Green Manufacturing Framework Development and Implementation

in Industry

M-Kh. R. Umarkhadzhiev

1a

and Z. M. Tazbieva

2

1

Kadyrov Chechen State University, 32 Sheripova Street, Grozny, Russia

2

Grozny State Oil Technical University, Kh. Isaev Ave., Grozny, Russia

Keywords: Green Manufacturing, development, recycling, nature pollution, green technology, nature clean up.

Abstract: The automotive industry covers every country on our planet. But only a few of them are engaged in waste

processing. The introduction of green production is one of the salvations of our planet. What is green

production and how to implement it in the automotive industry. This is what will be discussed in this scientific

work.

1 INTRODUCTION

Green production, also called environmentally safe

production, environmental environment-oriented

production and So Further. it comprehensive

consideration environmental impact and efficiency

use resources contemporary production models. Goal

"Green production" is in minimum negative impact

on the surrounding Wednesday and maximum usage

resources from development product, production,

packaging, transportation, usage and processing

product. ultimate goal "green production" consists in

volume, to coordinate development enterprises and

social benefit.

At present, the manufacturing industry is

developing rapidly. However, it also produces a ton

of garbage and resource consumption. Nowadays the

idea of sustainability and environmental friendliness

is very popular. "Green production" is a problem that

every manufacturer must solve. taken into

consideration. However, in fact, many manufacturing

companies would not like to apply green production

and are not able to apply it. The reasons are mainly

that those companies misunderstand green

manufacturing and the lack of green technology

manufacturing. Therefore, the author will analyse it

and develop a new structure so that readers can better

understand green production and learn more practical

experience about green production.

a

https://orcid.org/0000-0001-9141-3668

The new structure of "Green Production" includes

the principles of 4R and five core technologies. The

implementation of this new structure will also be

present in the automotive and electronics industries.

This thesis is important for the author himself due to

the fact that the Chinese government planned to

reduce the environmental problem by the full-scale

use of "green production" (Association for

Manufacturing Excellence, 2007).

The first step towards green manufacturing is

green design. It requires consideration of

environmental influences in the design process. For

example, recoverability, manufacturing complexity,

the green level of the material used. The enterprise

must also apply some advanced manufacturing

systems to reduce waste, waste and improve

production efficiency. Maintenance can extend the

life of the product. It is better to consider the product

design process in time. After "green" design, attention

should be paid to "green" production. The company

must use new technologies to reduce resource

consumption and emission losses. The green package

requires the manufacturer to use an appropriate

package to achieve sustainability through design and

material selection. The refined product must

eventually turn into a reusable resource. Green

recovery technology helps the company return

defective products to their previous state close to new

products.

306

Umarkhadzhiev, M. and Tazbieva, Z.

Green Manufacturing Framework Development and Implementation in Industry.

DOI: 10.5220/0011570900003524

In Proceedings of the 1st International Conference on Methods, Models, Technologies for Sustainable Development (MMTGE 2022) - Agroclimatic Projects and Carbon Neutrality, pages

306-311

ISBN: 978-989-758-608-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MATERIALS AND METHODS

Green production" has received a lot of attention from

experts and scientists, where some measures have

been taken. Although the literature on green

production is theoretically focused on key issues,

including the implementation of the mechanism, as

well as the information system, and empirically

quantitative researchers on some data in surveys,

when it comes to status around the world, there are

still many difficulties in green production.

It is very important for society to realize the

importance of Green Production in order to realize

this. It is undeniable that "green production" can be

easily accepted and supported by the population,

government and non-profit organizations. However,

the theme of "Green Production", enterprises, plays a

key role in the process of consciousness, which is

long and continuous.

In developing countries such as China, most

enterprises do not consider "green production" with

little concern for resource consumption and

environmental emissions. Many corporations viewed

"green manufacturing" as an environmental burden

that would not bring any efficiency or even some

trouble. In fact, even some of those corporations that

have passed the ISO 14001 Environmental

Management System authentication, the ultimate goal

of which is simply to meet the requirements of the

environment department, were not aware of the value

of green production.

However, some businesses are suffering direct

economic damage due to lack of resources,

deteriorating pollution and an ever-growing barrier to

green trade. For example, two EU regulations, ROHS

(Restriction of the Use of Certain Hazardous

Substances) and WEEE (Waste Electrical and

Electronic Equipment), mechanical and electrical

products from China. At the same time, industries

affected by Green Trade Barriers are starting to find

solutions to gradually shift our Green Production

while these unaffected corporations remain

indifferent to Green Production. On the contrary, a

group of leading companies in the world considers

"green production" as one of the priority development

strategies, in which many multinational enterprises

have set specific strategic goals for "green

production", striving to be green leaders and set

environmental criteria for the entire industry.

Obviously, awareness of Green Production is a key

issue in its implementation. Green production is well-

tuned images for the corporation, the formation of a

green brand and the promotion of its market

competitiveness in the market, which will ultimately

create more profits.

Cost is one of the inevitable problems that green

manufacturing has faced since the development of

green products, and the application of new green

manufacturing, methods require some cost without

instant benefit, so some corporations may consider it

unprofitable, which limits implementation to some

extent. Green Manufacturing.

In fact, if new methods to help reduce energy and

resource consumption are put in place, costs will be

reduced directly, which will increase economic

benefits in a short time. From a long-term

perspective, once consumers become more

sympathetic towards sustainable products that turn

eco-efficiency into marketing benefits, the company's

economic profits will also increase. Like other

advanced model manufacturing, the introduction of

green manufacturing seems expensive at first, but

brings long-term benefits. Thus, corporations need to

make ends meet and intelligently plan the

implementation of "green production". Not

surprisingly, these days almost all leaders in Green

Manufacturing are international tycoons (Chinese

government specialized planning).

Up until today, green production methods are not

thorough enough, because the critical idea is green

production is a specific green production technology,

while most of the existing research is focused on the

study of theories and concepts, that is, such research

has not delved into industrial practice. production,

there is a particular lack of green technologies for

each individual industry.

The introduction of green manufacturing in

corporations should depend on the leadership of the

market, as well as laws, regulations, financial policies

and standard specifications that are mandatory. Take

the automotive industry as a model, green mobile

devices such as hybrid cars and electric vehicles have

developed rapidly in the United States, while in

China, it has developed at a slower pace, which is due

to the fact that so far, when it comes to the automotive

industry in In China, cost reduction is still in first

place due to the lack of relative preferential policies

to boost corporate enthusiasm. Another epitome is car

refurbishment, which is currently well developed in

Europe and America, but still slowly developed in

China because China's laws forbid the privacy of used

mobile phone recycling businesses. Thus, the

implementation of Green Production requires

coordinated support from laws and regulations,

financial policies along with customary standards.

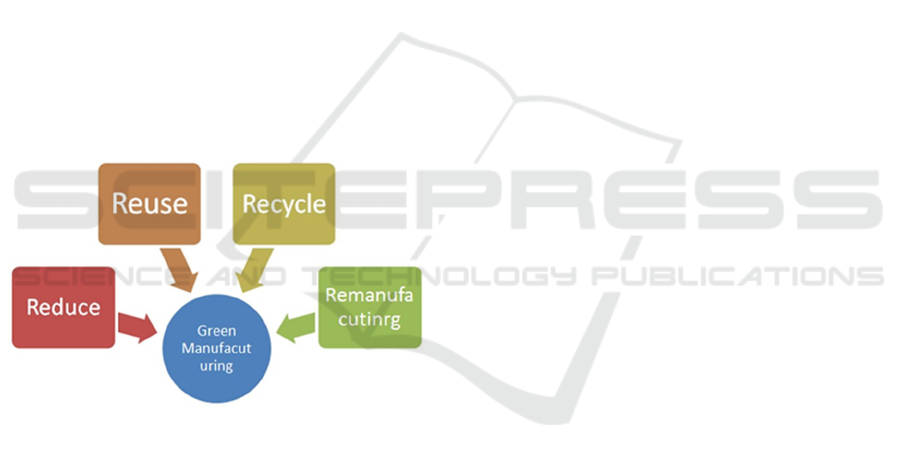

The main ideas of "green production" refer to the

implementation of the "4R" theory, i.e., reduce, reuse,

Green Manufacturing Framework Development and Implementation in Industry

307

recycle and remanufacture. Reducing requires

reducing the consumption of resources, including

energy, as well as the release of waste, which can help

reduce environmental pressure, resulting in less harm

to human health (Treehugger, 2015).

Reuse requires the reuse of products or

components in order to extend the life of the product

to reduce waste. Recycling requires products to be

able to turn into reusable resources rather than waste

that can no longer be used. There are two recycling

methods, one is recycled at the same level, which

means that the waste can be recycled to produce the

same kind of new products, the other is recycling,

when the waste is transferred to the raw materials of

other products.

Remanufacturing is the approach of restoring

dragged products back to those that were close to new

products after a series of processes including

disassembly, cleaning, inspection, refurbishment,

repair, and refurbishment.

Reproduction is an approach to restoring cleaned

products to those that were close to my products after

a series of processes, including disassembly,

cleaning, inspection, refurbishment, repair, and

refurbishment.

Figure 1: The principle of "green production" 4R.

3 RESULTS AND DISCUSSION

The automotive industry, the epitome of the industry,

includes almost all other industries such as

machinery, foundry, chemical, energy, electronics,

rubber, and leather. In other words, the level of the

automotive industry in a country can be thought of as

the general level of the industry, the peculiarity and

significance of which makes all advanced

manufacturing technologies enter it for the first time,

such as Lean Manufacturing, Six Sigma, etc. Thus,

Green Manufacturing in the automotive industry

plays a vital role. important role in sustainable

development.

At present, the automotive industry has become an

indispensable branch of modern construction, which

plays a significant role in the national economy.

However, since the traditional vehicle industry is

based on a large consumption of resources and

energy, with the increase in the number of cars

produced, a lot of energy and steel is used, while the

constant increase in scrapped vehicles leads to heavy

pollution of land, air and water. Faced with

environmental pressure as well as resource scarcity,

striving for long-term development, reuse of

resources and energy is of great importance as a

prerequisite for continuous sustainable industrial

development.

Products and production are the two main areas of

the negative environmental impact of the automotive

industry, where the former can be reduced by cutting

down emissions and energy consumption, which can

be divided into green design, green production and

green package in five main methods, while the latter

can be minimized through equipment and structural

dismantling and reuse, also known as green recycling

and green manufacturing.

Currently, waste-free recycling methods are being

promoted in the EU and the US, where new

environmentally friendly materials are widely used.

The most famous automobile factories are actively

implementing "Green Manufacturing" in research and

practice, and regularly publish their resource and

environmental reports to show their achievements to

the public.

In the automotive industry, special Green

Manufacturing technologies are popular. For

example, Austenitic bainitic ductile iron has replaced

hardened steel for vehicle manufacturing. Spiral

bevel rear axles in automotive corporations such as

GM, reducing 50% energy consumption and 40%

cost. In addition, Chevrolet has developed a new type

of car engine that can be recycled and reused, which

can be used in 43% of the engine is directly

dismantled, and most of the components can be

reused (Rusinko, 2021).

To study "Green Production" in the automotive

industry, the entire PLC and automobile production

processes should be known at the beginning. The

whole PLC is shown in Figure 2, including research

and feedback on market requirements, product

development and design, organization of production

resources, production resources delivery, component

production, production equipment, product sales,

product maintenance and repair, product disposal,

product recycling, dismantling, reuse of components,

recovery and regeneration of materials.

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

308

Figure 2: The life cycle of an automobile "green

production" product.

Figure 3: Stamping process and problem.

The stamping process includes banking, pre-

forming, heating, stamping, pressure holding,

descaling, laser cutting and oil coating, where die-cut

sheet metals to produce components such as car

bodies, bodies, chassis, in time what problems may

occur like sheet metal consumption as well as noises.

Pressure shop noise can be eliminated in two

ways: proactive and passive. The former is to manage

from resource, i.e., use low noise equipment, while

the latter is to minimize the impact of noise during its

delivery. The initiative path is complex with

difficulties, but with the highest efficiency. For

example, to replace the hydraulic pressure punching

machine will greatly reduce the noise. Passive

approaches mainly include absorption, attenuation,

isolation and attenuation with silencers, acoustic

ceilings and walls, soundproofing coating, baffle and

shock absorber (Guo, 2018).

The welding process is mainly composed of base

plate, side body, front side panel, stringer, frame

assembly, car body, car door, front cover and black

door, where the motor transport system inside each

step and car body with completed are delivered to the

paint shop transport line. All six assemblies of the

engine, transmission, vehicle axle, vehicle frame,

vehicle body and carriage are involved in the process.

The solution to reduce the resource consumption of

the ownership process is to use efficient and energy-

saving equipment such as MIG and MAG, advanced

ownership methods such as electric resistance

welding, arc welding, friction welding, laser welding,

braze welding, advanced transportation equipment,

such as a laser automated driving system and energy

providers (for example, to provide multiple

exchanges with cooling towers). Environmental

issues in the process of ownership concentrate on

recycling and cleaning of welding fumes, adjusted

sealing noise treatment during inspection, and noise

suppression device equipment.

Figure 4: Welding process and problem.

The coating process consists of pre-treatment,

electrophoresis, electrophoresis drying oven,

electrophoretic polishing, sealant, PVC coating,

sealant oven, floating coating, floating coating oven,

finishing coating and finishing coating oven. Between

the various processing steps, hanging chains are used

for transport and hoists are used for connection. The

main environmental problem in this process is the

generation of a large amount of liquid waste, which is

a key issue of green improvement. Such liquids

should be treated by a series of chemical reactions

such as acid-base neutralization, coagulation,

sedimentation and dephosphorization, after which it

enters the management of hazardous substances, as

well as water recycling (Huang, 2020).

The final assembly process is the last process of

production, storage and operation of vehicles of the

transportation line, trim assembly line, chassis

assembly line, final assembly line, final inspection

line, dashboard assembly line and car door assembly

line. Green improvements in this process include

treatment of contaminated water, sludge testing for

recirculating water in the assembly shop, off-gases

from static fan speed measurement, and disposal of

packaging and assembly solids.

Traditional automotive recycling is focused on the

recycling of raw materials, multi-components

disposed of by destructive dismantling, which results

in low reuse costs, since the dismantled components

are simply separated and reassembled without

effective separation, where materials with a high

reuse value, such as aluminium and magnesium, are

waste, in while other materials that are not easily

disposed of, such as plastic, rubber, and waste oil, are

Green Manufacturing Framework Development and Implementation in Industry

309

stockpiled, dumped, and incinerated if desired,

resulting in severe pollution of soil and water

resources. Often found in underdeveloped areas.

There was a time when a number of environmental

problems arose in China due to the untimely

processing of the method, which caused inefficient

use of resources, low profits from processing, as well

as unbalanced development of industries. However,

green recycling benefits from recycling and reduce

environmental damage through technology

dismantling and maximizing management (Zhang,

2011).

Traditional automotive recycling is focused on

recycling raw materials, multi-components are

disposed of by destructive disassembly, resulting in

low reuse costs as dismantled components are simply

separated and reassembled without efficient

separation, where materials with high reusable value,

such as aluminium and magnesium, are waste, while

other materials that are not easily disposed of, such as

plastic, rubber, and waste oil, are stockpiled, dumped,

and incinerated if desired, resulting in severe

pollution of soil and water resources. Often found in

underdeveloped areas. There was a time when a

number of environmental problems arose in China

due to untimely recycling methods, which caused

inefficient use of resources, low profits from

recycling, and unbalanced development of industries.

However, green recycling benefits from recycle and

reduce environmental damage through disassembly

technology and maximizing management.

A car is an assembly of thousands of components

made from different materials. materials. Thus,

simple remelting has little to do with green scrap

recycling. a vehicle that requires scientific

approaches to disassemble them and handle them

accordingly.

The green recycling process in the automotive

industry includes acquisition, disassembly, cleaning,

testing and reuse, where the dismantling process

plays a vital role. In the US, car stripping was a large

industry that employed about 15,000 corporations

stripping components from vehicles, selling valuable

car parts to manufacturers for fixing and

refurbishment, and then reusing them. When the

valuable parts are dismantled, the car frames will be

smashed in the spray guns, after which the magnetic

separation is supplied to separate the steels.

The disassembly process of green recycling is

very important, whose recycling value can only be

illustrated after scientific disassembly with the

premise of reuse, rework, and regeneration of

component materials. In this section, the green

recycling of the automotive industry will be

introduced in terms of the dismantling and recycling

of materials.

There are 3 types of disassembly: complete

disassembly, partial disassembly, and target.

Complete disassembly means the careful

disassembly of a product into every detail of a

component, which is often used in theoretical

studies instead of practical applications.

Partial disassembly refers to the dismantling of

a portion of a product's components, usually out

of consideration for cost savings. When

dismantling a certain component, if the cost of

recycling the remaining components is less than

the cost of dismantling, we consider it useless

continue dismantling as recycled material; or

when the remaining components are in the same

materials, we stop disassembling and recycle

them entirely. This method is widely used in

practice.

Purposeful disassembly refers to dismantling

between or within certain components, mainly

due to reuse or environmental factors. For

example, the period of use of a product when its

component part has failed and requires

disassembly for repair or discard, while other

parts or components may still be useful for reuse

or replacement; or when the disposal of a part or

component causes great harm to the

environment, they should be considered as

target components to be disassembled. This

approach is also widely used in practice.

Disassembly level decisions depend on economic

evaluation. As the steps increase, the amount of

components received and recycled increases, which

leads to an increase in the profit from dismantling and

recycling, while the cost of the landfill decreases.

However, for the components are difficult to separate,

the processing profit is low, and then with low

economic value. Thus, when comparing the profit

from processing and the cost of dismantling, when the

economic effect decreases, the dismantling process

should be stopped (Li, 2021).

Let's start with the economics of dismantling the

product, the cost of recycling, and easily dismantled

components and equipment, when products are billed

with the premise of not affecting function during

design, aiming for fewer disassembly steps and fewer

connections for ease of disassembly, which is one of

the requirements of green design. Here, as we can see,

each process in "Green Production" is closely related

to each other, which reveals the integration of green

production (Flame Retardants, 2001).

Recycling at the level of parts and components

contributes greatly to environmental sustainability.

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

310

Production in the automotive industry, but with some

difficulties in implementation. In developed countries

such as the US, vehicle components are reused unless

they are expired or damaged. In Japan, 30% of

salvaged car components are reused and 50% are

recycled as raw materials. In Germany, the level of

recycling reaches even 90%. In contrast, it is illegal

in China to recycle parts and components where only

raw materials can be recycled, resulting in an

immature market for remanufactured components or

even belated recovery practices in the automotive

remanufactured industry. Green production is

necessary to maximize green production in the

automotive industry.

4 CONCLUSIONS

First, companies need to know "green production"

before implementing it. According to research and

analysis, the new structure of Green Manufacturing

has been developed by the 4 R production principles

: reduce, reuse, recycle, and recycle and five core

technologies: green technology design, green

manufacturing technology, green packaging

technology, green recycling with green recovery

technology. "Green production" is not only a theory,

but also a technology. Patterns Green production

differs across industries. The automotive industry is

selected to show the implementation of "Green

Manufacturing". Under the new structure, here I

present green design, green manufacturing, green

packaging, green recycling and green recovery in the

automotive industry. Each part is in the light of the

4R principles. The reason for choosing the

automotive industry is that it is so popular nowadays

with huge performance. This industry also has a huge

impact on other industries. For example, lean

manufacturing, developed in the Toyota automobile,

is now the epitome of almost every industry.

Therefore, the value of introducing Green

Manufacturing in this industry is excellent.

In the automotive industry, most of the problems

with "green production" occur in the production

(especially painting) and the restoration stage. The

automotive industry has a very practical method and

technology in restoration.

The structure and technology presented in this

study have a very high degree of generality. For

example, a tea bag manufacturer might start to

implement green manufacturing. This thesis will help

raise the awareness of decision makers about green

production. He will also guide them to think about

"green production" in reduction, reuse, recycling and

recovery. Perhaps they will find methods to reduce

and reuse package.

In the future, many governments will set high

budgets for pollutant emissions. The use of "green"

production is the key to the survival of companies,

and this article will greatly help these companies.

REFERENCES

Association for Manufacturing Excellence, 2007. Green

Manufacturing: Case Studies in Lean and

Sustainability. Productivity Press.

Chinese government specialized planning. Green

Manufacturing technology development.

http://www.most.gov.cn/tztg/201204/W020120424330

209534599.pdf.

Treehugger, 2015. World Energy Use over the Last 200

Years. http://www.treehugger.com/fossil-fuels/world-

energy-use-over-last-200-years-graphs.html.

Rusinko, C. A., 2021. Green manufacturing: An evaluation

of environmentally sustainable manufacturing practices

and their impact on competitive outcomes. IEEE Trans.

Eng. Manager. 54(3). pp. 445-454.

Guo, H., 2018. The research of key technology about

recycling and remanufacturing in parts of End-of-Life

Vehicle. A Thesis Submitted to Chongqing University

in Partial Fulfilment of the Requirement for the degree

of Master of Engineering. College of Mechanical

Engineering Chongqing University.

Huang, J. Y., Zhu, H. Y., 2020. Analysis of Implementation

the Key Technologies of Green Manufacturing. Applied

Mechanics and Materials. 522-524. pp. 787-790.

Zhang, Y., 2011. Research on Development & Application

of Information Resources of Green Manufacturing

Enterprise. IEEE.

Li, J., Tian, B., Liu, T., Liu, H., Wen, X., Honda, Shinichi,

2021. Status quo of e-waste management in mainland

China. Journal of Material Cycles and Waste

Management.

Flame Retardants, 2001. DG Environment Video 2000,

cited by AEA technology, January 2001.

http://www.guokr.com/article/439186/.

Green Manufacturing Framework Development and Implementation in Industry

311