Design, Fabrication, and Performance Evaluation of Shredding

Machines for Shredding Plastic Bottles and Cups Waste

Frans Mangngi

a

, Aris, Arianto B. Ama and Yudith E. Mase

Mechanical Engineering, State Polytechnic of Kupang, Indonesia

Keywords: Shredding Machine, Plastic Waste, Plastic Bottle, Plastic Cups.

Abstract: Plastic's function in human lifestyles is expanding. This boom is because of the truth that plastic is light-

weight, realistic, and reasonably priced and can replace other objects features. Plastic use is hastily increasing

in East Nusa Tenggara Province, especially in Kupang town, as evidenced by the enormous use of plastic

gadget. Some people in Kupang town see this problem as a possibility and opportunity to create jobs and a

generate of income by gathering plastic waste to be sold and despatched to some other island to be recycled.

Therefore, this study focused on designing and fabricating a low-cost plastic shredding machine that will

assist plastics collectors as small and medium-scale entrepreneurs in the city of Kupang in chopping plastic

waste i.e. bottles and cups into small fragments, making it easy to pack and ship it. The plastic shredder

machine is made up of four major parts: the hopper, the shredding unit, the power unit, and the machine frame.

The design parameters, such as hopper capacity, shaft diameter, reducer ratio, and required power, have been

calculated. The result of the calculated design parameters was being used for fabrication. The uniqueness of

this plastic shredder machine lies in the uniqueness of its design where at the bottom of the shredding unit

there are a metal sieve with the geometric shape of arc that allows the recirculation of crushed plastic not

conforming to the appropriate size to reintegrate it in the shredding process. This metal sieve will ensure the

chopped plastic are uniform in size. The performance evaluation of the machines was determined in terms of

the machine efficiency and the production rate. Following the successful completion of the fabrication, the

shredder machine is tested using 4500 gr of the plastic bottle and 2600 gr of plastic cups as a sample, with the

succeeding results obtained: At a machine speed of 135 rpm, the plastic bottle was shredded to an average

particle size of 30 mm

2

in 840 sec, and plastic cups was shredded to an average particle size of 28 mm

2

in 400

sec. The average machine efficiency was 98% for plastic cups, and 94% for plastic bottle.

1 INTRODUCTION

Plastic's use in human existence is expanding by the

day. Plastic is being used more because it is light,

practical, and affordable, and it may replace the

function of other goods. Because of their practical and

affordable character, plastics are frequently utilized

as disposable objects, increasing plastic waste as

more equipment made of plastic materials is used.

This is what causes the amount of plastic waste to

continue to rise, causing major environmental issues.

Plastic trash is an environmental issue that the people

of Indonesia and the rest of the globe face. The use of

non-environmentally friendly plastic products

generates a variety of major environmental issues.

Plastic garbage is one sort of waste that is extremely

a

https://orcid.org/0000-0003-0882-615X

difficult to degrade in the soil, taking decades or even

hundreds of years to completely decompose in nature.

Plastic garbage dumped directly into the final

disposal site will cause complications if not properly

managed (L. Habib, et all, 2018). The dumping of

plastic waste is one of the sources of environmental

damage that remains a significant concern for the

Indonesian people. The plastic trash takes tens.

However, the negative impact of plastic waste is

proportionate to its usefulness. Thus, if the trash is not

eliminated, it will pose a major hazard

In the city of Kupang, particularly in the sub-

district of Kelapa Lima, the usage of plastic is fast

increasing, as seen by the prevalence of plastic-made

equipment. This is exacerbated by the public's lack of

awareness regarding proper waste disposal, so in

several locations along the coast in Kupang City, such

82

Mangngi, F., Aris, ., Ama, A. and Mase, Y.

Design, Fabrication, and Performance Evaluation of Shredding Machines for Shredding Plastic Bottles and Cups Waste.

DOI: 10.5220/0011712900003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 82-88

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2024 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

as Pasir Panjang beach and Oesapa Beach, there is a

great deal of plastic waste that pollutes the

environment and will undoubtedly have further

repercussions if not addressed immediately.

The issue of plastic trash is not just an

environmental concern, but also an opportunity for

commercial growth. Therefore, several residents of

Kupang city view this opportunity as a source of

income-generating employment opportunities. The

scavengers will begin to collect and sell plastic waste

to plastic collectors, who will subsequently ship and

sell the plastic waste to the island of Java to be

converted into plastic raw materials.

Based on the preliminary study conducted by the

author in Kupang Regency of East Nusa Tenggara

Province, at various plastic collection sites run by

local citizens in the Kupang City, the collected plastic

was sent directly to the main island of java in

Surabaya without further processing. If the plastic has

been treated (crushed into shreds), it will be

significantly easier to pack and ship. In addition, the

selling price will be more than that of plastic garbage

sold in its entirety.

According to the findings of interviews with a

number of plastic collectors, there is hope that the

community will process the plastic waste into small

pieces before sending it to Java for recycling, but due

to the high cost of the chopper machine and

technological limitations, all plastics collector in

Kupang city continue to operate under the current

conditions. Seeing the data and the reality on the

ground, the author attempts to design and fabricate a

Shredding Machines for Shredding Plastic Bottles

and plastics cups with a simple cutting process so that

it can be more effective in packing and shipping

plastic waste than shipping plastic waste in its intact

form, which is deemed inefficient.

The objective of this research is to design a Plastic

Shredding Machine to obtain small plastic waste in

such a way that it enables recycling industry

professionals to obtain waste automatically and is

also very useful for reducing plastic pollution in the

environment.

2 RELATED WORKS

Plastic waste shredding machines are extremely

important, as a number of studies have demonstrated

as follows;

(A. Waleola Ayo, et all, 2017) recognized that

when disposable plastic is shredded, the small pieces

can be used to create new plastic products.

Accordingly, they proposed the development of a

plastic waste shredding machine. The machine's

performance is 27.3 kg/h and its efficiency is 53% for

all types of plastic and 95% for polyvinyl chloride

plastic, concluding that the machine could be very

useful in situations where large quantities of plastics

need to be crushed and is also effective in crushing

large sizes.

(Nuri Aryani et al., 2019) conducted a study to

design and fabricate a plastic shredder machine using

the Pahl and Beitz method, which consists of

designing and describing the job, designing the

product concept, constructing the machine, and

designing the details. The plastic shredder machine

consists of blades or a cutter, a spur gear-shaped

transmission element, an electric motor, and a

machine body. The types of plastic waste to be

shredded are LDPE, HDPE, PP, and PS Based on its

design, a plastic shredder machine can produce small

flakes measuring approximately 10 mm in length and

1 mm in width.

(Witman Alvarado-Diaz, 2021), conducted a

study to design a plastic shredding machine to obtain

small plastic waste to assist people in being dedicated

to the recycling industry in an automated way, it

would also generate jobs because it requires a staff in

charge of the machine, and it will also be extremely

useful in reducing plastic pollution in the

environment, which is increasing due to COVID-19

The plastic will be selected by color and type of

plastic composition, whether it is Polyethylene

Terephthalate (PET), High Density Polyethylene

(HDPE), Low Density Polyethylene (LDPE),

Polychloride vinyl (PVC), or Others (Plastic Mix),

then it will go through the shredding process to

become small plastic waste, which could be turned

into filament for 3D printers, using the design of the

plastic waste shredding machine.

Jaypalsinh Rana, (2020), Conduct a study to

design and construct a lightweight and inexpensive

plastic shredder machine. So, the goal of this project

is to process plastic garbage as cheaply as possible by

cutting where it is made to reduce labour work, which

results in cost savings. This project describes the trial

with plastic bottle cutting machines as well as the

examination of the machine's mechanism. A plastic

bottle cutter is a machine that cuts plastic into little

pieces to facilitate waste management. We are

developing this project model to be used for the

recycling of plastic waste in the home, industries, and

scrap collectors. This machine is a solution to the

space problem.

Adepo, S. O, and Obanoyen, N. O. (2017),

conducted a study to design and construct a plastic

shredding machine, which is an integral part of plastic

recycling process. By crushing used plastic bottles,

the plastic bottle crushing device assists in the

management and disposal of municipal waste. Due to

the use of readily available local raw materials during

Design, Fabrication, and Performance Evaluation of Shredding Machines for Shredding Plastic Bottles and Cups Waste

83

construction, the machine requires little upkeep and

maintenance. The performance test analysis, which

shows that the machine operates effectively and

efficiently to complete its task at a high level of

finished shredding efficiency of 97% at a speed of

11.5 m/s, defines the characteristics of the machine.

3 MATERIAL AND METHODS

During the design and material selection process, the

following elements were considered: locally

available, safety, strength, reliability, stability, size

and shape, power consumption, ease of maintenance,

and ease of operation. The shredding machine

represented in figure 1 was made up of the following

components: a hopper, a shredding unit, a power unit,

a machine frame, and a discharge chute. The

uniqueness of this plastic shredder machine lies in its

design, which includes a metal sieve with the

geometric shape of an arc at the bottom of the

shredding unit, allowing the recirculation of crushed

plastic that does not conform to the appropriate size

to be reintegrated in the shredding process. This metal

filter ensures that the chopped plastic is uniform in

size.

4 DESIGN CALCULATIONS

The design parameters, such as shredder hopper,

Shredder cutter, blade cutting force, required power,

shaft diameter, shredder machine capacity,

supporting frame have been calculated. The result of

the calculated design parameters was being used for

fabrication

4.1 Shredder Hopper

The shredder hopper is a pyramid with a truncated

rectangular base that is positioned on the shredder

chamber. The volume of the shredder hopper (VH)

through which recyclable plastics are fed is

determined by the equation (1).

𝑉𝐻

1

3

𝐵𝐻 𝑏ℎ

(1)

Where: B = the area of the rectangular base for the

big pyramid (mm), H = the height of the big pyramid

(mm), b = the area of the rectangular base for the

small truncated pyramid (mm), and h = is the height

of the small truncated pyramid. It is hoped that 75

percent of the hopper's volume will be occupied by

recyclable PET/PET plastic due to the spacing

between individual plastic elements.

Volume of PET bottle (Aqua Botle) in the shredding

chamber: Area × height = = (πd4/4) × h; No of bottle

to fill the hopper = volume of hopper/ volume of PET

Bottle

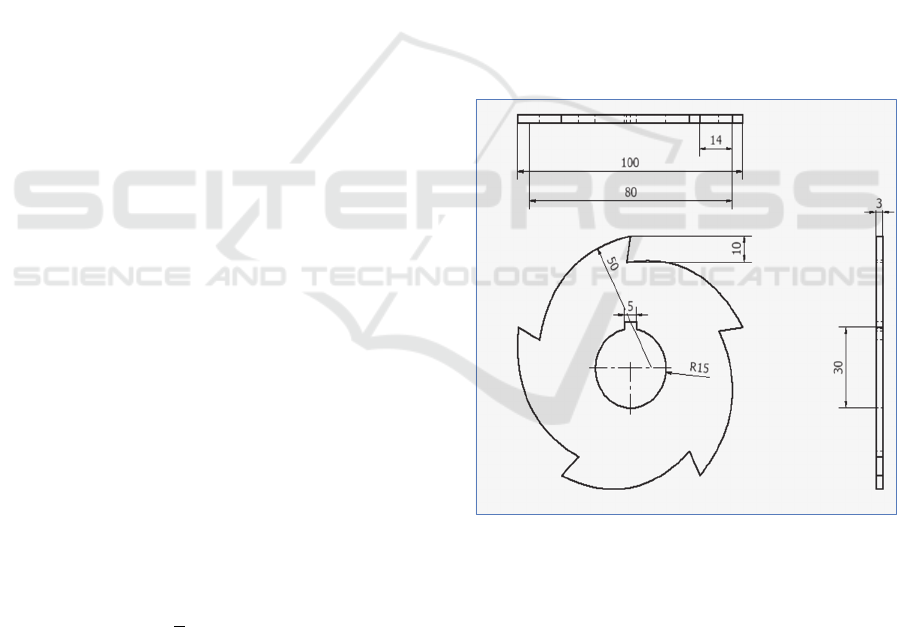

4.2 Shredder Cutter

The cutting system of the plastic shredder machine

employs two shafts with chopping blades placed

alternately and moving in opposite directions to work

by chopping, squeezing, and crushing the plastic

trash. Each shredder knife is made up of 5 cutting

blades with the design depicted in figure 1. The

following is the shredder blade design data: blade

diameter (𝐵

)= 100 mm, inner blade diameter 𝐵

=

80 mm, blade thickness 𝐵

) = 3 mm, blade length

𝐵

) = 10 mm, blade material = SC45 Carbon Steel,

blade cross-sectional area = 30 mm², total number of

blades = 72, modulus elasticity of plastic (PPT) = 2,76

GPA = 281,4 Kgf/mm², planned knife rotation (n):

135 rpm, the initial rotation of the electrical motor:

3600 rpm

Figure 1: Blade Geometric.

4.3 Finding Blade Cutting Force (F

blade

)

The blade cutting force (F

blade

) can be found using the

equation:

𝐹𝑏𝑙𝑎𝑑𝑒

𝐴

.𝐹

(2

)

Where: A = blade cross-sectional area, F

t

= modulus

elasticity of plastic. By getting the cutting force, the

Torque (T) on the blade can be found using the

equation:

𝑇

𝐹

𝑏𝑙𝑎𝑑𝑒

.𝑟

(3

)

Where: r = The blade diameter, T = Torque

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

84

4.4 Required Motor Driver Power

The driver motor or provides power to the machine.

There are two types of motor driver can be used to

provides the rotational motion and power needed to

rotate the shaft through belt and pulley which is the

electrical motor, or gasoline motor. The horsepower

of the motor driver needed can be calculated as follow

[7].

𝑃 𝑇

2

.𝑛

60

.

(4)

Where: n = The rotation of planned knife mounted on

the shaft

4.5 Shaft Diameter

The shredder shaft is a revolving component located

in the shredder chamber, and it is fitted with rings

bearing knife-edged teeth. As it rotates against

another stationary shaft in the chamber, this knife-

edge ring enables the shredding of waste plastic

materials. As its near end is supported by two

bearings, the shredder shaft is designed to endure both

torsional and bending loads that it is subjected to

during operation. Consequently, the shredder shaft

diameter (d

s

), can be calculated using equation

𝑑

5,1

𝐾

𝐶

𝑇

/

.

(4)

Where: n = The planned knife rotation

ds = shaft diameter, 𝑇 = Torque, 𝐾

= Torsional

moment correction factor vallue 1,0 – 1,5, 𝐶

=

flexural factor value 1,2 – 2,3,

= allowed shear

stress. The allowed shear stress (

) can be found

using equation

𝑆

𝑓

𝑥𝑆

𝑓

(5)

Where:

= tensile strength, 𝑆𝑓

= first safety factor,

𝑆𝑓

= second safety factor. The tensile strength value

for machine construction carbon steel (S45C) is 58

kg/mm2

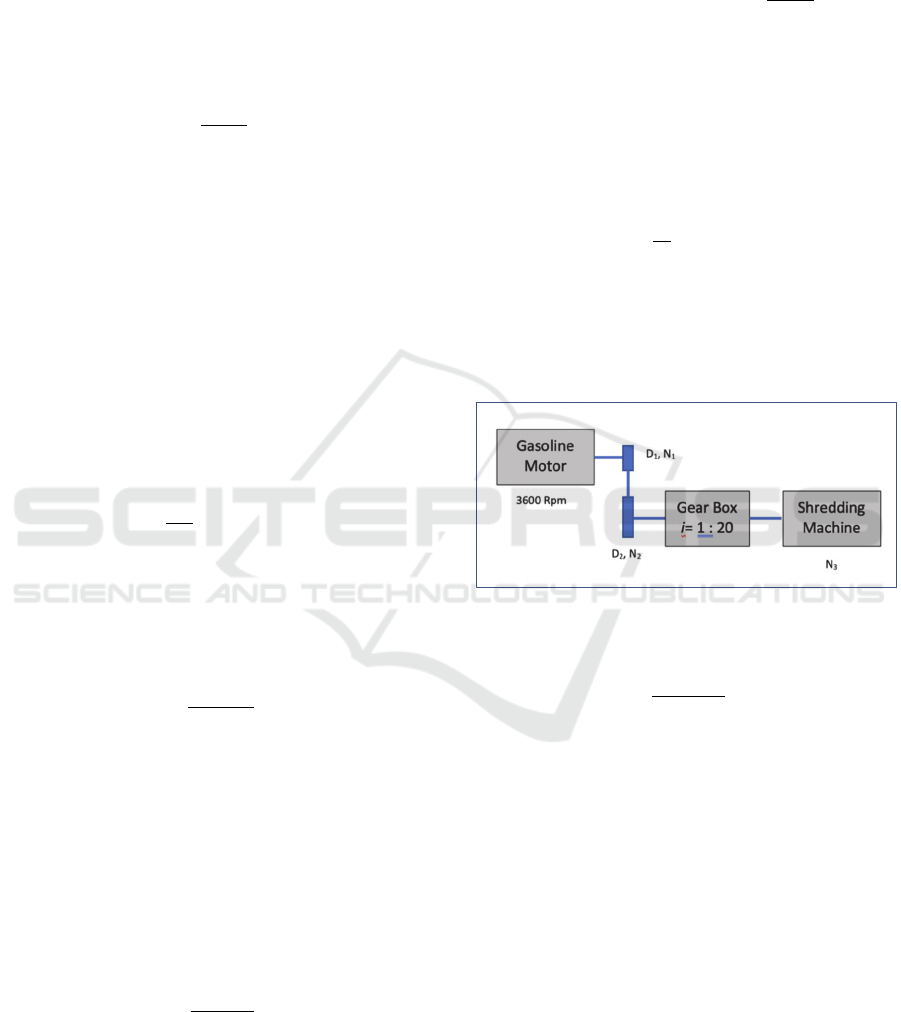

4.6 Power Transmission

In order to transport power from the electric motor to

the shaft of the plastic shredded machine, a V-belt and

pulley system is utilized. Principal transmission

parameters can be calculated as follows:

𝐷

𝑁

𝑥 𝐷

𝑁

(6)

Where: D

2

= diameter of the pulley connected to the

gear box (mm), D

1

= diameter of the pulley connected

to the electric motor, N

1

= speed of gasoline motor

(Rpm), and N

2

= speed of the pulley connected to the

gear box (Rpm).

Equation (7) can be used to determine the length of

the belt.

𝑡 2𝐶 1,257

𝐷

𝐷

)

(7

)

Where: t = belt length (m), C = centre distance

between pulley (m), D

1

= pitch diameter of the pulley

connected to the motor (m), D

2

= pitch diameter of

the pulley connected to the gear box.

The transmission utilized is a WPA 70 with a 1:20

ratio. The gearbox is linked to the rotation of the

electric motor, which has been reduced from N

1

to N

2

.

In order to calculate the output rotation of the gearbox

(N

3

), it is determined by the equation as follows.

𝑖

); 𝑖=20

(8

)

Where 𝑖=Gear box ratio = 20, 𝑁

= speed of the

pulley connected to the gear box (Rpm), 𝑁

= rotation

of the gearbox shaft that connected to the machine

shaft.

Figure 2: Power Transmission Design.

The belt speed is calculated uses eq. (9)

𝑉

.𝐷

.𝑁

60

.

000

(9

)

Where: V = belt speed (m/s), D

1

= diameter of the

pulley connected to the electric motor (m), and N

1

=

speed of the pulley connected to the shaft (Rpm).

4.7 Supporting Frame

A frame is a freestanding framework designed to hold

all of the plastics shredder machine's components.

The constructed frame should be capable of bearing

the machine's complete weight without collapsing.

The most important requirement for the design of the

machine frame is that it retains the correct relative

position of the units and parts installed on it during an

extended period of service. The stand structure should

be capable of supporting the machine without

Design, Fabrication, and Performance Evaluation of Shredding Machines for Shredding Plastic Bottles and Cups Waste

85

Figure 3: The Design of Shradding Maching.

collapsing. The frame is composed of 75 x 75 x 8 mm

angle iron manufactured of low carbon steel.

4.8 Finding Machine Capacity

Theoretically the machine capacity is estimated based

on the cutting area of each cutter that mounted on the

shaft, it is assumed that all cutting tips on each cutter

will be cutting perfectly.

The cutting area calculated using equation (10);

𝐴

ℎ 𝑥 𝐷

𝐷

(10)

Where: A = The Cutting Area (m

2

), h = Cutting tip

height, D

1

= cutter outer diameter (m), D

2

= cutter

inner diameter (m)

The cutting volume calculated using equation (11);

𝑉

𝐴

𝑥𝐿

(11)

Where: V

c

= cutting volume, A = cutting area, L = Tip

length.

If each cutter consists of 5 cutting tips; therefore, each

cutter will cut 5 x Vc. Since the total number of

cutters mounted on the two shafts are 76 cutters;

therefore, the volume of plastics chopped by the

shredding machine is 5 x V

c

x 76 m

3

for each shaft

revolution. If the planed shaft revolution is 135 RPM,

then the volume of plastics shredded become 135 x 5

x V

c

x 76 m

3

per minute = 135 x 5 x V

c

x 76 x 60 m

3

per hour. Since the plastic density for PET = 138000

Kg/m3, then the Shredding machine capacity can be

calculated as 135 x 5 x V

c

x 76 x 60 m

3

x 138000

Kg/hour. This theoretical calculation of machine

capacity is an ideal calculation with the assumption

that all blades mounted on the shaft are able to chop

plastic waste perfectly, which in reality is not possible

because during operation there are a number of blades

that cannot chop because of the position of plastic

waste that enters through the machine. the hopper is

still spinning and hasn't had time to touchthe cutting

edge

5 PRINCIPAL OPERATION OF

THE MACHINE

The plastic garbage to be chopped is gathered in a

container and positioned close to the shredder. To

start the engine, a gentle press of the on/off button is

required. When the drive motor is activated, its

rotation and power are sent via pulleys and belts to

the gear box, which is then transmitted to two shafts

that revolve in opposing directions in the counter

space. Due to the movement of the two shafts, the

blades connected to the shafts will also revolve. The

processed plastic garbage is then put into the

machine's hopper with the assistance of an operator.

When the waste plastic contacts the chopping knife

linked to the two shafts that move in opposing

directions, the waste plastic will be severed owing to

the sharp edge of the blade tearing and tearing the

waste plastic.

The plastic waste fragments will then fall into the

half-round filter part and accumulate in the filter. If

the chopped plastic granules reach a size smaller than

the filter's hole, the results will exit out the outlet.

Nevertheless, if the size of the chopped plastic is still

greater than the filter hole, the plastic waste will be

brought back by the chopping knife and chopped

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

86

again until its size is smaller than the filter hole.

Figure 2. Shows the final design of the Plastics

shredding machines

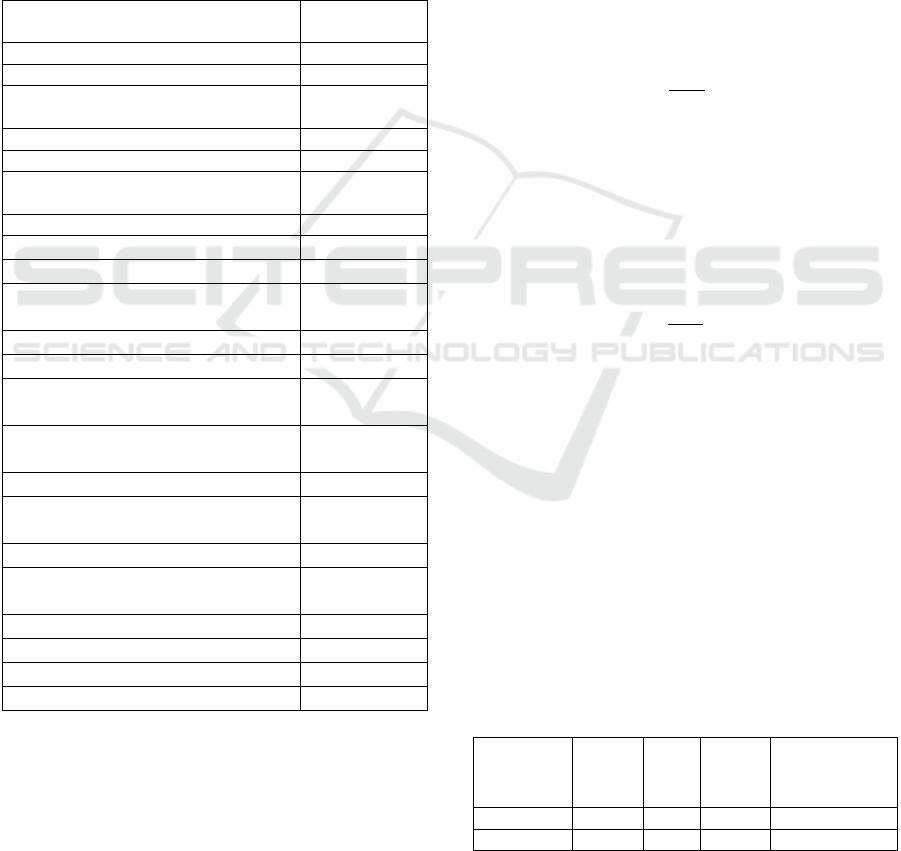

6 DESIGN CALCULATION

RESULTS

The outcomes of the calculated procedure are

presented in Table 1. All calculations are obtained

from equations 1 through 11, as described in the

section on design calculations.

Table 1: This caption has one line so it is centered.

Design Parameters Value

obtaine

d

Shredder ho

pp

er Volume 0,011m

3

Plastic Bottle Volume

(

A

q

ua 600ml

)

0,0006 m

3

Number of bottles filled in the hopper

for 1 batch

(

75% of ca

p

acit

y)

13 pcs

Wei

g

ht of 13

p

cs

p

lastic botles 2,6 K

g

Plastic cu

p

s volume

(

a

q

ua 240 ml

)

0,00024 m

3

Number of plastic cups filled in the

ho

pp

er for 1 batch

(

75% of ca

p

acit

y)

30 pcs

Wei

g

ht of 30

p

cs

p

lastic cu

p

s 4,5 K

g

b

lade cuttin

g

force

5148 N

Torque on the blade (T)

257,4 Nm

The horsepower of the motor

driver (P)

5 Hp

shaft diameter (d

s

)

31 mm

allowed shear stress

diameter of the pulley connected

to the

g

ear box (D

1

)

100 mm

diameter of the pulley connected

to the electric motor (D

2

)

80 mm

b

elt speed (V)

18,4 m/s

output rotation of the gearbox

(N

3

)

135 Rpm

speed of

g

asoline motor (N

1

)

3600 Rpm

speed of the pulley connected to

the

g

ear box (N

2

)

2700

the len

g

th of the bel

t

cuttin

g

area

30 mm

2

Cuttin

g

Volume

180 mm

3

Theoretical Machine Capacit

y

73,4 Kg/Hour

7 PERFORMANCE EVALUATION

Performance evaluation is a crucial element in the

machine development process. After the design,

fabrication, and assembly processes, testing is

required to identify the machine's performance,

uncovered issues, and improvement opportunities.

The intended evaluation was of the machine's

production rates and its efficiency.

The following procedures were used for the

performance test: (1) the dry plastic waste test

materials in the form of plastic bottles and plastic

cups packaged of mineral water are weighed; (2) the

shredding machine is turned on by turning on the

gasoline motor as the prime mover; (3) waste plastic

material is fed into the machine's hopper; (4) the time

is monitored using a stop watch during the

enumeration process; (5) collect and re-weigh the

chopped results from the outlet;

7.1 The Production Rates

Equation (12) may be used to calculate the machine's

production rate.

𝑃

𝑇𝑊

𝑇

(12

)

Where: P

r

= production rate (Kg/hour), TWo = weight

of waste plastics discharge from the hopper (Kg), T

o

= time needed to shredded the plastics (Hour)

7.2 Shredding Machine Efficiency

The efficiency of the shredding machine can be

evaluated uses equation (13)

𝑇

𝑇

(13

)

Whwre: = machine efficiency (%), T

wi

= total

weight of plastics fed in to the hopper (Kg), and T

wo

= total weight of plastics discharge from the cute

(Kg).

8 RESULTS AND DISCUSSIONS

Functional test is the latest form of testing of a waste

chopper design which aims to determine whether the

results of the design can function in accordance with

the expected design. If the design is not suitable,

modifications must be made to improve its

performance. The Test results can be seen in table 2

Table 2: Shredding machine test results.

Types of

Plastic

Waste

T

wi

(gr)

T

wo

(gr)

T

o

(sec)

average

particle size

(mm

2

)

PET Glass 2600 2550 400 28

PET Botle 4500 4250 840 30

Design, Fabrication, and Performance Evaluation of Shredding Machines for Shredding Plastic Bottles and Cups Waste

87

Remarks: T

wi

= total weight of plastics fed in to the

hopper (Kg), and T

wo

= total weight of plastics

discharge from the cute (Kg); T

o

= time needed to

shredded the plastics (hour)

The production rates and machine efficiency may

be expressed using equations (12) and (13), as shown

in table 3.

Table 3: The production rates, and the machine efficiency.

Types of

Plastic

Waste

Production rates

(Kg/Hour)

Machine

efficiency (%)

PET Glass 22,95 0,98

PET Botle 18,21 0,94

The trial machine's capacity is 18.21 kg/hr for

mineral water bottle packaging and 22.95 kg/hr for

plastic glass packaging. When compared to the 73.4

kg/h theoretical engine capacity, the test results

appear to be very low. This means that the plastic

shredding machine needs to be redesigned, including

the blades that cut the plastic, since the knives on the

machine tend to break.

9 CONCLUSIONS

The optimization of the machine designed and made

capable of shredding mineral water packaging waste

in the form of glass up to 22.95 kg/hour, and 18.21

for plastic waste mineral water packaging in the form

of bottles. Because the size of the shredded results is

an average of 30 mm

2

for plastic bottle and 28 mm

2

for plastic cups this machine may be more effective

and efficient in the process of enumerating plastic

glass trash and plastic bottle waste, reducing the

requirement for space for packaging rubbish. This

machine is ideal for first-level collectors because it is

simple to operate with maximum capacity, with a

counting efficiency of 0.98% for chopping plastic

glass waste and 0.94% for chopping plastic bottle

trash. The construction is also quite basic and can be

done in small-scale workshops, thus the prices to

build it are affordable. This machine design may

assist and have a favourable and effective impact on

the effectiveness of waste collectors' packaging and

shipping activities.

ACKNOWLEDGEMENTS

This study was funded by State Polytechnic of

Kupang through its annual research program of 2022;

thus, we would like to express our appreciation to the

director of State Polytechnic of Kupang for providing

the funding for this study. In addition, I appreciate the

support of the head of the mechanical engineering

workshop during the creation and fabrication of the

needed technology, and it gives me great pleasure to

recognise my researcher team's contribution to the

completion of this project

REFERENCES

L. Habib Almukti, Aladin Eko Purkuncoro,ST.MT, (2018)

"perancangan konstruksi mesin pencacah limbah,"

Jurnal Mahasiswa Teknik Mesin ITN Malang, vol. 01,

no. 01, pp. 54-58.

A. Waleola Ayo, O. Olukunle, and D. Adelabu, (2017)

“Development of a Waste Plastic Shredding Machine,”

Int. J. Waste Resour., vol. 07, no. 02, 2017, doi:

10.4172/2252-5211.1000281.

Nuri Aryani, Dede Buchori, and Albertus Budi Setiawan,

(2018), Design of a Plastic Shredder Machine, IPTEK

Journal of Proceedings Series No. (3) (2019), ISSN

(2354-6026), International Conference on Engineering,

Advance Science and Industrial Application

(ICETESIA), September 6-7 2018, Institut Teknologi

Sepuluh Nopember, Surabaya, Indonesia

Witman Alvarado-Diaz, Jason Chicoma-Moreno, Brian

Meneses-Claudio, Luis Nuñez-Tapia, (2021), Design of

a Plastic Shredding Machine to Obtain Small Plastic

Waste, International Journal of Advanced Computer

Science and Applications (IJACSA), Vol. 12, No. 6,

2021, pp 478-483

Jaypalsinh Rana, Sahil Shah, Mit Shah, Mikul Prajapati,

Harshil Mehta, (2020), Design and Fabrication of

Plastic Bottle Shredder, International Research Journal

of Engineering and Technology (IRJET),

www.irjet.net, Volume: 07 Issue: 04, Apr 2020, e-

ISSN: 2395-0056, p-ISSN: 2395-0072, pp 1738-1745

Kurmi R. S. and Gupta J. K. (2005). Machine Design, 14 th

edition, New Delhi: Eurasia Publishing House (PVT.)

Ltd.

Adepo, S. O, and Obanoyen, N. O (2017). Design And

Construction Of A Plastic Shredding Machine. Journal

of Multidisciplinary Engineering Science and

Technology (JMEST) ISSN: 2458-9403 Vol. 4 Issue 9,

September - 2017

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

88