Wireless Industrial Communication and Control System: AI Assisted

Blind Spot Detection-and-Avoidance for AGVs

Sergiy Melnyk

1 a

, Shreya Tayade

1 b

, Mervat Zarour

1 c

and Hans D. Schotten

1, 2 d

1

Intelligent Networks, German Research Center for Artificial Intelligence, Kaiserslautern, Germany

2

Indtitute for Wireless Communication and Navigation, University of Kaiserslautern, Kaiserslautern, Germany

Keywords:

Edge Cloud, Industrial Control, Wireless Closed Loop Control, AI based Channel Prediction, Communication

Control Co-design, Multi-link Communication, Flexible Coding, Low Latency, High Reliability

Abstract:

An Edge cloud based industrial control systems set high requirements on the latency and reliability of wire-

less communication link. In order to improve the performance of the communication system, an approach

of industrial control and communication co-design is proposed. The system consists out of three compo-

nents; Artificial Intelligence(AI) control, Industrial control and Communication control. An AI predictive

algorithm forecasts the expected signal strength and detects the potential coverage blind spots on a factory

floor. Based on this, industrial control system adjusts the paths for AGVs in order to spatially as well as

timely avoid the communication drops. The communication control manages the communication resources

taking into consideration the present control requirements and AI predicted channel information. Besides, the

communication system is enhanced by multi-RAT capability in order to further increase the communication

reliability. The investigations show that AI based industrial control and communication co-design approach

provides an increase of the reliability of communication link. Even more, the proposed system features the

ability of reliability guarantee, based on the applications’ requirements.

1 INTRODUCTION

One of the major achievements of the industrial rev-

olution Industry 4.0 is the introduction of the wire-

less communication to manufacturing areas (Aktas

et al., 2017). Since the manufacturing devices or even

the parts of the devices gained the ability to com-

municate with each other, new possibilities for flex-

ible and scalable industrial applications of the future

have emerged. Among the targeted application fields

are factory automation, process automation, closed

loop control. Also, human related applications such

as human-machine interaction or different kinds of

workers assistance gain advantages of wireless com-

munication. This large variety of applications also

put heterogeneous requirements on the wireless com-

munication system. Thus, the Radio Access Tech-

nology (RAT) utilised should provide high amount of

flexibility in order to serve different kind of applica-

tions.

a

https://orcid.org/0000-0001-7724-7202

b

https://orcid.org/0000-0003-3144-0263

c

https://orcid.org/0000-0003-3325-2637

d

https://orcid.org/0000-0001-5005-3635

Further promising technology emerged in recent

years is edge cloud computation. It provides some

benefits also to industrial control applications. The

actuators are usually less powerful devices which are

tailored to low energy consumption. Offloading the

processing and the controller to the cloud may reduce

the power consumption at the device. Moreover, an

edge cloud as a centralized entity provides a possibil-

ity of an easy interconnection of applications running

on different devices and promotes collaborative work-

ing.

In this paper, Automated Guided Vehicle (AGV)

control use case is considered as an illustrative ex-

ample. Especially mobile devices are more prone to

interference, Doppler shifts and channel deep fading,

which leads to drop of communication link quality.

Thus, the reliable communication, which is critical

for control applications, cannot be guaranteed. Un-

fortunately, this effects are of stochastic nature and

cannot be easy modeled. Nevertheless, an AI algo-

rithm shown in this paper is able to predict the drops

of the link quality, which we call blind spots, so that

counter measures can be applied on time.

Melnyk, S., Tayade, S., Zarour, M. and Schotten, H.

Wireless Industrial Communication and Control System: AI Assisted Blind Spot Detection-and-Avoidance for AGVs.

DOI: 10.5220/0011583100003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 307-313

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

307

In order to effectively withstand link quality

drops, a communication control co-design approach

is proposed. On the one hand, the communication

system itself is enhanced to mitigate deep fading ef-

fects. It is realized by utilising a combination of sev-

eral RATs such as WLAN, 5G or other. Since any

RAT is utilising an other frequency band, the proba-

bility of deep fading on every channel is significantly

lowered. Thus, distributing communication via sev-

eral links provide an improvement on the overall link

reliability. On the other hand, AGVs are mobile plat-

forms, which are centrally controlled from the edge

cloud. By means of AI predictions, a blind spot may

be physically avoided by planning a path around it.

Due to outsourcing the industrial control to the edge

cloud, the overall complexity of the system is then

also reduced.

Even though AGV control is the leading use case

of this paper, the investigations fit also other control

applications. This is why we propose a flexible func-

tional architecture of the system, which is also appli-

cable to various industrial scenarios. Section 2 an

overview on the proposed architecture as well as a

brief description of its components. In following sec-

tions, the detailed insight in the three main compo-

nents AI based channel prediction, Industrial Control

and Communication Control is given. Finally, sec-

tion 6 summarizes the results of the paper.

2 FUNCTIONAL

ARCHITECTURE

The upcoming industrial revolution Industry 4.0 have

exemplified the necessity of wireless communications

in an industrial control. The transitioning of indus-

try from wired to wireless have imposed stringent re-

quirements on latency, reliability of wireless commu-

nications. In order to achieve the performance sim-

ilar to wired technology, the wireless system needs

to be adapted to fulfill the KPI requirements of an

Industrial control. Therefore, we present an Edge-

cloud based functional architecture of wireless indus-

trial control, as shown in Figure 1. An industrial con-

trol consists of a controller that is located in an edge

cloud. Based on the sensors data as well as actua-

tors feedback received, the controller generates con-

trol commands and sends them to the actuators. The

functions and in-depth description is presented in this

section.

2.1 Edge Cloud

An Edge cloud enables faster data computation and

processing to reduce latency for processing large

amount of data. Moving industrial control system to

the edge cloud enables centralized processing, collab-

oration and coordination of actuators and sensors in a

factory devices to realize a task. Moreover, the edge

cloud based industrial control allows faster informa-

tion exchange between the industrial control and the

communication control.

2.2 Industrial Control

The main functionality of an industrial controller is

to generate the control commands and inputs for the

actuators in the factory. The control commands are

applied to actuators to perform a specific task. The

control commands can be generated periodically or

even-triggered depending on the characteristic of the

control system. In a closed loop feedback control sys-

tem, i.e. AGV control, the control commands are gen-

erated and updated periodically. In the process au-

tomation and monitoring, the control command gen-

eration can be event-triggered and needs to be per-

formed only when the measurement data from sen-

sors are not within desired threshold. Depending on

the state of actuators and measurement data, the error

evaluation block determines the error by comparing

the current state with the desired state (output). The

evaluated error is then used by controller to generate

the control commands to mitigate the error. The er-

ror is evaluated from the feedback received from the

sensors and actuators over an uplink wireless channel.

2.3 Communication Control

Communication control is a spectrum-aware man-

agement component that controls the transmission of

control updates over a wireless channel. The com-

munication control ensures the availability of high

quality link to industrial control applications while si-

multaneously optimizing the utilisation of communi-

cation resources. The communication resources are

optimized by control aware resource allocation tech-

niques, such as presented (Tayade et al., 2020). The

Channel State Information (CSI) feedback received,

the link quality and the current control state are used

to optimally allocate resources over available RATs.

The RAT selection functionality selects the best per-

forming link from 5G, LTE WiFi or other, according

to the requirements of control application and current

communication channel state. Moreover, the com-

munication control provides optimal Modulation and

ETCIIM 2022 - International Workshop on Emerging Trends and Case-Studies in Industry 4.0 and Intelligent Manufacturing

308

Figure 1: Functional Architecture of Edge Cloud based industrial control.

Coding Scheme (MCS) selection based on the control

state of industrial application.

Furthermore, in presence of deep channel fading,

the communication control can delay the transmission

of control updates in order to save resources and pre-

vent losses of control information. For example, the

communication control can perform the task of re-

source management in an multi-AGV scenario assur-

ing that every AGV get enough resources to remain

stable. This means, the settings of any communica-

tion link should meet the latency as well as reliability

requirements of industrial control applications.

2.4 AI based Decision Making

In industrial control applications like process automa-

tion or multi-AGV control and coordination, a larger

amount of data from the sensor devices needs to be

processed. An AI based techniques can be adapted

to analyse the data and predict the future outcomes of

the control state as well as channel condition. As the

communication occurs over a wireless channel, out-

ages and packet losses could lead to the instability of

industrial control. As a consequence, the control in-

formation is not available at the actuators within the

latency constraints. AI based techniques can predict

the error and channel state and provide these informa-

tion to the industrial and communication control. The

AI based decider collects channel information, con-

trol state and the factory environment for evaluating

and predicting the future states.

3 BLIND SPOTS DETECTION

The automatic robust blind spot detector solves a

binary classification problem of identifying the blind

spots using Support Vector Classifier (SVC) and up-

dates the industry received power map. The classifi-

cation model must first be trained to optimally deter-

mine the model parameters. In the validation phase, it

needs to check whether the model has over-fitting or

under-fitting problems so that the classification model

can be generalized.

In the testing phase, the classifier should be able to

classify the industry map into two classes. Each posi-

tion in the industry map has one of the two class as-

signments, positions with or without sufficient recep-

tion power. The model must have high performance

to make a positive decision about the blind spot po-

sitions, so the blind spots detection class must have a

high positive predictive value and low miss rate.

SVC has to provide the solution to the positions

separation in the industry power map in online phase.

The blind spots position is taken as positive decision

During the design phase of an industrial communi-

cation system, the industry floor map is created to

provide the area with sufficient receiving power, tak-

ing into account the industry layout and the antenna

pattern. For analysis purposes, the industry map is

partitioned into square areas of 1 × 1 m

2

. These po-

sitions should have sufficient connectivity, reliability

and lower packet loss for the real time networked con-

trol system. However, the guarantee of reliable wire-

less connection is not provided due to time-varying

effects such as shadowing or multi-path fading which

occur in a highly dynamic environment with a lot of

metal surfaces.

Wireless Industrial Communication and Control System: AI Assisted Blind Spot Detection-and-Avoidance for AGVs

309

with industry map sampling distance 1 m. If the posi-

tion is provided with the required power within cov-

erage map, but the received signal power at these po-

sitions is less than the receiver sensitivity, the class

assignment is positive. If the positions is located out-

side the coverage map and has a large distance to the

transmitter or has received signal power more than the

receiver sensitivity, then the decision is for negative

class. In this way, SVC inspects the industry map at

each position with sampling distance of 1m.

Channel Data Generation. In training, validation

as well as model testing phase, the SVC needs chan-

nel measurement information in the industry envi-

ronment. This is generated using the channel mea-

surements in the QUAsi Deterministic RadIo chan-

nel GenerAtor (QuaDRiGa) model in industry sce-

nario. Multiple communication models are simulated

for line-of-sight (LOS) and non-line-of-sight (NLOS)

scenarios. The power map is generated under con-

sideration of all possible signal propagation path loss,

shadowing, multi path fading effect. Several differ-

ent power maps can be obtained for the same industry

layout with different communication system param-

eters. After that, each sampled position has to be la-

beled from prospective of the distance path loss power

map. Thereafter, the model is trained and L-fold is

validated.

Support Vector Classifier: the SVC can be con-

sidered as a function between input information and

output position classes. The input information is the

industrial wireless channel information, which is con-

sidered as a feature matrix [X] = x

j

(i); i = (1 : m); j =

(1 : n), whereas m is the number of features and n

is the number of positions to be considered. As the

output, the system must be able to assign the posi-

tion from industrial map in binary class assignments

y = {+1, −1}. The separation of the two classes

requires a nonlinear hyperplane. Moreover, a cor-

respondent linear separated hyperplane is preferred

based on the mapping Φ(x

i

) in the infinite dimension

using the radial basis kernel. With the kernel func-

tion, the nonlinear separation level can be achieved

without increasing the dimension value m of the vec-

tor space, i. e., either a mapping Φ(x

1

, x

2

) to the height

dimension space is used until linear separation is pos-

sible, or a kernel function K(x

i

, x

j

) = Φ(x

i

)

T

· Φ(x

j

)

is used, which has the condition that the kernel func-

tion must be an inner product in at least one feature

space. This will avoid the internal product in the op-

timization problem in the height-dimensional space.

The penalty parameter C represents the inverse effect

of the regularization parameter. The penalty param-

eter C and the kernel parameter σ can be optimally

configured using L-fold cross validation.

4 AGV TRAJECTORY PLANER

WITH BLIND SPOTS

AVOIDANCE SYSTEM

In this section, the AGV edge cloud control system

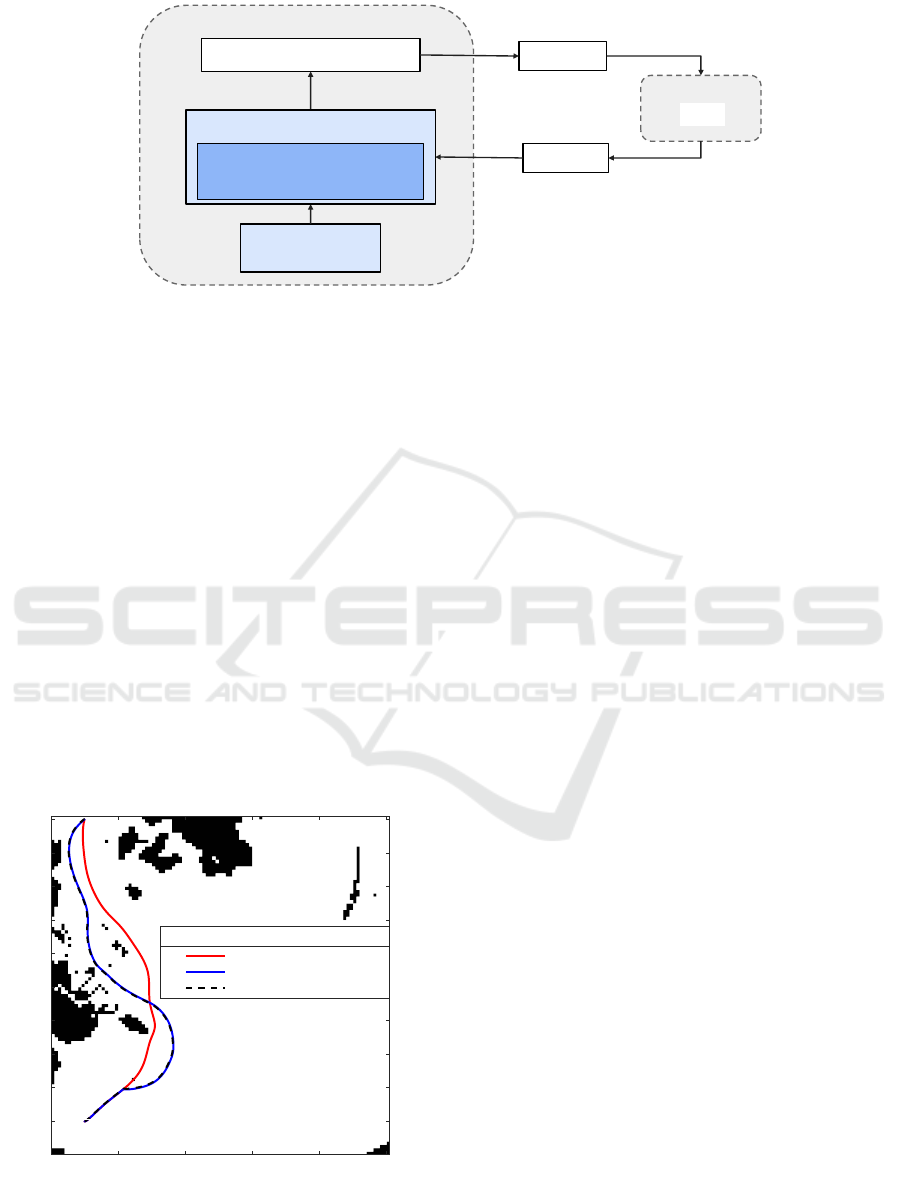

is considered. As shown in Figure 2, the AGVs are

moving on the factory floor. Due to low computation

power of the AGVs, they do not feature capabilities

for path planning or trajectory following. Any AGV

expects the control input signals to be provided by ex-

ternal control system, which is located on the edge

cloud. The AGVs follow the control signals and give

a feedback on their control states. The power consum-

ing computations of control signals are performed on

the edge cloud. Thus, edge cloud control system has

full control over the behaviour of the AGVs.

Edge cloud has to use wireless channel to com-

municate with AGVs, since these are highly mobile

platforms. In this case, wired communication chan-

nel is not feasible. However, the wireless link is the

critical part of the system, since both up- as well as

downlink may suffer deep fading effects, which af-

fects the whole control loop. This behaviour might be

mitigated by means of AI based blind spots detection

algorithm described in section 3.

The coverage blind spots elimination (CBSE) sys-

tem is the trajectory planning algorithm, which takes

periodic blind spots forecast updates into account in

order to avoid the communication link outage. In

following, detailed description of the CBSE system

components is presented.

Reference Trajectory Planning. Initially, a start as

well as a destination position, which must be reached

within a given time T , is reported to the controller.

The AGV has to follow a shortest blind spot free path

to the destination. Trajectory planning starts with a

creation of a binary occupation map of the factory

floor. As can be seeing in Figure 3, white areas can

be accessed by an AGV, whereas black areas rep-

resent obstacles. Those are physical obstacles such

as walls, pillars, machines etc. Besides, blind spot

areas are also declared as obstacles to be avoided.

Thereby, blind spot detection algorithm provides an

up-to-date blind spot forecast. Afterwards, proba-

bilistic roadmap (PRM) algorithm (Kavraki et al.,

1996) is utilised in order to find the optimal trajectory

from start to the destination. This path is represented

with the red color in Figure 3.

ETCIIM 2022 - International Workshop on Emerging Trends and Case-Studies in Industry 4.0 and Intelligent Manufacturing

310

Edge-Cloud

Trajectory follower

Control state

Control input

• Channel state

• Industry layout

Factory floor

AGV

CBSE system

• Blind spots detector

• Refrence trajectory planner

Figure 2: Coverage blind spot elimination system.

Trajectory Replanning. needs to be performed pe-

riodically, since blind spots may occur spontaneously

and can be predicted on short time scale only. Thus,

on any update by blind spots detection algorithm, the

AGV’s trajectory needs to be reconsidered. If the tra-

jectory does not collide with the new occured blind

spots, no action is required.

However, Figure 3 shows the situation, in which

an AGV would suffer a connection drop, if it would

follow the red path. Thus, the PRM algorithm is ap-

plied again in order to plan an alternative trajectory,

which is shown with blue color. In this manner, an

AGV would avoid potential blind spots and keeps the

reliable communication channel to the edge cloud.

Trajectory Follower. is required to generate the

control inputs for the AGVs. The available trajec-

tory information in the trajectory (re-)planner out-

put presents only the xy-coordinates of the nodes,

SVC power predicted industry map

0 20 40 60 80 100

x-coordinate in m.

0

10

20

30

40

50

60

70

80

90

100

y-coordinate in m.

Initial reference path

Alternative reference path

Actual AGV traked path

LAD=1sec, cubic B-spline interpolation

Start position

(10,10)

Figure 3: Path replanning example – reference, alternative

and actual AGV path from start to destination.

whereas the path segments are non-uniform. How-

ever, the uniform path sampling with controller fre-

quency leads to an unfavorable jumping velocity pro-

file. With cubic Basis spline (B-spline) interpolation,

the availability of the first as well as the second path

derivative is assured. In Figure 3, the final trajectory

of the AGV is depicted with dashed line.

5 ADAPTIVE CODING FOR

MULTI-RAT RESOURCE

ALLOCATION

In order to further improve the reliability of a commu-

nication link, the packets to be sent may be distributed

via several communication channels, or RATs. In this

manner, local signal power drops like blind spots may

be mitigated, since this effects depend on transmitter

frequency, which differs for different RATs. How-

ever, packet duplication techniques such as Parallel

Redundancy Protocol (PRP) (Ehrig et al., 2017) or

MultiPath TCP (Paasch and Bonaventure, 2014) lead

to inefficient resource utilisation, since they do not

feature error correction capability for corrupted pack-

ets.

In contrast, fountain codes are able to produce as

many sub-codewords out of one packet, as it is re-

quired. That means, this codes are raterless, because

the coding rate can be flexibly adjusted due to re-

quirements. On the decoder side, a certain number of

sub-codewords should be received in order to decode

the packet (K-out-of-N-principle). However, fountain

codes require an erasure-channel, i. e., they can with-

stand a drop of sub-codewords, but they are not able

to correct the erroneous sub-codewords. In order to

mitigate this issue, fountain codes should be used in

conjunction with error-correcting codes, as proposed

in (Berger et al., 2008).

Wireless Industrial Communication and Control System: AI Assisted Blind Spot Detection-and-Avoidance for AGVs

311

(a) Estimated number N of RaptorQ sub-codewords per chan-

nel

(b) PER simulation with NS3

Figure 4: RaptorQ enhanced multi-RAT system for PER guarantee (PER threshold: 10

−3

).

Combined with multi-RAT transmission, fountain

codes provide a flexible tool to distribute a packet over

multiple links. Especially utilising channel prediction

algorithms, the number of sub-codewords to be sent

may be tailored to real channel conditions but chan-

nel estimations. This provides further improvement of

reliability, whereas resource utilisation remains opti-

mal.

In our investigations, we considered a system

based on two OFDM communication links. As a

fountain code to work with, RaptorQ code was cho-

sen. A packet should be encoded with RaptorQ, and

the generated sub-codewords should be sent through

both links. The goal is to generate the number of

sub-codewors sufficient to meet a reliability theshold

based on the Signal-to-Noise-Ratio (SNR) prediction

for each channel.

For the estimation of the number N of packets to

be sent per channel, analytical error estimation for

OFDM signals was performed. In order to reduce

simulation time, Packer Error Rate (PER) thresh-

old of 10

−3

was selected. However, the result can

be translated to such demanding thresholds as 10

−9

and less. Figure 4a shows the estimated number N

for both channel models based on SNR per chan-

nel. Hereby, x-axis shows the SNR (in dB) of the

channel 1, whereas y-axis show the additional sig-

nal attenuation A (in dB) on the channel 2. Thus,

SNR

2

= SNR

1

− A.

The results were verified by a simulaiton setup

with network simulator NS3. Figure 4b shows the

achieved PER over the considered SNR range. It can

be seeing, that for the most combinations of SNR

1

and SNR

2

, the estimations yield a reliable PER which

meets the required threshold of 10

−3

. Nevertheless,

Figure 4b still features some areas, where the PER

drops below the threshold. The reason is, that more

sophisticated channel model should be used for the

estimation in order to better fit the fading behaviour

of the channels. Nevertheless, the combination of

multi-link transmission and rateless coding may be

used in order to provide guaranteed PER, whereas the

resource usage can be flexibly tailored to channel con-

ditions.

6 CONCLUSIONS

In this paper, an Edge-cloud based industrial con-

trol functional architecture is proposed for enabling

control communication co-design. Furthermore, we

discuss applicability of AI based decision making to

adapt the control and communication system design.

We present channel condition based AGV navigation

control to avoid the coverage blindspots and adapt

the tracks in real-time. Moreover we adapt the com-

munication system by performing the channel cod-

ing across RAT based on link quality. Furthermore,

AI based channel state predictions can be utilised by

communication control. Utilising multi-RAT system

in conjunction with rateless coding, it is possible to

tailor the coding rate as well as the distribution of the

sub-codewords to different links to the expected chan-

nel quality, or SNR. By doing so, the required relia-

bility of a communication link could be guaranteed.

In future, the coding rate adaptation algorithm

needs to be improved in order to provide better re-

liability of the communication links. Further, it is

also possible to enhance this algorithm with machine

learning techniques in order to provide more precise

results based on the AGV position. Besides, further

investigations on the overall reliability of the commu-

nication as well as the impact of the forecast time are

required.

ACKNOWLEDGEMENTS

This work has been supported by the Federal Min-

istry for Economic Affairs and Climate Action of the

ETCIIM 2022 - International Workshop on Emerging Trends and Case-Studies in Industry 4.0 and Intelligent Manufacturing

312

Federal Republic of Germany (Foerderkennzeichen,

01MT19006A, AIRPoRT). The authors alone are re-

sponsible for the content of the paper.

REFERENCES

Aktas, I., Bentkus, A., Bonanati, F., Dekorsy, A., Dom-

browski, C., Doubrava, M., Golestani, A., Hofmann,

F., Heidrich, M., Hiensch, S., Kays, R., Meyer, M.,

M

¨

uller, A., Brink, S. t., Petreska, N., Popovic, M.,

Ruchhaupt, L., Saad, A., Schotten, H., W

¨

oste, C., and

Wolff, I. (2017). Funktechnologien f

¨

ur Industrie 4.0.

VDE-Positionspapier. VDE, Frankfurt a. M.

Berger, C. R., Zhou, S., Wen, Y., Willett, P., and Pattipati, K.

(2008). Optimizing joint erasure-and error-correction

coding for wireless packet transmissions. IEEE Trans-

actions on Wireless Communications, 7(11):4586–

4595.

Ehrig, M., Petri, M., Sark, V., Tesfay, A. G., Melnyk, S.,

Schotten, H., Anwar, W., Franchi, N., Fettweis, G.,

and Marchenko, N. (2017). Reliable wireless commu-

nication and positioning enabling mobile control and

safety applications in industrial environments. In 2017

IEEE International Conference on Industrial Technol-

ogy (ICIT), pages 1301–1306. IEEE.

Kavraki, L., Svestka, P., Latombe, J.-C., and Overmars, M.

(1996). Probabilistic roadmaps for path planning in

high-dimensional configuration spaces. IEEE Trans-

actions on Robotics and Automation, 12(4):566–580.

Paasch, C. and Bonaventure, O. (2014). Multipath tcp.

Communications of the ACM, 57(4):51–57.

Tayade, S., Rost, P., Maeder, A., and Schotten, H. D.

(2020). Impact of short blocklength coding on sta-

bility of an agv control system in industry 4.0. In

2020 IEEE International Conference on Communica-

tions Workshops (ICC Workshops), pages 1–6.

Wireless Industrial Communication and Control System: AI Assisted Blind Spot Detection-and-Avoidance for AGVs

313