Preliminary Design of Shallot (Allium Ascalonicum L.) Dryer Instore

Hybrid Model with Control of Temperature and RH

I Kadek Ervan Hadi Wiryanta and Achmad Wibolo

Politenik Negeri Bali, Kampus Bukit, Jimbaran, South Kuta, Badung Regency, Bali 80364, Indonesia

Keywords: Design, Shallot Dryer, Instore Hybrid, Glass House Effect.

Abstract: Shallots (Allium ascalonicum L.) is one of the leading commodities of horticultural crops in Bali with a total

land area of around 1315 ha, and production reaching 246,679 quintals. The post-harvest process of shallots

that must be considered is withering and drying. If drying process were not optimal, it can cause the onion to

rot and sprout. The purpose of this research was to make a shallot dryer by controlling temperature and relative

air humidity (RH). The design of rack arranged in staggered arrangement, where the heat source combined

from the sun power and with the heat of lamp. The hot air produce from a heater and the air flow will circulate

using a fan. The temperature and RH sensors were installed in the drying chamber and connected to a control

system that will cut off the flow of hot air from the radiator if the desired temperature and RH were reached.

The results showed that the design of the drying machine that has been made can work properly.

1 INTRODUCTION

Shallots (Allium ascalonicum L.) is one of the leading

commodities of horticultural crops in Bali with a total

land area of around 1315 ha, and production reaching

246,679 quintals. (BPS Provinsi Bali, 2021). Shallots

are widely used as a spice, either in its whole form as

a traditional chopped spice (base genep) in Bali. The

post-harvest process of shallots that must be

considered is withering and drying. The drying

process by farmers in general is still traditional by

drying or hanging, so it requires a long processing

time ranging from 7-9 days. If drying is not optimal,

this can cause the onion to rot and sprout. (Tahiru,

2019). Instore drying, which is a dryer made by The

Ministry of Agriculture by displaying the room

temperature, is a drying solution for shallots.

(Balitbang Kementerian Pertanian, 2015).

Research about instore drying application on

shallot post-process have done by D Histifarina et al,

2019. The research used an experimental method with

T-test, consist of 2 treatments, conventional drying

method (sun drying) and in-store drying method. The

observed parameters include physical properties,

tuber hardness, sensory properties, chemical

properties, tuber damage, equipment performances

and financial feasibilities. The results showed that the

application of in-store drying technology has a good

efficiency (58.26%), financially feasible (R/C 1.27,

BEP 200.92, PBP 4.8 months and net B/C 1.85) and

significantly better than conventional way.

Another study on shallot drying process have

done by C L Hii, 2021. Microwave drying was chosen

to be used due to its numerous advantages such as

improved drying time, high drying efficiency and

better product quality. Results showed that drying

kinetics (moisture content and drying rates) decreased

the fastest at higher microwave power and the slowest

using convective drying. Microwave drying is

therefore able to improve drying kinetics compared to

convective drying. Post-harvest handling in shallot

such as drying of bulbs can influence bulb seeds

quality during and after storage. A study to determine

the quality of shallot bulbs during 12 weeks of storage

as the impact of drying and storage treatments have

done by Lestari, 2018. The research was arranged in

factorial randomized complete block design (RCBD)

and consisted of two factors. The first was the drying

treatments. The results showed that all treatments

indicated fluctuating changes of water content and

Total Soluble Solids in the bulb to the end of storage

while bulb firmness tended to decrease. Another

shallot drying and post processing also made by

(Indah Widanarti,2018) which was made a shallot

dryer using fumigation. (Nugraha S, 2019) made

another study showed that In-store drying system

could take 2 days faster than sun drying and has a

20

Wiryanta, I. and Wibolo, A.

Preliminary Design of Shallot (Allium Ascalonicum L.) Dryer Instore Hybrid Model with Control of Temperature and RH.

DOI: 10.5220/0011710600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 20-24

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1.

lower damage rate (0.83% for in-store drying and

3.82% for conventional way). (Setyadjit, 2015) made

an experiment to made a powder of shallot during

post processing of shallot.

Different model and method to drying

horticulture product has also made in the past. The

model of multi racks with staggered arrangement has

been introduce by (Santosa, 2020) to drying clove.

The dryer also builds with control of temperature and

RH to optimize the drying quality. (Jamil, F., 2018)

has made a design, fabrication and evaluation of

rotary hot-air dryer for the value addition of fruit

waste. This research showed that the optimum drying

conditions for citrus fruit waste was at 60˚C

temperature, 1m/sec air flow rate and 40 rpm of drum

speed.

According to a press release from the Director

General of EBTKE, Ministry of Energy and Mineral

Resources (2021), the potential for solar energy as a

source of electricity is 200,000 MW, while the

utilization of solar energy itself is currently only

around 150 MW or 0.08% of its potential.

Based on the description above, is it interesting to

made an instore hybrid shallot dryer. The dryer will

be made with temperature and humidity control and

use solar cells as an alternative power source.

2 RESEARCH METHODOLOGY

The methodology in this research were divided into

two sections. The first was creates a design of the

dryer machine, and the second was fabrication or

build the shallot dryer machine.

2.1 Design

The design of the instore hybrid shallot dryer machine

shown in figure 2 below:

Figure 2: Design of instore hybrid model of shallot dryer.

The heat transfer rate from inside of the

drying chamber across the wall can be expressed

by equation below:

q

'

U.A.∆T (1)

Yes

N

o

Start

Design prototype of Shallot

Dryer Instore Hybrid Model

Desi

g

n of Multi racks of Instore Dr

y

e

r

Build and fabrication of Shallot Dryer Instore

Hybrid model

Experimental report

Testing of

Shallot Dryer

Machine

Finish

Preliminary Design of Shallot (Allium Ascalonicum L.) Dryer Instore Hybrid Model with Control of Temperature and RH

21

(2)

Humidity is a level of state of the wet air

environment caused by the presence of moisture or

moisture in the air. Dew is a very small H2O particle

that fills air volume (Incroepera F P, 2011).

3 RESULT AND DISCUSSION

3.1 Fabrication of Dryer

The shallot instore hybrid dryer was build based on

the design above. The drying chamber was made from

aluminium with flat plate model. The heat of dryer

was made with light bulb that connected with electric

battery. The battery source from the solar panel

collector. Beside from the heater, the heat source of

the dryer also came from the glasshouse effect that

created by the solar absorption of the dryer’s wall

which was made from glass panel. To maintain

Figure 3: The shallot instore hybrid dryer model.

the air circulation, an exhaust fan also attached

on the top of drying chamber. To control the

temperature and humidity of the air, a control

module made with Arduino is used.

3.2 Experimental Analysis

The experimental investigation was observed from

the instore hybrid shallot dryer. The heat source of

dryer produces from light bulb, where the air

circulated using an exhaust fan with a flow rate of 2.8

m/s. The temperature of the drying chamber,

temperature of the tray observed using a K-type

thermocouple. The temperatures of the shallot dryer

controlled and maintain between 40°C - 50°C.

The result of performance test of the instore

hybrid dryer machine shown in table 1 below:

Table 1: Experimental test result.

Time

(Minutes)

Temperatures (

°

C) RH

Test 1 Test 2 Test 3

0 28.8 29.5 32.3 80.9

30 34.1 35.5 38.1 69.7

60 47.3 44.1 45.8 53.2

90 47.3 47.1 48.6 66.7

120 47.3 47.3 48.3 66.1

150 47.4 47.5 48.5 64.4

180 47.5 48.2 48.6 64.2

210 47.7 48.5 48.9 63.2

240 47.3 49.1 48.9 63.2

270 47.5 49.2 48.8 62.6

300 47.3 49.3 49 61.5

330 47.7 49.4 48.4 60

360 45.8 49.5 48.3 58.4

The result of shallot’s mass and water content are

shown in table 2 and 3 below:

Table 2: Mass content of shallot.

Mass

(

k

g)

Test 1 Test 2 Test 3

before

drying

(

m0

)

after

drying

(

m1

)

before

drying

(

m0

)

after

drying

(

m1

)

before

drying

(

m0

)

after

drying

(

m1

)

1.5 0.8 1.5 1 1.5 0.9

Table 3: Water content of shallot.

Water Content (%)

Test 1 Test 2 Test 3

before

drying

(

Wc0

)

after

drying

(

Wc1

)

before

drying

(

Wc0

)

after

drying

(

Wc1

)

before

drying

(

Wc0

)

after

drying

(

Wc1

)

50 28.1 50 28.8 50 28.5

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

22

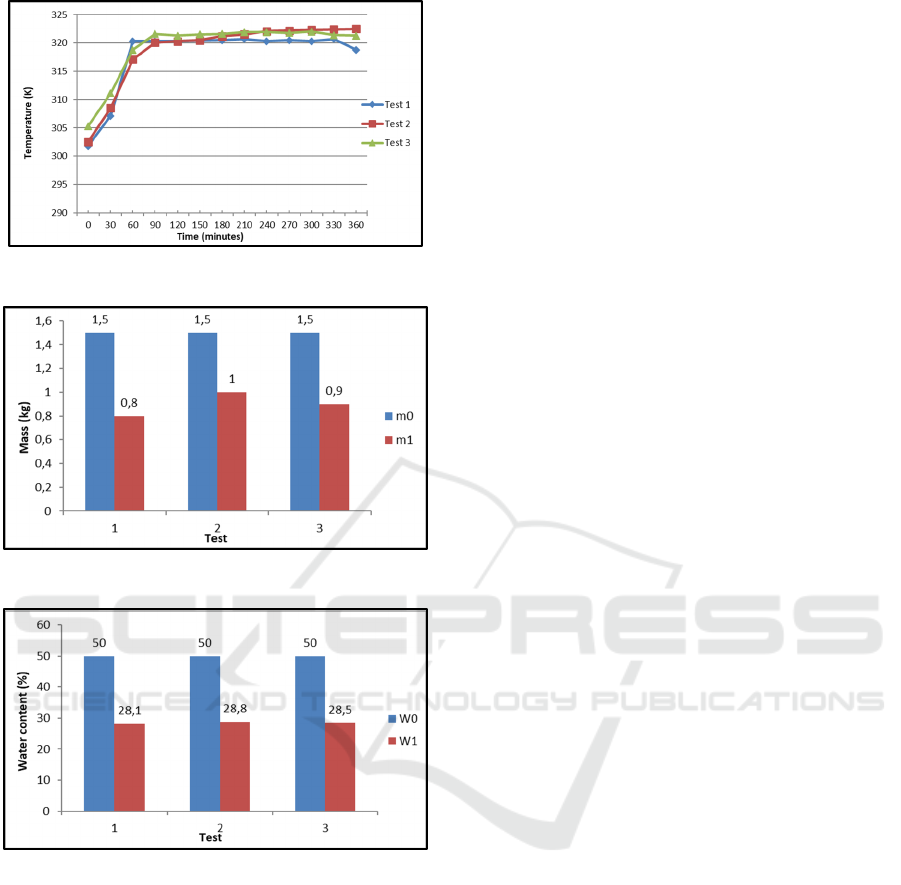

Figure 4: Temperature Distribution.

Figure 5: Mass content of shallot.

Figure 6: Water content of shallot.

Figure 4 above shows that at the temperature of

drying chamber evenly distributed. Temperatures

control in drying chamber work very well, where the

highest temperatures were on the second test which

was about 322.5 K. Figure 5 and figure 6 show the

test result for drying shallot during the process. The

mass and water content of shallot measured 3 times,

and the result showed that both the mass and water

content decreasing after the drying process. This can

explain that the shallot instore dryer hybrid

glasshouse effect can work properly. The temperature

and RH that maintained with control module Arduino

can help the shallot in their optimum condition during

the drying process. The mass content of shallot after

drying process decreasing about 40% and the water

content were decreasing about 44 %.

4 CONCLUSIONS

From the foregoing analysis, it can be concluded that

the shallot dryer instore hybrid model that has been

design and with controlling the temperature and

relative air humidity in the drying chamber can work

properly. The result showed that the drying of the

shallots uniform for different test, that described the

heat in the drying chamber distributed properly. The

decreasing of shallot mass contents about 40% after

drying and the decreasing of shallots water content

about 44%.

From the results of experimental it can be

suggested several things to improve the dryer

performances. The first is an improvement on the

system design, including the material of dryer, tray

and insulation.

ACKNOWLEDGEMENTS

The authors would like to acknowledge The Director

and Head of P3M State Polytechnic of Bali for

funding this research. Authors also likes to thanks full

to the research team and all the staff of Mechanical

Engineering Department of Bali State Polytechnic for

the support.

REFERENCES

2015 Balitbang Kementrian Pertanian

2021 BPS Provinsi Bali (www.bali.bps.go.id)

2021 www.esdm.go.id

C L Hii et al, (2021). Modelling the kinetics of microwave

drying of shallot (Allium cepa) slices. IOP Conf.

Series: Materials Science and Engineering. 1195

012033.

D Histifarina et al, (2019). In-store drying application on

shallot postharvest handling. IOP Conf. Ser.: Earth

Environ. Sci. 230 012034.

Incropera, Frank.P, David P. Dewitt, (2011). Fundamentals

of Heat and Mass Transfer. John Wiley & Son, New

York, Seventh edition.

Jamil F, Rizwan A and Muhammad A Ali, (2018). Design,

fabrication and evaluation of rotary hot-air dryer for the

value addition of fruit waste. Earth Sciences Pakistan

(ESP) Vol. 2 (2), pp. 07 – 11.

Lestari, H S L, Endang Sulistyaningsih, and Aziz

Purwantoro, (2018). The effect of drying and storage on

the quality of shallot (Allium Cepa L. Aggregatum

Preliminary Design of Shallot (Allium Ascalonicum L.) Dryer Instore Hybrid Model with Control of Temperature and RH

23

Group) bulbs. Ilmu Pertanian (Agricultural Science).

Vol. 3 (3), pp. 117 – 126.

Nugraha, S, Resa S A, and Yulianingsih, (2011). Withering

and drying shallots using instore drying to maintain

quality and reduce the level of damage. J. Pascapanen

Vol. 8 (2), pp. 72 – 81. [In Indonesian]

Santosa, I.G., Wiryanta, IKEH, (2020). The development of

multi-racks clove dryer machine with control of

temperature and Relative Air Humidity (RH). J. Phys.:

Conf. Ser. Vol. 1450, 012100.

Saraswati, Irma, et al., (2021). Design of Temperature and

Humidity Monitoring System for Drying and Storage of

Allium Ascalonicum L. (Onion). Advances in

Biological Sciences Research, Vol. 9.

Setyadjit and Ermi Sukasih, (2015). Effect of addition of

filler on the production of Shallot (Allium cepa var.

ascalonicum L.) powder with drum dryer. Procedia

Food Science, Vol. 3, pp. 396 – 408.

Tahiru, David D, et al, (2019). Room temperature

performance characteristics hybrid dryer in drying

process red onion. Jurnal Teknik Elektro dan

Komputer, Vol. 8 (2), pp. 43 – 50 [In Indonesian]

Widanarti, Indah, Sunardi, and N L Sri Suryaningsih,

(2018). Design to build a shallots drying house with

fumigation in district Tanah Miring, Merauke.

Musamus AE Featuring Journal. Vol. 1 (1), pp. 28 – 34.

[In Indonesian].

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

24