Analysis of the Reliability Compliance with Delivery Time

E. Maksimova

a

Russian University of Transport RUT (MIIT), Moscow, Russia

Keywords: Reliability, risks, operational difficulties, delivery time, technological operations.

Abstract: The practical application of the idea of sustainable freight transportation requires improving the methods of

accounting for possible deviations from the technological standards at all stages of the transportation process,

increasing the reliability of meeting the transportation deadlines and assumed contractual obligations. This

article presents an analysis of the reliability of compliance with freight and empty car delivery time based on

a retrospective analysis of statistical data. The article provides an analysis of the number of shipments that

arrived at the stop station past their delivery time, the reasons for freight delays on route and the number of

claims filed, using one of the technological polygons of the transportation process management for a case

study.

1 INTRODUCTION

Railroads are one of the key modes of transportation

worldwide thanks to their unique characteristics, such

as high capacity, safety, reliability, punctuality and

environmental friendliness. By the end of 2019, all

rail systems in the world had about 1.1 million

kilometers of track and transported more than 4.1

trillion passenger-km and 11 trillion ton-km of

freight. However, these systems often suffer from

various malfunctions that are profoundly detrimental

to the efficiency of their production activities (Hong,

2019). Consequently, in recent years the challenges

of how to better protect railway systems and reduce

systemic losses when various disruptions occur have

drawn increasing attention from stakeholders and

researchers.

The efficiency of production activities of transport

companies depends on many factors - the changing

structure of freight flows; competitive advantages

concerning interchangeable types of vehicles;

competition between different private owners;

regional conditions affecting the transportation

process; the presence of restrictions, etc. (Kozlov,

2020). Under current conditions, the train car rolling

stock of operators is often out of sync with the cargo

flows, causing additional shunting and freight work

and often leading to non-compliance with delivery

times.

a

https://orcid.org/0000-0001-6790-3173

Experts estimate that railway stations lose 10-

15% of their productivity due to technological

failures. It is believed that the bottleneck of a

structure is its busiest element. The study

(Timukhina, 2012) presents that the relationship

between the loading of an element and delays it

causes is more complex and ambiguous. Selection of

the elements that cause the greatest vulnerability

should be based on the bottlenecks of a structure or

bottlenecks of a technology.

2 LITERATURE REVIEW

Reliability compliance with delivery time is one of

the most important assets. Various international

studies indicate that the guarantee of reliable delivery

times is a strategic competitive advantage.

Transportation time, as well as the cost of

transportation represent time and money costs in the

global trading system. The study of the reliability of

transportation time compliance is crucial for

understanding the dynamics of time costs, including

in international transportation (Jia, 2020).

The international publications on the importance

of freight transportation reliability are quite few in

number. Reviews of the methods used and the results

obtained in studies of the cost estimation of

transportation time in freight transportation around

94

Maksimova, E.

Analysis of the Reliability Compliance with Delivery Time.

DOI: 10.5220/0011579500003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 94-99

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

the world can be found in (Zamparini, 2007; de Jong,

2009; Feo-Valero, 2011; Report for the Ministry of

Infrastructure and the Environment, Significance,

The Hague, 2013). The study (RAND Europe, SEO

and Veldkamp/NIPO, 2004) is one of the first to

present the value of freight transportation reliability

in the form of standard deviation of transportation

time. The key result in (Significance, VU University,

John Bates Services, TNO, NEA, TNS NIPO and

PanelClix, 2013) is that most of the empirical results

of freight reliability assessment are related to the

proportion of shipments that arrive too late

(sometimes with a minimum delay threshold).

The works (Hague Consulting Group, Rotterdam

Transport Centre and NIPO, 1992) discuss the use of

the factor cost method for the cost estimation of

transportation time. It is argued that the study of the

cost estimate of time for freight transportation is

necessary to determine the "marginal time

transportation costs": transportation costs that will

change as a result of changes in transportation time.

It is a derivative of the total logistics cost function of

transportation time. Total logistics costs are

comprised of transportation personnel costs, fuel and

energy costs, vehicle costs, overhead costs, which are

all costs incurred by carriers and transportation

companies, as well as costs of damage to goods,

interest costs on the value of goods during

transportation and the cost of having a safety reserve

(the last three factors directly affecting the

transportation component in the price of goods).

A number of authors consider the use of

mathematical models to assess the reliability of the

transport process and the creation, on their basis, of

appropriate modules in information management

systems. The use of methods to assess and ensure the

reliability of transportation based on business process

modeling is particularly important for increasing the

competitiveness of transport companies in unstable

economic conditions (Kurganov, 2018).

Studies have appeared recently in the field of

reliability of intermodal transportation, in particular

transportation with the use of railway-automotive and

railway-water transport. According to the goals stated

by many countries, by 2030 30% of freight transport

over 300 km should be transferred from road

transport to other, more environmentally friendly

modes of transport. Most importantly, this

assumption applies to rail transport and water

transport. Rail transport has the best chance of taking

over some of the freight traffic in the coming years.

Rail transport, like water transport, has much

more inertia (larger vehicles and ships used for

transportation, longer transportation times, etc.).

Goods transported by these modes of transport tend

to have a lower cost per tonne than goods transported

by road and air, therefore, the transport component in

the price of goods will be relatively small.

The development of rail transportation depends

on its ability to adapt to a number of market

requirements related to transportation time, cost,

flexibility, information flow and reliability of the

production process. Currently, the main obstacle to

development is its low competitiveness, especially in

relation to road transportation. This is mainly

influenced by low flexibility, limited cost-

effectiveness over long distances, and lack of

reliability, manifested mainly in problems with timely

transportation (Zhao, 2020). The bottleneck may be

an underdeveloped railway connection (Roso, 2013),

the low flexibility of rail transport (Behrends, 2015),

the low quality of railway infrastructure, the use of

different information systems, the reluctance to share

information (Kramarz, 2021), the higher priority of

passenger trains over freight trains, the lack of

integration between transportation tasks and terminal

tasks (Hu, 2019). Such limitations reduce the

reliability of the entire transport system.

Transportation services performed with such

restrictions will not be able to meet the requirements

of modern supply chains, which require a high degree

of flow reliability (Elbert, 2017).

3 MATERIALS AND METHODS

Carriers, operators and owners of railway rolling

stock estimate delivery time through the costs of

providing transportation services. If transportation

time were reduced, vehicles and personnel would be

freed up to perform other productive activities,

resulting in savings in vehicles and labor. Greater

reliability means that the carrier and operator can

have confidence when planning transportation. The

results of foreign researchers obtained to date show

that the value of time related to transport services is

indeed more or less equal to the cost of the vehicle

and labor per hour (de Jong, 2009).

For shippers, the valuation of transportation time

is directly related to the goods themselves. It includes

the working capital invested in the goods during the

time required for transportation (especially important

for high-value goods), the potential reduction in value

of perishable goods during transportation, and the

possibility of disruption of the production process due

to lack of resources or inability to deliver due to lack

of inventory. The two latter factors play a significant

role in assessing the reliability of freight

Analysis of the Reliability Compliance with Delivery Time

95

transportation. Shippers with their own rolling stock

evaluate both the costs of transportation proper and

their component in the cost of goods.

Estimation of violation of cargo delivery time

through train delays using the average delay does not

reflect the full picture. The value of delays increases

slower than the risk of their occurrence. In other

words, reducing the risk of delays by half reduces the

cost of delays by less than half. This provision can be

derived from a simple microeconomic model, where

more and more customers choose sufficient margins

to eliminate late delivery and contractual failure, as

the risk of delay increases (Börjesson, 2011). For

small risks of delay, this phenomenon can also be

caused by low planning costs: the higher the risk of

delay, the more customers find it appropriate to make

contingency plans, including overstating the

necessary norms for bringing in cargo and empty

rolling stock, thereby creating additional reserves of

necessary resources.

Every year more than a billion tons of cargo of

various nomenclature are moved through the Russian

railroad network. The Russian Railways Holding

Company sets itself many objectives, among which

are: increasing production and economic efficiency,

scaling up transportation business, and improving

transportation safety and service quality. However,

for various reasons, including through no fault of the

carrier, there are cases of violation of the technology

of organization of the transportation process and

failure to meet deadlines for delivery of cargoes and

empty cars. All technological violations of

manufacturing processes have a direct impact on the

reliability of cargo delivery time - compliance by

railroads (carriers) with obligations to freight owners

in terms of meeting delivery time in accordance with

the accepted contractual obligations. Reliability is

measured as a percentage and reflects the share of

shipments that arrived without violation of delivery

time.

In the carriage of goods, the carrier assumes

responsibility for the safety of cargo en route, as well

as for the performance of other obligations under the

contract of carriage, including, but not limited to, the

delivery of cargo and empty cars on time. In cases

where the carrier has not fulfilled one or more

obligations, the cargo owners are entitled to file a

claim, specifying what clauses of the contract the

carrier violated and the amount of penalty they want

to recover.

In accordance with federal regulations, the

consignee or consignor may file a claim for damages

in the amount of 6% of the freight charge for each day

of delay, but not more than 50% of the total freight

charge. As a rule, cargo owners unreasonably claim

damages without taking into account various factors

beyond carrier's control, such as cases stipulated by

Article 29 of the Statute on Railway Transport of the

Russian Federation. In such cases the carrier invokes

Article 333 of the Civil Code of the Russian

Federation "reduction of forfeit". In 85% of cases

cargo owners' claims are groundless and claims are

rejected. All cases of violation of delivery time are

considered by a special commission - the working

group.

In accordance with the adopted technology the

railway transport has a fairly wide range of reasons

for freight and empty cars delays, while the number

of delays due to the fault of cargo owners or owners

of private tracks amounts to only 1-2% of the total

number. For clarity, the entire list of causes is

summarized in 7 main reasons, among them are the

following:

− delays due to force majeure;

− track occupancy, non-acceptance, demurrage

and accumulation;

− untimely operations and restrictions;

− waiting, refusal, diverting car traffic from the

shortest routes;

− absence of or waiting for a locomotive;

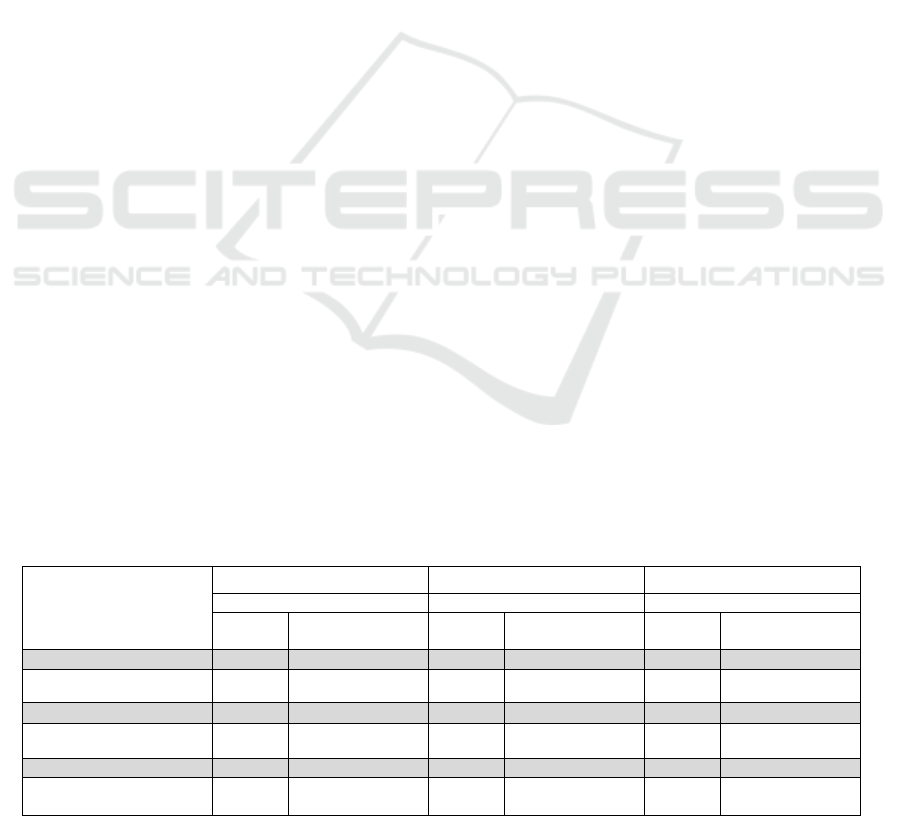

Table 1: Analysis of the reliability of meeting railway delivery time.

Railway

2019 2020 2021

share of shi

p

ments, % share of shi

p

ments, % share of shi

p

ments, %

on

time

with violation

on

time

with violation

on

time

with violation

Okt

y

abrska

y

a 99.00 1.00 99.50 0.50 97.10 2.90

Gorkovskaya 99.30 0.70 99.50 0.50 97.50 2.50

Severnaya 96.60 3.40 99.10 0.90 94.90 5.10

Sverdlovskaya 99.90 0.10 99.60 0.40 97.10 2.90

West Siberian 99.20 0.80 99.90 0.10 99.70 0.30

Average value 98.80 1.20 99.52 0.48 97.26 2.74

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

96

− reasons that depend on the cargo owners and

owners of private tracks;

− other reasons.

4 RESULTS AND DISCUSSION

Let us consider the analysis of statistical data on the

number of shipments arriving at the destination

station with a violation of the delivery time, the

reasons for freight delays in transit, the number of

claims for 2019, 2020 and 2021 in the North-West

technological polygon of the transportation process

management. The period under consideration covers

three years, including the year with the most adverse

epidemiological situation, which affected the causes

of delays in transit.

Table 1 shows statistical data on shipments

arriving without and with a violation of the delivery

time and empty cars.

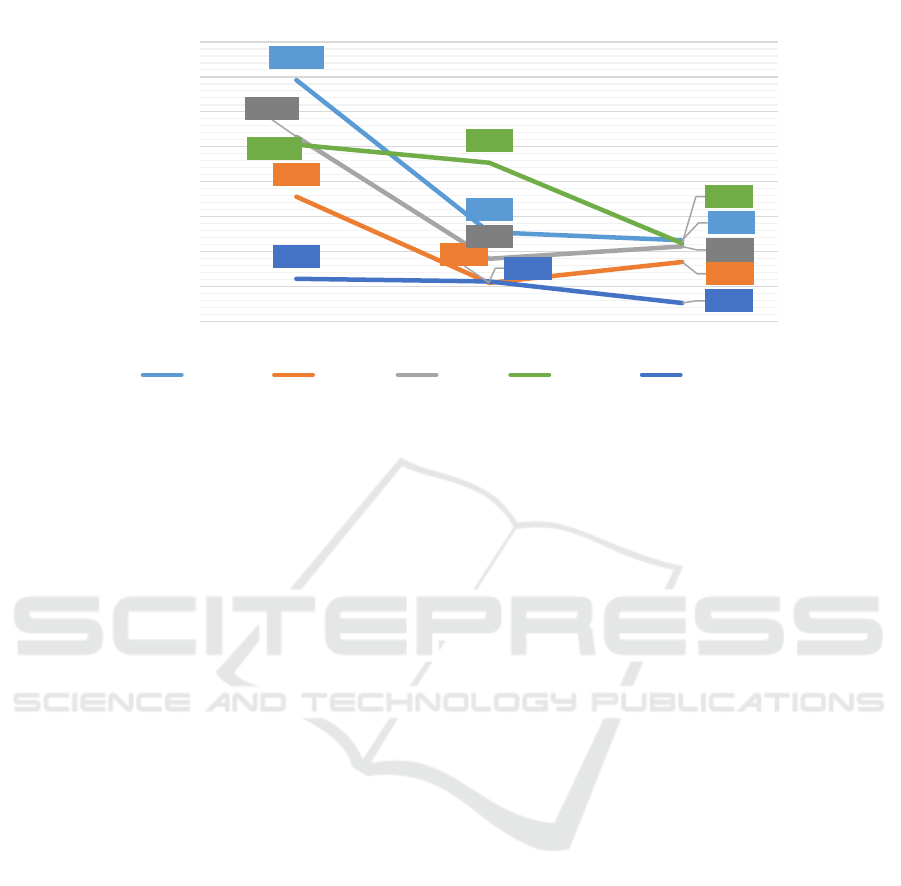

We used Table 1 to plot the dependence of the

reliability index on the roads of the technological

(Figure 1).

The technological polygon of the transportation

process management under consideration has quite a

high level of reliability of delivery of cargo and empty

cars - on average, 98.53% of shipments arrived on

time over three years. As can be seen from the graph,

Severnaya Road has the highest rate of late delivery,

with 94.9% of shipments arriving on time in 2021, the

lowest reliability level in three years. The

Sverdlovskaya (2019) and West Siberian (2020)

Railways have the best reliability indicator (99.9%).

The amount of penalties on claims filed decreased

significantly relative to 2019, by 54.22%, with the

number of complaints filed decreasing as well, by

52.04%. Primarily, this may indicate an increase in

the actual reliability of meeting freight delivery time,

as well as a greater degree of cargo preservation

relative to 2019. Payments of penalties after court

proceedings decreased by 39%.

Figure 2 shows the data on the number of

violations of the delivery time for freight and empty

cars by the railways of the technological

transportation polygon of the process management

under consideration.

Despite the high value of the number of claims in

2019, their number decreased on average by 2 times

as early as by 2020, however, by 2021 there is again

a slight increase on the Severnaya, Oktyabrskaya and

Gorky railways. The main problem remains a

distorted reflection of the true causes of delays, which

is the main force holding back the solution of this

problem. The existing systems for monitoring and

determining responsibility for violations of standard

delivery times require a unified technology for

determining the degree of influence of Russian

Railways divisions, consignors, consignees, and

third-party organizations on the permitted causes of

delays in freight shipments in transit.

According to the statistics for the technological

polygon the main reason for failure to meet delivery

time is the absence or waiting for a locomotive - 61%

(506,250 cases), with by delays, track occupancy,

non-acceptance, demurrage and accumulation

ranking second - 15% (121,679 cases), followed by

complaints about untimely operations and rejections,

as well as about waiting, technical equipment failures,

diverting of car traffic from the shortest routes - 8%

each (67,423 and 61,917 cases respectively). The

rarest other reasons are 6% (11,461 cases), as well as

Figure 1: Diagram of dependence of reliability indices.

1

0,7

3,4

0,1

0,8

0,5

0,5

0,9

0,4

0,1

2,9

2,5

5,1

2,9

0,3

0

1

2

3

4

5

6

Oktyabrskaya Gorkovskaya Severnaya Sverdlovskaya West Siberian

Share of shipments arriving with a violation

of the delivery time, %

2019 2020 2021

Analysis of the Reliability Compliance with Delivery Time

97

complaints about force majeure and reasons

dependent on the cargo owners or owners of private

tracks - 1% each (10,961 and 11,461 cases,

respectively).

5 CONCLUSION

Reliability of existing cargo flows, regardless of the

organizational solutions used, along with costs and

time is a priority for all participants of the

transportation process and is one of the important

criteria determining the choice of mode of transport.

Rail transport allows obtaining the effects associated

with the reduction of internal costs of freight

transportation, however, due to the low flexibility,

time and reliability, it is still not sufficiently

competitive with other modes of transport. In order to

improve the reliability of compliance with

transportation times, it is necessary to monitor the

passage of freight and empty cars along the

infrastructure while recording all technological and

temporal deviations of the transportation process

from the established standard values and identifying

those responsible for the violation of technology. For

this purpose, the car-hours of cargo shipments on the

infrastructure need to be recorded, and a forecast of

delivery of cargo and empty freight cars needs to be

generated, taking into account possible deviations

from technological standards at all stages of the

transportation process.

REFERENCES

Hong, L., Ye, B., Yan, H., Zhang, H., Ouyang, M., He, X.

S., 2019. Spatiotemporal vulnerability analysis of

railway systems with heterogeneous train flows,

Transportation Research Part A: Policy and Practice

130, pp. 725-744.

Kozlov, P., Osokin, O., Timukhina, E., Tushin, N., 2020.

Optimization of Fleet Size and Structure While Serving

Given Freight Flows. VIII International Scientific

Siberian Transport Forum. TransSiberia 2019.

Advances in Intelligent Systems and Computing 1116.

Timukhina, E. N., Kashcheeva, N. V., 2012, Functional

reliability - theoretical foundations and calculation

principles. Modern problems of the transport complex

of Russia 2, 1, pp. 98-108.

Jia, H., Lam, J. S. L., Tran, N. K., 2020. Spatial variation of

travel time uncertainty in container shipping,

Transportation Research Procedia, 48, pp. 1740-1749.

Zamparini, L., Reggiani, A., 2007. Freight transport and the

value of travel time savings: a meta-analysis of

empirical studies. Transp. Rev., 27-5, pp. 621-636.

de Jong, G. C., Kouwenhoven, M., Kroes, E. P., Rietveld,

P., Warffemius, P., 2009. Preliminary monetary values

for the reliability of travel times in freight transport.

Eur. J. Transp. Infrastruct. Res., 9 (2), pp. 83-99

Feo-Valero, M., Garcia-Menendez, L., Garrido-Hidalgo,

R., 2011. Valuing freight transport time using transport

demand modelling: a bibliographical review. Transp.

Rev. 201, pp. 1-27

Significance, VU University, John Bates Services, TNO,

NEA, TNS NIPO and PanelClix, 2013. Values of time

and reliability in passenger and freight transport in The

Netherlands. Report for the Ministry of Infrastructure

and the Environment, Significance, The Hague.

Figure 2: Diagram of comparison of the number of violations by railways.

138134

51051

46482

71393

22098

34044

105749

35917

42919

101207

90829

44760

24451

22895

10594

0

20000

40000

60000

80000

100000

120000

140000

160000

2019 2020 2021

The number of violations by railways

Oktyabrskaya Gorkovskaya Severnaya Sverdlovskaya West Siberian

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

98

RAND Europe, SEO and Veldkamp/NIPO, 2004.

Hoofdonderzoek naar de reistijdwaardering in het

goederenvervoer, rapport TR-154-AVV voor AVV,

RAND Europe, Leiden.

Hague Consulting Group, Rotterdam Transport Centre and

NIPO, 1992. De reistijdwaardering in het

goederenvervoer, rapport hoofdonderzoek. Rapport

142-1 voor Rijkswaterstaat, Dienst Verkeerskunde,

HCG, Den Haag.

Kurganov, V., Gryaznov, M., Dorofeev, A., 2018.

Management of transportation process reliability based

on an ontological model of an information system,

Transportation Research Procedia, 36, pp. 392-397.

Zhao, J., Zhu, X., Wang, L., 2020. Study on scheme of

outbound railway container organization in rail-water

intermodal transportation. Sustainability, 12 (4), pp. 1-

19.

Roso, V., 2013. Sustainable intermodal transport via dry

ports – Importance of directional development. World

Review of Intermodal Transportation Research, 4 (2/3),

pp. 140-156.

Behrends, S., 2015. The modal shift potential of intermodal

line-trains from a haulier’s perspective: Drivers and

barriers in the mode choice process. World Review of

Intermodal Transportation Research, 5(4), pp. 369-

386.

Kramarz, M., Przybylska, E., Wolny, M., 2021. Reliability

of the intermodal transport network under disrupted

conditions in the rail freight transport, Research in

Transportation Business & Management, 100686.

Hu, Q., Wiegmans, B., Corman, F., Lodewijsk, G., 2019.

Integration of inter-terminal transport and hinterland

rail transport. Flexible Services and Manufacturing

Journal, 31, pp. 807-831.

Elbert, R., Seikovsky, L., 2017. The influences of

behavioral biases barriers and facilitators on the

willingness of forwarders’ decision makers to modal

shift from unimodal road freight transport to intermodal

road-rail freight transport. Journal of Business

Economics, 87 (8), pp. 1083-1123.

Börjesson, M., Eliasson, J., 2011. On the use of “average

delay” as a measure of train reliability, Transportation

Research Part A: Policy and Practice, 45, 3, pp. 171-

184.

Analysis of the Reliability Compliance with Delivery Time

99