The Analyses of the Polymer Materials Use with Multidirectional

Friction Properties in the Suspension Elements of Land Transport

Vehicles

V. V. Makarov

1

, O. V. Cherepov

1

and D. I. Buyaev

2

1

Ural State University of Railway Transport, Ekaterinburg, Russia

2

A.N. Nesmeyanov Institute of Organoelement Compounds of Russian Academy of Science (INEOS RAS), Moscow, Russia

Keywords: Car vehicle, suspension element, polymer materials, wear, bearing.

Abstract: The work for the decrease of cars cost price without loss of quality and safety demands is of great

importance for the salvation of the demands to increase the efficiency of car vehicles exploitation. To

achieve this aim on projecting and constructing car vehicles the use of the composite polymer materials is

being regarded more actively. Due to the peculiarities of such materials their use can be limited by the outer

factors and characteristics of the elements they are used in – extra shock, temperature ratings and friction.

These factors can decrease economical effect of their use due to the necessity of frequent replacement. The

use of the polymer composite materials in a car suspension elements is mostly dependant on the noted

factors. Considering and analyzing different kinds of polymer composite materials a solution of their

effective use in the elements can be found. The use of separate car elements in the movable suspension parts

made of polymer composite materials lets reduce not only the cost price of cars but increase their durability.

The constriction technology, durability and shock rating resistance let use polymer composite materials

instead of anti-friction bearings of movable suspension parts which lets reduce expenses to produce car

vehicles keeping the safety characteristics.

1 INTRODUCTION

Students’ scientific community of the USURT has

participated in interuniversity competition of

technical projects Formula Student since 2012. The

competition sets the aim to project and construct a

formula-type open wheel racing car (“open-wheels”

body type), and also to provide technical and

commercial documentation for the projected car.

In connection with this, the University created a

project center where the students project and

construct the car. The center is equipped with the

complex of constructing equipment, the equipment

of quick prototyping and CAD for the models

construction and analyses.

The competition sets a range of organizational

and technical restrictions and demands including the

safety of the designed vehicle. The prototype should

pass a range of dynamical tests which contain

stability tests, an acceleration characteristics

evaluation and a durability run. The list of tests is set

by the regulations developed by the Society of

Automotive Engineers, SAE (2022 Formula SAE

Rules, www.fsaeonline.com).

Moreover, the students’ community is obliged to

present a technical documentation for a newly

designed car reconstructed with not less than 70 %

of changes and now-how. Projects participating in

the competition for more than a year are not

admitted.

These restrictions oblige the design team to

develop a vehicle with a high level of durability

including the movable parts of the suspension

elements under conditions of moderate and extra

weight, and frictional shocks.

More than that, due to the demands for the

optimization of the dynamic characteristics the

design team has a task to find the ways to reduce the

car sprung weight. The reduce of the weight lets

improve the vehicle speed characteristics and

reduces the consumption of energy carriers while

moving (Lyu, 2015).

Increasingly important factors in projecting a car

prototype are also the expenses for the production

Makarov, V., Cherepov, O. and Buyaev, D.

The Analyses of the Polymer Materials Use with Multidirectional Friction Properties in the Suspension Elements of Land Transport Vehicles.

DOI: 10.5220/0011581300003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 181-186

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

181

and the efficiency of the chosen production

technologies.

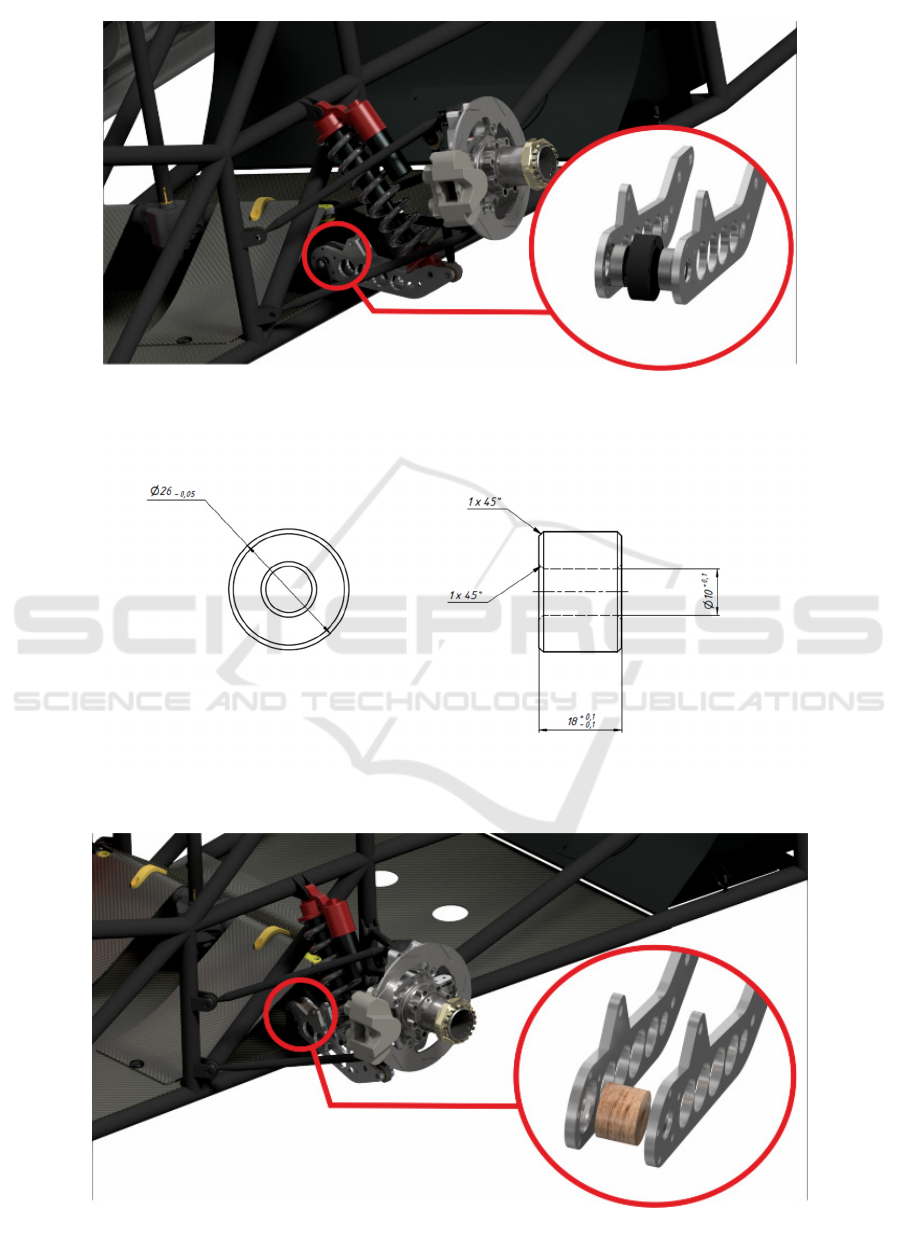

For the demands, the mostly satisfying point

within the work on the material collection became

an offer to use parts made from polymer composite

materials instead of antifriction bearings in the

suspension elements shown in picture 1.

The analyses of the researches (Cherkasova,

2011; Imoshkov, 2017) set the fact that such

decisions have been realized in some elements in the

rail, automobile and other spheres of machinery

construction. The efficiency of the use of composite

materials in different kinds of knots has been

experimentally confirmed (Alshahrani, 2022).

The use of polymer composite materials lets

minimize the use of such expensive materials as

titan, cobalt, chrome, nickel, molybdenum, and

tantrum. The cost and energy expenses for the

production and processing of polymer composite

materials is much less than the mentioned materials.

Also, the wear of the parts and knots caused by

friction is reduced due to the optimization of the

polymer composite materials anti-friction capacities

up to the elimination of the necessity of using

lubricating oil (Chukalovsky, 2009). More than that,

the cost and customer performance can be optimized

with the help of the methodologies of the projecting

and implementation of the polymer materials

elements (Romero, 2022).

As a result of the research there was the decision

to change antifriction bearings in the movable parts

of rockers fixings of the shock absorbers of the

suspension on the bush (picture 2, 3), made from the

domestic material “Oxaphene”.

The structure of “Oxaphene” is based on a

complex thermo reactive composition. As a binding

element phenolic compounds are used. As a

strengthened material the fifth generation organic

fiber “Arselon” – a special thermo resistant organic

polyoxadiazole filling. The “Oxaphene” use was

conducted during exploitation tests on the trolleys of

the model 18-100 of freight cars – hoppers (Buyaev,

2005).

The physical properties of the material shown in

table 1 increase the demanded indicators of a wide

range of the polymer composite materials used in the

machine building industry.

The experience of useing the parts produced

from this material in the knots of railway rolling-

stocks, as well as in the sphere of agricultural

machinery engineering let suppose, that the use of

“Oxaphene” in the suspension fixing elements can

improve a range of an automobile characteristics

(Fakhtullin, 2016).

To widen the sphere of using the polymer

composite materials and also to study and effective

implementation of the features of new polymer

materials in the sectors of the national economy,

there have been exploitation tests and researches

conducted. To evaluate the effectiveness of a

polymer material durability with multidirectional

friction properties in the suspension elements a

series of road tests has been conducted (figure 1-3).

Table 1: Physic-Chemistry Property of “Oxaphene” Material.

Indicator Value

Solidity, not less than, g/sm

3

1,32

Failure stress, not less than, MPa

In tension

Compression in direction parallel to pressing

Compression in direction perpendicular to pressing stress

120

140

115

Solidity on Rockwell, scale numbe

r

85

Impact properties on Sharpy, kJ/m

3

34

Water absorbing in cold water (24 hours), % 0,14

Specific volume electric resistance, Ohm/sm

3

11*10

13

Oil resistance

(

24 hours

)

, % 0,037

Petrol resistance

(

24 hours

)

, % 0,005

Shrinkage on the models (80x10x4mm) on value, % 0,15

Coefficient of steel, titan, cast iron friction depending on exploitational

conditions

0,05-0,3

Linear wear intensity mm/k

m

1*10

-7

Rider wear Reduce to 2-3 times comparing

to traditional durable materials

Friction heat resistance,

0

C From -80 to +250

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

182

Figure 1: Rocker fixing knot with ball bearings.

Figure 2: Polymer composite material bush.

Figure 3: The construction of the rocker fixing knot with a polymer bush.

The Analyses of the Polymer Materials Use with Multidirectional Friction Properties in the Suspension Elements of Land Transport Vehicles

183

2 MATERIALS AND METHODS

A set of parts for the fixing knot of a rocker shock

absorber of the front and rear suspension has been

developed – 4 bushes – one for each point of fixation

of rockers bases. A bush is set instead of a pair of

rolling bearings and interposing spacer. Weight

pressure on the elements of the front and rear

suspension is determined proportionally: 46% front

axle, 54% rear axle (the total car weight is 254 kg).

Series of road tests in real conditions was

conducted by the design team. As a test field an

asphalt road and a pathway with straight parts not

more than 70 m and curves of 9 m radius had been

chosen. The tests were conducted within the speed

ratio from 50 to 80 km/h, which corresponds to the

speed usually achieved in this class. In real

conditions the profile of the racing track is full of the

curves of both directions of a small radius – not less

than 9 meters, and short straight parts – not more

than 75 meters aiming to create “Testing” conditions

for the machinery. An approximate race mileage is

50 km. That is, the action is organized to create the

most complicated conditions for the cars.

Preparatory and test tracks duplicate the same

conditions close to the real road conditions.

The total mileage of the tested models is 1000

km. The wear control was conducted step by step

within the period of autumn-winter. Table 2 contains

the results of the sensor monitoring of the bush wear

from the polymer composite materials in the rocker

suspension elements. The monitoring of the

elements was conducted by a digital caliper Matrix

with the accuracy of 0,01 mm.

The data analyses of table 1 lets conclude, that at

the first stage (mileage 110 km) all the models show

an attrition wear (within the measurement accuracy

of the tool). In the end of the tests cycle the total

wear for NN 1 and 2 models is 0,03 and 0,02 mm

respectively. At the same time, the intensity of the

wear for the car front axle is 0,0025 mm per 100 km

mileage and for the rear axle 0,0035 mm

respectively. Such wear difference is explained by

the car weight split – rear axle is pressed 8 % more

than the front one.

Based on the fact that for the test period the car

mileage is 100 km during the tests and not more than

100 km during the races, the use of the elements

provides minimum 5 race cycles without geometry

changes and the need of changing the elements.

Before the beginning of the initial run there was

the control weighing of the set of bearings (the

previous knot version) and the installed bushes

(instead of the bearings) made from “Oxaphene”.

Taking into account that the set of bearings for one

of four suspension rockers – two bearings and one

plastic positioning spacer is 63,34 g., and the weight

of one composite polymer materials bush

“Oxaphene” is 10,31 g. the total weight economy is

212,12 g. It means that the weight of the movable

elements of the rockers fixings is reduced to more

than 6 times.

The costal price component of the decision to

change the antifriction bearings to the bush made

from “Oxaphene” has also a vivid effect. The cost of

one of the four fixing sets is 420 rubles – two

bearings 6200-2RSH [10x30x9] SKF is 175 rubles

each and the plastic spacer costs 70

rubles (TreidImport, treidimport.ru). The cost of one

Table 2: Sensor monitoring results of the bush wear from the polymer composite materials in the rocker suspension

elements.

Mileage,

km

Model N1 (front left) Model N2 (front right) Model N3 (rear left) Model N4 (rear right)

The bush

inside

diameter,

mm

Wear,

mm

The bush

inside

diameter,

mmм

Wear,

mm

The bush

inside

diameter,

mm

Wear,

mm

The bush

inside

diameter,

mm

Wear,

mm

0 10,08 10,10 10,04 10,06

110 10,08 0,00 10,10 0,00 10,05 0,01 10,07 0,01

219 10,09 0,01 10,11 0,01 10,06 0,02 10,07 0,01

304 10,09 0,01 10,11 0,01 10,06 0,02 10,07 0,01

407 10,10 0,02 10,11 0,01 10,06 0,02 10,08 0,02

505 10,10 0,02 10,11 0,01 10,06 0,02 10,08 0,02

623 10,10 0,02 10,11 0,01 10,07 0,03 10,08 0,02

770 10,10 0,02 10,12 0,02 10,07 0,03 10,08 0,02

854 10,10 0,02 10,12 0,02 10,07 0,03 10,08 0,02

906 10,11 0,03 10,12 0,02 10,07 0,03 10,09 0,03

1000 10,11 0,03 10,12 0,02 10,08 0,04 10,09 0,03

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

184

“Oxaphene” bush is 193 rubles (retail price for

February 2022). Totally the economy for the four

fixing elements of the rockers suspension fixing

elements is 908 rubles.

To get a more detailed data on the elements

work, the decision to continue the test run and to

increase the mileage for determining the life time of

the elements until their critical wear, deformation, or

failure was taken. Also, taking into account the

developing tendency of the increase of the amount

of polymer elements in the automobile

manufacturing (Hagnell, 2020), it is supposed to set

“Oxaphene” bushes to other movable elements of

cars.

3 RESULTS AND DISCUSSIONS

According to the program of the tests the installed

bushes were under a non-destructive testing every

100 km approximately. The evaluation of the

condition of the tested models on the results of the

run of 1000 km did not show mechanical or thermal

failure of any model. The frictional area – the inner

bush surface – is not deformed and has insignificant

grinding traces. The rider surface is not deformed

and also has insignificant grinding traces. The

contact area with the movable parts – rockers, as

well as the surface of rockers themselves is not

deformed. Taking into account overweighting of rear

suspension against the pressure on the elements of

rear suspension, while carrying out the test activities,

the greatest attention was paid to the rockers bushes

of the rear suspension. The results of the track tests

of the rockers bushes of the front and rear

suspension are identical.

The crushed and fallen out bushes are not

identified. The bushes are tightly set in their

mounting seats and are contiguous tightly enough to

the contact areas.

The determined by the tests 1000 km bushes life-

time, taking into account that the run does not

exceed 200 km per season, let use the “Oxaphene”

bushes in the suspension of rockers fixings during

not less than five cycles. The regulations set an

obligatory annual renovation of the vehicle.

However, up to 30 % of the elements may be

installed into a new evolutionary model. It means

that providing the bushes to be reinstalled within

their life-time period, it is possible to save not less

than 4540 rubles.

4 CONCLUSIONS

The use of the composite polymer materials allows

to greatly reduce the wear of the contact area of the

fixing knots of the car suspension movable elements.

The use of “Oxaphene” in the suspension

elements is admitted. It is more effective, in some

cases, against the use of bearings due to over-

abrasion and dust in the fixing elements, and as a

result an over-wear of ball bearings.

Under moderate friction, weight and shock

ratings the use of “Oxaphene” in the fixing elements

of the car suspension is possible without any

lubrication, dust cover and other additional

mechanical protection.

Moreover, the ball bearings changed to the

“Oxaphene” bushes reduced the sprung weight of

the car, as well as it reduced the expenses for the

vehicle construction and it simplifies the process of

the elements production.

It is necessary to increase the test run for a

further research of the elements durability. The

durability tests in mostly shocked elements are also

needed.

REFERENCES

2022 Formula SAE Rules.

https://www.fsaeonline.com/cdsweb/gen/DocumentRe

sources.aspx.

Lyu, M. Y., Choi, T. G., 2015. Research trends in polymer

materials for use in lightweight vehicles. International

Journal of Precision Engineering and Manufacturing.

16. pp. 213-220.

Cherkasova, S. A., 2011. Polymeric materials in

mechanical engineering and their experience of using

in cars. Vestnik SGTU. 3 (58). 2. pp. 142-145.

Imoshkov, P. N., 2017. Composite materials in the

automobile industry. Proceedings of VIAM. 6 (54). pp.

61-68.

Alshahrani, H, Sebaey, T. A., 2022. Bearing Properties of

CFRP Composite Laminates Containing Spread-Tow

Thin-Plies. Polymers. 14. p. 2076.

Chukalovsky, P. A., 2009. Study of wear resistance of

organoplastic oxaphene. Engineering and

technosphere of the XXI century. Proceedings of the

XVI International Scientific and Technical

Conference. pp. 245-250.

Romero, V. J., Sanchez-Lite, A., Liraut, G., 2022.

Development of a Multi-Criteria Design Optimization

Methodology for Automotive Plastics Parts. Polymers.

14. 156.

Buyaev, D. I., 2005. The use of new materials to ensure

the operational reliability and wear resistance of

tribounits of brake linkage of freight car bogies.

The Analyses of the Polymer Materials Use with Multidirectional Friction Properties in the Suspension Elements of Land Transport Vehicles

185

Problems and prospects for the development of freight

car building. Materials of the I scientific-practical

conference. pp. 94-98.

Fakhtullin, A., 2016. On the possibility of using polymer

composite materials in agricultural engineering.

Agribusiness: economics - equipment - technologies.

4. pp. 55-62.

TreidImport.

https://treidimport.ru/shop/podshipniki/podshipniki-

sharikovye-radialnye-odnoriadnye-s-

uplotneniiami/podshipnik-6200-2rsh-10309-

skf/?v=f9308c5d0596.

Hagnell, M., Kumaraswamy, S., Nyman, T., Åkermo, M.,

2020. From aviation to automotive—A study on

material selection and its implication on cost and

weight efficient structural composite and sandwich

designs. Heliyon. 6, e03716.

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

186