Application of an Industry 4.0 Assessment Model: A Case Study

Application in Material Supply for Assembly

Matthias Horvath

1a

, Matteo De Marchi

2b

, Erwin Rauch

2c

and Dominik T. Matt

2,3 d

1

Department of Industrial Engineering and Management, Management Center Innsbruck (MCI), Maximilianstrasse 2,

Innsbruck, Austria

2

Industrial Engineering and Automation (IEA), Faculty of Science and Technology, Free University of Bolzano,

Universitätsplatz 1, Bolzano, Italy

3

Innovation Engineering Center (IEC), Fraunhofer Italia Research Scarl, A.-Volta Street 13A, Bolzano, Italy

Keywords: Industry 4.0, Assessment, Material Supply, Assembly, Semi-structured Interview, Case Study Research.

Abstract: Material supply in production companies is currently facing numerous challenges. This paper therefore

pursues the goal of analysing the potential of single Industry 4.0 concepts for the further development and

efficiency optimization of material supply in assembly in an industrial case study. The determination of

potentials in the context of the individual case study at an internationally active rail vehicle manufacturer is

done by using a maturity level based Industry 4.0 assessment. Subsequent semi-structured interviews have

been conducted to further explore the potential and feasibility of the identified Industry 4.0 measures for

optimizing efficiency of material supply in assembly. This study represents an application oriented research

for validation of a previously developed Industry 4.0 assessment model.

1 INTRODUCTION

Digitalization is having a considerable impact on

companies and in some cases are placing completely

new challenges on the entire organization (Parviainen

et al., 2017; Sony, 2020). This makes it important for

companies to constantly develop and adapt to new

conditions in order to maintain the company's success

in the future.

After a long period of organizational optimisation

based on Lean Production and the introduction of

Lean methods for waste reduction (Dallasega et al.,

2015; Jiang et al., 2021), in particular, the proclaimed

fourth industrial revolution, known as Industry 4.0, is

intended to contribute to maintaining competitiveness

by applying the most innovative technologies

(Oztemel & Gursev, 2020; Shuttleworth et al., 2022).

Thus, it is essential for companies to design their own

strategy and roadmap for long-term sustainable

digital transformation (Martinez-Olvera, 2022).

a

https://orcid.org/0000-0002-0297-2888

b

https://orcid.org/0000-0001-7965-4338

c

https://orcid.org/0000-0002-2033-4265

d

https://orcid.org/0000-0002-2365-7529

In addition to the digital transformation of

manufacturing and assembly systems also supporting

areas like production logistics and material supply are

showing a high potential for applying Industry 4.0

concepts and technologies (Junge, 2019).

For many companies, however, the

transformation to Industry 4.0 represents a major

challenge (Vuksanović et al., 2020; Nardo et al.,

2020). In addition to a missing overview of existing

Industry 4.0 concepts and technologies, they lack the

knowledge of how such concepts can be implemented

and which ones should be given priority in terms of

introduction. However, in order to successfully

manage this challenge and to find one's way in the

development of a comprehensive "big picture", it is

important for companies to go through a self-

assessment and to determine the potential laying in

Industry 4.0. To give other manufacturing companies

an example of how to face this challenges a case study

based research has been conducted and results are

summarised in this paper.

176

Horvath, M., De Marchi, M., Rauch, E. and Matt, D.

Application of an Industry 4.0 Assessment Model: A Case Study Application in Material Supply for Assembly.

DOI: 10.5220/0011591000003329

In Proceedings of the 3rd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2022), pages 176-183

ISBN: 978-989-758-612-5; ISSN: 2184-9285

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 RESEARCH QUESTIONS AND

METHODOLOGY

The aim of this case study research carried out in

collaboration with a Swiss rail vehicle manufacturer

was to analyse the potential of Industry 4.0 for

optimizing the efficiency of internal material supply

in assembly and to test and validate a previously

developed Industry 4.0 assessment model (Rauch et

al., 2020) for derivation of the most suitable Industry

4.0 technologies for these purpose. The investigation

is carried out with a specific view on production

logistics, especially in the field of material supply of

the assembly department. The following research

questions can be defined:

RQ1: Which Industry 4.0 concepts show a high

potential for efficiency optimization for material

supply in assembly at the case study company?

RQ2: To what extent is a maturity level based

Industry 4.0 assessment helpful in the selection of

those Industry 4.0 concepts?

For this purpose, a mixed method research

approach has been applied combining quantitative

research (Industry 4.0 assessment model) as well as

qualitative research (based on semi-structured

interviews). The determination of potential Industry

4.0 technologies is based on a maturity-based

Industry 4.0 assessment model according to Rauch et

al. (2020). This comprises a catalogue of a total of 42

individual Industry 4.0 concepts identified by

literature analysis, as well as four standard strategies

to assist in the introduction of corresponding

measures. This approach provides an overview of the

current status of Industry 4.0 technologies applied in

the case study company. Using this approach, the

significance of potential Industry 4.0 technologies is

encoded and the current status and medium-term

target status of individual Industry 4.0 concepts or

technologies in the company are determined. These

findings then form the basis for a preselection. Based

on this analysis, semi-structured interviews with 10

experts from the company has been conducted to, to

examine in more detail the feasibility of

implementation and to derive a roadmap for

implementation. This holistic roadmap is intended to

guide the case study company to implement selected

Industry 4.0 concepts in this field of material supply.

Finally this paper discusses the findings and lessons

learned of this case study research and provides an

outlook for further research.

3 OVERVIEW OF THE APPLIED

INDUSTRY 4.0 ASSESSMENT

MODEL

The model considered is based on a total of 42

Industry 4.0 concepts and technologies identified by

systematic literature analysis (Rauch et al., 2020).

These concepts are assigned on a first level to four

dimensions as follows:

1. Operational Dimension: Focus on operational

and operational processes;

2. Organizational Dimension: Focus on

organizational and management-oriented

processes;

3. Socio - cultural Dimension: Focus on corporate

culture and employee-related issues;

4. Technological Dimension: Focus on data and

process-oriented technologies.

In addition, a second sub-level contains a total of

21 defined categories to which the individual

concepts are assigned. An overview of these two

levels, including all 42 Industry 4.0 concepts included

in this assessment model, is summarized in Table 1.

Table 1: Industry 4.0 dimensions, categories and concepts

(Rauch et al., 2020).

N° Level 1 Level 2 Level 3

1

Operations

Agile

Manufacturing

Systems

Agile Manufacturing Syste

m

2 Self-Adapting Manufacturing

Systems

3 Continuous and Uninterrupted

Material Flow Models

4 Plug and Produce

5

Monitoring &

Decision

Systems

Decision Support Systems

6 Integrated and Digital Real-Time

Monitoring Systems

7 Remote Monitoring of Products

8 Big Data Big Data Analytics

9 Production

Planning and

Control

Enterprise Resource Planning /

Manufacturing Execution System

10

Organization

Business Model

4.0

Digital Produc

t

-Service Systems

11 Servitization and Sharing

Economy

12 Digital Ad

d

-on or Upgrade

13 Digital Loc

k

-In

14 Freemiu

m

15 Digital Point of Sales

16 Innovation

strategy

Open Innovation

17 Strategy 4.0 Industry 4.0 Roadmap

18

Supply Chai

n

Management 4.0

Sustainable Supply Chain Design

19 Collaboration Network Models

20

Social-

Culture

Human

Resource 4.0

Training 4.0

21 Work 4.0 Role of the Operato

r

22 Culture 4.0 Cultural Transformation

Application of an Industry 4.0 Assessment Model: A Case Study Application in Material Supply for Assembly

177

Table 1: Industry 4.0 dimensions, categories and concepts

(Rauch et al., 2020) (cont.).

N° Level 1 Level 2 Level 3

23

Technology

Big Data Cloud Computing

24

Communication

& Connectivity

Digital and Connected

Workstations

25 E-Kanban

26 IoT and Cybe

r

-Physical Systems

27 Cyber Security Cyber Security

28 Deep Learning,

Machine

Learning,

Artificial

Intelligence

Artificial Intelligence

29

Object Self Service

30 Identification

and Tracking

Technology

Identification and Tracking

Technology

31 Additive

Manufacturing

Additive Manufacturing (3D

Printing)

32

Maintenance

Predictive Maintenance

33 Telemaintenance

34

Robotics &

Automation

Automated Storage Systems

35 Automated Transport Systems

36 Automated

Manufacturing/Assembly

37 Collaborative Robotics

38 Smart Assistance Systems

39 Product Design

and

Developmen

t

Product Data Management and

Product Lifecycle Management

40

Standards 4.0

Cyber-Physical System

Standards

41 Virtual Reality,

Augmented

Reality, and

Simulation

Virtual and Augmented Reality

42 Virtual Reality,

Augmented

Reality, and

Simulation

Simulation

For each of these concepts, corresponding

maturity levels are defined in a Likert scale from 1 to

5. In order to improve understanding, a brief

description of the respective maturity level is always

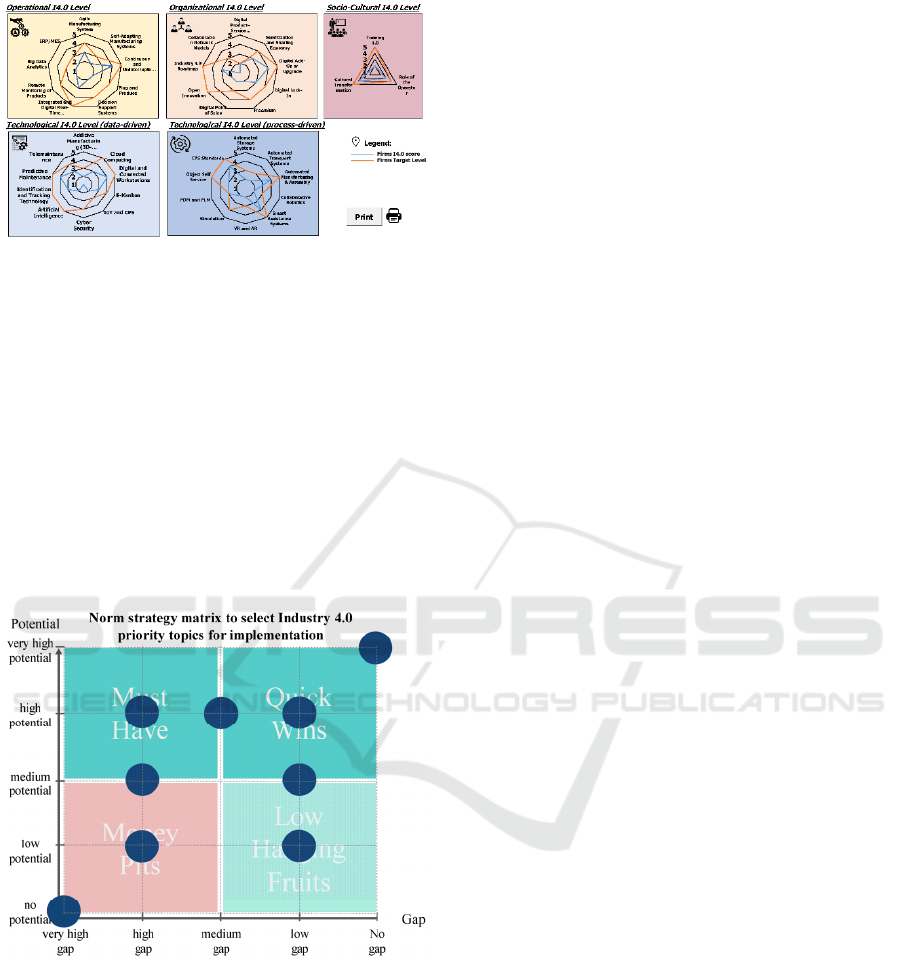

accompanied by a relevant example. Figure 1 shows

an example of a section of the assessment model with

their Industry 4.0 concepts and associated maturity

levels.

Figure 1: Maturity levels of the Industry 4.0 assessment

(Rauch et al., 2020).

In addition to the current state of implementation

of Industry 4.0 concepts, an aspired target state and

the significance / potential of the individual

technologies are assessed on the basis of the maturity

levels. The current state of implementation of

individual concepts and technologies is referred to as

the "I4.0 Score". The information on the future

maturity level is the "Target Score". This should take

into account both the factors of medium-term

achievability of the targeted state and realistic

feasibility of implementation. The additional

information on the importance of the respective

concept is likewise provided on the basis of a Likert

scale, from 1 to 5. This value is of corresponding

relevance, as not every concept appears to be equally

important for the respective company. This

assessment is thus an expression of the potential of

the individual Industry 4.0 concept in the case study

company. Figure 2 shows the fields to be encoded by

the user to determine the "I4.0 Score" and "Target

Score" as well as the "Importance”.

Figure 2: Fields to be filled in by the user of the assessment

model (Rauch et al., 2020).

The assessment regarding the current and the

medium-term target state form the basis for

calculating the so-called "I4.0 Gap". This thus

describes the difference between the stated "I4.0

Score" and the "Target Score" of the company. As a

result, this expression provides a helpful

quantification with regard to the difficulty of

achieving the desired target state of the individual

Industry 4.0 concept. For evaluation purposes, the

"I4.0 Scores" and the "Target Scores", are visually

represented in radar diagrams for operational,

organizational, socio-cultural and technological

(further subdivided into process-driven and data-

driven levels) dimension. Figure 3 shows an example

of the result of such a "Gap Analysis", which is

generated automatically by the assessment tool.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

178

Figure 3: Automatically generated radar charts in the

Industry 4.0 assessment (Rauch et al., 2020).

To support the gradual and systematic

implementation of Industry 4.0 concepts, the

collected data are combined in a standard strategy

matrix. This matrix is divided into four quadrants:

Quick-Wins: high potential - low gap.

Must-haves: high potential - high gap

Low Hanging Fruits: low potential - low gap.

Money Pits: low potential - high gap.

The following Figure 4 shows a schematic

representation of the standard strategy matrix.

Figure 4: Standard Strategy Matrix (Rauch et al., 2020).

4 CASE STUDY APPLICATION

In the following, we apply the presented method in

combination with semi-structured interviews to a case

study company. The case study company is an

internationally active rail vehicle manufacturer with

two plants employing a total of up to 1,300 people.

4.1 Research Design

In general, the research design can be seen as the way

in which the investigation is designed (Kuckartz,

2014). In addition to the description of the approach,

this also includes the selection of the methods, the

study participants, and the approach for data

preparation and subsequent data analysis (Becker et

al., 2017).

The investigation within the empirical research

part of this study is basically conducted as a single

case study at a European rail vehicle manufacturer.

By means of the individual case study as a general

research design, this work analyses the potentials and

applicability of Industry 4.0 technologies for the

efficiency optimization of the material supply in the

assembly department. Because of the same "data

source" in the industrial case study, the individual

results of the investigation can therefore be directly

related to each other. This makes it possible to

generate an individual result for the case study

company, which thus contributes significantly to

answering the first research question (Lamnek &

Krell, 2016).

The single case study in this work is based on a

mixed methods design using a sequential approach,

namely the qualitative in-depth approach

("explanatory design"). In a two-phase procedure,

data is first collected quantitatively, within the

framework of the previously presented maturity-

based Industry 4.0 assessment and analysed by using

descriptive statistics. In a second step, the results of

the quantitative part will be better understood with the

help of qualitative interview research. In this sense,

the results of the quantitative survey will be used to

design semi-structured expert interviews. In these

interviews, explanatory gaps that arose from the

maturity-based Industry 4.0 assessment are to be

closed in a targeted manner. Accordingly, the

interviews conducted have been evaluated using a

qualitative content analysis.

In this data collection, 15 identified managers and

experts of the case study company took over the role

of study participants in the first step of the

investigation (quantitative Industry 4.0 assessment).

Persons from different organizational levels

(management, department management, team

management, group management, employees) have

been selected. They work in the departments

"Systems and Processes", "Production", "Logistics",

"Purchasing" and "Digital Products". In this way, the

analysis from different perspectives on Industry 4.0

technologies and their potential with regard to

optimizing the efficiency of the company's material

Application of an Industry 4.0 Assessment Model: A Case Study Application in Material Supply for Assembly

179

supply in assembly is intended to be as

comprehensive as possible.

10 of the before mentioned 15 study participations

have been identified as experts in the field and have

been selected for the semi-structured interviews.

Either these interviewees have specific knowledge of

the company's internal material supply of assembly

due to their professional fields of activity, or they

have a fundamental technical knowledge of the topic

of Industry 4.0, its technologies or also of the general

process management at the case study company.

4.2 Results of the Industry 4.0

Assessment

The results in this section ("I4.0 score", "Target

Score", "Importance") always refer to average values

(arithmetic mean), which were formed on the basis of

the information on the Industry 4.0 self-assessment

model. The result is a visual representation of the

current status and the desired target state, as well as

the gap between these specific states.

In the first step of the analysis, the focus was on

the participants' responses to the current status of the

individual concepts. The ratings tend to be at a low

level. This can be deduced from the results, as only

one concept has an average score of greater than 4. In

addition, the standard deviations and coefficients of

variation determined indicate that there is not really a

uniform opinion among the responses in these cases.

It can therefore be concluded that there are most

probably different levels of knowledge regarding the

current maturity of the respective Industry 4.0

individual concepts. Starting with the concept with

the highest average maturity rating, the ten individual

concepts or technologies with the highest ratings are

listed below in Table 2. Ratings in Table 2 to Table 4

are always indicated in a range from 1-5.

Table 2: I4.0 Score - Top 10 Industry 4.0 concepts.

Industry 4.0 concept Average

Standard

Dev.

Variation

coefficient

E-Kanban 4,25 1,26 30%

Automated Warhouse

Systems

3,50 0,63 18%

Cloud Computing 3,17 0,77 24%

Computer Aided Design 3,08 0,73 24%

Cyber Security 2,92 1,17 40%

ERP-MES 2,83 0,42 15%

Technology Partnerships 2,83 1,24 44%

Open Innovation 2,75 1,07 39%

Sustainable Supply Chain

Design

2,67 1,25 47%

Acceptance and Warranty 2,67 0,91 34%

In the analysis of the target state, the following

order emerged on the basis of the participants'

responses to the "Target Score" column, as shown in

Table 3, for the ten concepts with the highest average

ratings. The standard deviation and coefficient of

variation shows a quite coherent opinion of the study

participants regarding the target to be achieved.

Table 3: Target Score - Top 10 Industry 4.0 concepts.

Industry 4.0 concept Average

Standard

Dev.

Variation

coefficient

E-Kanban 4,83 0,36 7%

Automated Warhouse

Systems

4,58 0,63 14%

Technology Partnerships 4,42 0,75 17%

ERP-MES 4,33 0,84 19%

Open Innovation 4,25 0,91 21%

Digital and Connected

Workstations

4,25 0,80 19%

Cyber Security 4,25 1,05 25%

Business Process Mining 4,25 1,07 25%

Digital Shopfloor

Management

4,17 0,80 19%

Industry 4.0 Roadmap 4,17 0,83 20%

In the next step of the presentation of results, the

average importance of the individual Industry 4.0

concepts is shown according to the assessments of the

survey participants in the "Importance" column of the

assessment model (see Table 4).

Table 4: Importance - Top 7 Industry 4.0 concepts.

Industry 4.0 concept Average

Standard

Dev.

Variation

coefficient

E-Kanban 4,58 0,74 16%

Identification and Tracking 4,25 0,82 19%

Automated Warehouse

Systems

4,25 0,77 18%

ERP-MES 4,25 0,82 19%

Cyber Security 4,17 1,10 26%

Industry 4.0 Roadmap 4,00 1,04 26%

Real-Time Monitoring 4,00 1,00 25%

Seven of the top 10 individual concepts have a

value greater than or equal to 4. According to the

Industry 4.0 assessment model used, this means that

the participants in the study rate them as "important"

to "very important". The standard deviation and the

coefficient of variation for the "Importance" rating

were calculated. These two values indicate that

opinions on the topics of "cyber security", "Industry

4.0 roadmap" and "real-time monitoring" diverge

more than the other top level concepts.

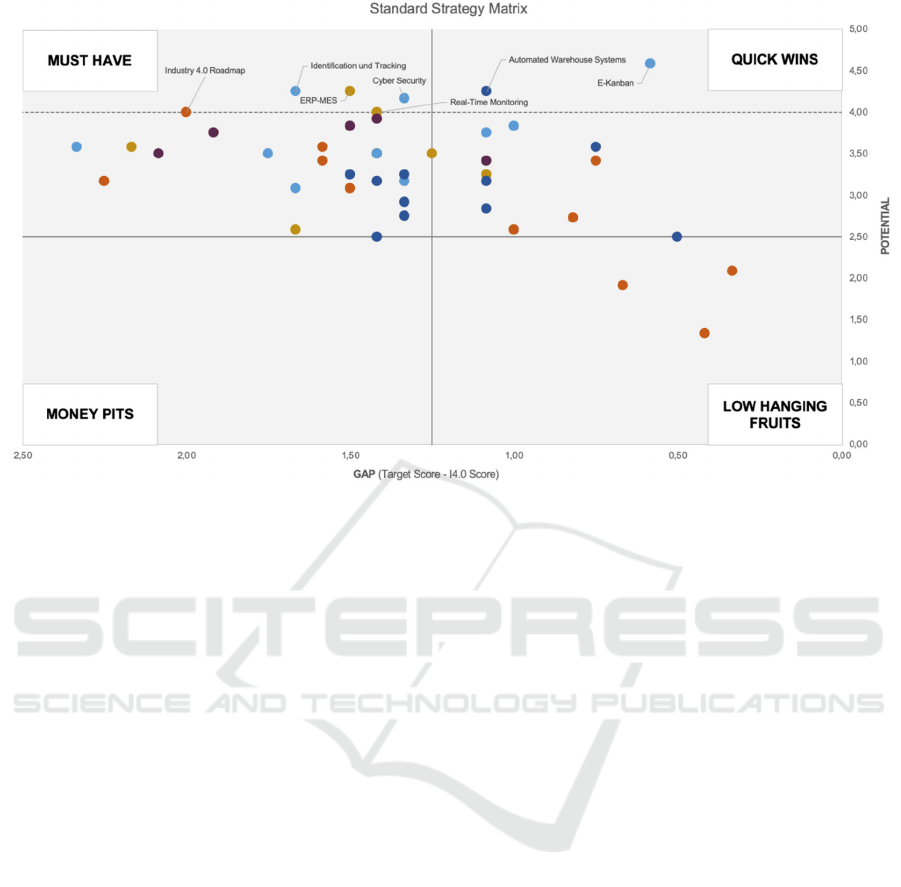

Based on the results of the study the Standard

Strategy Matrix has been created (see Figure 5).

These helped the research team together with the

company management to select the Industry 4.0

concepts that are of highest importance to reach the

set goal. Doing this the research team defined as a

threshold a potential (“importance”) of minimum 4.

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

180

Figure 5: Standard Strategy Matrix in the case study.

In accordance to this threshold, the following

seven Industry 4.0 concepts have been identified as

key concepts for optimizing the efficiency of the

internal material supply in assembly:

1) Industry 4.0 Roadmap

2) Identification and Tracking

3) ERP-MES

4) Real-Time Monitoring

5) Cyber Security

6) Automated Warehouse Systems

7) E-Kanban.

4.3 Implementation Roadmap based on

Semi-structured Interviews

The interview results of the semi-structured

interviews refer to the key concepts identified in

Section 4.2. The following main questions have been

used in the interviews:

1. Where do you see the specific potential of each

individual concept with regard to the area of

internal material supply of the assembly? What

does it entail?

2. Have you ever had any experience with the

implementation of the indicated concepts? If so,

what is your experience?"

3. If we take a more concrete look at each concept,

how do you evaluate its feasibility to be

implemented in the case study company?

4. How do you think are new technologies and

processes accepted by the employees? What could

be done to facilitate the change?

Based on the selected Industry 4.0 concepts and the

interviews, an implementation roadmap has been

created.

The duration for the introduction of the individual

Industry 4.0 concepts was derived from the estimates

and suggestions of the interview participants.

According to the interview analyses, the creation of

an Industry 4.0 roadmap stood out as the first step in

the overall further development toward the target

status. Following this, the expansion of the current

Kanban system into an E-Kanban system should be

started. As a reason for this, the interview participants

mentioned the easy manageable effort for an E-

Kanban. This is because a Kanban system is already

in use. Immediately following, the implementation of

an identification and tracking system is considered

important. A major reason for this is, for example, the

issue of internal material losses and large numbers of

search processes. In the same course, the effort for the

introduction of a real-time monitoring is seen. In the

next steps, the implementation of the topic "ERP-

MES", as well as that of the automatic storage

systems, especially for the area of the pallet

warehouse, should be initiated and carried out. The

topic "Cyber Security" is considered as a measure to

be treated continuously throughout the

implementation project. This means that parallel to

Application of an Industry 4.0 Assessment Model: A Case Study Application in Material Supply for Assembly

181

the introduction of the individual concepts

mentioned, work is constantly being carried out on

this. This is because a reduction of security gaps and

possibly data losses, manipulations or entire system

failures due to cyber-attacks cannot be postponed, but

must be started out immediately.

4.4 Identified Challenges for

Implementation

Based on the results of the interviews the following

challenges for implementation could be identified and

supported the project team in risk mitigation:

1) Industry 4.0 Roadmap:

High effort and needed time for elaboration of

the roadmap;

Lack of expertise;

Finding consensus among stakeholders.

2) E-Kanban:

Insufficient space in the warehouse;

Poor article definition and standardization;

Matching between Kanban inventories and

ERP system.

3) Identification and Tracking:

Clarification of the specific mode of operation;

Lack of capacity among internal IT specialists.

4) Real-time Monitoring:

Correct master data maintenance;

Data protection;

Predefinition of optimal process parameters.

5) ERP-MES:

Correct master data maintenance;

Lack in employee qualification;

High cost.

6) Automated Warehouse Systems:

Infrastructural adjustments;

Temporary storage of stocks;

Different load carriers.

7) Cyber Security:

Possible interface problems;

Increased competence requirements for the

parties involved;

Identification of the data to be protected.

An additional challenge relevant for all planned

changes is employee acceptance (see also Sony &

Mekoth, 2022). The general attitude of employees

and managers at the case study company toward the

implementation of new technologies and concepts of

Industry 4.0 is considered by the interview

participants to be rather conservative and reserved.

One of the main aspects mentioned in this context is

that the products to be produced are always

customized products with a high diversity of

components.

5 DISCUSSION

The discussion section is subdivided in a part

discussing the potential for generalisation of the

presented approach. A next part discusses then

identified limitations as well as the relevance to

theory and practice.

5.1 Generalisation of the Approach

The results of the individual case study may well be

of use to general production companies as well.

Particularly for large companies and companies in the

rail vehicle industry, the insights into which

individual Industry 4.0 concepts have a high potential

for optimizing the efficiency of material provision in

assembly can be of great interest. In particular,

however, the information on the potential background

and the implementation also offer the companies

great added value. Namely, precisely these

companies have similar structures, financial

resources or even employee numbers and

qualifications due to their size. With this information,

they can drive forward the further development of

material provision more quickly and in a more

targeted manner.

5.2 Limitations and Implications

Despite the results achieved, the elaboration has

shown that certain limitations also go hand in hand

with this. One point here is that only people from

within the company took on the role of study

participants during the data collection. Thus, there is

certainly a limitation, in the sense of a restricted

company view. Integrating external consultants,

experts or even supply partners in the selection of the

study participants would lead to an improved quality

of the results and increase the objectivity.

The research presented provides a practical

picture of the potential of individual Industry 4.0

concepts for optimizing the efficiency of material

provision in assembly and its implementation. Thus,

the results provide information with regard to a

IN4PL 2022 - 3rd International Conference on Innovative Intelligent Industrial Production and Logistics

182

clearly practice-relevant goal, namely the further

development and increase in efficiency of company-

internal processes. Thus, this work has a much greater

practical relevance than relevance to theory.

6 CONCLUSION AND OUTLOOK

As a results of this case study research based work,

both initially set research questions could be

answered.

First of all the results of the Industry 4.0

assessment and the semi-structured interviews

showed which concepts for optimizing the efficiency

of material supply in assembly have high potential, if

there is given feasibility for implementation and how

they can be introduced as part of a holistic Industry

4.0 concept in the case study company.

Secondly the applied approach using the proposed

Industry 4.0 assessment model proved to be very

helpful. According to the own experience in its

application and feedback from the study participants,

the model helped above all to gain an overview of

possible Industry 4.0 concepts and to determine the

current status in the implementation as well as the

desired target state.

As outlook for the future the research team will

apply the model to other case study companies to gain

a broader overview of the applicability in different

industry sectors. The case study company will now

start the implementation of the seven shortlisted key

concepts for Industry 4.0 based on the proposed time

plan.

REFERENCES

Becker, W., Ulrich, P., & Botzkowski, T. (2017). Industrie

4.0 im Mittelstand: Best Practices und Implikationen

für KMU. Springer-Verlag.

Dallasega, P., Rauch, E., Matt, D. T., & Fronk, A. (2015,

March). Increasing productivity in ETO construction

projects through a lean methodology for demand

predictability. In 2015 International Conference on

Industrial Engineering and Operations Management

(IEOM) (pp. 1-11). IEEE.

Jiang, W., Sousa, P. S., Moreira, M. R., & Amaro, G. M.

(2021). Lean direction in literature: a bibliometric

approach. Production & Manufacturing Research, 9(1),

241-263.

Junge, A. L. (2019). Digital transformation technologies as

an enabler for sustainable logistics and supply chain

processes–an exploratory framework. Brazilian

Journal of Operations & Production Management,

16(3), 462-472.

Kuckartz, U. (2014). Mixed methods: methodologie,

Forschungsdesigns und Analyseverfahren. Springer-

Verlag.

Lamnek, S., Krell, C.(2016). Qualitative Sozialforschung.

6. Edition, Weinheim, Basel: Beltz.

Martínez-Olvera, C. (2022). The role of manufacturing

efficiency in the achievement of sustainable mass

customization 4.0. Production & Manufacturing

Research, 10(1), 132-159.

Nardo, M., Forino, D., & Murino, T. (2020). The evolution

of man–machine interaction: The role of human in

Industry 4.0 paradigm. Production & manufacturing

research, 8(1), 20-34.

Oztemel, E., & Gursev, S. (2020). Literature review of

Industry 4.0 and related technologies. Journal of

Intelligent Manufacturing, 31(1), 127-182.

Parviainen, P., Tihinen, M., Kääriäinen, J., & Teppola, S.

(2017). Tackling the digitalization challenge: how to

benefit from digitalization in practice. International

Journal of Information Systems and Project

Management, 5(1), 63-77.

Rauch, E., Unterhofer, M., Rojas, R. A., Gualtieri, L.,

Woschank, M., & Matt, D. T. (2020). A maturity level-

based assessment tool to enhance the implementation of

industry 4.0 in small and medium-sized enterprises.

Sustainability, 12(9), 3559.

Shuttleworth, L., Schmitz, S., & Beier, G. (2022). Impacts

of Industry 4.0 on industrial employment in Germany:

A comparison of industrial workers’ expectations and

experiences from two surveys in 2014 and 2020.

Production & manufacturing research, 10(1), 583-605.

Sony, M. (2020). Pros and cons of implementing Industry

4.0 for the organizations: a review and synthesis of

evidence. Production & Manufacturing Research, 8(1),

244-272.

Sony, M., & Mekoth, N. (2022). Employee adaptability

skills for Industry 4.0 success: a road map. Production

& Manufacturing Research, 10(1), 24-41.

Vuksanović Herceg, I., Kuč, V., Mijušković, V. M., &

Herceg, T. (2020). Challenges and driving forces for

industry 4.0 implementation. Sustainability, 12(10),

4208.

Application of an Industry 4.0 Assessment Model: A Case Study Application in Material Supply for Assembly

183