Digital Twin Architecture of a Cyber-physical Assembly Transfer

System

Matteo De Marchi

1a

, Rafael A. Rojas

1b

, Benedikt G. Mark

1c

, Tanel Aruväli

1d

,

Erwin Rauch

1e

and Dominik T. Matt

1,2 f

1

Industrial Engineering and Automation (IEA), Faculty of Science and Technology, Free University of Bozen-Bolzano,

39100 Bolzano, Italy

2

Innovation Engineering Center (IEC), Fraunhofer Italia Research s.c.a.r.l., Via A. Volta 13a, 39100 Bolzano, Italy

Keywords: Industry 4.0, Cyber Physical Systems, Digital Twin, Smart Manufacturing.

Abstract: In recent years, the introduction of Internet of Things ready devices set new standards in the exploitation of

Industry 4.0 related concepts. The growing complexity of Cyber-Physical Systems makes industrial

machinery to be more connected, interoperable, and controllable. Hereby, topics such as edge/cloud

computing, cyber security, and sustainability are gaining considerable importance. In this scenario, the Digital

Twin paradigm aims at establishing a safe and seamless integrated data flow from the physical world to the

virtual one and vice versa, ensuring a constant optimization of the system and its real-time monitoring. This

work aims to design and implement a DT architecture for a cyber-physical intelligent manufacturing line. The

implementation of a DT node for a flexible transfer line allows users to simply interface it with other systems,

such as collaborative and traditional industrial robots as well as to enable the smart routing and tracing of

shuttles. The development of the technological demonstrator has been conducted at the Smart Mini Factory

laboratory of the Free University of Bolzano.

1 INTRODUCTION

The rapid advancements of technology make the

interconnection and communication of smart devices

over the Internet possible. In addition, the storage

capabilities and processing power of these devices

increased while the size could be reduced. Smart

devices have the capabilities of real-time data

monitoring, accumulation, saving and processing

(Grieves, 2014). Internet of Things (IoT) is a

technology which is rapidly growing and offers

various functions and applications in many domains

and in everyday life. IoT aims at linking the digital to

the physical world while letting devices and people

connect anywhere, anytime, with anyone and

anything (Barricelli et al., 2019) (Negri et al., 2017)

IoT and specifically Industrial Internet of Things

(IIoT) together with automation and digitalization are

a

https://orcid.org/0000-0001-7965-4338

b

https://orcid.org/0000-0002-3668-7719

c

https://orcid.org/0000-0001-8211-4682

d

https://orcid.org/0000-0003-2077-6642

e

https://orcid.org/0000-0002-2033-4265

f

https://orcid.org/0000-0002-2365-7529

seen as enablers of Industry 4.0, the so-called fourth

industrial revolution (Grieves, 2014). Industry 4.0

stands for a combination of industrial practices and

traditional manufacturing with these new

technologies such as the aforementioned IoT (and/or

IIoT) and, among others, new machine

communications and Cyber-Physical Systems (CPS).

CPS are highly integrated and interconnected systems

including interacting networks of computational and

physical components (Kritzinger et al., 2018).

Meaning, a CPS typically consists of a digital part,

e.g., data or software, and a physical part, e.g., a

machine or device. The state of the physical part is

represented by the cyber part which impacts it by

automated control (ISO, 2002). Digital Twins (DT)

are reciprocally synchronized and connected via

actuators and sensors and the term stands (Bellman &

Landauer, 2000). The DT of CPS presents a medium

168

De Marchi, M., Rojas, R., Mark, B., Aruväli, T., Rauch, E. and Matt, D.

Digital Twin Architecture of a Cyber-physical Assembly Transfer System.

DOI: 10.5220/0011589900003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 168-175

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

to manifest, visualize and control a physical twin

(Vernadat, 2007) and enables companies to cope with

nowadays challenges such as ever more fast-paced

complex and uncertain boundary conditions .

After the introduction in the current Section 1,

Section 2 focuses on a theoretical background of

modularity in DT. Therefore, the DT paradigm and

the interoperability and scalability of DT applications

are presented. Subsequently, the conceptual

framework of standard modules for DTs is presented

in Section 3 and exemplary application is shown in

Section 4. Following, a discussion is conducted

(Section 5) and a conclusion and outlook is presented

(Section 6).

2 THEORETICAL

BACKGROUND

2.1 The Digital Twin Paradigm

The fourth industrial revolution set new standards for

industrial environments thanks to the introduction of

innovative technologies including, but not limited to,

the Internet of Things (IoT), Cyber Physical Systems

(CPS), Big Data analytics, and simulation.

Furthermore, thanks to the deployment of AI features,

computational systems have gained significant

power, being more capable, more robust, and more

efficient. The concept of DT rises following the

integration of the above-mentioned technological

aspects and their coexistence. The first formalization

of the term “Digital Twin” has to be attribute to

Michael Grieves, who formalized it in 2014 (Grieves,

2014). Even though many different definition has

been provided (Barricelli et al., 2019), a generally

valid one, applicable to the industrial sector has been

provided by (Negri et al., 2017) and defines the DT

as “a virtual representation of a production system

that is able to run on different simulation disciplines

that is characterized by the synchronization between

the virtual and real system, thanks to sensed data and

connected smart devices, mathematical models and

real time data elaboration. The topical role within

Industry 4.0 manufacturing systems is to exploit these

features to forecast and optimize the behaviour of the

production system at each life cycle phase in real-

time”. This definition can be further elaborated

introducing the concepts of Digital Model (DM) and

Digital Shadow (DS) (Kritzinger et al., 2018), that

differ from the DT given their level of integration. A

DM physical world and its virtual counterpart are not

connected, meaning that the information should be

collected and transported manually from one world to

the other. The DS is characterized by an autonomous

data collection feature, but still requires the human

presence to transfer the data back, from the virtual

environment to the physical world. Finally, the DT is

characterized by a fully integrated virtual

environment, which enable an autonomous data flow

in both directions.

2.2 Interoperability and Scalability of

DT Applications

Integration may be understood as the necessary steps

that allow a body of disparate systems to be treated as

a whole, so that it can be understood, monitored and

controlled (ISO, 2002) (Bellman & Landauer, 2000).

In what refers to digital systems, where information

plays a key role, interoperability is required,

intending that each system must be able to use and

process the information produced by another system

(Vernadat, 2007). This poses several challenges that

spans different layers of the digital structure of the

system that we desire to integrate (Lin et al., 2015).

At its deepest, this involves the nature of the data

representation at chip-level and the internal use and

meaning that each software gives to data. However,

this complex dimension is often simplified by the

communication interfaces and protocols that systems

expose to successfully communicate. However, these

interfaces are rarely homogenous among system

types and generations. As a consequence, achieving

interoperability poses the challenges of designing a

communication solution among disparate systems.

As it is remarked in (Rojas et al., 2017),

interoperability needs to be implemented at different

layers of the OSI model (Zimmermann, 1980) and can

be classified into technical, syntactic and semantic.

With technical interoperability, we refer to the

capacity of exchanging raw and autonomous

sequence of bites. Syntactic interoperability is

associated with data formats, i.e., the symbols

represented by such sequences of bits. Finally,

semantic interoperability is the capacity of

exchanging meaning between systems. Semantic

interoperability depends on syntactic interoperability

that depends on technical interoperability. Among all

existing solutions to achieve technical

interoperability, Ethernet has become a de-facto

choice in industrial systems (Yang et al., 2005) that

implement the OSI 1 and 2, 3 and 4 layers. If follows

that Interoperability solutions are mainly syntactic

and sematic interoperability solutions that depends on

the architecture and the intended use of the system as

a whole.

Digital Twin Architecture of a Cyber-physical Assembly Transfer System

169

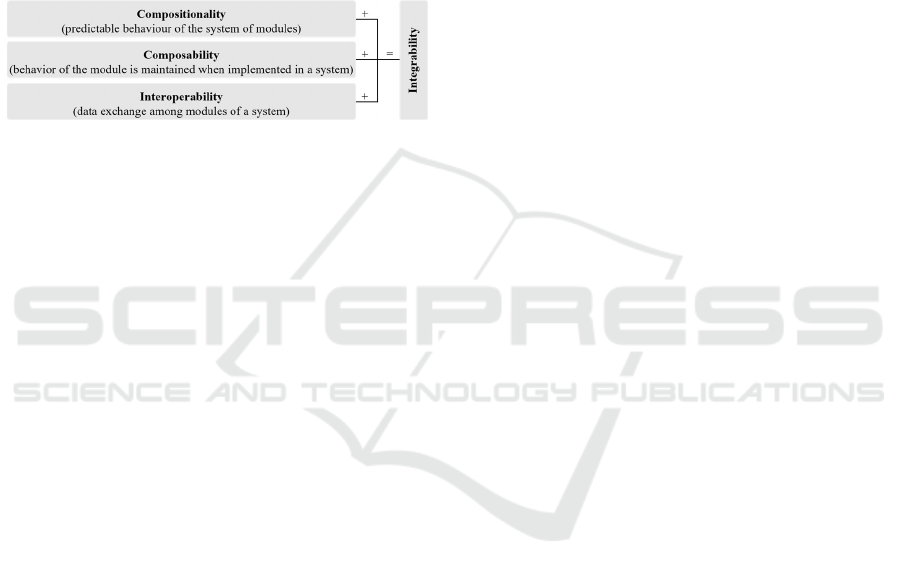

We underline that interoperability is a key feature

to achieve three key conditions for integrability

(Gössler & Sifakis, 2005), as displayed in Figure 1.

On the one hand, compositionality, i.e., that the

behaviour of the system is predictable from the

behaviour of its components. On the other hand,

composability, i.e., that the properties of a component

do not variate when it is placed inside the system. In

fact, interoperability allows exchange the data

required to the coordination and orchestration of

system components. In addition, this enables system

scalability, in the sense that allows adding new

components to the system with new functionalities.

Figure 1: Compositionality, composability, and

interoperability as elements of integrability.

3 CONCEPTUAL

FRAMEOWORK OF

STANDARD MODULES FOR

DIGITAL TWIN

In this section the authors aim at proposing an

inclusive definition of standard modules for DT

application. A number of examples of modular DT

application is available in literature, while a clear,

shared definition of module is missing yet. The

authors of (Guo et al., 2019) suggest that the modular

approach must be based on parametrization.

Parametrization allow modules that have similar

functions and structure to be clustered in larger,

functional modules. In this perspective, the final

functional modules users will be able to easily

replicate the implementation of modules, reducing the

programming workload and the effort required for

modelling. In (Negri et al., 2019), DT modules are

referred to as Functional Mock-up Units (FMUs).

FMUs are referred to as black boxes that are capable

of interacting with different simulation environment,

requiring only little arrangements. FMUs can be

instantiated as many times as necessary, allowing

users to easily scale their DT applications. (Yun et al.,

2017) asses that DT characteristics such as

complexity, resolution, programming languages and

data formats may represent an issue for DT

implementation and its eventual scalability. In

addition, the authors of (Yun et al., 2017) underline

the fact that centralized DT application may consume

too big resources and energies, and therefore suggest

the realization of DT applications which are

geographically and logically distributed for better

addressing data transportation and energy

consumption efficiency.

In our view, it is legit to rise various definitions of

DT modules, depending on the desired architectural

resolution and the targeted product life cycle phases.

Nevertheless, a general definition of DT module,

which is not constrained, nor limited, by the

architectural resolution focus nor by its peculiar

function is proposed next: DT modules are

standardized, reconfigurable, parametrized software

packages which share similar internal operative

structural elements (data collection, data pre-

processing, data storage, data exploitation, data

visualization and feedback/control) (Rocha et al.,

2021) and differ the ones from the others due to the

necessary inputs and desired outputs. Standing with

this definition, DT modules achieve compositionality

thanks to the shared internal architecture,

composability due to input-output-bounded design,

and interoperability whenever input and output data

formats are homogeneous in type and format,

enabling system scalability. The synergy of two or

more DT modules results in a DT system.

Conceptually, it is possible to subdivide DT

modules into five application levels, ranging from the

product level, up to the Supply Chain (SC) level,

passing through the work cell, system, and factory

levels. At the product level, DT modules operate in

several product life-cycle phases. In particular, DT

modules addressing Product Life-cycle Management

(PLM) aim to monitor, simulate and optimize each

life-cycle phase of a product (Tao et al., 2018), from

the early design up to the retirement. If the benefits of

the DT paradigm are trivial for the design,

manufacturing and service life-cycle phases of a

product, the potential of a DT application for

products’ retirement phase requires further research

(Liu et al., 2020). The product simulation field could

be ideally a part of a PLM DT system that serves

during the design phase. The implementation of a

product simulation DT module ensures a lower time-

to-market, reducing the time required for the

prototyping phase. In as much, in DT-driven product

development, the design is generated by the DT

application based on real user experience, thus

eliminating (or drastically reducing) the need of

design modifications and re-prototyping (Lo et al.,

2021). At work cell level, DT modules are employed

to manage the work cell as whole. For example, DT

modules monitoring and optimizing the performance

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

170

of robotics systems through real-time robot behaviour

adaption features based on adaptive motion planners

lead to improvement of motion speed, energy

consumption and safety (She, 2021). Safety, in

particular, is crucially important for Human-Robot

Collaboration (HRC), where human operators and

robotic manipulator share the same workspace at the

same time. DT modules for HRC enable the dynamic

task allocation based on task properties and assembly

characteristics, aiming to improve the human-robot

workload balance (Bilberg & Malik, 2019).

Employed in HRC, but also in quality inspection,

autonomous driving or authentication applications,

Computer Vision DT modules allow DT system to

access data retrieved from 2D, 3D or Infrared (IR)

cameras.

Especially in collaborative assembly workstation,

to exploit Computer Vision (CV) devices, for

predictive maintenance purposes as well as for fault

detection and diagnosis. The system level is

embodied by the ensemble of work cells and all those

entities aimed moving row material, semi-finished

products and finished product from one work cell to

another. At the system level DT modules can embody

virtual representations of transfer lines, Autonomous

Guided Vehicles (AGVs) and Autonomous Guided

Robots (AGRs) for solving optimal path planning

algorithms and to simulate their behaviour in the

physical shopfloor (Bottani et al., 2017). DT based

Production Management Systems (DTPMS) enable

the real-time monitoring of production processes,

allowing simulation and forecasting elements of the

DTPMS module to efficiently optimize production

planning tasks (Ma et al., 2020). In addition,

performance prediction (Zhuang et al., 2021) and

energy consumption optimization (Zhang et al., 2018)

are made possible by the inclusion of forecasting DT

modules who rely on the real-time monitoring of the

system. On the factory and supply chain levels, DT

modules aim at monitoring and optimizing higher

level processes. E.g., factory layout planning DT

modules allow layout planners to generate a

conceptual design of the factory shopfloor before

constructing the facility. This ensures resource

saving, avoiding the need of reconfiguration. This is

also supported by Building Information Modelling

(BIM) DT modules, that merges the real-time

collected data of a piece of equipment, its static data

and its 3D representation to facilitate the access to

information when needed (Coupry et al., 2021).

Cybersecurity (Saad et al., 2020) is a topic that ideally

affects every application level, but can be addressed

with dedicated DT modules deployed at factory level,

considering the transfer of data between one facility

and another more risky than intra-factory data

transfer. Supply Chain DT (SCDT) application

observe and optimize the behaviour of supply chains

(Park et al., 2021).

4 EXEMPLARY APPLICATION

The idea of treating DT applications as a body of

interoperable and replicable modules that have been

explained in Section 3 has been put into practice at

the Smart Mini Factory laboratory for Industry 4.0 of

the Free University of Bozen-Bolzano, which has the

objective of replicating an industrial environment,

both from manufacturing and logistics perspectives,

to allow undergraduate students as well as

practitioners from industry to learn Industry 4.0

related concepts through hands-on experiences.

In this case a technological demonstrator has been

set up to explain the benefits and potential of a

modular DT application. In particular, the

demonstrator consists of the assembly of a product

that requires the orchestration of several entities in

order to be successfully manufactured. For this

purpose, a “gopher holes” puzzle will be employed.

The puzzle is made out of a bottom plate, by six laths

(four unique parts and two equal parts), and a top

plate. The assembly of the product is carried on

autonomously by a smart assembly line. The

components of the puzzle are randomly scattered on

a conveyor belt. A DT module of the conveyor belt is

deployed and is in charge of dynamically adjusting

the speed of the belt conveyor based on the future

requirements of the production line. The conveyor

belt brings the components under a CV system that

recognizes the Reference Frame (RF) and the identity

of each part. The CV system also features its own DT

module, which is in charge of creating a virtual

representation of the components sparse on the

conveyor belt and to produce actual and future

(simulated) data to be shared with a delta robot. The

robotic system picks the puzzle elements through

suction caps and placing them on a shuttle, that runs

on an intelligent monorail transfer line. Each shuttle

can host one base of the puzzle or three laths. The DT

module of the delta robot receives information about

the actual and future (simulated) position of puzzle’s

elements on the conveyor belt. Thanks to this

synergy, the delta robot is capable of continuously

replanning its trajectories, preventing the arrival of

components, thus optimizing speed performance.

Moreover, the delta robot DT module is informed by

the CV DT module about the identity of the arriving

component. This information is required by the delta

Digital Twin Architecture of a Cyber-physical Assembly Transfer System

171

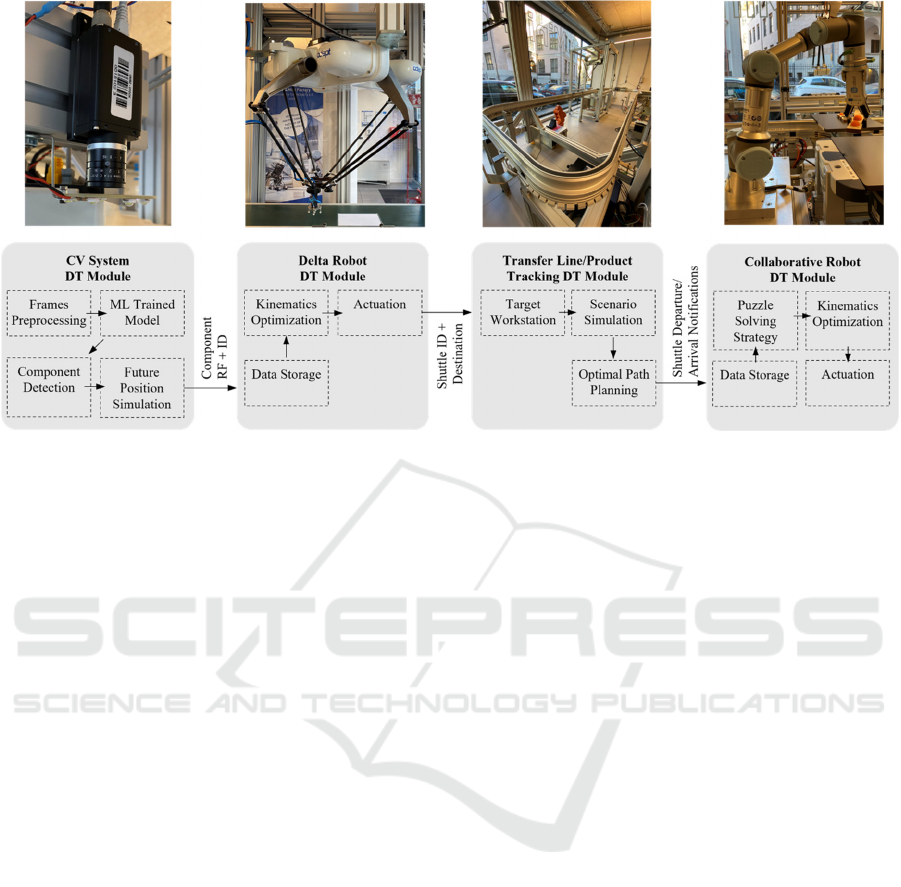

Figure 2: DT modules arrangement.

robot to easily plan the picking of the incoming

component, as components show varying surfaces.

This same information is then forwarded to the

product tracking DT module, which is in charge of

virtualizing the logical location of products along the

production line, together with the address of the

shuttle that is carrying the component(s). The

intelligent transfer line DT module solves an optimal

path planning problem to ensure the optimization of

one or more Key Performance Indicators (KPIs) (e.g.,

speed, idle time, path length, energy consumption,

jerk avoidance) for moving the shuttle from the delta

robot workstation towards the collaborative robot

workstation. Here, a lightweight collaborative robot

is notified about the arrival of a loaded shuttle by the

transfer line DT module, and immediately retrieves

the information about component ID and position on

the shuttle by the product tracking module. The

collaborative robot must unload the components from

the incoming shuttle. Given the unpredictable

components arrival order, the collaborative robot

workstation features a rack onto which components

that cannot be immediately assembled are

temporarily stored. The collaborative robot is driven

by a DT module similar to the one driving the delta

robot, with additional features for human-robot

collaboration. Even though in this peculiar

application a collaborative robot is employed on its

own (without the constant presence of a human

operator), the robotic arm is not fenced, hence, the

eventuality of a collision with a human operator

cannot be excluded. In addition, the collaborative

robot DT module simulates the cinematics of the

collaborative manipulator aiming at finding the best

set of joints motion for flexibly assembling the

puzzle. Completed puzzles are loaded on a shuttle

which will move to a representative warehouse.

Figure 2 graphically reports the arrangement of DT

modules that concur to the successful assembly of the

product. Only the most important parts of the DT

system have been reported in Figure 2 for space

saving reasons.

5 DISCUSSION

The union of the DT modules gives life to a DT

application which is finally capable of managing the

assembly of a product, whose components supply

does not attend the Just in Time (JIT) nor the Just In

Sequence (JIS) principles. This introduces

unpredictability and randomness in the system, which

would be impossible to tackle with traditional

assembly lines, that require long reconfiguration

times and costs and provide low flexibility during the

assembly phases. These issues are easily tackled by

the introduction of decentralized control of machines

provided by DT modules. All the items composing

the presented case study (conveyor belt, CV system,

delta robot, intelligent transfer line, and collaborative

robot) have been programmed in such a way that it is

possible for them to exchange information with

external DT modules through XMLRPC calls over

the local Ethernet Infrastructure. Practitioners from

industry as well as students can consider this work as

a starting point for learning the features and the

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

172

potential of DT application, together with the concept

of modular DT implementation. The work, in its

current form, is structured in such a way that each DT

module can be teared apart and presented in detail,

both from an architectural perspective and from an

informatic point of view. The strength of the

presented work resides in the facilitated combination

of several DT modules, which are capable to

construct a large-scale DT application for an entire

production line. In addition, the modularity of the

proposed architecture enables system

reconfigurability, flexibility and scalability.

Two major issues can be met during the

development and deployment of a modular DT

application:

(1) Systems integrability is not always easy to

realize. For example, great effort has been spent

to create an external controller for the delta

robot, which is originally driven by proprietary

programming language, that strongly limits

system’s integrability.

(2) Cybersecurity plays a major role in DT

applications since they strongly rely on data

transportation over the Internet. In this sense,

dedicated research should be carried on for

ensuring the security of data transportation in

the DT era.

6 CONCLUSIONS AND

OUTLOOK

This paper presents the design and implementation of

a DT architecture for a cyber-physical assembly

transfer line. The implementation of a DT node

enables an easy-to-implement connection with other

systems. The authors give a definition of DT module

and describe their internal structure. In addition, the

authors list and describe a list of possible DT modules

application in industry. For validating the novel

definition, a practical case study is presented. Here, a

demonstrative assembly line composed by a conveyor

belt, a delta robot equipped with a CV system, an

intelligent transfer line, and a collaborative robot are

in charge of assembling a logically difficult to

assemble product, a puzzle, for this demonstrative

case study. The implementation of DT modules

remarks existing challenges in Industry 4.0

environment such as cybersecurity and the need of

integrable systems and opens new horizons such as

the fine granularity and level of detail that is possible

to obtain through the adoption of modular DT

applications. In the future, more research is needed on

cyber-security, as this will play an increasingly

important role in DT applications. In the next future,

the authors aim at developing the case study,

including more DT modules in the production line, as

well as more equipment. Moreover, the objective is to

demonstrate the potential flexibility of such a

production line assembling more than one product at

the same time on the same line. In addition, ways and

possibilities should be elaborated to simplify the

integration process.

ACKNOWLEDGEMENTS

This research was funded by the Autonomous

Province of Bolzano under the Grant TN220V

(project title: ASSIST4RESILIENCE - Increasing

Resilience in Manufacturing - Development of a

Digital Twin Based Worker Assistance).

REFERENCES

Aivaliotis, P., Georgoulias, K., & Chryssolouris, G. (2019).

The use of Digital Twin for predictive maintenance in

manufacturing. International Journal of Computer

Integrated Manufacturing, 32(11), 1067–1080.

Ansys Twin Builder. (n.d.). https://www.ansys.com/it-

it/products/digital-twin/ansys-twin-builder

Anylogic. (n.d.). https://www.anylogic.com/features/

digital-twin/

AnyLogistix. (n.d.). https://www.anylogistix.com/

Autodesk Tandem. (n.d.). https://intandem.autodesk.com/

Barricelli, B. R., Casiraghi, E., & Fogli, D. (2019). A survey

on digital twin: Definitions, characteristics,

applications, and design implications. IEEE Access, 7.

Scopus.

https://doi.org/10.1109/ACCESS.2019.2953499

Barykin, S. Y., Bochkarev, A. A., Dobronravin, E., &

Sergeev, S. M. (2021). The place and role of digital twin

in supply chain management. Academy of Strategic

Management Journal, 20, 1–19.

Bellman, K. L., & Landauer, C. (2000). Towards an

integration science: The influence of Richard Bellman

on our research. Journal of Mathematical Analysis and

Applications, 249(1), 3–31.

Biesinger, F., Meike, D., Kraß, B., & Weyrich, M. (2019).

A digital twin for production planning based on cyber-

physical systems: A Case Study for a Cyber-Physical

System-Based Creation of a Digital Twin. Procedia

CIRP, 79, 355–360.

Bilberg, A., & Malik, A. A. (2019). Digital twin driven

human–robot collaborative assembly. CIRP Annals,

68(1), 499–502. Scopus. https://doi.org/10.1016/j.cirp.

2019.04.011

Digital Twin Architecture of a Cyber-physical Assembly Transfer System

173

Bottani, E., Cammardella, A., Murino, T., & Vespoli, S.

(2017). From the Cyber-Physical System to the Digital

Twin: The process development for behaviour

modelling of a Cyber Guided Vehicle in M2M logic.

XXII Summer School Francesco TurcoIndustrial

Systems Engineering, 1–7.

Coupry, C., Noblecourt, S., Richard, P., Baudry, D., &

Bigaud, D. (2021). BIM-Based Digital Twin and XR

Devices to Improve Maintenance Procedures in Smart

Buildings: A Literature Review. Applied Sciences,

11(15), 6810.

De Marchi, M., Gualtieri, L., Rojas, R. A., Rauch, E., &

Cividini, F. (2021). Integration of an Artificial

Intelligence Based 3D Perception Device into a

Human-Robot Collaborative Workstation for Learning

Factories. Available at SSRN 3863966.

Gehrmann, C., & Gunnarsson, M. (2019). A digital twin

based industrial automation and control system security

architecture. IEEE Transactions on Industrial

Informatics, 16(1), 669–680.

Google—Supply Chain Twin and Pulse. (n.d.).

https://cloud.google.com/solutions/supply-chain-twin

Gössler, G., & Sifakis, J. (2005). Composition for

component-based modeling. Science of Computer

Programming, 55(1–3), 161–183.

Grieves, M. (2014). Digital Twin: Manufacturing

Excellence through Virtual Factory Replication. Digital

Twin: Manufacturing Excellence Through Virtual

Factory Replication. Scopus.

Guo, J., Zhao, N., Sun, L., & Zhang, S. (2019). Modular

based flexible digital twin for factory design. Journal of

Ambient Intelligence and Humanized Computing,

10(3), 1189–1200.

ISO. (2002). Iso 19439, cim system architecture-framework

for enterprise modelling. Technical report, ISO,

Kritzinger, W., Karner, M., Traar, G., Henjes, J., & Sihn,

W. (2018). Digital Twin in manufacturing: A

categorical literature review and classification. IFAC-

PapersOnLine, 51(11), 1016–1022. Scopus.

https://doi.org/10.1016/j.ifacol.2018.08.474

Kunath, M., & Winkler, H. (2018). Integrating the Digital

Twin of the manufacturing system into a decision

support system for improving the order management

process. Procedia Cirp, 72, 225–231.

Lin, S.-W., Miller, B., Durand, J., Joshi, R., Didier, P.,

Chigani, A., Torenbeek, R., Duggal, D., Martin, R.,

Bleakley, G., & others. (2015). Industrial internet

reference architecture. Industrial Internet Consortium

(IIC), Tech. Rep.

Liu, M., Fang, S., Dong, H., & Xu, C. (2020). Review of

digital twin about concepts, technologies, and industrial

applications. Journal of Manufacturing Systems.

Scopus. https://doi.org/10.1016/j.jmsy.2020.06.017

Lo, C., Chen, C., & Zhong, R. Y. (2021). A review of digital

twin in product design and development. Advanced

Engineering Informatics, 48, 101297.

Ma, J., Chen, H., Zhang, Y., Guo, H., Ren, Y., Mo, R., &

Liu, L. (2020). A digital twin-driven production

management system for production workshop. The

International Journal of Advanced Manufacturing

Technology, 110(5), 1385–1397.

Nåfors, D., Berglund, J., Gong, L., Johansson, B.,

Sandberg, T., & Birberg, J. (2020). Application of a

hybrid digital twin concept for factory layout planning.

Negri, E., Fumagalli, L., Cimino, C., & Macchi, M. (2019).

FMU-supported simulation for CPS digital twin.

Procedia Manufacturing, 28, 201–206.

Negri, E., Fumagalli, L., & Macchi, M. (2017). A Review

of the Roles of Digital Twin in CPS-based Production

Systems. Procedia Manufacturing, 11, 939–948.

Scopus. https://doi.org/10.1016/j.promfg.2017.07.198

Oracle IoT Production Monitoring Cloud. (n.d.).

https://docs.oracle.com/en/cloud/saas/iot-production-

cloud/index.html

Park, K. T., Son, Y. H., & Noh, S. D. (2021). The

architectural framework of a cyber physical logistics

system for digital-twin-based supply chain control.

International Journal of Production Research, 59(19),

5721–5742.

Reply. (n.d.). https://www.reply.com/en/topics/internet-of-

things/the-digital-companion-for-manufacturing

Riverlogic. (n.d.). https://www.riverlogic.com/solutions

Robot Operating System (ROS). (n.d.).

https://www.ros.org/

Rocha, C. A. P., Rauch, E., Vaimel, T., Garcia, M. A. R., &

Vidoni, R. (2021). Implementation of a Vision-Based

Worker Assistance System in Assembly: A Case Study.

Procedia CIRP, 96, 295–300.

Rojas, R. A., Rauch, E., Vidoni, R., & Matt, D. T. (2017).

Enabling connectivity of cyber-physical production

systems: A conceptual framework. Procedia

Manufacturing, 11, 822–829.

Saad, A., Faddel, S., Youssef, T., & Mohammed, O. A.

(2020). On the implementation of IoT-based digital

twin for networked microgrids resiliency against cyber

attacks. IEEE Transactions on Smart Grid, 11(6),

5138–5150.

Samir, K., Maffei, A., & Onori, M. A. (2019). Real-Time

asset tracking; a starting point for Digital Twin

implementation in Manufacturing. Procedia Cirp, 81,

719–723.

She, M. (2021). Deep Reinforcement Learning-Based

Smart Manufacturing Plants with a Novel Digital Twin

Training Model. Wireless Personal Communications,

1–20.

Siemens NX. (n.d.). https://www.plm.automation.siemens.

com/global/it/products/nx/

Siemens PLM. (n.d.). https://www.plm.automation.

siemens.com/global/

Tao, F., Cheng, J., Qi, Q., Zhang, M., Zhang, H., & Sui, F.

(2018). Digital twin-driven product design,

manufacturing and service with big data. International

Journal of Advanced Manufacturing Technology, 94(9–

12), 3563–3576. Scopus. https://doi.org/10.1007/

s00170-017-0233-1

Vernadat, F. B. (2007). Interoperable enterprise systems:

Principles, concepts, and methods. Annual Reviews in

Control, 31(1), 137–145.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

174

Wang, G., Zhang, G., Guo, X., & Zhang, Y. (2021). Digital

twin-driven service model and optimal allocation of

manufacturing resources in shared manufacturing.

Journal of Manufacturing Systems, 59, 165–179.

Wang, P., Liu, W., Liu, N., & You, Y. (2020). Digital twin-

driven system for roller conveyor line: Design and

control. Journal of Ambient Intelligence and

Humanized Computing, 11(11), 5419–5431.

Wang, Y., Wang, X., & Liu, A. (2020). Digital twin-driven

supply chain planning. Procedia CIRP, 93, 198–203.

Xu, Y., Sun, Y., Liu, X., & Zheng, Y. (2019). A digital-

twin-assisted fault diagnosis using deep transfer

learning. IEEE Access, 7, 19990–19999.

Yang, S.-P., Sang, N., & Xiong, G.-Z. (2005). Safety

critical real-time networks based on ethernet

technology. Ruan Jian Xue Bao(J. Softw.), 16(1), 121–

134.

Yun, S., Park, J.-H., & Kim, W.-T. (2017). Data-centric

middleware based digital twin platform for dependable

cyber-physical systems. International Conference on

Ubiquitous and Future Networks, ICUFN, 922–926.

Scopus. https://doi.org/10.1109/ICUFN.2017.7993933

Zhang, M., Zuo, Y., & Tao, F. (2018). Equipment energy

consumption management in digital twin shop-floor: A

framework and potential applications. 2018 IEEE 15th

International Conference on Networking, Sensing and

Control (ICNSC), 1–5.

Zhuang, C., Miao, T., Liu, J., & Xiong, H. (2021). The

connotation of digital twin, and the construction and

application method of shop-floor digital twin. Robotics

and Computer-Integrated Manufacturing, 68, 102075.

Zimmermann, H. (1980). OSI reference model-the ISO

model of architecture for open systems interconnection.

IEEE Transactions on Communications, 28(4), 425–

432.

Digital Twin Architecture of a Cyber-physical Assembly Transfer System

175