH (kafka_topic=’indoor_climate’,

TIMESTAMP=’timestamp’,

TIMESTAMP_FORMAT=’yyyy-MM-dd’’T’

’HH:mm:ssX’,

value_format=’json’, partitions=1);

The following stream processing logic continu-

ously monitors and processes CO

2

sensor data in real-

time. The CO

2

level in parts per million (ppm) is the

key indicator to decide when is the best time to venti-

late. The processing logic assigns a category (green,

yellow and red) to the individual events based on the

CO

2

range and forwards it to another Kafka topic

and/or data store. Any interested consumer/connector

can get this notification, for example, a dashboard to

display the events in real time based on the severity

levels.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

140

CREATE STREAM indoor_air_quality_levels

AS SELECT *, CASE

WHEN co2 < 800 THEN ’GREEN’

WHEN (co2 >= 800 AND co2 <= 1000)

THEN ’YELLOW’

WHEN co2 > 1000 THEN ’RED

END AS indoor_air_quality_level

FROM indoor_climate

Further, only relevant events showing CO

2

spikes

over 1000 ppm are forwarded to another Kafka topic

for a batch report.

CREATE STREAM poor-indoor-air-quality WITH

(kafka_topic= poor-indoor-air-quality,

value_format=’json’, partitions=1);

AS

SELECT * FROM indoor_climate

WHERE (co2 > 1000);

4.1.2 Peak Detection

This idea of peak detection is completely based on the

work of (de Rizzio, 2021). The processing logic iden-

tifies the peaks that are above a certain threshold level

(1000 ppm in this example) and provides the details

with respect to time/duration (Fig. 3). Any consumer

that is interested in peaks that last more than a specific

amount of time (30 minutes in this example) can get

this notification, for instance, a real-time alerting app.

SELECT unit, TIMESTAMPTOSTRING(WINDOWSTART,

dd-MM-yyyy HH:mm:ss) AS start,

TIMESTAMPTOSTRING(WINDOWEND,

dd-MM-yyyy HH:mm:ss) AS end,

TIMESTAMPTOSTRING(WINDOWEND - WINDOWSTART,

mm) AS peak_width_in_mins,

COUNT(co2) AS num_data_points

FROM indoor_climate_data

WINDOW SESSION (15 MINUTES)

WHERE co2 > 1000

GROUP BY unit

HAVING peak_width_in_mins > 30

EMIT CHANGES;

15:00 15:05 15:10 15:15 15:20 15:25 15:30 15:35 15:40 15:45 15:50 15:55 16:00

1000 ppm

Peak duration

Pd = t2 - t1

Bad indoor air quality

t1

t2

Figure 3: Peak duration.

4.1.3 Outlier Detection using a Threshold

A 45-minutes sliding window continuously monitors

and aggregates CO

2

spikes over 1000 ppm. The pro-

cessing logic identifies the peaks that are above a cer-

tain threshold level (1000 ppm in this example) and

counts the number of peaks in a time-based sliding

window. A batch processing report analysed by do-

main experts may reveals that more than 6 CO

2

spikes

of over 1000 ppm in a 45-minutes period may result

in poor indoor air quality and could considerably in-

creases the risk of infection, hence a real-time notifi-

cation can be sent to an alerting app.

CREATE TABLE anomaly_detection_Tschool_4

AS

SELECT unit, count(*)

FROM indoor_climate_data

WINDOW HOPPING (SIZE 45 MINUTE,

ADVANCE BY 5 MINUTE)

WHERE co2 > 1000

GROUP BY unit

HAVING count(*) > 6

EMIT CHANGES;

4.1.4 Health Score

Another stateful condition monitoring technique is to

calculate the room’s health score (HS) as condition

estimator based on the current health status of the

room (Fig. 4). HS normally consists of a combination

of parameters, as presented in this paper. The ideas

of calculating normalized parameter value (x

n

) and

HS are entirely based on the work of (Weaver et al.,

2014).

x

n

=

x − min(x)

max (x) − min (x)

(1)

Equation 1, calculates the normalized value x

n

,

where x is the value of the parameter, for instance

CO

2

is the parameter and its value is 600 ppm, max(x)

and min(x) are maximum and minimum values of

x in a time-based window and x

n

is the normalized

value of x that will satisfy 0 < x

n

≤ 1. For exam-

ple, CO

2

value of 1050 ppm will be normalized to

(1050 − 700)/(1220 − 700) = 0.67, where 1050 ppm

is the current CO

2

value and 1220 ppm is the maxi-

mum value and 700 ppm is the minimum value in the

IC-Meter data snapshot (Section 4.1).

hs =

j

∏

i=1

(x

n

i

w

i

)

!

1

j

(2)

In Equation 2, health score hs is calculated, where

j is the number of parameters, and the hs is computed

Condition based Maintenance on Data Streams in Industry 4.0

141

Health Score

Health Score

Figure 4: Real-time dashboard with room’s health score.

for a given time-based window by multiplying the val-

ues of x

n

for each normalized parameter with their as-

signed weights w and raising the product to the j

th

root.

hs = [(x

n

1

w

1

) ∗ (x

n

2

w

2

) ∗ (x

n

3

w

3

) ∗ (x

n

4

w

4

)]

1

4

(3)

Further, Equation 3 demonstrates how the hs is

calculated for a given IC-Meter data snapshot, where

x

n

1

represents temperature, x

n

2

stands for humidity, x

n

3

denotes CO

2

and x

n

4

represents noise. Similarly, w

1

to

w

4

represents their respective weights.

4.1.5 Outlier Detection using Statistical

Modeling

In order to identify outliers in Gaussian-like distri-

butions (Fig. 5), mean (M) and standard derivation

(STD) are the most common approaches. Neverthe-

less the classical M and STD models cannot be used

if the data is on-the-move as these models require that

all data-points to be known in advance, which is not

possible in the case of streaming data. In order to ob-

tain the STD of streaming data, an approximation of

STD value is required. Welford’s online algorithm

13

paves the way for computing moving average (MA)

and moving standard derivation (MSTD) of stream-

ing data (Fig. 6). In this paper, an adjusted version of

Welford’s method

14

has been used such that only the

value entering the window needs to be considered.

The following three equation are repeatedly ap-

plied to the streaming data to compute moving aver-

age ma and moving standard derivation mstd.

ma

c

= ma

c−1

+ (x

c

− ma

c−1

)/c (4)

s

c

= s

c−1

+ (x

c

− ma

c−1

) ∗ (x

c

− ma

c

) (5)

13

https://jonisalonen.com/2013/deriving-welfords-

method-for-computing-variance

14

https://github.com/nestedsoftware/iterative stats

15:00 15:05 15:10 15:15 15:20 15:25 15:30 15:35 15:40 15:45 15:50 15:55 16:00

Bad indoor air quality

Average

Standard Deviation

Figure 5: Classical mean and standard derivation.

15:00 15:05 15:10 15:15 15:20 15:25 15:30 15:35 15:40 15:45 15:50 15:55 16:00

Bad indoor air quality

Moving Average

Sliding Window Size: 45 minutes

Moving Standard Deviation

Figure 6: Moving average and moving standard derivation.

mstd

c

=

p

s

c

/(c − 1) (6)

In Equation 4, moving average ma

c

is calculated,

where x

c

is the value of the parameter, c is the count

of the values and ma

1

= x

1

. In addition, 2 ≤ c ≤ n,

where n represents the window size and it can be cal-

culated as follows. For example if the window length

is 45 minutes with a granularity of 5 minutes, then n

= 9. Further, in Equation 5 and Equation 6, moving

sum s

c

and moving standard derivation mstd

c

are cal-

culated, respectively. Whereas, mstd

1

= 0 and s

1

=

0. Furthermore, once the window is full, the follow-

ing two equations (Equation 7 and Equation 8) are

adjusted for window size, where value popped vp is

the leftmost value subtracted/popped from the current

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

142

window of size n.

ma

c

= ma

c−1

+ (x

c

− vp)/n (7)

s

c

= s

c−1

+ (x

c

− vp)∗ (x

c

− ma

c

+ vp − ma

c−1

) (8)

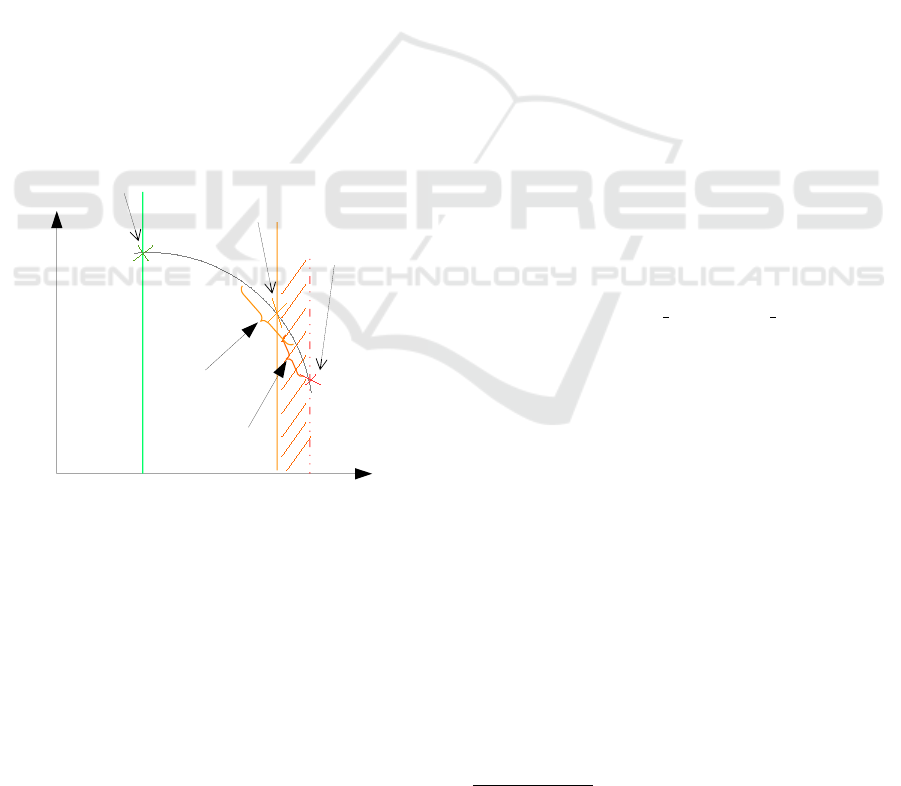

4.2 Predictive Maintenance

As mentioned earlier, CM and PdM are the two main

approaches of CbM. Hence, the goal of both these ap-

proaches is to reduce the likelihood of asset failure by

taking corrective measures before failure happens in

order to minimize manufacturing downtime and un-

scheduled maintenance. Nevertheless there are some

differences between these two approaches. PdM uses

advanced statistical/machine learning models to pre-

dict when a maintenance action should be performed

or in order words when an asset is going to fail, where

as CM can only give some insight based on a cer-

tain threshold that some corrective action needs to be

taken quickly in order to avoid asset failure. Further,

it can be seen in Fig. 7 that the focus of PdM-based

techniques is to detect a failure in its early stage, while

CM-based techniques tries to spot a failure at a late-

stage, though before it occurs.

Time

A

s

s

e

t

C

o

n

d

i

t

i

o

n

Acceptable Condition

Minimal Acceptable Condition

(Condition Indicator)

Failure Condition

Condition

Monitoring

Predictive

Maintenance

Figure 7: Condition monitoring vs predictive maintenance.

In general, PdM has three levels: anomaly detec-

tion, fault detection and diagnostic and prediction of

RUL/TTF. Anomaly detection is one of the most com-

mon use cases of predictive analytics in order to detect

anomalous patterns that deviate from normal behav-

ior. Anomalies are somewhat different from outliers,

an outlier is an unlikely event or a rare event given

the overall event distribution, where as an anomaly is

an event which is different from previous events or

patterns. Fault detection and diagnostic is the second

level, where predictive analytics is used in order to

detect specific faults that may occur and/or their root

causes, such as misalignment in rotating components.

Finally, RUL/TTF is the final level that uses advanced

analytics to predict asset reliability. In this paper, the

main focus is on anomaly detection, hence the rest of

the PdM techniques are not discussed further.

4.2.1 Anomaly Detection using Machine

Learning

Time series based anomaly detection techniques are

mainly based on stochastic models, statistical models

and ML models. In this paper, ML model based tech-

niques are used for detecting anomalies. ML-based

techniques usually need historical data for training

purposes, however a new approach for model train-

ing and predictions is emerging, which is known as

streaming ML. Streaming ML does not requires pre-

stored historical data to start with. Streaming ML

models use online model training/retraining, for ex-

ample a stream processing application based on Ten-

sorFlow

15

can take a collection of the recently con-

sumed events in order to train or retrain a ML model.

Thus, for streaming ML there is no master data stor-

age required.

CREATE STREAM indoor_health_score AS

SELECT unit,

INDOOR_ANOMALY_SCORE(INDOORCLIMATEDATA)

FROM indoor_climate_data_preprocessed;

The above-mentioned KSQL code is based on

the work of (Waehner, 2021). In this application

a ML model is embedded in the user-defined func-

tion (UDF) “INDOOR ANOMALY SCORE()”. It

is also possible to deploy the model to a dedicated

model server. The model uses a special type of neural

network known as autoencoder

16

(an unsupervised

learning algorithm for streaming data). An autoen-

coder is able to discover the structure within data

in order to develop a compressed representation of

the data. To start with, predictions generated by the

model are not accurate, however with online train-

ing/retraining the predictions will get better, still not

as good as a model trained with historical data.

CREATE STREAM anomaly AS

SELECT * FROM indoor_health_score

WHERE INDOOR_ANOMALY_SCORE > 2.0

Moreover, it can be seen in the above-mentioned

KSQL steaming application code, the UDF returns

an indoor health score of each event. Those events

that exceed the given threshold (2.0 in the given case)

will be considered to be anomalous.

15

https://www.tensorflow.org

16

https://www.tensorflow.org/tutorials/generative

Condition based Maintenance on Data Streams in Industry 4.0

143

5 CONCLUSIONS

In the manufacturing industry, production line break-

downs cost ∼ 50,000 US$ per hour, worldwide. Fur-

ther, maximum availability of machines and systems

must be preserved in order to meet the demands of

Industry 4.0. This paper presented a scalable data

pipeline along with several condition monitoring and

predictive maintenance techniques to detect anoma-

lous behaviour. The proposed techniques may help

manufacturing industry to reduce unplanned down-

time due to asset failures. These techniques are prac-

tical, easy-to-use and easy-to-maintain. In addition,

they work well in the case of streaming data, unla-

beled data and/or lack of historical data.

In the future, the proposed data pipeline as well

as condition monitoring and predictive maintenance

techniques presented in this paper should be deployed

to production in SMEs.

ACKNOWLEDGEMENTS

Special thanks to Kai Waehner

17

for his inspirational

tutorials, videos and GitHub repository especially in

relation to Kafka Streams and KSQL by Confluent

18

.

In addition, most of the CM and PdM techniques pre-

sented in this paper are based on the ideas suggested

by Kai Waehner.

REFERENCES

Boniol, P., Paparrizos, J., Palpanas, T., and Franklin,

M. J. (2021). Sand: streaming subsequence anomaly

detection. Proceedings of the VLDB Endowment,

14(10):1717–1729.

Butler, Q., Ziada, Y., Stephenson, D., and Gadsden, S. A.

(2022). Condition monitoring of machine tool feed

drives: A review. Journal of Manufacturing Science

and Engineering, 144(10):100802.

Chatterjee, A. and Ahmed, B. S. (2022). Iot anomaly detec-

tion methods and applications: A survey. Internet of

Things, page 100568.

de Rizzio, R. (2021). Apache kafka and time series.

Available online at: https://rogerio-rizzio.medium.

com/apache-kafka-and-time-series-7f1a9db47053.

Dinardo, G., Fabbiano, L., and Vacca, G. (2018). A smart

and intuitive machine condition monitoring in the in-

dustry 4.0 scenario. Measurement, 126:1–12.

Guo, J. and Shen, Y. (2022). Online anomaly detection of

industrial iot based on hybrid machine learning ar-

17

https://www.kai-waehner.de

18

https://www.confluent.io

chitecture. Computational Intelligence and Neuro-

science.

Hsieh, R. J., Chou, J., and Ho, C. H. (2019). Unsuper-

vised online anomaly detection on multivariate sens-

ing time series data for smart manufacturing. In 12th

Conference on Service-Oriented Computing and Ap-

plications. IEEE.

Iftikhar, N., Baattrup-Andersen, T., Nordbjerg, F. E., and

Jeppesen, K. (2020). Outlier detection in sensor data

using ensemble learning. Procedia Computer Science,

176:1160–1169.

Iftikhar, N., Nordbjerg, F. E., Baattrup-Andersen, T., and

Jeppesen, K. (2019). Industry 4.0: sensor data analy-

sis using machine learning. In International Confer-

ence on Data Management Technologies and Applica-

tion, pages 37–58. Springer.

Lin, J. (2017). The lambda and the kappa. IEEE Internet

Computing, 21(5):60–66.

Liu, X., Iftikhar, N., Nielsen, P. S., and Heller, A. (2016).

Online anomaly energy consumption detection using

lambda architecture. In International Conference on

Big Data Analytics and Knowledge Discovery, pages

193–209. Springer.

Marz, N. and Warren, J. (2015). Big Data: Principles and

Best Practices of Scalable Real-time Data Systems.

Manning Publications Co., New York.

Paolanti, M., Romeo, L., Felicetti, A., Mancini, A., Fron-

toni, E., and Loncarski, J. (2018). Machine learn-

ing approach for predictive maintenance in industry

4.0. In 14th IEEE/ASME International Conference

on Mechatronic and Embedded Systems and Applica-

tions. IEEE.

Pimenov, D. Y., Bustillo, A., Wojciechowski, S., Sharma,

V. S., Gupta, M. K., and Kunto

˘

glu, M. (2022). Artifi-

cial intelligence systems for tool condition monitoring

in machining: Analysis and critical review. Journal of

Intelligent Manufacturing, 109(3):1–43.

Pittino, F., Puggl, M., Moldaschl, T., and Hirschl, C. (2020).

Automatic anomaly detection on in-production manu-

facturing machines using statistical learning methods.

Sensors, 20(8):2344.

Serin, G., Sener, B., Ozbayoglu, A. M., and Unver, H. O.

(2020). Review of tool condition monitoring in ma-

chining and opportunities for deep learning. The In-

ternational Journal of Advanced Manufacturing Tech-

nology, 109(3):953–974.

Waehner, K. (2021). Condition monitoring and predictive

maintenance with apache kafka. https://www.kai-

waehner.de/blog/2021/10/25/apache-kafka-condition-

monitoring-predictive-maintenance-industrial-iot-

digital-twin.

Weaver, S., Dai, D., Stauber, C. E., and Luo, R. (2014). The

urban health index: a handbook for its calculation and

use.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

144