Semantic Interoperability in Industrial Maintenance-related

Applications: Multiple Ontologies Integration towards a Unified

BFO-compliant Taxonomy

Chiara Franciosi

1a

, Adalberto Polenghi

2b

, Mario Lezoche

1c

, Alexandre Voisin

1d

,

Irene Roda

2e

and Marco Macchi

2f

1

Université de Lorraine, CNRS, CRAN UMR 7039, F-54000, Nancy, France

2

Department of Management, Economics and Industrial Engineering, Politecnico di Milano,

P.zza Leonardo da Vinci 32, 20133 Milan, Italy

Keywords: Taxonomy, Ontology, Knowledge Formalization, Semantics, Interoperability, Maintenance, PHM, Industry.

Abstract: Maintenance is an essential process for guaranteeing the reliability and availability of physical assets towards

sustainable performance. The way maintenance could effectively impact on operations management highly

relies on available data, whose volume and variety are increasing, challenging how they are stored and

processed within an organization. To tackle this issue, ontology engineering seeks for guaranteeing semantic

and technical interoperability for shared underlying meaning of concepts and consistent data formats. Despite

the growing adoption of ontologies for industrial maintenance, some pitfalls may be envisaged by scientific

and industrial practice, specifically referring to the development of multiple non-compatible ontologies that

cannot be reused. Therefore, the goal of this research work is to promote semantic interoperability in

industrial-maintenance related application. This is achieved by reviewing existing ontologies, later integrated

and aligned, to realise a BFO (Basic Formal Ontology)-compliant taxonomy for maintenance, including

physical decomposition of systems and maintenance processes. Hence, this research attempts a first step

towards a unified taxonomy that, then, is the ground on which ontologies could be built upon so to be

consistent each other. In the long run, semantic-based digital twin, referred to as cognitive digital twin, may

be consistently established to improve sustainable performance of production systems.

1 INTRODUCTION

Nowadays the attention towards sustainability-related

performance is increasing and manufacturing systems

and their processes make no exception (Acerbi &

Taisch, 2020; Franciosi et al., 2020). Improvement of

the energy efficiency while reducing consumed

resources are challenging industrial companies to

identify novel solutions to meet SGDs (Sustainable

Development Goals) as well as reducing costs while

keeping the same performance and guarantee

a

https://orcid.org/0000-0002-9983-1386

b

https://orcid.org/0000-0002-3112-1775

c

https://orcid.org/0000-0002-3271-1742

d

https://orcid.org/0000-0002-4637-6826

e

https://orcid.org/0000-0001-7795-1611

f

https://orcid.org/0000-0003-3078-6051

operational continuity. In this new, ever-changing

context, maintenance could play the lion’s share

(Franciosi et al., 2021; Holgado et al., 2020;

Liyanage, 2007) as it acts as the contact point

between the shopfloor and the top management, to

make the later more informed about systems status

and transmit to the former the medium to long-term

objectives of the company. Apart from maintenance,

this could be also seen in the wider view of Industrial

Asset Management (Niekamp et al., 2015).

Nonetheless, the challenges to face are manifold

(Iung & Levrat, 2014; Jasiulewicz-Kaczmarek &

218

Franciosi, C., Polenghi, A., Lezoche, M., Voisin, A., Roda, I. and Macchi, M.

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant Taxonomy.

DOI: 10.5220/0011560800003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 218-229

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Gola, 2019). In the path from data to information, the

data management represents a pillar as it allows to

acquire, store and distribute data across information

systems to support different decision-making

processes. The capability to distribute data across

users and departments is hence of paramount

importance, even though interoperability issues are

present. Interoperability could be stratified according

to technical, semantic and organizational levels,

coherently with the EIF (European Interoperability

Framework) (Vernadat, 2010). Indeed, establishing

the semantic interoperability between information

systems is currently under study as the meaning each

concept carried with is as relevant as the value of the

same data with respect to the decision-making

process (Panetto et al., 2012). For these reasons,

several ontologies have been proposed over the years,

but there exists incompatibilities that prevent the full

exploitation of the maintenance domain-related

knowledge formalization (Polenghi, Roda, Macchi,

Pozzetti, et al., 2022) and prevent two or more

ontologies to work synergistically without applying

ontological integration approaches (Izza, 2009).

Considering these gaps and relying on the current set

of ontology development methodologies, this

research work assumes that, to promote the

development of compatible ontologies, they must

share the same domain-dependent taxonomy of

concepts, which should be general enough to be

applied to multiple contexts.

Hence, the research question that this work aims

at answering is how to formalise a domain-dependent

taxonomy to improve semantic interoperability for

industrial maintenance applications?

In compliance with the above question, the goal

of this research work is to define a unified BFO-

compliant taxonomy to enhance semantic

interoperability for maintenance-related applications.

Indeed, this is a first work of a wider project called

KARMA (Knowledge-augmented maintenance

model for sustainable manufacturing). Overall, the

KARMA project aims at extending the use of

ontologies to complement data-driven knowledge

from the field thanks to sensors through reasoning

capabilities. In the long-term the ontology will

augment field-level data or information by means of

additional static or dynamic knowledge, starting from

the condition-based and predictive maintenance

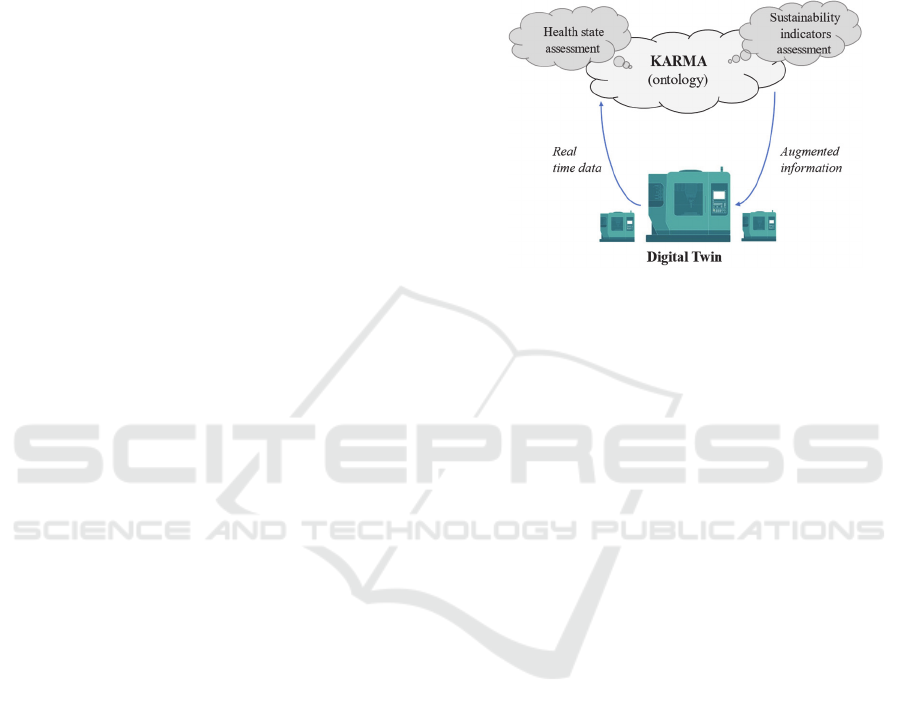

towards machine-aware scheduling. Figure 1

visualizes the overall idea of the project.

Within the project, the first steps relate to the

conceptualization and knowledge elicitation.

Specifically, the selection of one concept, and related

meaning, with respect to another one is not

straightforward, and it may depend on the specific

application. As such, the novelty of this work is to

formalise and propose the underlying taxonomy of

the ontology. Therefore, in this article, it is shown the

reasoning behind the identification and selection of

some concepts with respect to others towards a

unified BFO-compliant taxonomy.

Figure 1: KARMA project overview.

Hence, the paper is structured as follows: Section

2 sets the background for ontology engineering with

specific reference to maintenance; Section 3 reviews

BFO as relevant, industry-accepted top-level

ontology; Section 4 describes the adopted research

methodology; Section 5 details out the concepts that

will be part of the taxonomy according to three main

groups: failure management-related concepts,

physical system-related concepts, maintenance

process-related concepts. Eventually, some

conclusions are drawn based on the findings from the

semantic analysis of maintenance-related concepts.

2 ONTOLOGY BACKGROUND

Interoperability can be defined as the ability of two or

more systems to share, to understand and to consume

information (IEEE, 1990). Interoperability could be

tackled at various levels, technical, semantic and

organisational (Vernadat, 2010). Our work focuses on

the semantic level of interoperability, namely the

ability to understand the exchanged information.

Information may be defined as data linked to

knowledge about this data. It is represented by so-

called concepts. A concept is a cognitive unit of

meaning (Vyvyan, 2006). At semantic level, an

ontology, defined as “an explicit specification of a

conceptualization” (Gruber, 1993), represents an

answer to guarantee seamless and consistent

information exchange between parties and systems

(Szejka & Junior, 2017); this is especially perceived

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

219

in industrial contexts, where a systematic approach in

ontology development will define a common and

shared IT ecosystems for companies (Ameri et al.,

2021), looking for enterprise-based interoperability

where distributed systems use multi-domain

information and the entire company may have access

to it (Panetto, 2007).

However, the development of ontologies is not

straightforward, and several are the methodologies

that may be adopted, from lightweight ones like

Ontology Development 101 (Noy & McGuinness,

2001) to the most demanding, semantic-focused ones

like DOGMA (Spyns et al., 2008) and NeOn (Suárez-

Figueroa et al., 2015). Also, there exist multiple

ontological layers, which represent the levels of

details the related ontologies aim at representing.

There is no unique view on how many layers should

be considered, but at least four are recognised

according to scientific literature (IOF and (Polenghi,

Roda, Macchi, Pozzetti, et al., 2022)): top-level

ontologies, domain independent ontologies, domain

dependent ontologies and application ontologies.

Top-level ontologies aim at setting the ground for

ontological commitment, shaping the reality in very

general terms, such as material and immaterial

entities, objects, and processes; examples are BFO,

DOLCE and SUMO. Domain independent ontologies

are those that introduce concepts, like time, or unit of

measure that could be applied to any contexts given

their generality; domain dependent ontologies are

instead already thought for specific contexts. Finally,

application ontologies are specific for some contexts,

hence they include concepts that are not valid in other

situations. From the first (top-level ontologies) one to

the last (application ontologies) ones, the specificity

and dependency levels on specific contexts increase.

In industry, the use of ontologies may bring

advantages and maintenance makes no exception.

The potentialities of ontologies for maintenance are

manifold and some applications could be in PHA

(Process Hazard Analysis) and PHM (Prognostics

and Health Management) (Polenghi et al., 2021).

Indeed, maintenance-related ontologies have a wide

variety of usage, including advanced diagnosis (Chen

et al., 2022) and prognosis (May et al., 2022) of

failure, FMEA/FMECA knowledge formalisation

(Wu et al., 2021), evaluation of system-level impact

of failure (Hodkiewicz et al., 2021), maintenance

management process formalisation (Karray et al.,

2019), joint maintenance and production decisions

(Polenghi, Roda, Macchi, & Pozzetti, 2022). All of

them rely on the reasoning capabilities of ontologies

to augment the information content and empower the

decision-making process. As such, ontologies for

maintenance are perceived as symbolic AI models

that could either improve semantic interoperability,

specifying and fixing the meaning each concept has,

and exploit the potentialities of non-symbolic AI

through logic inference.

Despite the ever-increasing adoption of

ontologies for industrial maintenance, some gaps still

remain that are worth to be tackled to guarantee

semantic interoperability (Polenghi, Roda, Macchi,

Pozzetti, et al., 2022) and a wider dissemination and

use, amongst which:

1. Alignment with top-level ontologies is not always

guaranteed by newly developed ontologies. This

reflect in consistencies between ontologies that

are difficult to integrate.

2. Knowledge reuse and alignment is not an

established practice, even if central in ontology

development methodologies. Hence, useful

concepts are usually formalised multiple times

instead of being reused by already established and

tested ontological models.

Therefore, this work aims to align the knowledge

present in the BFO-compliant ontologies for

industrial maintenance through their comparison, as a

first step, to set then the path towards a unified

taxonomy based on BFO for maintenance-related

ontological applications.

The selection of BFO, as top-level ontology

reference, has been made given the newly published

ISO 21838-1/2:2021 standard on domain-neutral top-

level ontologies and that latest works highly rely on

BFO as reference top-level ontology. In this regard, it

is worth to introduce briefly BFO in the following

section 3, before presenting the methodology in

section 4 and the semantic analysis in section 5.

3 BASIC FORMAL ONTOLOGY

The top-level BFO ontology is “a small, upper level

ontology that is designed for use in supporting

information retrieval, analysis and integration in

scientific and other domains” as stated in the official

website and described in (Arp et al., 2015). It is top-

level as it is domain-independent and does not contain

terms specific of some application. Also, it became a

standard to build industrial ontologies (ISO 21838).

The first level branching of BFO is between

continuant and occurrent, where the first ones are

three-dimensional entities that persist through time,

while the second ones are spread out also in time.

From these 2 afore-mentioned concepts, several

additional branches are defined. Overall, the first two

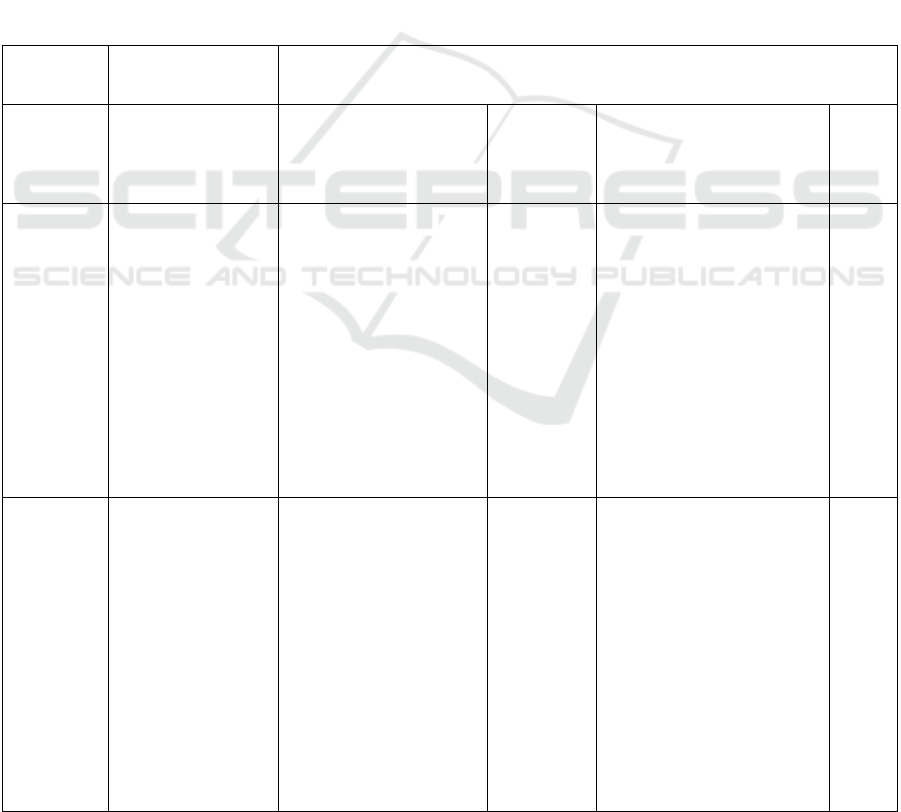

levels of BFO are reported in Figure 2, but the reader

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

220

is referred to the book by (Arp et al., 2015) or the ISO

21838-2 for the whole description of BFO.

The formalisation of BFO also enabled the

development of domain-independent ontologies that

ease the definition of new ontological models as they

define more specific concepts than BFO, but enough

general to be applied to any domain. Examples of

these ontologies are CCO (Common Core

Ontologies) and IAO (Information Artifact Ontology)

that could be reused in domain-specific ontologies.

Figure 2: First two levels of BFO taxonomy.

4 RESEARCH METHODOLOGY

The methodology followed to realise a unified BFO-

compliant taxonomy for maintenance purposes,

starting from the existing BFO-based ontologies,

comprises several steps and criteria that allow the

identification of relevant sources and the

inclusion/exclusion of those that did not fit with

current goals and best practices. Indeed, the steps of

specification and knowledge elicitation are ground

steps as recognised by the scientific literature

(Polenghi, Roda, Macchi, Pozzetti, et al., 2022).

Hence, to come up with a unified taxonomy, multiple

sources must be firstly identified, elaborated and then

synthesised, as follows:

1. The first phase includes the identification of

relevant ontological and non-ontological sources

whose research scope includes industrial

maintenance. The search for those sources

involves both scientific literature and industrial

standard:

a. Scientific literature was spanned so to

identify relevant scientific articles compliant

with the following requirements: i) full-text-

available article, ii) owl (Web Ontology

Language) file available, iii) formal or semi-

formal definitions of concepts available, and

iv) BFO compliant.

b. International standards on maintenance so to

gather definitions and usage of terms, with

agreed-upon semantics.

2. The second phase includes the comparison

between the concepts under the semantic point of

view via brainstorming sessions among the

authors and by leveraging on the use of the

concepts in maintenance applications. The goal

of this phase is to set the ground towards a

taxonomy that integrates knowledge from the

identified sources in a unified way.

The methodology was applied to gather and

identify those terms that fit with the purpose of

creating a BFO-compliant taxonomy for industrial

maintenance-related applications.

5 TOWARDS A UNIFIED

BFO-COMPLIANT TAXONOMY

FOR INDUSTRIAL

MAINTENANCE

Three scientific articles providing ontological

sources, compliant with the defined requirements,

were identified: (Karray et al., 2019), (Montero

Jiménez et al., 2021), (Polenghi, Roda, Macchi, &

Pozzetti, 2022). Also, the resources publicly made

available by IOF (www.industrialontologies.org,

Industrial Ontologies Foundry) were considered,

namely the ontology on maintenance. Several

worldwide recognised standards were considered for

the non-ontological sources, such as: IEC

60812:2018, ISO 14226:2006, IEC 60300-3-11:2009.

The most recurring and relevant maintenance-

related concepts provided in the analysed ontological

and non-ontological sources are then identified and

their definitions as well as their positioning in the

BFO top-level ontology are evaluated. Several

concepts related to (1) the failure management, (2) the

physical decomposition of the systems and (3) the

maintenance processes are found and compared. As

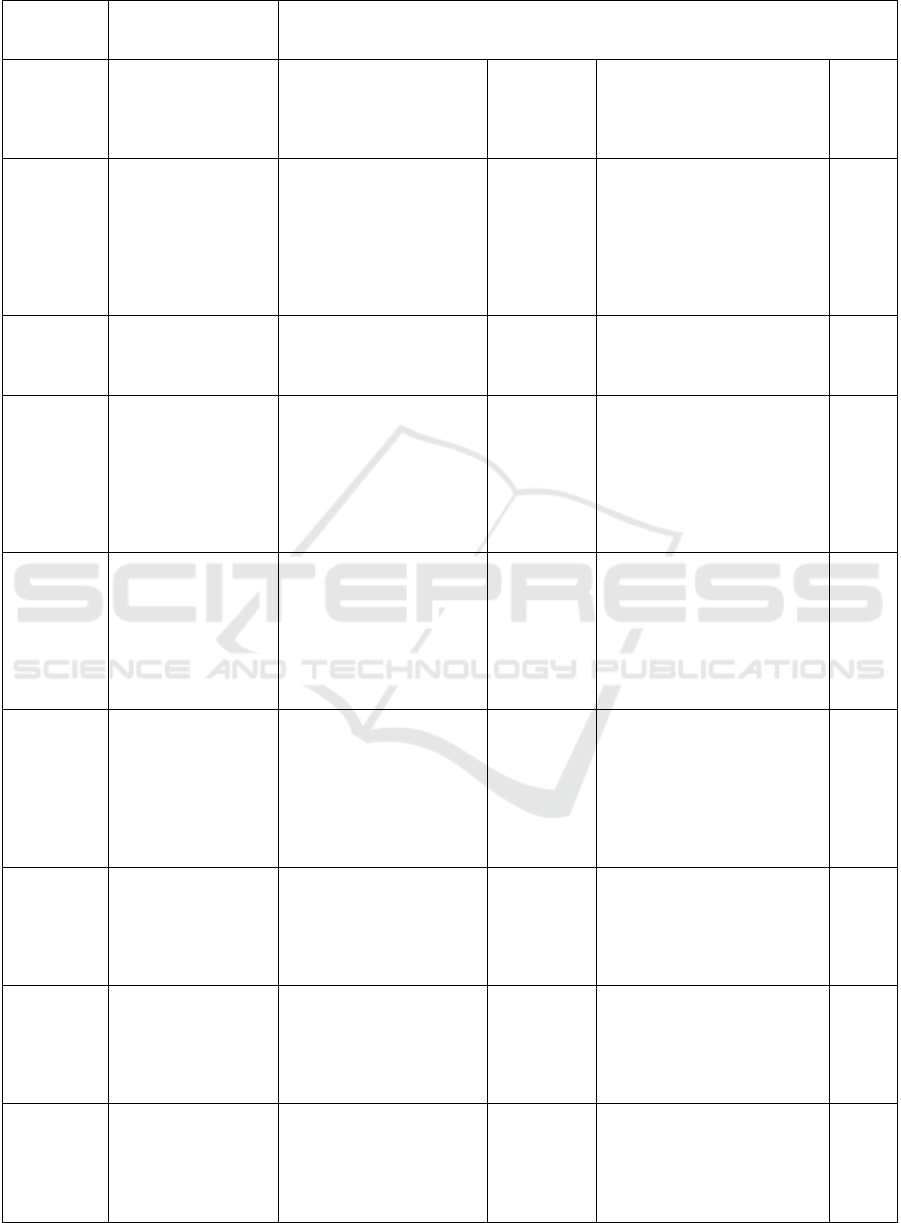

an example, Table 1 reports the comparison among

the failure management-related terms, while in the

next sub-sections a detailed description of the

concepts for the 3-aforementioned is provided.

5.1 Failure Management-related

Concepts

Concerning the FAILURE CAUSE concept, several

coherent definitions from the standards (IEC

60812:2018, ISO 14226:2006, IEC 60300-3-

11:2009) were found and reported in Table 1.

Regarding the ontological resources, only IOF and

(Montero Jiménez et al., 2021) provide the semi-

formal definition of failure cause. Anyway, the

Entity

Continuant

Occurrent

Independent

continuant

Generically

dependent

continuant

Specifically

dependent

continuant

Process

Spatiotemporal

region

Process

boundary

Temporal

region

is-a

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

221

positioning of the concept in the BFO is different:

indeed, according to the IOF, the failure cause is an

“occurrent” that has led to a state of failure of

machine or a component, i.e. the failure cause is an

event that happens, occurs; according to (Montero

Jiménez et al., 2021), the failure cause is a

“continuant” and, in particular, a descriptive

information content entity that describes the cause of

a failure mode, hence persists through time as it is

seen more as a fixed, never-changing information

type. This is aligned with the very same approach to

Failure Modes, Effects, and Criticality Analysis

(FMECA) by (Montero Jiménez et al., 2021) as they

see related data to be stored in the “descriptive

information content entity” class; at the same time,

some data from the field will be collected during

machine operation, therefore, some events related to

the “occurrence” class (i.e. IOF definition) are

present. Consequently, it is proposed to re-name the

concept of failure cause, which is in the descriptive

class, as “failure cause description” so to distinguish

between the failure cause itself and related

information. Therefore, to achieve a complete

taxonomy, both concepts should be included.

Concerning the concept of FAILURE MODE,

the standards IEC 60812:2018, ISO 14226:2006 and

IEC 60300-3-11:2009 provide the definition, and all

the ontological sources, except for (Karray et al.,

2019), defined the concept. In particular, according to

IOF, the failure mode is a “realizable entity” that is a

consequence of a failure mechanism through which a

failure occurs. Also, (Polenghi, Roda, Macchi, &

Pozzetti, 2022) positioned this concept in the

“realizable entity” class of BFO. Indeed, according to

this positioning of the concept in the BFO, when a

production process starts, then the failure mode

exhibits. Instead, according to (Montero Jiménez et

al., 2021), the failure mode is a “Descriptive

information content entity” that describes a failure of

an item and the corresponding fault that can cause the

failure. As for the failure cause concept, (Montero

Jiménez et al., 2021) consider the failure mode as an

output of the FMECA.

As for the failure cause, the proposal is that both

perspectives must be maintained in the ontology: the

failure mode exhibits as a “realizable entity” and the

failure mode information must be included in the

“descriptive information content entity” and related.

These two classes should be connected each other

because when a failure mode happens, it will be

possible to know which other failure modes will

happen thanks to the relationships established in the

failure mode information and, therefore, even if only

one failure mode happens (as a “realizable entity”), it

will possible to predict the other failure modes that

will occur soon through the inference in the ontology.

This means that when the first event of failure mode

is occurring, it could imply other failure modes, but it

is not possible to understand this only with the

“realizable entity” class; whereas, thanks to the

relationships among failure modes information

established in “descriptive information content

entity”, it will be possible to predict if other failure

modes will exhibit. The general idea is to link the

static descriptions, relevant because give the relations

between the failure modes, reported in the

information content entity, with real data.

The FAILURE EFFECT/CONSEQUENCE

concept was defined by the standard IEC 60812:2018

and IEC 61882:2016 (Table 1). In the ontological

sources, only (Montero Jiménez et al., 2021) provided

a semi-formal definition of this concept as: a

“Descriptive Information Content Entity” that

describes the impacts of a failure in terms of safety,

environment, and operation; it is normally measured

by rank and it is about an effect that results from a

failure and consider the failure effect as an

information. Anyway, only the failure effect

information is not sufficient to be used in the ontology

for making some assessments and reasoning:

therefore, it is necessary to relate the information with

the “deviation of the flow” (HAZOP-inspired

terminology) in the production process. For example,

in (Polenghi, Roda, Macchi, & Pozzetti, 2022), they

analysed the effect of the failure on the feasibility of

the product. Indeed, if we consider the flow at the

“asset level”, this could be represented by the

product, and the deviation of the flow (i.e., the failure

effect) is the product unfeasibility.

Concerning the TRIGGERING EVENT class,

(Karray et al., 2019) define it as a “process” resulting

in an action, while (Montero Jiménez et al., 2021) as

a “process boundary” (process boundaries are the

beginnings and endings of the processes they bound)

that is the starting point for a maintenance action.

After some brainstorming sessions among the

authors, it was deemed to consider the triggering

event concept as a process boundary so that: the

triggering event triggers the maintenance action,

which is connected to the event that detects when a

threshold (of whatever nature) is reached, hence the

action is requested. Also, the writing of an ontology-

based database will consider the event (exceeding of

the threshold) and the related maintenance action.

Moreover, the database connected with the ontology

will be feed with the information related to the event,

the exceed of the threshold, not to the process.

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

222

Other definitions are provided by IOF that divides

the concept of triggering event in INSPECTION

TRIGGERING EVENT, MAINTENANCE

TRIGGERING EVENT and OPERATING

TRIGGERING EVENT, respectively defined as “a

process boundary of an Inspection Action that begins

a Maintenance Process. An inspection event that

causes a maintenance process to be initiated”, “a

Process Boundary that begins a Maintenance Process

through the production of a Maintenance Work

Specification”, and “a Process Boundary in the

operation of a Manufacturing Process that begins a

Maintenance Process”.

Concerning the concept of FAILURE, according

to the ISO 14224:2016, it is a loss of ability to

perform as required, while ontologically (Montero

Jiménez et al., 2021) and IOF the failure is a “process

boundary”. The related “failure event” is a “process”

that precedes the state of failure (Karray et al., 2019).

Specifically, according to IOF, a failure event is a

terminal process boundary where some process which

realizes the initial phase of a material product

production process plan ceases, while (Montero

Jiménez et al., 2021) define the failure as a triggering

event subclass related to corrective maintenance

strategy; the impossibility of an item to perform its

intended function triggers a maintenance action. After

some brainstorming among the authors, a failure can

be represented in the ontology as an event, as for the

triggering event, specifically a triggering event after

the process of degradation.

Other concepts are modelled by (Montero

Jiménez et al., 2021) as sub-classes of “triggering

event” are: DEGRADATION THRESHOLD

OVERSHOOT, FAILURE FORECAST, FAULT

DETECTION and FIXED TIME

RECOMMENDATION (Table 1).

After some brainstorming sessions, the proposal

is to re-allocate the concepts that for (Montero

Jiménez et al., 2021) are all sub-classes of “triggering

event” in the specific concepts provided by IOF of

“inspection triggering event”, “operating triggering

event” and “maintenance triggering event”.

Therefore, the idea is that all these concepts are

process boundaries, but there will be first a class of

“triggering event”, divided in the three types of

triggering event provided by IOF and the concepts of

“degradation threshold overshoot”, “failure forecast”,

“fault detection”, “fixed time recommendation” and

“failure” will be reallocated to the three types of

triggering events. Below what proposed in this

research work:

1. The concept of “failure” is an “operating

triggering event” related to a part of the physical

system (e.g. the component).

2. The concept of “degradation overall overshoot” is

a “maintenance triggering event”, because it is the

maintenance department that takes care of the

monitoring of the threshold overshooting, while

the production is in progress. The concept of

“degradation overall overshoot” is strictly

interconnected with the condition-based

maintenance (CBM) strategy.

3. The concept of “failure forecast” is a

“maintenance triggering event”.

4. The concept of “fixed time recommendation” is a

“maintenance triggering event”. We also propose

to include the concept of “fixed age

recommendation”, to consider another possible

periodic maintenance strategy.

5. The concept of “fault detection” is a “maintenance

triggering event” because it is performed by the

predictive maintenance module. The event of fault

detection highlights that, even if the failure does

not occur, something is happening on the physical

system, so the “fault detection” concept can

trigger the degradation assessment, which can

imply the “degradation overall overshoot”.

Consequently, the maintenance action can be

carried out once the overshoot appears or planned

after a prognostic. This is in part coherent with the

OSA-CBM (www.mimosa.org/mimosa-osa-

cbm/) principles, for which there is first the fault

detection, then the diagnostics to understand the

type of fault, and then the maintenance action; but,

when the maintenance action is not urgent, it is

possible to use prognostics. This means that some

relationships need to be clarified in the ontology

because currently the “fault detection” is allocated

as sub-class of “triggering event”, therefore

should imply directly a maintenance action, but

based on MIMOSA OSA-CBM, fault detection

does not imply directly a maintenance action.

Finally, (Montero Jiménez et al., 2021) did not

explicitly differentiate between the predictive

maintenance and the CBM strategies, but they only

include the preventive, corrective and predictive.

Therefore, it may be interesting to consider and

formalise the difference between CBM and predictive

maintenance with proper relationships.

Several definitions of STATE, FUNCTIONAL

FAILURE, STATE OF FAILURE, STATE OF

FAILURE COMPONENT, STATE OF

FAILURE MACHINE and STATE OF

DEGRADATION are provided (Table 1). For

example, according to (Karray et al., 2019), a “state

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

223

of failure” is defined as a state during which an

artifact is unable to perform its function. This concept

is positioned as a sub-class of “state” in the “process”

class, whereas IOF defines a “functional failure” as a

state in which a physical asset or system is unable to

perform a specific function to a desired level of

performance, but the concept is still not positioned in

the BFO top-level ontology. IOF provides also the

definition of “state of failure component” and “state

of failure machine”, directly as a sub-class of “state”.

The definition of “state of degradation” is also

provided by (Karray et al., 2019) as a state during

which an artifact bears an undesirable quality or

function and by IOF as a state in which some

component endures and is moving towards non-

conformity; it describes when a component is in the

process of degrading.

Of course, we agreed that the two concepts of

“state of failure” and “state of degradation” must be

separated because they refer to two different states of

the asset (unable to perform the service and reduced

capability to provide the service, respectively) as well

as two types of information in the FMECA analysis:

on the degradation process is possible to perform

prognostics (connected with the predictive

maintenance), while the failure is a process boundary

and, as such, is unpredictable or is the result of a

degradation, therefore is not possible to perform

prognostic on the failure (connected to the corrective

maintenance, but we can consider the concept of

failure also in the predictive maintenance).

Based on the several definitions provided by the

analysed resources and the brainstorming sessions,

our proposal is to consider a macro-class “state”

including two sub-classes of “state of failure” and

“state of degradation”; in the “state of failure” class,

a difference is done between “state of functional

failure” related to the asset and “state of physical

failure” related to the component.

5.2 Physical System-related Concepts

Several concepts related to the physical

decomposition of the systems are provided in the

analysed sources: ITEM; MAINTAINABLE

ITEM; ASSET; COMPONENT; FUNCTIONAL

UNIT; PART; SYSTEM; ASSET PLANT; ASSET

SYSTEM; SENSOR; MACHINE;

MANUFACTURING MACHINE;

MANUFACTURING TOOL; EQUIPMENT;

PIECE OF EQUIPMENT; TOOL. (Polenghi,

Roda, Macchi, & Pozzetti, 2022) and IOF also

provide the concept of PRODUCT, as physical

material entity.

These concepts are positioned in the “independent

continuant” BFO class because all the concepts are

“material entity”, therefore, all the sources agree on

the positioning of the concepts in the BFO. The

differences are on the level of indentation of the

concepts: for example, IOF includes in the ontology

many concepts as “system”, “component”,

“maintainable item”, “machine”; “manufacturing

machine”; “manufacturing tool”; “equipment”;

“piece of equipment”; “tool”, whereas (Karray et al.,

2019) only considers the “asset” that is composed of

some “maintainable item”.

After reviewing the standards and the scientific

literature, that do not provide a unique level of

indentation, and based on the authors’ experience, the

level of indentation can vary based on the industrial

context. For this reason, our proposal is coherent with

(Karray et al., 2019) , i.e. to consider only two levels,

one for the asset and another level for the

components; this allow a major generalizability as the

component is than related to itself via reflexive

relationship. This is also coherent with the proposal

done in the failure management-related terms, i.e.

“state of functional failure” related to the asset and

“state of physical failure” related to the component.

The levels should be then adapted based on the

industrial context.

5.3 Maintenance Process-related

Concepts

Several maintenance process-related terms were

analysed: all these concepts are positioned in the BFO

“process” class.

(Polenghi, Roda, Macchi, & Pozzetti, 2022)

define the MONITORING PROCESS as a process

to monitor an artifact by measuring a specific

phenomenon, while (Montero Jiménez et al., 2021)

define the CONDITION MONITORING as a

process that has as output condition data. The two

concepts can be identified as a unique term and one

definition can be provide as a process to monitor an

artifact by measuring a specific phenomenon and that

has as output condition data. A further difference can

be done between condition continuous monitoring

and condition discrete monitoring (Polenghi, Roda,

Macchi, & Pozzetti, 2022).

Concerning the concept of PROCESS OF

DEGRADATION, IOF and (Karray et al., 2019)

define it respectively as a process that results in the

loss of ability to perform a function and as a process

that results in the loss of a desired quality or function,

while (Montero Jiménez et al., 2021) provide the

concept of DEGRADATION ASSESSMENT

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

224

PROCESS defined as a process performed on a

physical equipment by a predictive maintenance

module to assess degradation until this degradation

overshoot a specific threshold. After some

brainstorming sessions among the authors, we agreed

that the concept of degradation assessment process

allows the achievement of the degradation

information thanks to the comparison of the measured

values with thresholds, enabling the understanding of

the magnitude of the degradation and the deviation of

the flow, while the process of degradation is more a

representation of the process in the real world.

Also, (Montero Jiménez et al., 2021) provide the

definition of FAULT DETECTION PROCESS as a

process performed on a physical equipment by a

predictive maintenance module to detect incipient

faults, therefore it is automatically performed by a

system, whereas the concept of INSPECTION

ACTION, only defined by the IOF as examination of

an item against a specific standard, is generally

performed by an operator that manually inserts the

data in the information system. IOF puts this last

concept in the class “need to be placed”, therefore the

inspection action is still not positioned in the BFO.

Anyway, both concepts of fault detection process and

inspection action have to be included in the taxonomy

considering all current activities at shopfloor level.

The concept of MAINTENANCE PROCESS is

also provided by the IOF as a process comprised of

maintenance action to retain or restore a maintainable

item to perform a function, all activities necessary to

retain or restore the functionality of an asset;

accordingly, IOF defines also the MAINTENANCE

ACTION concept as a process to perform work on a

component according to a maintenance work order

specification; one of more tasks necessary to retain an

item in or restore it to a specified condition. The

concept of maintenance action is also provided by

(Karray et al., 2019) as a process to perform work on

an artifact according to a Maintenance Work Order

Specification and by (Montero Jiménez et al., 2021)

as a process performed on a physical equipment to

restore or keep it in its operational state. All the

definitions are consistent with each other.

Moreover, the concept of MAINTENANCE

STRATEGY DEVELOPMENT PROCESS is

defined by IOF as a process to produce a maintenance

strategy specification, describes the process to

produce a maintenance strategy for a maintainable

item, and by (Montero Jiménez et al., 2021) as

process subclass, which includes all activities and

sub-processes to select the right maintenance strategy

to apply for the different failure modes of a physical

equipment.

Finally, the PROGNOSTIC PROCESS is only

defined by (Montero Jiménez et al., 2021) as a

process performed on a physical equipment by a

predictive maintenance module to estimate the time

to a future failure of a physical equipment or one of

its components.

All these concepts must be then integrated, to be

as exhaustive as possible in the taxonomy, taking into

account the general classification of the maintenance

processes from the standards that can be taken as a

reference: for example, MIMOSA OSA-CBM, a

standard architecture for moving information in a

condition-based maintenance system, or the (BS EN

17007, 2017) reporting a generic description of the

maintenance processes, as management, action and

support processes.

6 CONCLUSIONS

Semantic interoperability is becoming the new

bottleneck for companies willing to exploit the full

potentialities of new technologies in exchanging

information. Indeed, semantic interoperability does

refer to the capability of preserving the meaning of

concepts when several systems talk each other. The

effect of idiosyncrasies in ontology development is

not only a matter to ease IT development, but hugely

impacts on decision-making in general and,

specifically for this work, for maintenance, and,

consequently, for the whole organization. Hence,

fixing the semantics becomes a cornerstone to share

the meaning underlying various concepts on which

decision-makers judge decisions. A first step towards

the formalisation of a domain-specific ontology is the

definition of a taxonomy of concepts which allows to

characterise the features of entities.

Therefore, it is the goal of this research work to

pave the way towards a unified BFO-compliant

taxonomy for maintenance-related applications. On

the one hand, the selection of BFO depends on its

diffusion as world-wide recognised, normative-

supported top-level ontology. On the other hand, its

application to maintenance is due to the new role

maintenance is nowadays experiencing in gluing the

shopfloor, and related data, with mid to high level

decision-making, and vice versa as decisions to be

made concrete.

The performed analysis is based on a review of

the already existing ontologies that are already BFO-

compliant as well as international standards, which

already represent an agreed-upon vocabulary.

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

225

The result of the analysis is an aid to fix which

concepts are relevant to formalise ontologies in the

maintenance domain.

Future works include first the semantic validation

by interviewing other academic experts and industrial

practitioners. Then, after the formalisation of the

relationships between entities so to enable the

KARMA ontology reasoning and make inference,

ontology evaluation tools will be used to identify

formal pitfalls in the final ontology release.

The first maintenance subdomain to tackle will be

the health assessment to achieve automatic

diagnostics for failures. Furthermore, this will be

extended to include both production-aware health

state definition of machine, thus influenced by the

load, as well as machine-aware scheduling, so to

account for the health states when schedule

production activities.

REFERENCES

Acerbi, F., & Taisch, M. (2020). A literature review on

circular economy adoption in the manufacturing sector.

Journal of Cleaner Production, 123086.

https://doi.org/10.1016/j.jclepro.2020.123086

Ameri, F., Sormaz, D., Psarommatis, F., & Kiritsis, D.

(2021). Industrial ontologies for interoperability in

agile and resilient manufacturing. International Journal

of Production Research, 1–22.

https://doi.org/10.1080/00207543.2021.1987553

Arp, R., Smith, B., & Spear, A. D. (2015). Building

ontologies with basic formal ontology. Mit Press.

BS EN 17007. (2017). Maintenance process and associated

indicators. BSI Standards Publication.

Chen, J., Hu, Z., Lu, J., Zheng, X., Zhang, H., & Kiritsis,

D. (2022). A Data-Knowledge Hybrid Driven Method

for Gas Turbine Gas Path Diagnosis. Applied Sciences,

12(12), 5961.

Franciosi, C., Voisin, A., Miranda, S., Riemma, S., & Iung,

B. (2020). Measuring maintenance impacts on

sustainability of manufacturing industries: from a

systematic literature review to a framework proposal.

Journal of Cleaner Production, 260, 121065.

Franciosi, C., Roda, I., Voisin, A., Miranda, S., Macchi, M.,

& Iung, B. (2021, September). Sustainable

Maintenance Performances and EN 15341: 2019: An

Integration Proposal. In IFIP International Conference

on Advances in Production Management Systems (pp.

401-409). Springer, Cham.

Gruber, T. R. (1993). A translation approach to portable

ontology specifications. Knowledge acquisition, 5(2),

199-220.

Hodkiewicz, M., Klüwer, J. W., Woods, C., Smoker, T., &

Low, E. (2021). An ontology for reasoning over

engineering textual data stored in FMEA spreadsheet

tables. Computers in Industry, 131, 103496.

https://doi.org/10.1016/j.compind.2021.103496

Holgado, M., Macchi, M., & Evans, S. (2020). Exploring

the impacts and contributions of maintenance function

for sustainable manufacturing. International Journal of

Production Research, 58(23),7292–7310.

https://doi.org/10.1080/00207543.2020.1808257

Iung, B., & Levrat, E. (2014). Advanced Maintenance

Services for Promoting Sustainability Advanced

Maintenance Services for Promoting Sustainability.

Procedia CIRP, 22(April 2015), 15–22.

https://doi.org/10.1016/j.procir.2014.07.018

Izza, S. (2009). Integration of industrial information

systems: From syntactic to semantic integration

approaches. Enterprise Information Systems, 3(1),1–

57. https://doi.org/10.1080/17517570802521163

Jasiulewicz-Kaczmarek, M., & Gola, A. (2019).

Maintenance 4.0 technologies for sustainable

manufacturing-an overview. IFAC-PapersOnLine,

52(10), 91–96.

Karray, M. H., Ameri, F., Hodkiewicz, M., & Louge, T.

(2019). ROMAIN: Towards a BFO compliant reference

ontology for industrial maintenance. Applied Ontology,

14(2), 155–177. https://doi.org/10.3233/AO-190208

Liyanage, J. P. (2007). Operations and maintenance

performance in production and manufacturing assets:

The sustainability perspective. Journal of

Manufacturing Technology Management, 18(3), 304–

314.

May, G., Cho, S., Majidirad, A., & Kiritsis, D. (2022). A

Semantic Model in the Context of Maintenance: A

Predictive Maintenance Case Study. Applied Sciences,

12(12), 6065.

Montero Jiménez, J. J., Vingerhoeds, R., Grabot, B., &

Schwartz, S. (2021). An ontology model for

maintenance strategy selection and assessment. Journal

of Intelligent Manufacturing.

https://doi.org/10.1007/s10845-021-01855-3

Niekamp, S., Bharadwaj, U. R., Sadhukhan, J., &

Chryssanthopoulos, M. K. (2015). A multi-criteria

decision support framework for sustainable asset

management and challenges in its application. Journal

of Industrial and Production Engineering, 32(1), 44–

57. https://doi.org/10.1080/21681015.2014.1000401

Noy, N., & McGuinness, D. L. (2001). Ontology

development 101. Knowledge Systems Laboratory,

Stanford University, 2001.

Panetto, H. (2007). Towards a classification framework for

interoperability of enterprise applications. International

Journal of Computer Integrated Manufacturing, 20(8),

727–740. https://doi.org/10.1080/09511920600996419

Panetto, H., Dassisti, M., & Tursi, A. (2012). ONTO-PDM :

Product-driven ONTOlogy for Product Data

Management interoperability within manufacturing

process environment. Advanced Engineering

Informatics, 26(2), 334–348.

https://doi.org/10.1016/j.aei.2011.12.002

Polenghi, A., Roda, I., Macchi, M., & Pozzetti, A. (2021).

Multi-attribute Ontology-based Criticality Analysis of

manufacturing assets for maintenance strategies

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

226

planning. 17th IFAC Symposium on Information

Control Problems in Manufacturing INCOM 2021,

54(1), 55–60.

https://doi.org/10.1016/j.ifacol.2021.08.192

Polenghi, A., Roda, I., Macchi, M., & Pozzetti, A. (2022).

Ontology-augmented Prognostics and Health

Management for shopfloor-synchronised joint

maintenance and production management decisions.

Journal of Industrial Information Integration, 27,

100286. https://doi.org/10.1016/j.jii.2021.100286

Polenghi, A., Roda, I., Macchi, M., Pozzetti, A., & Panetto,

H. (2022). Knowledge reuse for ontology modelling in

Maintenance and Industrial Asset Management.

Journal of Industrial Information Integration, 27,

100298. https://doi.org/10.1016/j.jii.2021.100298

Spyns, P., Tang, Y., & Meersman, R. (2008). An ontology

engineering methodology for DOGMA. Applied

Ontology, 3(1–2), 13–39.

Suárez-Figueroa, M. C., Gómez-Pérez, A., & Fernandez-

Lopez, M. (2015). The NeOn Methodology framework:

A scenario-based methodology for ontology

development. Applied Ontology, 10(2), 107–145.

Szejka, A. L., & Junior, O. C. (2017). The Application of

Reference Ontologies for Semantic Interoperability in

an Integrated Product Development Process in Smart

Factories. Procedia Manufacturing, 11, 1375–1384.

https://doi.org/10.1016/j.promfg.2017.07.267

Vernadat, F. B. (2010). Technical, semantic and

organizational issues of enterprise interoperability and

networking. Annual Reviews in Control, 34(1), 139–

144. https://doi.org/10.1016/j.arcontrol.2010.02.009

Vyvyan, E., 2006. Lexical Concepts, Cognitive Models and

Meaning-Construction. In Cognitive Linguistics 17 (4):

491-534.

Wu, Z., Liu, W., & Nie, W. (2021). Literature review and

prospect of the development and application of FMEA

in manufacturing industry. The International Journal of

Advanced Manufacturing Technology, 112(5), 1409–

1436. https://doi.org/10.1007/s00170-020-06425-0

Table 1: Failure management-related concepts.

NON-

ONTOLOGICAL

RESOURCES

ONTOLOGICAL RESOURCES

CONCEPT STANDARDS IOF

KARRAY

ET AL.,

2019

MONTERO ET AL., 2021

POLE

NGHI

ET

AL.,

2022

FAILURE

CAUSE

Set of circumstances

that leads to failure

(IEC 60812 : 2018);

Circumstances

associated with design,

manufacture,

installation, use and

maintenance that have

led to a failure (ISO

14226 : 2006); The

circumstances during

design, manufacture or

use which have led to a

failure (IEC 60300-3-

11 : 2009)

A BFO:Occurrent that have

led to a MNT:

State_Of_Failure_Machine

or MNT:

State_Of_Failure_Compone

n

t

-

A CCO: Descriptive

Information Content Entity that

describes the cause of a failure

mode. It is about a CCO: Cause

that can lead to an OMSSA:

Failure -

FAILURE

MODE

Manner in which

failure occurs (IEC

60812 : 2018);

The effect by which a

failure is observed on

the failed item (ISO

14226 : 2006); one of

the possible states of a

failed item for a given

required function (IEC

60300-3-11 : 2009).

The consequence of

the mechanism

through which failure

occurs (MIL-STD-

721-C)

Def. A BFO: Realizable

Entity that is the

UNK:Consequence of a

MNT: FailureMechanism

through which the MNT:

StateOfFailue occurs -

It is a CCO: Descriptive

information content entity that

describes a failure of an item

and the corresponding fault that

can cause the failure. It is an

output of the Failure Modes,

Effects, and Criticality Analysis

(FMECA)

A

BFO:R

ealizabl

e Entity

that

inheres

in a

ORMA

:Comp

onen

t

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

227

Table 1: Failure management-related concepts (cont.).

NON-

ONTOLOGICAL

RESOURCES

ONTOLOGICAL RESOURCES

CONCEPT STANDARDS IOF

KARRAY

ET AL.,

2019

MONTERO ET AL., 2021

POLE

NGHI

ET

AL.,

2022

FAILURE

EFFECT /

CONSEQU

ENCE

Consequence of a

failure, within or

beyond the boundary

of the failed item (IEC

60812 : 2018);

outcome of an event

affecting objectives

(IEC 61882 : 2016) - -

A CCO: Descriptive

Information Content Entity that

describes the impacts of a

failure in terms of safety,

environment, and operation. It is

normally measured by rank. It is

about a CCO: Effect that results

from an OMSSA: Failure -

TRIGGERI

NG EVENT

-

A

BFO:process

resulting in

an action.

A BFO: process boundary that is

the starting point for a

maintenance action -

INSPECTI

ON

TRIGGERI

NG EVENT -

A BFO:Process_Boundry

boundary of an UNK:

Inspection_Action that

begins a MNT:

Maintenance_Process.

An inspection event that

causes a maintenance

p

rocess to be initiate

d

-- -

MAINTEN

ANCE

TRIGGERI

NG EVENT -

Maintenance_Triggering_E

vent = Def. A

BFO:ProcessBoundary that

begins a

MNT:MaintenanceProcess

through the production of a

MNT:Maintenance_Work_S

p

ecification - - -

OPERATIN

G

TRIGGERI

NG EVENT -

A BFO:Process_Boundary

in the operation of a IOF:

Manufacturing Process that

begins a MNT:

Maintenance_Process.

An operational event that

causes a maintenance

p

rocess to be initiate

d

-- -

DEGRADA

TION

THRESHO

LD

OVERSHO

OT - - -

A COMSA: triggering event

subclass related to predictive

maintenance strategy. It is

prescribed by a degradation

assessment module of a

p

redictive maintenance system. -

FAILURE

FORECAS

T - - -

A COMSA: triggering event

subclass related to predictive

maintenance strategy. It is

prescribed by a failure forecast

module of a predictive

maintenance system. -

FAULT

DETECTIO

N - - -

A COMSA: triggering event

subclass related to predictive

maintenance strategy. It is

prescribed by a fault detection

module of a predictive

maintenance system. -

EI2N 2022 - 16th IFAC/IFIP International Workshop on Enterprise Integration, Interoperability and Networking

228

Table 1: Failure management-related concepts (cont.).

NON-ONTOLOGICAL

RESOURCES

ONTOLOGICAL RESOURCES

CONCEPT STANDARDS IOF

KARRAY ET

AL., 2019

MONTERO ET AL., 2021

POLE

NGHI

ET

AL.,

2022

FIXED

TIME

RECOMME

NDATION - - -

A COMSA: triggering event

subclass related to preventive

maintenance strategy. It is

p

rescribed by a preventive

maintenance plan. A

recommendation based on

fixed operation intervals or

from fixed basic inspections

triggers a maintenance action. -

FAILURE

(FAILURE

EVENT)

Loss of ability to

p

erform as required

(ISO 14224 : 2016)

a BFO: terminal process

b

oundary where some

p

rocess which realizes the

initial phase of a material

p

roduct production process

p

lan ceases

A BFO:process that

p

recedes the

ROM:State of

Failure

An OMSSA: triggering event

subclass related to corrective

maintenance strategy. The

impossibility of an item to

p

erform its intended function

triggers a maintenance actio

n

-

STATE - -

A BFO:Process in

which some

BFO:independent

continuant endures

and one or more of

the dependent

entities it bears does

not change in kind

or intensity - -

FUNCTION

AL

FAILURE

A state in which a

p

hysical asset or system

is unable to perform a

specific function to a

desired level of

p

erformance (SAE JA

1012)

A state in which a physical

asset or system is unable to

p

erform a specific function to

a desired level of

p

erformance - -

STATE OF

FAILURE - -

A ROM:state

during which a

CCO:artifact is

unable to perform

its BFO:functio

n

STATE OF

FAILURE

COMPONE

NT -

Def. A IOF:State in which

some IOF:component

endures and does not meet a

requirement.

Describes when a component

is in a failed state - - -

STATE OF

FAILURE

MACHINE -

Def. A IOF:State in which

some IOF:machine endures

and does not meet a

requirement.

Describes when a machine is

in a failed state - - -

STATE OF

DEGRADAT

ION -

Def. A IOF:State in which

some IOF:component

endures and is moving

towards non-conformity.

Describes when a component

is in the process of degrading

A ROM:state

during which a

CCO:artifact bears

an undesirable

BFO:quality or

BFO:function. - -

Semantic Interoperability in Industrial Maintenance-related Applications: Multiple Ontologies Integration towards a Unified BFO-compliant

Taxonomy

229