Preliminary Study of the Characteristics of Nipah Fruit Bioadsorbent

as Greenhouse Gas Adsorption

Dodi Satriawan

1a

, Fadhillah Hazrina

2

and Agus Santoso

3

1

Department of Environmental Pollution Control Engineering, Cilacap State Polytechnic, Cilacap, Indonesia

2

Department of Electrical Engineering, Cilacap State Polytechnic, Cilacap, Indonesia

3

Department of Mechanical Engineering, Cilacap State Polytechnic, Cilacap, Indonesia

Keywords: Nipah Fruit, Bioadsorbent, Adsorption, SNI 06-3730-1995.

Abstract: This research is a preliminary study that aims to determine the bioadsorbent characteristics of nipah fruit

based on SNI 06-3730-1995. Nipah fruit bioadsorbent that is made will later be applied as a medium for

absorbing pollutants from greenhouse gas emissions. Nipah fruit obtained from Kampung Laut, Cilacap

Regency, Central Java, was carbonized at a temperature of 500

o

C for 4 hours. The charcoal obtained is then

pulverized to a size of 50, 100, and 150 mesh. The activation process is carried out using 0% KOH; 2.5%;

5%; and 7.5%. The results obtained in the form of water content and iodine absorption that have met the

quality requirements of SNI 06-3730-1995. However, the ash content and volatile matter content did not meet

the quality requirements of SNI 06-3730-1995. This is because the nipah fruit bioadsorbent has high metal

oxides and organic compounds.

1 INTRODUCTION

Vehicles powered by fossil fuels have altered the side

of the earth over the last few century. The arrival of

these vehicles covered the way for industrialization

though we have been grappling with their ill effects

for a decade. Hydrogen is the neatest fuel known to

people and advances in hydrogen technology are

expected to impact transportation and energy

markets. In addition, greenhouse gases (GHGs)

produced from exhaust fumes from automobiles and

industrial factories are a major cause of global

warming and further harmful environmental impacts

(Mukherjee et al., 2019). The rejection of the global

warming phenomenon by world leaders underscores

the task of scientists in addressing this man-made

catastrophe.

Adsorption of greenhouse gases for instance

carbon dioxide and methane is one of the useful

methods to reduce these effects. In contrast, burning

fossil fuels produces greenhouse gases (GHG) and

dangerous gases such as CO

2

, H

2

S, CH

4

, NO

2

for the

environment, which are improving in line with recent

energy needs for rapid economic improvement

(Mukherjee et al., 2019). Consequently, it is highly

a

https://orcid.org/0000-0001-7064-8484

desired to find a cheap and environmentally

responsive adsorbent to remove pollutants from air.

Many techniques can be used to reduce

greenhouse gas emissions such as filtration,

oxidation, reverse osmosis, flocculation, aerobic,

anaerobic, magnetic separation and adsorption. Of all

the techniques, adsorption is one of common methods

for removing contaminants from wastewater and air

pollution because it is inexpensive, easy to use,

environmentally responsive, harmless to health and

non-harmful (Wickramaratne & Jaroniec, 2013). The

adding of bioadsorbent in the adsorption practice

helps remove various contaminants and carcinogenic

composites such as metallic, drugs and non-metal

pollutants, colorants, and even taste then odor from

aqueous solutions (Idrees et al., 2018).

Compared to other adsorbents such as zeolites,

polymers and clays, activated carbon takes improve

performance and firmness in conditions of adsorption

(Narkiewicz & Morawski, 2016). Recently, the

adsorption of pollutant gases by bioadsorbent has

been established as a capable technology for the

mechanism of attraction among pollutants and

superficial functional groups (Xu et al., 2014).

Bioadsorbent making from biomass can be realized

Satriawan, D., Hazrina, F. and Santoso, A.

Preliminary Study of the Characteristics of Nipah Fruit Bioadsorbent as Greenhouse Gas Adsorption.

DOI: 10.5220/0011723900003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 127-131

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

127

as an advantage in two aspects, firstly it can avoid

CO

2

production by sequestering carbon and secondly

bioadsorbent can enter the soil naturally (Alabadi et

al., 2015).

Bioadsorbent has more benefits other adsorbents

due to its high thermal constancy and low feedstock

costs. Bioadsorbent can be produced from some of

materials, such as coal, manufacturing by-products,

and wood or more biomass sources (Jia et al., 2020).

Bioadsorbent is generally produced by chemical and

physical activation. Physical activation is commonly

undertake with carbon dioxide, air steam, or mixtures

thereof. Chemical activation requires several agents

such as HCl, Ca(CO)

2

, ZnCl

2

, H

2

SO

4

, KOH, HNO

3

,

and K

2

CO

3

(Erawati & Fernando, 2018; Hendrawan

et al., 2017; Hui & Zaini, 2015; Pallarés et al., 2016;

Satriawan et al., 2021). Bioadsorbent adsorption

performance hinge on the structure of pore and

properties of surface. Bioadsorbent achieved by

activation of chemical often have large surface of

areas and well-developed of micropores, making

them desirable materials for carbon dioxide (CO

2

)

adsorption (Heidari et al., 2014).

This study aims to examine the characteristics of

bioadsorbents made from nipah fruit biomass with

variations in size and chemical activation. The

characteristics of the bioadsorbent in the form of

adsorption of iodine content, volatile matter content,

moisture content, and ash content were carried out to

see whether the bioadsorbent of nipah fruit activated

with KOH had complied with SNI 06-3730-95, 1995

regarding technically activated charcoal. This

bioadsorbent will be used for the adsorption of air and

water pollutants in future research.

2 METHODOLOGY

This research was conducted in the Environmental

Pollution Control Engineering study program,

Cilacap State Polytechnic. The raw material for

bioadsorbent comes from the biomass of nipah fruit

obtained in Kampung Laut, Cilacap Regency. Nipah

fruit is split into four parts which are then dried in the

sun. The pyrolysis process was carried out at 500

o

C

for 4 hours to get nipah fruit charcoal. Nipah fruit

charcoal was then mashed with variations of 50 mesh,

100 mesh, and 150 mesh.

The refined charcoal was then activated using

KOH with various concentrations of 0%: 2.5%; 5%;

and 7.5%. Activation of nipah fruit charcoal was

carried out by heating at 70

o

C for 2 hours with 300

rpm stirring. Activation of nipah fruit charcoal is then

left for 24 hours after the heating process.

The filtering process was carried out using filter

paper and the obtained bioadsorbent was then

neutralized with hot distilled water to a neutral pH

(6.5 - 7.5). The neutralized bioadsorbent is then

placed in the oven to remove the water content. The

process of bioadsorbent analysis in the form of iodine

analysis, volatile matter content, ash content, water

content refers to the method of SNI 06-3730-95,

1995.

3 RESULTS AND DISCUSSION

3.1 Moisture Content

Analysis of the water content of the bioadsorbent

refers to SNI 06-3730-95, 1995 regarding technically

activated charcoal. 1 gram of bioadsorbent was put

into the oven at 115

o

C for 3 hours. The bioadsorbent

that has been baked is then put into a desiccator and

weighed with an analytical balance. The difference

between the initial and final weight reduction is the

water content that evaporates in the bioadsorbent. The

results of the analysis of the water content of the

bioadsorbent made from nipah fruit are presented in

figure 1.

Figure 1: The effect of KOH concentration on the water

content of nipah fruit bioadsorbent.

The purpose of analyzing the water content of this

nipah fruit bioadsorbent is to determine and analyze

the hygrascopic properties of rice husk charcoal.

Satriawan et al., (2021) stated that the hydroscopic

nature of the bioadsorbent or activated carbon shows

the ability of the bioadsorbent to absorb water vapor

in the air when it is in the cooling process. In addition,

this hydroscopic nature shows the percentage of water

vapor that is still absorbed in the carbonization

process of the bioadsorbent (Husin & Hasibuan,

2020). Based on SNI 06-3730-95, 1995, the water

content that meets the quality requirements of

activated charcoal is a maximum of 15%. This

2

3,5

3

4

4

5,5

5,5

6

4

5

5,5

6

0

1

2

3

4

5

6

7

0,0% 2,5% 5,0% 7,5%

Water content (%)

KOH concentration (%)

50 mesh

100 mesh

150 mesh

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

128

maximum level indicates the ability of dry activated

charcoal to absorb moisture in the air. Figure 3.1

shows that all nipah fruit bioadsorbents have met the

standard of SNI 06-3730-95, 1995 with a maximum

moisture content of 15%.

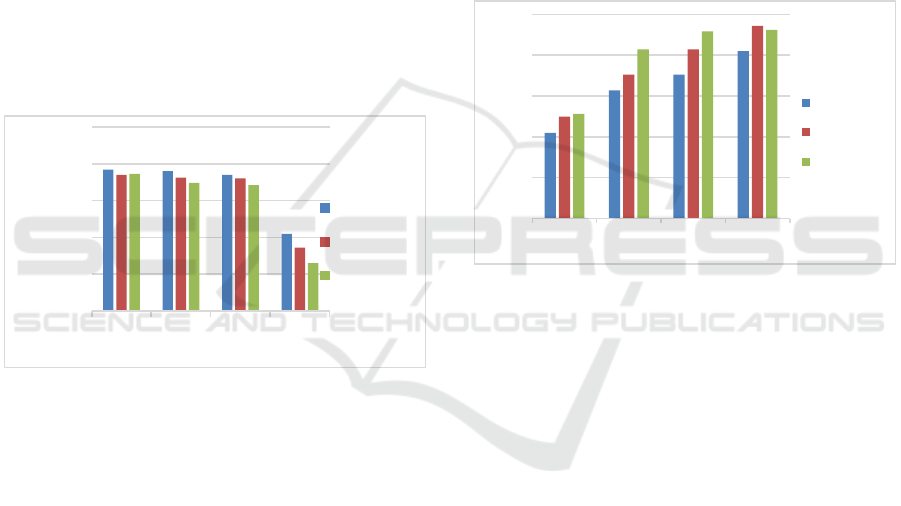

3.2 Ash Content

Analysis of ash content of bioadsorbent made from

nipah fruit refers to SNI 06-3730-95, 1995 regarding

technically activated charcoal. 2.5 grams of

bioadsorbent was weighed and put into porcelain. The

bioadsorbent was then put into the furnace for 1 hour

at a temperature of 600

o

C. This temperature was used

to ash the test sample for the nipah bioadsorbent.

After one hour, the temperature of the furnace was

raised to 900

o

C for 2 hours. The bioadsorbent that

has been in the furnace is then put into a sedikator and

weighed. The results of the analysis of the ash content

of the bioadsorbent made from nipah fruit are

presented in figure 2.

Figure 2: The effect of KOH concentration on ash content

of nipah fruit bioadsorbent.

The ash content indicates the weight of metal

oxides contained in the nipah fruit bioadsorbent. This

metal oxide is a mineral that has an influence on the

quality of the bioadsorbent adsorption made

(Satriawan et al., 2021). High ash content indicates

the amount of metal oxides contained in the

bioadsorbent. This metal oxide will cause blockage of

the pores of the nipah bioadsorbent so that the

adsorption process that occurs cannot be optimal

(Suherman et al., 2021). Based on SNI 06-3730-95,

1995, the requirement for ash content that meets the

standard of activated carbon or bioadsorbent is a

maximum of 10%. Figure 3.2 shows that the nipah

fruit bioadsorbent does not meet the ash content

standard based on SNI 06-3730-95, 1995. The ash

content of unactivated nipah bioadsorbent was 81.5 -

85.5%; while the ash content of activated nipah fruit

reaches >90%. From these data it can be shown that

the addition of KOH activation can increase the ash

content of the nipah fruit bioadsorbent.

3.3 Volatile Matter Content

Analysis of volatile substances or missing parts in

bioadsorbents made from nipah fruit refers to SNI 06-

3730-95, 1995 regarding technically activated

charcoal. Nipah fruit bioadsorbent was weighed as

much as 1.5 g and put into porcelain. The

bioadsorbent is then put into the furnace at a

temperature of 950

o

C. After the temperature reaches

950

o

C, the furnace is then cooled. The bioadsorbent

is then put into a desiccator and weighed. The results

of the analysis of volatile substances are presented in

figure 3.

Figure 3: The effect of KOH concentration on the level of

volatile substances of nipah fruit bioadsorbent.

The analysis of volatile substances or the missing

part of the bioadsorbent aims to find out how many

organic compounds are bound to the nipah fruit

bioadsorbent made (Erawati & Fernando, 2018).

Based on SNI 06-3730-95, 1995, the content of the

volatile substance or part lost in the bioadsorbent is a

maximum of 25%. Figure 3.3 shows the value of the

volatile content of the nipah fruit bioadsorbent has

exceeded the SNI limit for the volatile substance

content that has been set up to >70%. This indicates

that the nipah fruit bioadsorbent has high organic

compounds in the form of methanol, acetic acid

vapor, tar, and hydrocarbons (Rezvani et al., 2019).

3.4 Iodine Absorption Analysis

Analysis of iodine absorption in bioadsorbent made

from nipah fruit also refers to SNI 06-3730-95, 1995

regarding technically activated charcoal. The nipah

fruit bioadsorbent sample was first oven-dried at 115

o

C for 1 hour. The bioadsorbent that has been baked

in the oven is then cooled in a desiccator. Weigh 0.5

g of nipah bioadsorbent and add 50 ml of 0.1 N iodine

94,2

94

93,5

85,5

93,5

93,1

93

83,6

93,6

92,4

92,1

81,5

75

80

85

90

95

100

0,0% 2,5% 5,0% 7,5%

KadarAbu(%)

KOHconcentration(%)

50mesh

100mesh

150mesh

70,5

75,7

77,6

80,5

72,5

77,6

80,7

83,6

72,8

80,7

82,9

83,1

60

65

70

75

80

85

0,0% 2,5% 5,0% 7,5%

Volatile Matter Content (%)

KOH concentration (%)

50 mesh

100 mesh

150 mesh

Preliminary Study of the Characteristics of Nipah Fruit Bioadsorbent as Greenhouse Gas Adsorption

129

solution. Stirring was carried out for 15 minutes and

then filtered. Take 10 ml of the obtained filtrate and

titrate with 0.1 N sodium thio-sulphate. Titrate until a

faint yellow color. Added 1% starch solution and

titrate again with 0.1 N sodium thio-sulfate until the

blue color disappears. The results of the analysis of

iodine absorption are presented in figure 4.

Figure 4: Effect of KOH concentration on iodine absorption

in nipah fruit bioadsorbent.

Iodine absorption analysis aims to determine the

ability of nipah fruit bioadsorbent in absorbing

pollutants. Based on SNI 06-3730-95, 1995, the

bioadsorbent quality requirement based on iodine

absorption is at least 750 mg/g. The higher the value

of iodine absorption, the better the ability of the

bioadsorbent to absorb pollutants. Figure 3.4 shows

the results of the analysis of iodine absorption in the

nipah fruit bioadsorbent. Iodine absorption in nipah

fruit bioadsorbent has met the quality requirements of

SNI 06-3730-95, 1995, namely >750 mg/g. Iodine

absorption in nipah fruit bioadsorbent without

activation also has a good value for iodine absorption,

namely 1154.79 - 1180.17 mg/g. This is because the

nipa fruit bioadsorbent has been physically activated

by using heating during the pyrolysis process

(carbonization) so that the nipa fruit bioadsorbent is

physically activated (Ogungbenro et al., 2018).

4 CONCLUSIONS

Nipah fruit bioadsorbent has met the quality

requirements of activated charcoal based on SNI 06-

3730-1995 for water content and iodine absorption.

However, nipah fruit bioadsorbent did not meet the

quality requirements for activated charcoal based on

SNI 06-3730-95, 1995 based on analysis of ash and

volatile matter content. This is because the nipah fruit

bioadsorbent has high metal oxides and organic

compounds. These high metal oxides and organic

compounds can reduce the effectiveness of nipah

bioadsorbent adsorption.

ACKNOWLEDGEMENTS

Thank you to the Directorate General of Vocational,

Ministry of Education, Culture, Research and

Technology for providing research grants to

researchers so that this research can be carried out

smoothly.

REFERENCES

Alabadi, A., Razzaque, S., Yang, Y., Chen, S., & Tan, B.

(2015). Highly porous activated carbon materials from

carbonized biomass with high CO2 capturing capacity.

Chemical Engineering Journal, 281, 606–612.

https://doi.org/10.1016/j.cej.2015.06.032

Erawati, E., & Fernando, A. (2018). Pengaruh Jenis

Aktivator Dan Ukuran Karbon Aktif Terhadap

Pembuatan Adsorbent Dari Serbik Gergaji Kayu

Sengon (Paraserianthes Falcataria). Jurnal Integrasi

Proses, 7(2), 58–66. https://doi.org/10.36055/

jip.v7i2.3808

Heidari, A., Younesi, H., Rashidi, A., & Ghoreyshi, A. A.

(2014). Evaluation of CO2 adsorption with eucalyptus

wood based activated carbon modified by ammonia

solution through heat treatment. Chemical Engineering

Journal, 254, 503–513. https://doi.org/10.1016/

j.cej.2014.06.004

Hendrawan, Y., Sutan, S. M., & Kreative, R. Y. R. (2017).

Pengaruh Variasi Suhu Karbonisasi dan Konsentrasi

Aktivator terhadap Karakteristik Karbon Aktif dari

Ampas Tebu (Bagasse) Menggunakan Activating

Agent NaCl. Jurnal Keteknikan Pertanian Tropis Dan

Biosistem, 5(3), 200–207. https://jkptb.ub.ac.id/index.

php/jkptb/article/view/420

Hui, T. S., & Zaini, M. A. A. (2015). Potassium hydroxide

activation of activated carbon: A commentary. Journal

Carbon Letters, 16(4), 275–280. https://doi.org/10.

5714/CL.2015.16.4.275

Husin, A., & Hasibuan, A. (2020). Studi Pengaruh Variasi

Konsentrasi Asam Posfat (H3PO4) dan Waktu

Perendaman Karbon terhadap Karakteristik Karbon

Aktif dari Kulit Durian. Jurnal Teknik Kimia USU,

9(2), 80–86. https://doi.org/10.32734/jtk.v9i2.3728

Idrees, M., Rangari, V., & Jeelani, S. (2018). Sustainable

packaging waste-derived activated carbon for carbon

dioxide capture. Journal of CO2 Utilization Journal,

26(May), 380–387. https://doi.org/10.1016/j.jcou.

2018.05.016

Jia, L., Shi, J., Long, C., Lian, F., & Xing, B. (2020).

Science of the Total Environment VOCs adsorption on

activated carbon with initial water vapor contents :

Adsorption mechanism and modi fi ed characteristic

curves. Science of the Total Environment, 731, 139184.

https://doi.org/10.1016/j.scitotenv.2020.139184

Mukherjee, A., Okolie, J. A., Abdelrasoul, A., Niu, C., &

Dalai, A. K. (2019). ScienceDirect Review of post-

combustion carbon dioxide capture technologies using

1154,79

1218,24

1218,24

1243,62

1167,48

1230,93

1230,93

1230,93

1180,17

1218,24

1230,93

1243,62

1100,00

1120,00

1140,00

1160,00

1180,00

1200,00

1220,00

1240,00

1260,00

0,0% 2,5% 5,0% 7,5%

Iodine absorption analysis

(mg/g)

KOH concentration (%)

50 mesh

100 mesh

150 mesh

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

130

activated carbon. Journal of Environmental Sciences,

83, 46–63. https://doi.org/10.1016/j.jes.2019.03.014

Narkiewicz, U., & Morawski, A. W. (2016). Modification

of Commercial Activated Carbons for CO2 Adsorption.

Vol. 129 (2016) ACTA PHYSICA POLONICA A,

129(3), 394–401. https://doi.org/10.12693/APhysPolA.

129.394

Ogungbenro, A. E., Quang, D. V., Al-Ali, K. A., Vega, L.

F., & Abu-Zahra, M. R. M. (2018). Physical synthesis

and characterization of activated carbon from date

seeds for CO2 capture. Journal of Environmental

Chemical Engineering, 6(4), 4245–4252. https://

doi.org/10.1016/j.jece.2018.06.030

Pallarés, J., González-Cencerrado, A., & Arauzo, I. (2016).

Production and characterization of activated carbon

from barley straw by physical activation with carbon

dioxide and steam (Issue July).

Rezvani, H., Fatemi, S., & Tamnanloo, J. (2019). Activated

carbon surface modification by catalytic chemical

vapor deposition of natural gas for enhancing

adsorption of greenhouse gases. Journal of

Environmental Chemical Engineering, 7(3), 1–10.

https://doi.org/10.1016/j.jece.2019.103085

Satriawan, D., Santoso, A., & Widianingsih, B. (2021).

Analisis Kuantitatif Pengaruh Waktu Karbonisasi Dan

Kosentrasi Koh Pada Pembuatan Karbon Aktif Sekam

Padi. Seminar Masional Terapan Riset Inovatif

(SENTRINOVE), 6(2), 139–146.

SNI 06-3730-95. (1995). Arang Aktif Teknis. In Badan

Standardisasi Nasional - BSN.

Suherman, Hasanah, M., Ariandi, R., & Ilmi. (2021).

PENGARUH SUHU AKTIVASI TERHADAP

KARAKTERISTIK DAN MIKROSTRUKTUR

KARBON AKTIF PELEPAH KELAPA SAWIT (Elaeis

guinensis) The Effect of Activation Temperature on The

Characteristics and Microstructure of Active Carbon

From Palm Oil Fronds (Elaeis guinensis). Jurnal Industri

Hasil Perkebunan, 16(1), 1–9.

Wickramaratne, N. P., & Jaroniec, M. (2013). Activated

carbon spheres for CO2 adsorption. ACS Applied

Materials and Interfaces, 5(5), 1849–1855.

https://doi.org/10.1021/am400112m

Xu, J., Chen, L., Qu, H., Jiao, Y., Xie, J., & Xing, G. (2014).

Preparation and characterization of activated carbon

from reedy grass leaves by chemical activation with H

3 PO 4. Applied Surface Science, 320, 674–680.

https://doi.org/10.1016/j.apsusc.2014.08.178.

Preliminary Study of the Characteristics of Nipah Fruit Bioadsorbent as Greenhouse Gas Adsorption

131