Design Analysis of Bamboo Drying Oven Using CFD Software

Kurniawan

a

, Heri Setiawan, Dede Sujana and Rivaldi Muhammad Alyansyah

Manufacturing Polytechnic Bandung, Kanayakan, Bandung, Indonesia

dede_edo@polman-bandung.ac.id, rivaldiam24@gmail.com

Keywords: Heat Transfer, CFD, Oven, Drying Bamboo.

Abstract: There is a design validation stage in the process of designing an oven. This step is crucial to demonstrate the

oven's ability to perform as planned, which was to be able to dry 700 kg of bamboo material with an initial

humidity of 14.08% and dry to a humidity of 10% in 8 hours. A trial tool is typically used for validation.

However, it takes a lot of effort and money to create a prototype tool for trailing. As a result, with current

technical advancements, software simulation can take the role of the trail tool method. Ansys software was

used in this investigation to assess the oven. The program receives the oven specs as well as the outcomes of

the calculations that have been done. A simulation of the heat distribution, oven temperature, and heat

absorbed by the material will be calculated by Ansys and displayed.

1 INTRODUCTION

There is a design validation stage in the design

process. This stage is required to demonstrate that the

designed solution serves the intended purpose. This is

crucial to prevent a mismatch between the designer's

expectations and the final product.

In the construction of an oven whose primary

purpose is to dry materials. It is necessary to analyze

the heat produced in the oven space. It is intended that

by using the application to observe the simulation

approach, the oven design may be verified to dry the

material to a specific humidity level in the anticipated

amount of time.

The oven in the situation under investigation

must be capable of drying 700 kg of bamboo material

in 8 hours. Bamboo that was previously 14.08

percent humid was dried till it reached 10%

humidity.

It is envisaged that performing an examination of

the oven space using the ansys application will allow

the simulation results to validate the accomplishment

of the oven's intended function.

a

https://orcid.org/0000-0003-4323-3325

2 RESEARCH STAGES

The research flow chart below is referenced in the

analysis study addressing the finding of hot air in this

oven.

Figure 1: Research stages.

Kurniawan, ., Setiawan, H., Sujana, D. and Alyansyah, R.

Design Analysis of Bamboo Drying Oven Using CFD Software.

DOI: 10.5220/0011766300003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 317-323

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

317

3 STUDY

3.1 Carculation Parameter

Identification

Figure 2: Dimension bamboo.

The humidity level of the bamboo that needs to be

dried is 14.08%.(Tri Wulandari, 2020) Bamboo must

be dried untuk humidity level of bamboo 10%. The

properties of bamboo have a specific heat of

1.700J/kg⁰C. Bamboo to be dried has a size of

25x10x375mm.

Figure 3: Design oven.

The oven must have be able to dry 700kg/day

material bamboo. Knowing the heater and blower

specs as calculation inputs is essential for heat

transfer analysis.The oven have 4 blower, 2 blower

each side and 3 finned coil heater each side in total 6

heater.

Figure 4: Finned coil heater.

The oven uses a finned coil heater with a 1500

watt power rating and a 240 volt operating voltage

each heater.

Figure 5: Catalog of blower by Hanil.

The blower being used is a Hanil KE-400

industrial blower. The specification of blower have

dimension blade 400mm with airflow 1540 𝑚

/

ℎ𝑜𝑢𝑟.

3.2 Calculation

3.2.1 Heat Requirement

Heat is required to dry the skewer material, which

initially had a humidity of 14,08% to 10%. Up until it

reaches a humidity of 10%, bamboo material's heat

demand is calculated.

Table 1: Calculation of heat requirement.

N

o Description Value

1

Temperature

normal

27℃

2

Temperature

when dr

y

in

g

70℃

3

∆𝑇 70℃ 27℃ 43℃

4

Characteristic

termal of

bamboo(𝐶

1.700J/kg⁰C

5

𝑄

𝑀∙𝐶

∙∆𝑇

51201798,5 𝐽

6

Mass of

water to be

evaporated

(m)

700 𝑘𝑔

∙

14,08% 10%

28,56 𝑘𝑔

7

Specific laten

water (L)

22,6x10

J/kg

8 Q2 𝑚 ∙ 𝐿 64545600𝐽

9

Heat

requirement

(Q

Q1 + Q2

= 1,157 𝑥 10

𝐽

So to dry bamboo material to a humidity of 10

requires 1,157 𝑥 10

𝐽 of calor (Tobing et al., 2019).

3.2.2 Heat Transfer

The item being dried receives heat either directly

from the heat source or indirectly in the instance of

drying bamboo in an oven. The material will dry more

quickly or slower depending on how quickly heat is

transferred during this drying process(Putra, 2010).

Temperature, wind speed, material, and the surface

area that needs to be dried all affect how quickly heat

transfers. The anticipated drying time can be

calculated using the rate of heat transfer that takes

place. The bamboo material in this instance weighs

700 kg, and the drying procedure aims to reduce the

humidity from 14.08% to 10% in under 8 hours.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

318

Table 2: Calculation of heat transfer.

N

o Desc

r

iption Value

1

Area of

projection

blower blade

(

𝐴

r

∙ 𝜋 125600mm

2

Air volume

(𝑄

1540 𝑚

/ℎ𝑜𝑢𝑟

3

Velocity of

air (𝑉

𝑄

𝐴

3,404 𝑚/𝑠

4

Lenght of

p

late (L)

3,210𝑚

5

Kinematic

Viscosit

y

(v)

27,8 𝑥 10

𝑚

/𝑑𝑒𝑡𝑖𝑘

6

Reylond

number (Re)

∙

= 3,926

7

Conductivity

termal (k)

0,03489 W/m.K

8

Prandtl

number(Pr)

0,684

9

coefficient of

heat transfer

(h)

0,664 ∙

𝑘

𝐿

∙𝑅𝑒

.

∙𝑃𝑟

.

3,985 𝑊/𝑚

⁰𝐶

10

Surface area

perpendicular

to the

direction of

the heat flux

(A)

375𝑚𝑚 ∙ 10𝑚𝑚

∙ 9595𝑠𝑡𝑖𝑐𝑘

4,556𝑚

11

Temperature

coil (𝑡

250℃

12

Temperature

room(𝑡

27℃

13

Heat

transfer(𝑞

ℎ

𝐴

𝑡

𝑡

4,049 𝑘𝐽/𝑠𝑒𝑐

14

The time

required for

the drying

process

(𝑡

𝑄

𝑞

7,941 ℎ𝑜𝑢𝑟

Accordingly, it takes 7,941 hours for bamboo

material to dry to 10% humidity with a heat

transmission coefficient of 4,049 𝑘𝐽/𝑠𝑒𝑐 (Hadi,

2012).

3.3 CFD (Computational Fluid Dynamic)

The term "computational fluid dynamics" is derived

from the phrases "computational" and "dynamics,"

where computational refers to anything having to do

with mathematics, numerical computing, or

computational methods. By definition, CFD refers to

the study of predicting fluid flow, heat transfer,

chemical reactions, and other phenomena by the

solution of mathematical models. PDEs, or partial

differential equations, which stand in for the

principles of conservation of mass, momentum, and

energy, are the fundamental building blocks upon

which mathematical model fluid equations are

constructed and studied. When running CFD

simulations, there are three steps that must be

completed: pre-processing, solution, and post

processing. (Damayanti, 2012)

a. Pre-Processing

The first step in creating and analysing a CFD model

is pre-processing. The process entails building a

model using a CAD (Computer Aided Design)

program, meshing the model as necessary to complete

it, and setting up the model in accordance with the

boundary conditions and fluid parameters that will be

simulated.(Damayanti, 2012)

b. Resolving

The pre-processing phases from earlier are used by

the CFD solution search algorithm to determine the

conditions that arise.(Damayanti, 2012)

c. Post Processing

The final stage of CFD analysis is postprocessing.

Organize and evaluate the CFD simulation data that

has been obtained at this point by contrasting it with

manual calculations.(Damayanti, 2012)

With a model that closely resembles the actual

state of the oven, this simulation is used to examine

the convection heat distribution circumstances that

arise between the coil heater and the wind from the

blower. Moreover, to guarantee that the dried material

receives the necessary heat and energy. The following

steps are carried out as the simulation progresses

through various stages.

3.3.1 Model

Figure 6: Model for simulation.

The simulation model receives tray construction as

input. The tray model is then deleted and the

"boolean" tool is used to turn the tray into an empty

space in the rectangle model. When using the

Design Analysis of Bamboo Drying Oven Using CFD Software

319

"boolean" feature, the blower model is still present

and is not deleted. Figure above depicts the model's

shape in its final form.

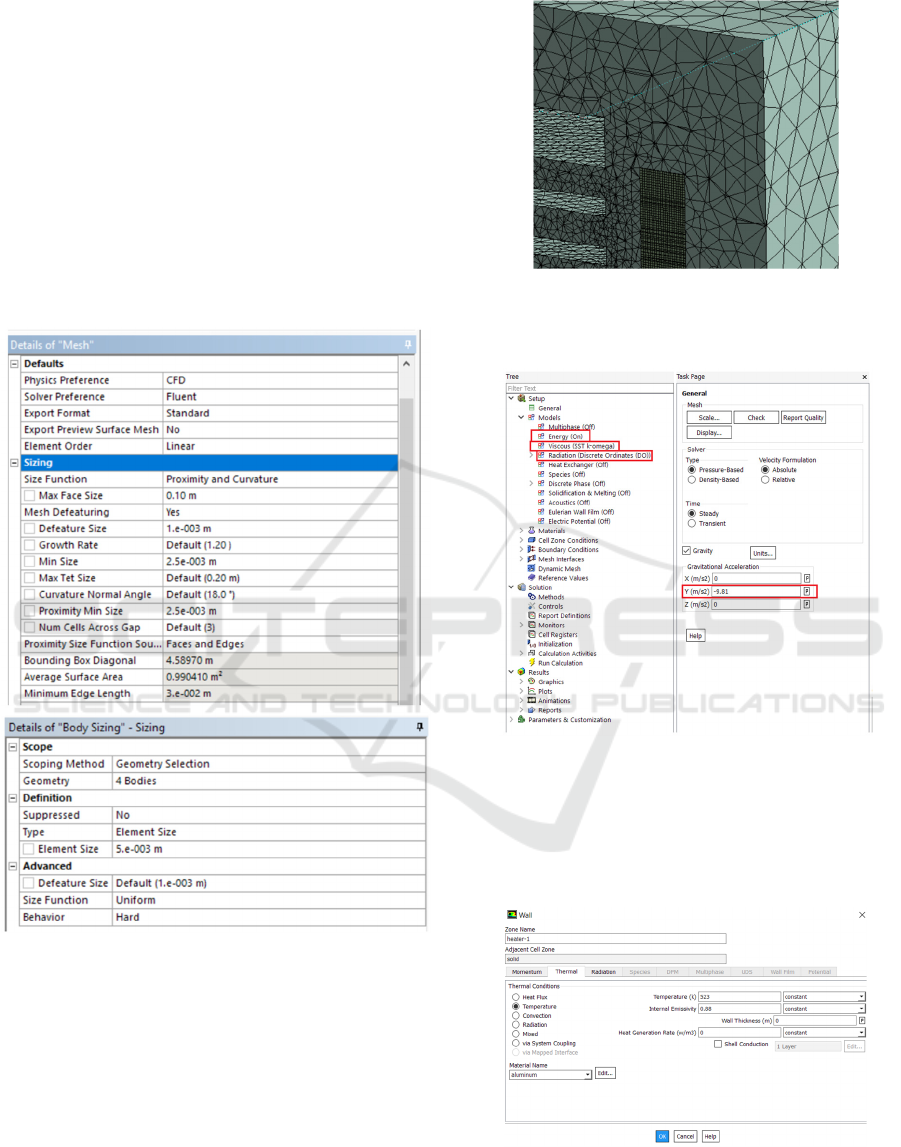

3.3.2 Mesh

Choose the type of CFD and Fluent in the "Defaults"

setting based on the simulation that will be run. Given

that the oven has a pretty large size, the "Max Face

Size" setting in the "Sizing" parameter is quite large

at 0.1m. The "Min Size" setting, however, is now set

at 0.0025m or 25mm. This size is narrower than the

model's narrowest size, which is 50mm apart from the

trays.

Figure 7: Setting mesh.

To achieve better

simulation outcomes, the "Body

Sizing" function is set to a smaller mesh size in the

blower section. The mesh size is set to 0.005 meters,

or 50 millimeters.

Figure 8: Result mesh.

3.3.3 Setup

Figure 9: Setup energy.

Viscous is in SST k-omega mode, radiation is in DO

mode, and the energy parameter is set at setup time.

settings due to the simulation's inclusion of heat-

related elements.

Figure 10: Setup heater.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

320

Then use the preceding formula to determine the

heater's heat, which is 523K with a 0.88 emissivity.

The other six heaters all have this setting.

Figure 11: Setup tray.

The tray's material character in the simulation is set

to wood or wood. This is due to the bamboo material

not being used in the application; instead, it must be

brought very close to the wood in order to be used.

According to the outcomes of manual calculations,

where the thermal coefficient (h) occurs at 3.985

W/m20C, the value of "heat transfer coefficient" is

changed. The material is initially heated to the same

270C or 300K temperature as a typical room, and the

oven temperature of 700C or 343K is entered in the

value column for "external radiation temperature".

Figure 12: Setup blower.

The blower is programmed to increase the

pressure. The coefficients for the pressure jump value

are 496 and -50.

Figure 13: Setup air condition.

The oven room temperature before being operated

is set by changing the “wall-solid” parameter to have

a temperature of 300K or 27⁰C.

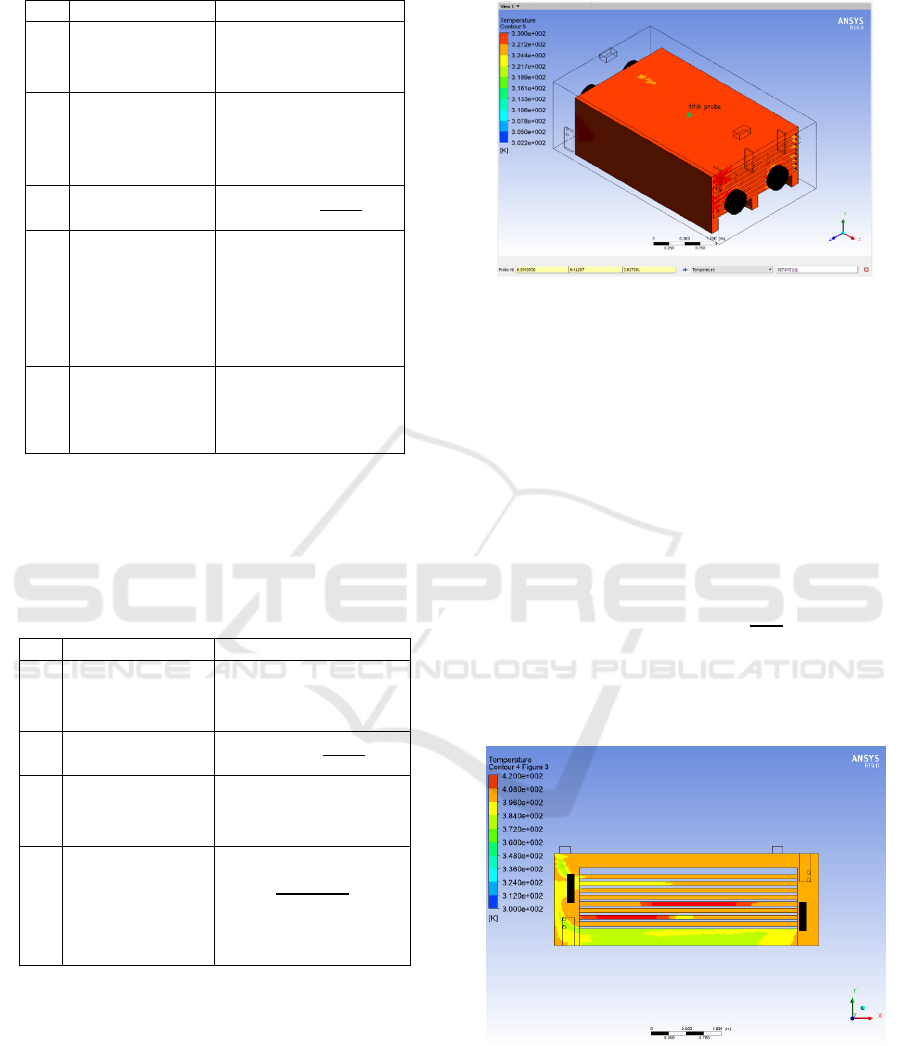

3.3.4 Result

a. Heat Absorption

To be able to determine the amount of heat absorbed,

it is necessary to observe the heat flux that occurs.

Figure 14: Heatflux on tray.

The average heat flux value is determined from 9

different sites using the simulation data. The table

below shows the outcomes of the 9 point.

Table 3: Average heatflux.

Titik

Heat Flux

W/m^2

1 16.2552

2 18.6113

3 13.7863

4 16.7524

5 18.4016

6 13.1118

7 14.258

8 19.8712

9 12.3409

Rata-Rata 15.93207778

The table shows that the average heat flux value

in the tray is 15,932

.. The heat energy that the

material has received can be calculated using the heat

flow value. The heat requirements that have

previously been established by manual calculations

can be directly correlated to these results. Here is how

to calculate it:

Design Analysis of Bamboo Drying Oven Using CFD Software

321

Table 4: Calculation of heat absorption.

No Descri

p

tion Value

1

Area of surface

material

b

amboo(

𝐴

0,028𝑚

2

Total area of

surface

material

b

amboo(

𝐴

𝐴

. 9595𝑠𝑡𝑖𝑐𝑘

268,18𝑚

3

Heat flux (ø

)

15,932

𝑤𝑎𝑡𝑡

𝑚

4

The time

required for

the drying

process

(𝑡

7,941 ℎ𝑜𝑢𝑟

5

Heat

absorption

Q

ø

.𝐿

.𝑡

1,221 ∙ 10

𝐽

In the simulation, the energy absorbed is s

1,221 ∙ 10

𝐽 if the drying process lasts for 7.941

hours. If the drying time necessary until heat energy

absorption happens as needed (Q tot) with the heat

flux value is calculated as follows.

Table 5: Calculation of time drying procces.

No Description Value

1

Heat

requirement

(Q

0,028𝑚

2

Heat flux (ø

15,932

𝑤𝑎𝑡𝑡

𝑚

3

Total area of

surface material

bamboo(

𝐴

268,18𝑚

5

The time

happend for the

drying process

in simulation

result t

Q

ø

.𝐿

7,525ℎ𝑜𝑢𝑟

So based on the conditions that occur in the

simulation, the results of the calculation of the time

needed are 7.525 hours.

b. Room Temperature

Figure 15: Temperature of room actual model.

The temperature of the tray was initially set at

300K to 330K or 57⁰C. Previously, the target

temperature was 70⁰C, but in the simulation results,

the tray temperature was 57⁰C .. This is not a concern

because what matters is that the required amount of

heat is absorbed.

In calculation with 300 iterations, it is impossible

to accurately examine the spread of heat while going

to do so. As a result, changes to the Ansys settings

were made to better understand how heat spreads

because of the device's limited characteristics.

The tray settings were changed from "mixed" to

"heat flux" with a value of 180

. Author may

observe the heat spread when absorption is good even

though only 300 iterations have been performed by

using a large heat flux value to speed up the heat

absorption process.

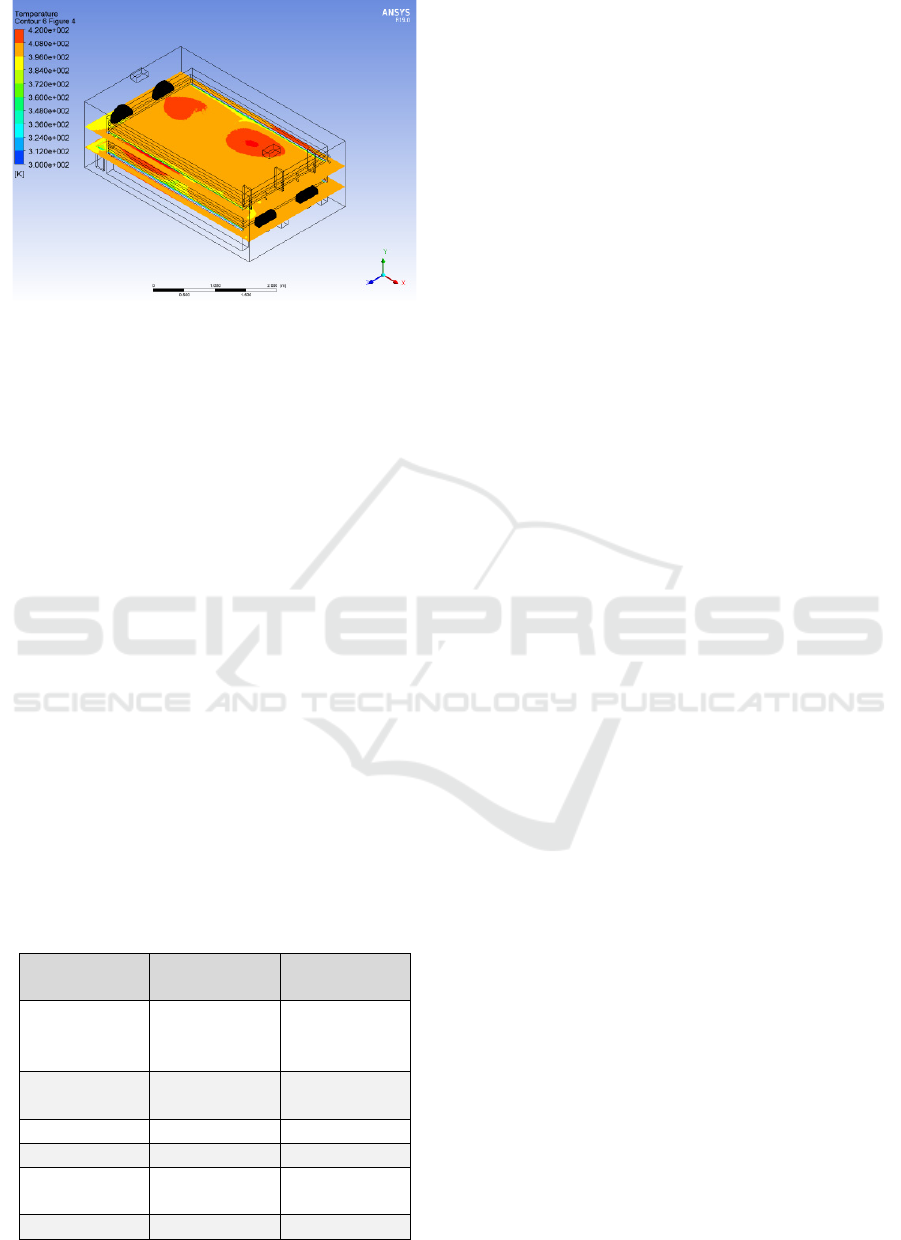

Figure 16: Heat distribution side view.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

322

Figure 17: Heat distribution up view.

The results show the evenness of heat that occurs

in the tray. It can be seen that the bottom of the trolley

has a temperature of 370K to 396K or 97⁰C to 119⁰C.

This temperature is lower than that which occurs in

each tray, which is an average temperature of 408K

or 135⁰C.

4 CONCLUSIONS

The heat flow value from the simulation results is

converted into energy received by the material, it can

be estimated. The findings of the thermal energy

acquired by the calculation material when done

manually and those from simulations differ. As a

consequence, when compared to the manual

calculation results, as follows.

The temperature in the oven space is below the

desired temperature, according to the temperature

observation. Nevertheless, it doesn't matter because

the substance has already absorbed enough heat

energy to meet its needs.

Table 6: Compare data between manual calculation and

simulation.

Manual

calculation

Simulation

calculation

Result

difference

Heat

requirement

(Q

)

Heat absorb

(Q

)

1,157

∙10

𝐽

1,221

∙10

𝐽

5.53%

Dr

y

in

g

time Dr

y

in

g

time

7,941

j

a

m

7,525

j

a

m

5,24%

Room

temperature

Room

temperature

70⁰C 57⁰C

18,57%

ACKNOWLEDGEMENTS

If any, should be placed before the references section

without numbering.

REFERENCES

Damayanti, Y. P. (2012). SIMULASI TEMPERATURE

CONTROL SYSTEM PADA INTERNAL FLOW

FLUIDA VISCOUS DENGAN MENGGUNAKAN

PERANGKAT LUNAK CFD (COMPUTATIONAL

FLUID DYNAMICS). Skripsi Universitas Sebelas

Maret.

Hadi, P. S. (2012). PENGERING PADI ENERGI SURYA

DENGAN VARIASI TINGGI CEROBONG. TUGAS

AKHIR.

Putra, A. K. (2010). RANCANG BANGUN OVEN

UNTUK MENGERINGKAN. Tugas Akhir.

Tobing, I. F., Agustina, R., Studi, P., Pertanian, T.,

Pertanian, F., & Syiah, U. (2019). Modifikasi Pengering

Tipe Tray Dryer Dengan Penambahan Insulator (

Modification Of Tray Dryer With Insulator ). Jurnal

Ilmiah, 4(November).

Tri Wulandari, F. (2020). KARATERISTIK SIFAT

FISIKA BAMBU TALI ( GIGANTOLOCHLOA

APUS KURZ ) SEBAGAI BAHAN BAKU BAMBU

KERAJINAN. Jurnal Fakultas Pertanian Universitass

Mataram, 3(1), 69–77.

Design Analysis of Bamboo Drying Oven Using CFD Software

323