Predictive Model of the Organization of Car Maintenance and Repair

Wagons using the Smoothing Algorithm the Extrapolation Method

Guzal Bubnova

Ural State University of Railway Transport, Yekaterinburg, Russia

Keywords: Railway carriage, technical maintenance, current repairs, dynamic series, extrapolation method, decision-

making structure.

Abstract: When developing a predictive organizational model for the maintenance and repair of railcars at large

marshalling yards, we take into account the multi-factor composition of variable values, many of which

should be within the required values without disrupting the order and activity of the transportation process.

In such cases, additional justification is required for the technical decisions taken to ensure normal and safe

operating conditions. The article provides a methodology for substantiating technical solutions for

improving the organization of car maintenance by determining forecast values for a given time interval. The

list of measures to improve the system within the framework of the selected factor is considered: installation

of floor-standing equipment in the form of an additional service channel for monitoring the sub-car space,

installation of SPIDER-type diagnostic equipment to provide an assessment of the technical condition of the

car according to external parameters. The effectiveness of implemented measures was evaluated.

1 INTRODUCTION

Along with the increased demand for freight

transportation, there was a problem associated with

the development of a set of tasks, the solution of

which will optimize the operation and increase the

efficiency of the use and operation of railcars. One

of these tasks is the development of up-to-date

regulatory and technical documentation for the

design of maintenance and repair technology. The

analytical solution of the problem is complex

(Zubkov, 2022; Zubkov, 2022; Zubkov, 2022;

Pershin, 2021), and in some cases is hardly feasible.

Modern approaches to solving such problems

actively use numerical modeling methods, in

particular the extrapolation method (Yushkova,

2021; Galkin, 2021; Zubkov, 2021; Zubkov, 2021;

Kamaretdinova, 2020). The article describes the

process describing the dynamics of restoring the

service life of railcars in the framework of

maintenance and repair of freight cars with various

types of technical malfunctions. The restoration

process consists of preliminary decisions on the

regulations and content of the necessary work to be

performed in order to increase the efficiency of

production of the car industry. A unified and adapted

structural model for decision-making development is

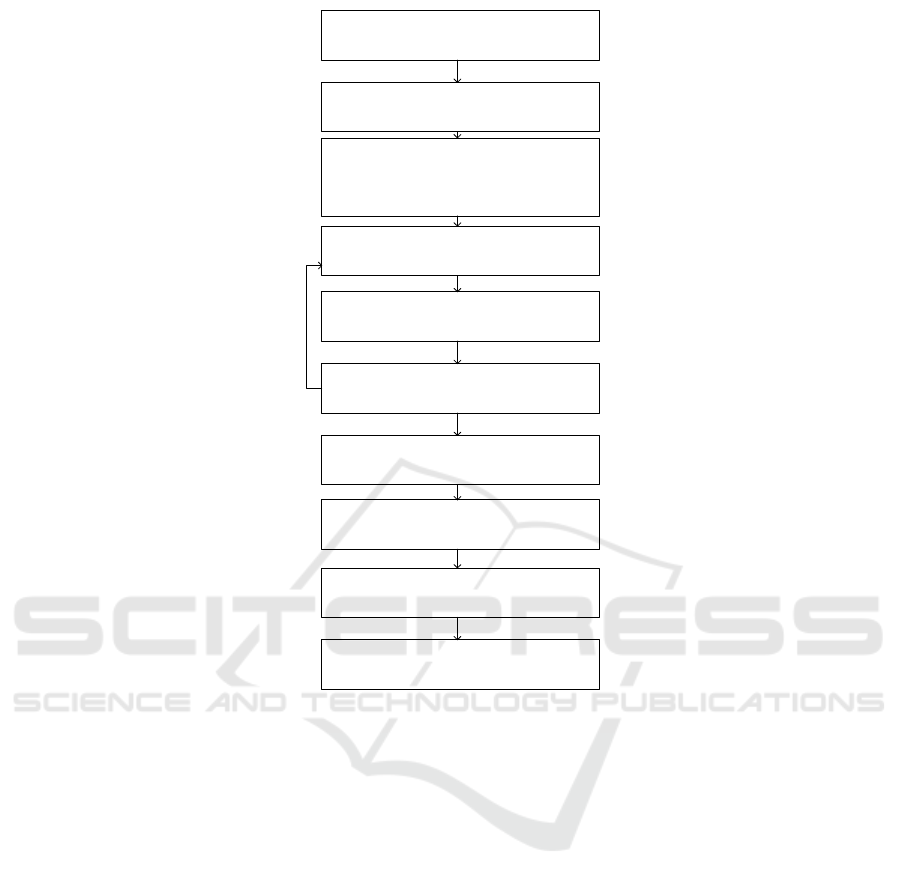

presented in figure 1.

The description of each block according to the

scheme shown in Figure 1 is defined as follows:

Block 1 is responsible for forming an

informative block that includes the results of an

analysis of situations that arise in the divisions of the

car industry with a problem statement based on the

multi-factor structure of events that occur, for

example, at the point of maintenance and current

uncoupling repairs.

Block 2 is aimed at forming a target function

with setting critical parameters and conditional

restrictions, for example, increasing the efficiency of

production of restoring the technical resource of

wagons in conditions of limited time and parameters

of maintenance and repair.

Block 3 determines the performance of work

related to the collection and analysis and

identification of the informative component of the

car farm division, as well as operational processing

of the obtained statistical data with subsequent

evaluation using known methods, for example,

extrapolation and fixing the distribution law of a

random variable, in order to predict the time interval

for the desired period under given conditions.

Block 4 based on the forecast values of the

324

Bubnova, G.

Predictive Model of the Organization of Car Maintenance and Repair Wagons using the Smoothing Algorithm the Extrapolation Method.

DOI: 10.5220/0011584700003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 324-330

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

multi-factor component of the car industry divisions,

a selection of the most dangerous factors affecting

the reduction of production efficiency is made.

Block 5 processes the obtained indicators in

block 4 by superimposing them on the mathematical

model of queuing with the introduction of variable

values, coefficients of alignment of future indicators

for a given time interval.

Block 6 evaluates alternative solutions based on

the model. Thus, the inverse problem of finding

effective tools for influencing current indicators is

solved, and a stochastic value of possible deviations

from the desired target function is laid. If the desired

indicators remain unchanged from the initially set

forecast parameters, the process returns to block 4.

The cycle of this process is repeated until the target

function is reached to the desired state.

Block 7 selects the optimal set of influence

coefficients, which ultimately determines the

optimal strategy for a given criterion.

Block 8 at the stage of the current block, using

expert assessment methods, the manager makes a

number of strategic decisions to choose the optimal

one, among the indicate dones. In some cases that

are particularly dangerous to security and cost-

effective, a pre-completion block is performed

aimed at developing a pilot project with an

assessment of bottlenecks.

Block 9 performing organizational and technical

work to implement the selected (from block 8)

strategic solution.

Block 10 performing an evaluation of the result

obtained that meets the criteria of economic

efficiency and safety criteria.

Based on the above, to assess the impact of

maintenance and repair on the technical condition of

rolling stock when performing work, the

extrapolation method and the queuing method were

used for predictive assessment and indicative

assessment, respectively. The article uses blocks 1-3,

so that the calculation is performed in the Excel

software package.

After setting the problem and determining the

goal of the solution, an important component of the

1. Analysis of the situation and formulation

of the problem in the organization of

production in the wagon economy

2. Determination of the purpose, criteria and

limitations in the process of repair and

maintenance of wagons

3. Collection, analysis and forecast of

information based on the parameters of the

production of restoring the resources of

wagons

5. Process modeling, research of operations

related to the restoration of the resource of

wagons

6. Evaluation of alternatives according to the

model in the organization of production in

the wagon economy

7. Choosing the optimal strategy according

to a given criterion of the process of

restoring the resource of wagons

8. Acceptance by the head of the final

decision in the organization of production in

the wagon farm

9. Organization of the implementation of the

decision taken in the organization of

production in the wagon farm

10. Evaluation of the result obtained in the

organization of production in the wagon

farm

4. Drawing up a list of alternatives in the

organization of production in the wagon

economy

Fi

g

ure 1: Decision makin

g

scheme.

Predictive Model of the Organization of Car Maintenance and Repair Wagons using the Smoothing Algorithm the Extrapolation Method

325

process of finding optimal strategies (strategic

decision) is the collection, analysis and forecasting

of information (block 1-3).

The main forecasting methods used in the railcar

industry are methods based on dynamic series. A

dynamic series is a sequence of numerical values

that characterize changes in a process over time.

When analyzing the dynamics series, statistical data

collected over a certain period of time are used to

determine the nature of the direction and intensity of

quantitative changes in processes. Distinguish

between the level of a series and a trend. Row level

– a member of the dynamics row. Trend – the main

deterministic trend of process change. The levels of

a series are considered as random variables that

change over time depending on the main and

random factors.

Forecasting – determining the probable state of

the process in the future. It is complicated by the

presence of areas of gradual, evolutionary

development, areas of abrupt, revolutionary

development, and factors that cause actual levels to

deviate from the trend. In forecasting, the process of

changing a variable is expressed by a general model:

()

() (),yt ft t

ε

=+

(1)

where

()

yt

is the production parameter under

study (the volume of production of cars with

maintenance and/or PTOR, the volume of cars that

have passed maintenance, etc.);

()

f

t

- trend, regular component.

()t

ε

- random component.

Trends are determined by numerous methods:

extrapolation method, queuing method, etc.

Extrapolation is understood as the spread of patterns,

relationships and relationships that operate in the

studied (past) period, beyond its limits (in the

future). The queuing method is understood as a

closed system with its existing service channels

(personnel, equipment, etc.) that perform the main

list of works and requests received for service

(products, rolling stock, visitors, etc.) with which or

on which work is being carried out to restore the

resource and other types of work that resemble

maintenance.

2 MATERIALS AND METHODS

2.1 Initial Data

One-step smoothing algorithm

1. The original dynamic series is formed from

statistical data for a certain period of time and

recorded as a table. We will conduct a study

of the implementation of forecasting changes

in the performance of maintenance and repair

at the point then the current uncoupling repair.

Related data are available for the period from

2019-2021 -2021 г.г, Table 1.

2. In accordance with the experimental data, one

or more functions are selected for the

procedure of smoothing equations.

Experimental data show that labor

productivity changes with time in an

approximately linear manner. Therefore, we

choose a linear function of the form 2 as a

model for smoothing and forecasting:

()

01

,vt a at=+

(2)

2.2 Design Equations and Boundary

Conditions

We determine the numerical values of the regression

coefficient estimates by forming systems of normal

equations using the least squares method. For this

purpose, we substitute the parameter ỹ(t) in equation

2 instead of the parameter ỹ (t).

As a result, we get:

2

2

1

2222

010011

1

(2 )

(2 2 2 )min.

n

î

iii

t

n

ii i

t

Fvvvv

v va vat a a at a t

=

=

=−+=

−− ++ +

To find the extremum of the function, we equate

the first partial derivatives of the objective function

with respect to the corresponding unknowns to zero,

obtaining a system of normal equations for finding

the unknowns a

0

, a

1

01

11

0

2

11

111

1

0, ;

0, .

nn

i

tt

nnn

i

ttt

F

na a t v

a

F

atat yt

a

==

===

∂

=+=

∂

∂

=+=

∂

To solve this system of equations, we apply the

matrix method X=A

1

B

where

1

11

1

1

11 1

,,.

nn

i

tt

nn n

tt t

nt y

a

AB

a

tyt vt

λ

==

== =

== =

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

326

The solution of the system was carried out using

Excel software tools.

3 RESULTS AND DISCUSSION

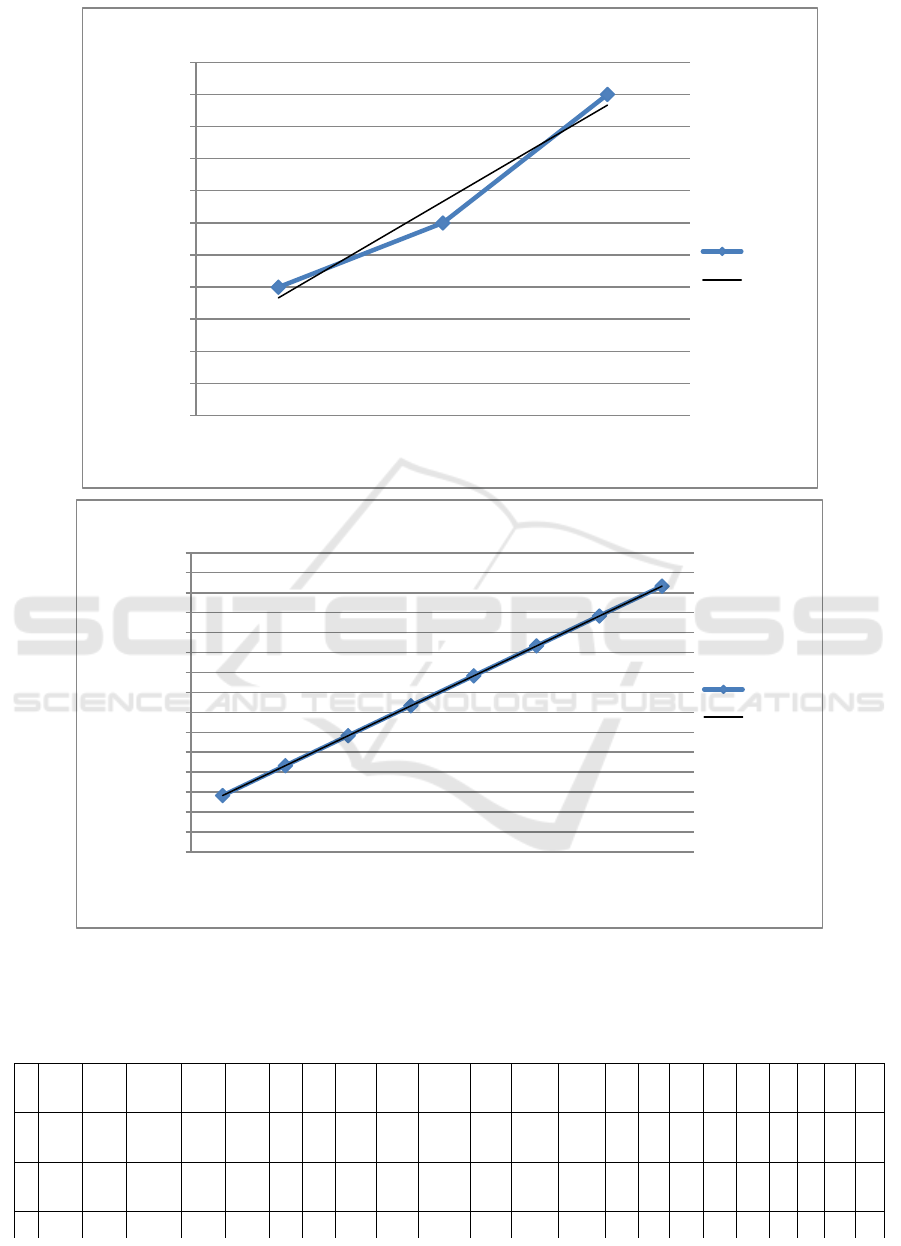

As a result of the calculation using the method

described above, prediction distributions are

obtained using the extrapolation method. Figure 2

shows an example of the distribution of the forecast

estimate of failures in the technical condition of

railcars in the period from 2019-2021.

Calculations show that the forecast estimate of

the output of cars with technical malfunctions does

not exceed the indicator of more than 450 cars per

year. Table 4 shows the results of calculating the

projected number of railcars released from the TOP

for the period from 2022 to 2027. figure 3.

Let's make a simulation based on Table the

values of estimated factors specified in Table 1for

the period from 2019-2021.we get the following

results:

To solve this system of equations, the matrix

method X=A

1

B is applied

where

36

.

614

A

=

The values of the vector of free values X for

matrix B are presented in Table 2.

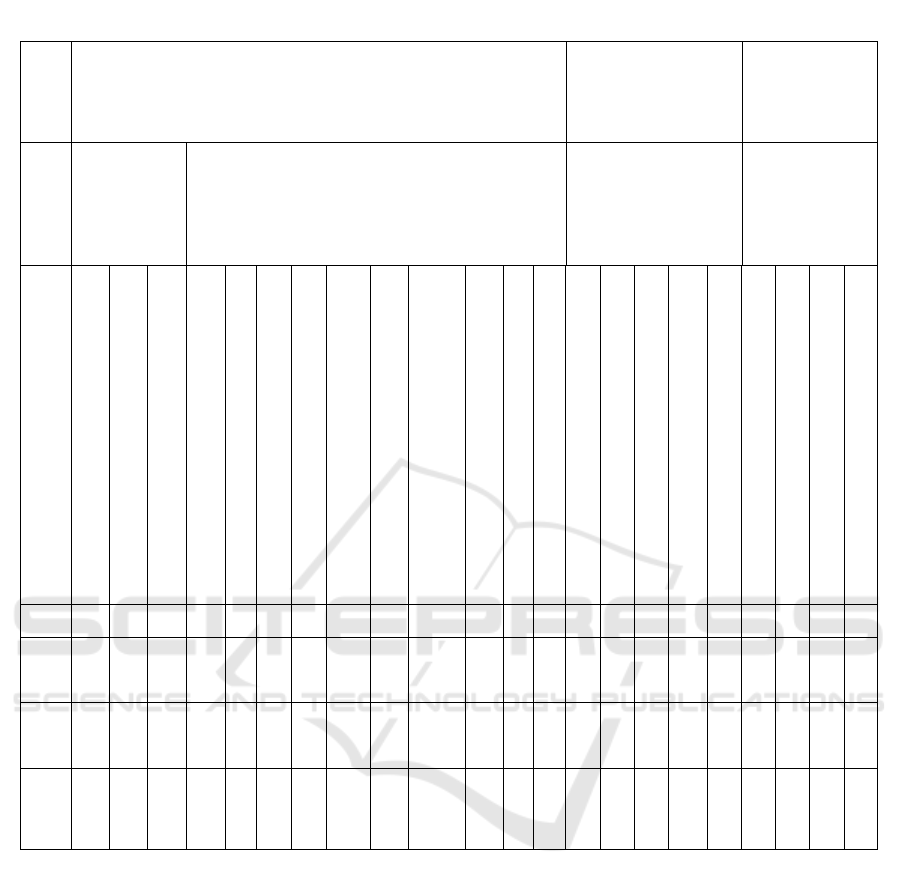

Table 1: Dynamic series for restoring the service life of faulty railcars

Map items

Rolling stock Enlarged car units Details of railcars

Time intervals

Restoration of

the technical life

of railcars in the

amount of

unplanned

repairs

Trouble shooting of rolling stock components

Digressions in current

uncoupling repair of

wagons of enlarged car

elements

Digressions in

current uncoupling

repair of wagons of

the running parts of

the car

Indicators that determine

the degree of development of factors

Number of defective freight cars in BOR

Number of defective freight cars in TR-1

Number of defective freight cars in TR-12

Disabled brakes restored

Replaced sets of air distributors

Replaced auto

modes Replaced autoregulators

Replaced рукавовR-17 hoses

Replaced end and release valves

Replaced brake pads

Replaced details auto coupler parts

Adjusting the brake lever gear

Other malfunctions

Bodywork

Frame

Auto coupler

Running gear

Brake system

Box node

Wheel crack

Side frame cracks/defects

Over the Spring beam crack

Year 1 2 3 4 5 6 7 8 9 10 11

1

2

1

3

1

4

1

5

1

6

17

1

8

1

9

2

0

2

1

2

2

2019

45

5

67

9

34

3

6

20

0

98

6

6

5

2

1

8

2

3

201

21

1

17

267

39

7

5

8

4

3

2

7

9

6

3

8

2

1

1

3

12

5

6 1 1 1

1

1

2020

42

8

15

8

66

7

6

24

6

69

9

1

9

8

9

1

7

284

29

9

25

883

57

8

7

9

8

5

3

4

1

4

3

9

1

4

2

4

21

7

6 1 2 3 0

2021

37

7

84

8

58

4

4

93

2

26

9

1

1

7

1

0

7 407

43

0

38

806

84

8

1

1

1

9

7

4

3

4

1

4

1

2

4

6

94

5

6

3

1

5

2

9

2

1

Predictive Model of the Organization of Car Maintenance and Repair Wagons using the Smoothing Algorithm the Extrapolation Method

327

Figure 2: Results of calculating the dynamic series of the distribution of body part failures: top - in the period from

2019-2021-2021 г.г.; bottom-forecast for the period from 2022-2029.

Table 2: Calculated values of unknowns

i

y

1

261

685

1

594

17

378

1

954

967 3

7

4

7

89

2

94

0

81

956

1

82

3

25

025

10

551

1

1

8

3

7

8

3

4

3

6

6

8

5 1

8

3

3

3

2

v

t

2

445

539

3

429

33

488

3

191

1

399

6

6

7

8

1

99

0

2

09

9

185

451

4

09

7

55

404

22

647

2

3

9

5

5

1

9

9

8

4

1

1

8

6

1

2

5

0

9

4

7

4

a 498

392

290 7060 136

8

857 2

0

3

2

91 94 5779 15

6

298

7

197

2

3

6

3

1

-

5

1

7

6

-

2

7

-

0

-

8

-

1

7

1

a

1

-

389

120 -634 -

358

-

267

-

4

-

8

10

3

10

9

1076

9

22

5

267

7

773 2 -

1

1

7

-

1

2

5

1 7 1

4

5

y = 1,5x + 36,333

R² = 0,9643

36

36,5

37

37,5

38

38,5

39

39,5

40

40,5

41

41,5

123

Efficiency, private carriages./person yi

Time, T

Forecast of the retreat in the repair of the car body

Fact

Line (fact)

y = 1,5x + 36,333

R² = 1

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

12345678

Efficiency, private carriages./person yi

Time, T

Forecast of the retreat in the repair of the railway car body

Fact

Line (Fact)

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

328

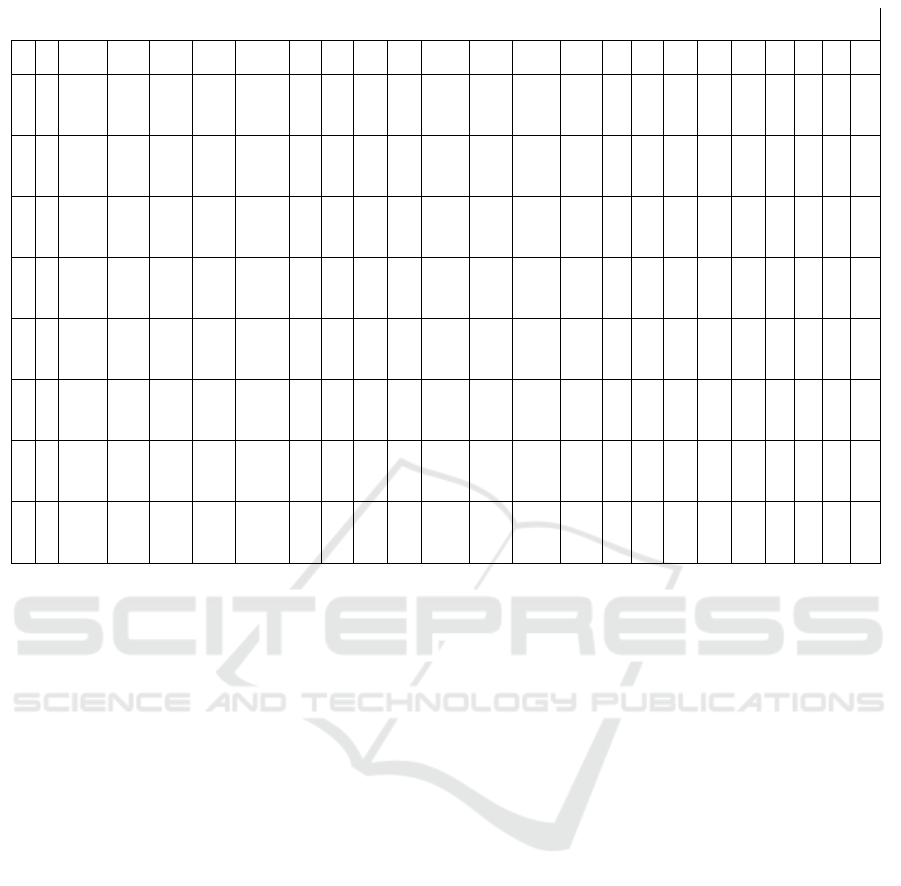

The obtained values form exponents of a

polynomial that allow us to determine the linear

distribution law of a random variable for each factor

indicated in Table 1.

Thus, it is possible to estimate the influence of

the factor on the technical condition of rolling stock

for several years in advance, the results obtained

according to linear distribution laws СВ They are

represented by Table 3.

Negative values in the tables indicate the absence

of a factor for the specified parameters of treatment

and repair of compositions, values that increase over

time in dynamics indicate the need to evaluate

alternatives according to the model.

Further studies are the implementation of blocks

4-10, the research consists in the selection of factors

that expose the organization of production of repair

and maintenance of wagons in the forecast interval

to a decrease in the efficiency of divisions. The

obtained values will be used as variable values

embedded in the mathematical queuing model, as

well as equalization coefficients for future indicators

for the period from 2023-2029. The model will be

aimed at identifying the values of possible

deviations from the desired objective function, the

purpose of which is to select the optimal set of

influence coefficients that do not threaten safety and

economic efficiency according to the decision made.

4 CONCLUSION

Based on the results of the work performed, the

following conclusions can be drawn:

1. It is revealed, that the basis of production

management in a car maintenance depot is to

make a strategic decision.

2. It is determined, that a strategic decision

consists of a number of proactive measures

combined into a decision-making scheme.

3. It is established that one of the first stages of

numerical evaluation of proactive impacts on

decision-making in the production organization

is a forecast.

4. It is determined that the forecast estimation is

performed using methods of extrapolation of

data-based indicators of the queuing method to

the HFE.

5. It is revealed that the forecast estimate for the

next five years does not exclude the need to

make a decision on increasing the capacity of

the station with the introduction of modern

maintenance and repair technologies.

Table 3: Forecast values

t 1 2 3 4 5 6 7 8 9 10 11 12 13 1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

1

459

477

411

6 427

1 010

590

16

24

194

204

16

549

382

5 665

2 745

38

22

11

161

-2

1

-1

-3

6

2

420

562

531

5 793

651

322

12

16

297

313

27

319

608

8 342

3 517

39

12

28

145

23

2

6

11

11

3

381

646

652

5 159

293

55

8

8

400

423

38

088

833

11

019

4 290

41

3

44

130

48

3

13

25

16

4

342

731

772

4 525

-66

-213

4

0

503

532

48

858

1 059

13

696

5 062

42

-7

61

114

73

4

20

39

21

5

303

815

893

3 891

-424

-480

0

-8

606

642

59

627

1 284

16

373

5 835

44

-16

77

99

98

5

27

53

26

6

264

900

1 013

3 257

-783

-748

-4

-16

709

751

70

397

1 510

19

050

6 607

45

-26

94

83

123

6

34

67

31

7

225

984

1 134

2 623

-1 141

-1 015

-8

-24

812

861

81

166

1 735

21

727

7 380

47

-35

110

68

148

7

41

81

36

8

187

069

1 254

1 989

-1 500

-1 283

-12

-32

915

970

91

936

1 961

24

404

8 152

48

-45

127

52

173

8

48

95

41

Predictive Model of the Organization of Car Maintenance and Repair Wagons using the Smoothing Algorithm the Extrapolation Method

329

REFERENCES

Zubkov, V., Sirina, N., 2022. Influence of transport

process participants on the quality of transport services

med. j. Safety in Aviation and Space

Technologies. Select Proceedings of the 9th World

Congress "Aviation in the XXI Century". Cham. 1(1).

pp. 301-310.

Zubkov, V., Sirina, N., 2022. Automation of cargo

correspondences in railway-water communication.

Lecture Notes in Civil Engineering. Cham. 1(180). pp.

405-416.

Zubkov, V., Sirina, N., 2022. Information and intelligent

models in the management of transport and logistics

systems. Lecture Notes in Civil Engineering. Cham.

1(180). pp. 433-445.

Pershin, V., Zubkov, V., Sirina, N., 2021. Public-private

partnership as a factor in the development of the

metropolitan transport system. AIP Conference

Proceedings. Сер. "Proceedings of the Scientific

Conference on Railway Transport and Engineering,

RTE 2021". 020005.

Yushkova, S., Sirina, N., 2021. Polygon principles for

integrative digital rail infrastructure management.

Transportation research procedia. Сер. "International

scientific siberian transport forum, Transsiberia

2020". p. 208-219.

Galkin, A., Zubkov, V., Sirina, N., 2021. M.

Transportation Research Procedia. "International

Scientific Siberian Transport Forum, TransSiberia

2020". pp. 228-235.

Zubkov, V., Sirina, N., 2021. Transport services

management on transport and logistic methods.

Transportation research procedia. "International

scientific siberian transport forum, transsiberia 2020".

p. 263-273.

Zubkov, V., Sirina, N., 2021. Polygon principles for

integrative digital rail infrastructure management.

Transportation research procedia. 54. p. 208.

Kamaretdinova, G., Sirina, N., 2020. The program for

simulation modeling of the process of maintenance of

freight cars at the interstate butt point (PIM PTO GV

MGSP). Certificate of registration of the computer

program ru 2020610967, 01/22/2020. Application No.

2020610116 dated 01/09/2020.

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

330