Limit of Long-term Strength of Shells Operated in an Aggressive

Environment

I. G. Emel’yanov

1,2,3 a

1

Ural State University of Railway Transport, Yekaterinburg, Russia

2

Ural Federal University, Yekaterinburg, Russia

3

Institute of Engineering Science, Russian Academy of Sciences (Ural Branch), Yekaterinburg, Russia

Keywords: Shell, aggressive environment, mechanical characteristics of steel, stress state, long-term strength limit.

Abstract: The paper proposes a method for determining the limit of long-term strength of metal thin-walled structures

in contact with an aggressive hydrogen-containing medium. The method is demonstrated on a structure in the

form of a steel cylindrical pipe, which is used for wells and gas gathering pipeline networks. The indicator of

the long-term strength of typical structures proposed in the article will allow the consumer to better navigate

the market of the proposed pipes when choosing them.

1 INTRODUCTION

In various industries, including transport, the issues

of assessing the degree of degradation of the strength

properties of various materials during the operation of

structures are topical. The change in mechanical

properties leads to various types of destruction of

structures. In (Collins Jack, 1981), more than 20 types

of mechanical failure during operation are given.

It is known that many metals during operation in

various environments change their mechanical

properties in comparison with tests in air. The

environment can have both beneficial and harmful

effects on the material and affects the value of the

long-term strength of the structure. The ability of a

material to resist fracture under long-term static

loading is called long-term strength. The limit of

long-term strength of a material is the maximum

stress that causes destruction in a certain time at a

fixed temperature. It is designated

T

t

ult

σ

, where

ult

t

is the limiting time to failure, T is the temperature

(Troshchenko, 1994).

The calculation of the durability of materials

under long-term static loading can be carried out in

two ways. The first method develops methods for

predicting the time to failure using various parameters

depending on the level of acting stresses, i.e., it

models parametric long-term strength curves. The

a

https://orcid.org/0000-0002-9733-5485

second method is associated with the development of

methods for extrapolation of long-term strength

curves for a time exceeding the time for which the

initial curves were experimentally obtained.

Apparently, for standard structures loaded with a

known static load, it is possible to determine the limit

of long-term strength of the structure

T

t

ult

q

, where q

is the generalized force,

ult

t

is the limiting time

before the destruction of the structure, T is the

operating temperature of the structure. Therefore, the

introduced limit will depend on the operating

conditions causing the destruction of the structure in

a certain time. Such an entered value will be useful

when choosing the geometric parameters and

materials of typical structures (for example, pipes for

wells) based on their operating conditions.

At present, the issues of assessing the degree of

degradation of the strength properties of steels during

the operation of various structures in aggressive

environments are becoming relevant.

The effect of aggressive media, including

hydrogen-containing media, on the mechanical

characteristics of metals is actively studied by various

physical methods and by mechanical tests for samples

(Jemblie, 2017; Fassina, 2012; Miresmaeili, 2010;

Mironov, 2020; Gorkunov, 2008). A variety of

phenomenological effects that arise when exposed to

230

Emelâ

˘

A

´

Zyanov, I.

Limit of Long-term Strength of Shells Operated in an Aggressive Environment.

DOI: 10.5220/0011582100003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 230-234

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

hydrogen-containing media will determine the long-

term strength of steels.

Predicting the behavior of loaded metal structures

that are operated in an aggressive hydrogen-

containing environment is an important scientific

problem of great practical importance. One of these

problems is the problem of changing the strength of

steels for pipes that transport the so-called "sour gas".

This is natural gas with a high content of hydrogen

sulfide. Predicting the behavior of the material in such

metal structures is a very important and not

completely solved problem. The issue of assessing

the strength and durability of structures during their

operation in corrosive media containing hydrogen

sulfide remains very important.

In this paper, a method is proposed for

determining the ultimate strength of a typical

structure, which is operated in an aggressive

environment under static loading. The method is

demonstrated on a structure in the form of a steel

cylindrical pipe, which is used for wells and gas

gathering pipeline networks. The indicator of the

long-term strength of typical structures proposed in

the article

T

t

ult

q

will allow the consumer to better

navigate the market of the proposed pipes when

choosing them.

2 METHOD FOR SOLVING THE

PROBLEM AND BASIC

EQUATIONS

Statement of the problem and methods of solution.

The general problem of determining the long-term

strength limit of a metal structure in contact with an

aggressive environment consists of several

independent tasks:

− development of a model that allows

determining the stress state of the structural

element under study,

− determination of the mechanical parameters of

the material depending on the time of contact

with an aggressive environment,

− the choice of the interpolation method for

determining the mechanical parameters of the

material, depending on the operating time of

the structure,

− development of a model that determines the

limit of long-term strength of the structure.

Determination of the stress-strain state of the

shell.

The investigated thin-walled structure is a shell

of revolution with variable geometric and mechanical

parameters along the generatrix. We will consider a

shell of thickness h using a continuous middle surface

with curvilinear orthogonal coordinates S,

θ

,

γ

.

Where s and

θ

are the meridional and circumferential

coordinates, and the

γ

( 2/2/ hh ≤≤−

γ

)

coordinate is in the direction of the outer normal to

the shell surface. A cylindrical shell loaded with a

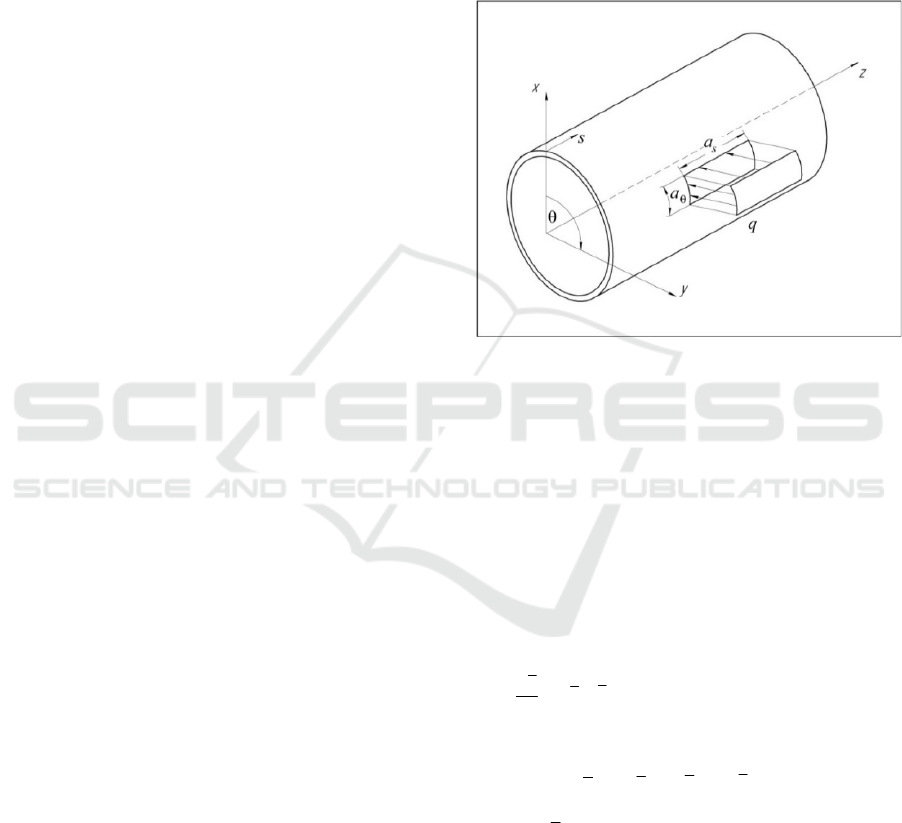

distributed mechanical force q is shown in fig. 1.

Figure 1: Shell of revolution.

The inner surface of the shell is in contact with an

aggressive water-containing medium with an

overpressure p. The stress state of a thin-walled

structure will be determined using the classical theory

of shells based on the Kirchhoff–Love hypotheses

(Donnell, 1976). Given that the structure under study

is loaded only with pressure, its stress state will be

axisymmetric. Thus, the problem of determining the

stress-strain state of the shell will be described by a

system of ordinary differential equations in the

Cauchy normal form of the following form

(Shevchenko, 2001; Shevchenko, 2006)

, ( , 1,2,....6)

ij

dY

PY f i j

ds

=+ =

,

)(

0 L

sss ≤≤

(1)

with boundary conditions

()

101

bsYB =

,

()

22

bsYB

L

=

(2)

Here

{

}

,

,, ,,,

rz srzs

YNNMuu

ϑ

=

– vector–function

of the required solution

r

N

,

Z

N

– radial and axial

forces;

r

u

,

z

u

- displacement;

s

M

– meridional

bending moment;

S

ϑ

- angle of rotation of the normal

to the shell surface. Matrix elements

ij

P

depend on

the geometric and mechanical parameters of the shell,

Limit of Long-term Strength of Shells Operated in an Aggressive Environment

231

f

– the vector depends on the loads applied to the

shell.

i

B

– given matrices;

i

b

are the given vectors.

When solving the linear boundary value problem

(1), the Runge-Kutta method with discrete

orthogonalization and normalization of S.K.

Godunov is used [11].

Solution of a physically nonlinear problem for

a shell. When the plastic deformation of the material

is considered, the problem becomes physically

nonlinear. The problem will be described by the same

system (1), and the relationship between stress and

strain is presented in the form of Hooke's law, with

additional terms that consider the dependence of the

mechanical properties of the material on strain. In this

case, the volumetric stress state of the shell will be

compared with the uniaxial state in a simple tension

of the sample.

3

σ

=S

,

ε

μ

3

1

*

+

=H

(3)

where σ and ε are stresses and strains during simple

tension of the sample

ε

σ

μ

μ

E2

21

2

1

*

−

−=

(4)

In formula (4) E – young’s modulus,

*

μ

– Poisson’s

ratio

The intensities of the shear stress S and shear

strain H for the shell are determined as follows

)()3/1(

22

θθ

σσσσ

+−⋅=

ss

S

(5)

]

)()()[()6/1(

222

ss

H

εεεεεε

θθγγ

−+−+−⋅=

(6)

where

s

σ

and

θ

σ

are the meridional and

circumferential stresses, respectively, and

s

ε

,

θ

ε

,

γ

ε

are the components of deformations along the

meridian, circumference and normal to the shell

surface.

Determination of the mechanical parameters

of the material. Since an aggressive environment

usually has a negative effect on the metal of structures

and changes the mechanical characteristics,

experimental studies are needed to record changes in

the mechanical properties.

To demonstrate the method for determining the

ultimate strength of thin-walled structures, we will

investigate shells made of 12GB pipe steel (an

analogue of X42SS steel API).

The article (Gorkunov, 2008) presents the results

of measurements of the mechanical and magnetic

characteristics of samples of pipe steel 12GB,

exposed to hydrogen sulfide for 384 hours, directly

under the action of uniaxial tensile stresses up to the

destruction of the sample. Tests were also carried out

for samples in the initial state. The temperature during

testing is 20°С.

In (Gorkunov, 2008), stress-strain diagrams are

given for a given material at fixed times t=96 h, t=192

h and t=384 h of contact with an aggressive medium.

It can be seen from the above diagrams that they can

be approximated quite accurately by bilinear straight

lines with points of yield strength

Y

σ

,

Y

ε

, and

ultimate strength

ult

σ

,

ult

ε

both for the initial state

and after contact with an aggressive medium (where

ult

σ

and

ult

ε

are the maximum values of stress and

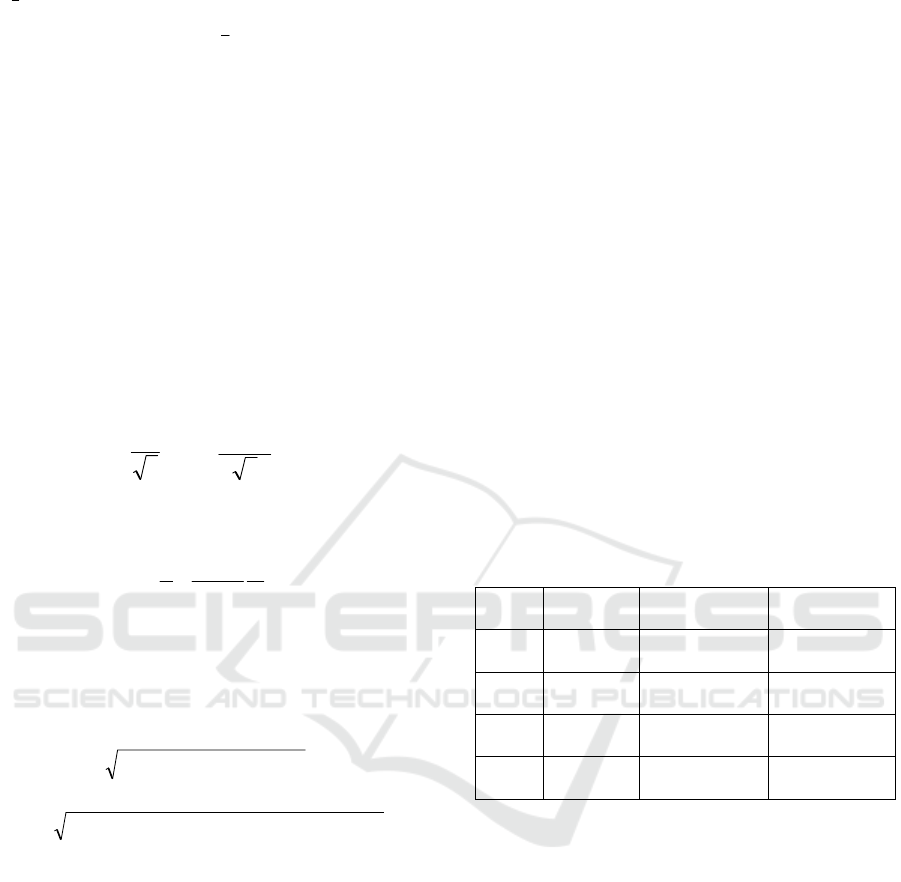

deformation upon failure). Table 1 shows the points

for plotting diagrams.

Table 1: The points for plotting stress-strain diagrams.

Time,

hou

r

point 1 point 2 point 3

0

ε

0

= 0

σ

0

= 0

ε

Y

=0,00187

σ

Y

=374 МPа

ε

ult

=0,23

σ

ult

=474 МPа

96

ε

0

= 0

σ

0

= 0

ε

Y

=0,00181

σ

Y

= 361 МPа

ε

ult

=0,22

σ

ult

=458 МPа

192

ε

0

= 0

σ

0

= 0

ε

Y

=0,00213

σ

Y

= 426 МPа

ε

ult

=0,14

σ

ult

=498 МPа

384

ε

0

= 0

σ

0

= 0

ε

Y

=0,00218

σ

Y

= 437 МPа

ε

ult

=0,12

σ

ult

=500 МPа

Approximation of stress state components.

After solving system (1), taking into account the

mechanical properties (Table 1), meridional and

circumferential stresses and strains

s

σ

,

θ

σ

, and

s

ε

,

θ

ε

, and invariant characteristics S and H will be

determined at each point of the shell. Considering that

the mechanical properties depend on time, these

characteristics will also depend on time of contact

with aggressive environment.

The criterion for the strength of structures is often

the condition when the intensity of shear stresses in

the shell (5) reaches the stress of the sample material

during its destruction. Therefore, the criterion for the

long-term strength of structures under fixed loading

(p=const) will be the condition

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

232

1

)3)(()(

−

≤ ttS

ult

σ

(7)

To determine the values of the intensity of shear

stresses

)(tS

within the time interval of saturation

with hydrogen sulfide, you can use the corresponding

approximating algebraic polynomial L

n

. Therefore,

the approximate value of the parameter of interest can

be represented in terms of its discrete value and time

),(

)( ii

tSS =

)(

)(

iin

StL =

ni ...1=

(8)

Here n is the number of experiments at different

times of sample saturation with hydrogen sulfide.

With a well-chosen polynomial

n

L

, the value of

the parameter of interest can be determined outside

the time of the experiment, i.e., at the time of interest,

such as

55

0

=

work

t hours.

The limit of long-term strength of the

structure. The value of the shear stress intensity

during operation can be represented as

i

n

i

i

taatS

=

+=

1

0

)(

(9)

Since the shell under study is loaded with internal

pressure p, therefore, the intensity of shear stresses

will be equal to

i

n

i

i

tbbptS

=

+=

1

0

),(

,

cons

t

p =

(10)

Considering the introduced criterion of long-term

strength of structures (7), we determine the limit of

long-term strength for a given shell structure

)(3),( tptS

ult

T

t

ult

σσ

≤=

,

при

constT =

(10)

3 CALCULATION EXAMPLE

Limit of long-term strength for a cylindrical shell.

Let us determine limit of long-term strength of a

cylindrical shell (pipe) operated in a hydrogen sulfide

environment. Pipe outer diameter D=0.114 m,

thickness h=0.013 m, material - steel 12GB.

During operation, the pipe experiences a plane

stress state from a variable internal pressure p.

Therefore, the shell can be investigated without edge

effects at a point far from the boundary conditions (2).

From table 1, the mechanical parameters change

depending on the time of exposure to hydrogen

sulfide. From physical considerations, the change in

these mechanical parameters should be monotonous,

since they should depend on the diffusion coefficient,

which characterizes the efficiency of the diffusion

movement of hydrogen sulfide into the metal and be

proportional to the time of contact with an aggressive

environment. Some solutions to the problems of

hydrogen diffusion into metal are considered in

(Emel’yanov, 2018; Emel'yanov, 2019). Considering

the physical monotony of the diffusion process, we

represent the change in the yield strength σ

Y

, ultimate

strength σ

ult

in the form of power functions. For

example, the change in ultimate strength σ

ult

with an

accuracy of 4% can be substituted as a quadratic

function

2

467.231 0.0869794 0.0000116704

ult

tt

σ

=+ +

(12)

According to the results of the calculation, it was

shown that at a pressure of p=80 MPa, the shell

material is in the region of elastic deformations. With

an increase in excess pressure to p=90 MPa, plastic

deformations occur at the most loaded point on the

inner surface of the shell. The problem becomes non-

linear and an iterative process is applied to achieve

the required accuracy of the problem solution.

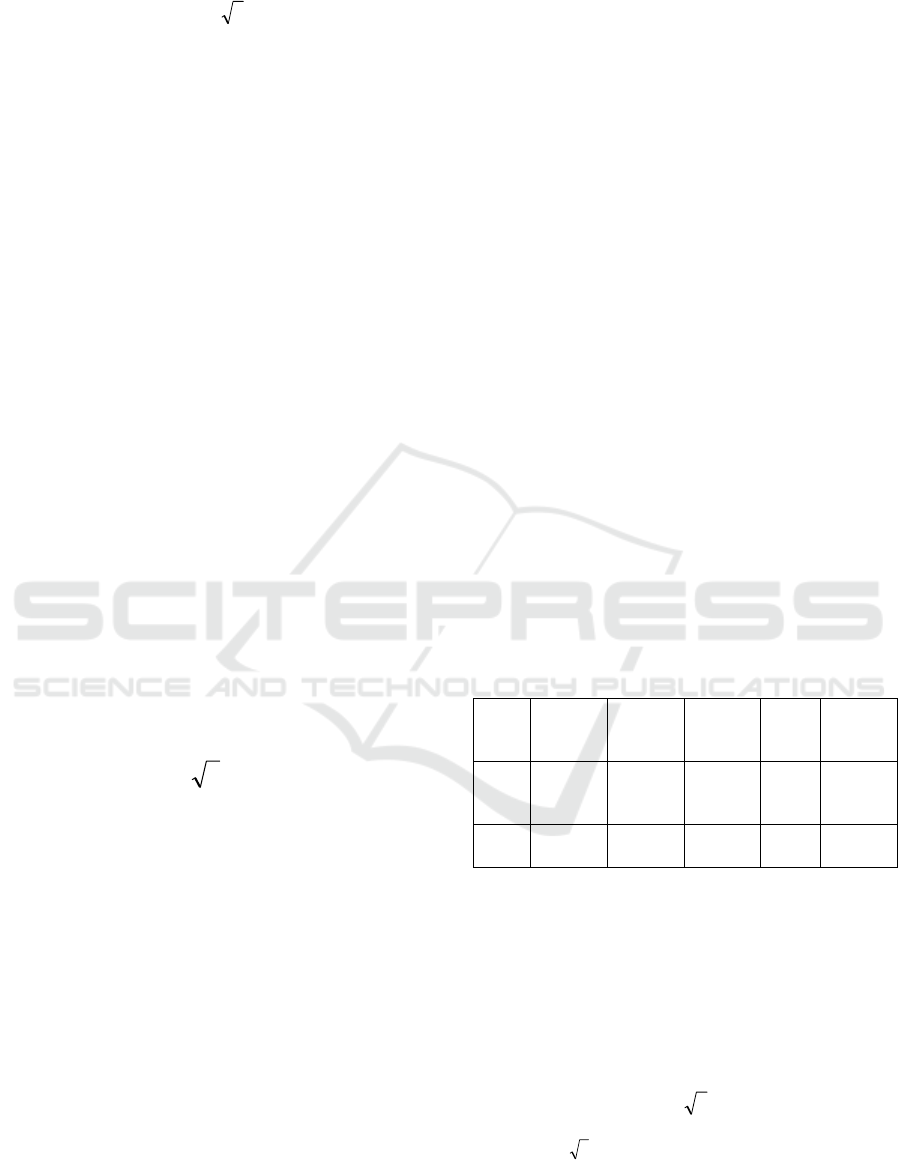

Table 2 shows the values of the intensity of shear

stresses S = f(p) and shear strains H = f(p) for various

shell pressure p, when the structure is operated in an

environment of hydrogen sulfide t

work

= 550 hours.

Table 2: The intensity of shear stresses and shear

strains for various pressure.

p,

МП

а

100 110 120 130 131

S,

МП

а

224 244 269 294 299

H

0.0014

2

0.0015

6

0.0173

4

0.06

8

0.0782

8

By increasing the pressure, it is possible to

determine the limiting pressure at which the strength

condition is violated. For this design, the burst

pressure will be p = 132 MPa. Therefore, at

p = 131 MPa, it is possible to determine the limit of

long-term strength of the structure. Considering the

values

ult

σ

calculated by relation (12) at t=550 h and

the intensity of shear stresses for pressure p=131

(Table 2), we have

ult

ptS

σ

≈3),(

≈3299

518.5 at

СT

0

20=

(13)

Limit of Long-term Strength of Shells Operated in an Aggressive Environment

233

Therefore, the limit of long-term strength of this

design for temperature T=20°С and pressure p=131

MPa is 550 h.

4 CONCLUSION

Thus, it is possible to determine the limits of long-

term strength of typical shell structures for various

combinations of material, temperature, operating

time, and internal pressure.

The proposed method will be useful in the design

and installation of various pipelines that operate in

contact with aggressive media.

REFERENCES

Collins Jack, A., 1981, Failure of Materials in Mechanical

Design. Analysis, Prediction, Prevention. The Ohio

State University. John Wiley & Sons. p. 624.

Troshchenko, V. T., Krasovsky, A. Ya, Pokrovsky, V. V.,

Sosnovsky, L. A., Strizhalo, V. A., 1994. Strength of

materials to deformation and destruction. Reference

manual, Part 2. Naukova Dumka, p. 703.

Jemblie, L., Olden, V., Akselsen, O., 2017. A coupled

diffusion and cohesive zone modelling approach for

numerically assessing hydrogen embrittlement of steel

structures. International Journal of Hydrogen Energy.

42 (16). pp. 11980-11995.

Fassina, P., Bolzoni, F., Fumagalli, G., Lazzari, L.,

Vergani, L., Sciuccati, A., 2012. Influence of hydrogen

and low temperature on mechanical behavior of two

pipeline steels. Engineering Fracture Mechanics. 81.

pp. 43-55.

Miresmaeili, R., Ogino, M., Nakagawa, T., Kanayama, H.,

2010. Accoupled elastoplastic-transient hydrogen

diffusion analysis to simulate the onset of necking in

tension by using the finite element method.

International Journal of Hydrogen Energy. 35 (3). pp.

1506-1514.

Mironov, V. I., Emelyanov, I. G., Vichuzhanin, D. I.,

Zamaraev, L. M., Ogorelkov, D. A., Yakovlev, V. V.,

2020. Effect of hydrogenation temperature and tensile

stress on the parameters of the complete deformation

diagram for steel 09G2S. Diagnostics, Resource and

Mechanics of materials and structures. 1. pp. 24-33.

Gorkunov, E. S., Zadvorkin, S. M., Veselov, I. N.,

Mitropol’skaya, S. Yu., Vichuzhanin, D. I., 2008.

Influence of Uniaxial Tension on Magnetic

Characteristics of the 12ÉÅ Pipe Steel Exposed to

Hydrogen Sulfide, Russian Journal of Nondestructive

Testing 44. 8. pp. 566–573.

Donnell, L. H. 1976, Beams, Plates and Shells. p. 453.

Shevchenko, Yu. N, Babeshko, M. E., 2001. The

thermoviscoelastoplastic state of shells of revolution

under axisymmetric deformation along various flat

paths. International Applied Mechanics, 37. pp. 967-

997.

Shevchenko, Yu. N., Babeshko, M. E., 2006. Numerical

Analysis of the Thermoelastoplastic Stress-Strain State

of Laminated Orthotropic Shells Under Axisymmetric

Loading. Journal of Thermal Stresses. 29. 12. pp. 1143-

1162.

Grigorenko, Ya. M., 2009. Using Discrete Fourier Series to

Solve Boundary-Value Stress Problems for Elastic

Bodies with Complex Geometry and Structure.

International Applied Mechanics, 45. 5. pp. 469-513.

Emel’yanov, I. G., Mironov, V. I., 2018. A

Thermodiffusion Problem of Hydrogenation of a Steel

Shell Structure. PNRPU Mechanics Bulletin, 3. pp. 27-

35.

Emel'yanov, I. G., Polyakov, A. A., Hodak, A. S., 2019.

Stressed state of a steel construction working in

hydrogen containing environment. 8th International

Conference on Mathematical Modeling in Physical

Science: Journal of Physics: Conference Series, 1391

012027.

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

234