Effect of Pressure on Mechanical Properties and Structural Evolution

of Diffusion-Bonded Al-Ni: Insight from Molecular Dynamics

Simulation

Mohamad Zaenudin

1

, Mohammed N. Abdulrazaq

2

, Salah Al-Zubaidi

3

and Adhes Gamayel

1

1

Jakarta Global University, Indonesia

2

Gulf University, Bahrain

3

University of Baghdad, Iraq

Keywords: Al-Ni Alloy, Diffusion Bonding, Mechanical Properties, Structural Evolution.

Abstract: Molecular dynamics simulation is a method to investigate the behavior of material at atomic scale. The

application of molecular dynamics in investigation of the phenomena in joining processes at atomic scale has

significantly increased. One of the advanced joining methods that nowadays used in joining dissimilar

materials is diffusion bonding. This paper discusses the effect of pressure on the mechanical properties and

structural evolution of diffusion-bonded Al-Ni. The results showed that both concentration distribution

profiles and ultimate tensile strength showed excellent joints with low applied pressure (10 MPa), while higher

welding pressure does not come with more benefits but decreasing the material performance. Defects and

deformation that occurs during diffusion welding process has affected to the lower ultimate tensile strength

which caused by the remarkably high applied welding pressure (100 MPa and 150 MPa) while at low applied

pressure (10 MPa) defects and deformation is relatively low and thus affect to an excellent result in ultimate

tensile strength value.

1 INTRODUCTION

The joining of metallic materials in industrial

processes is particularly important due to the need to

create desired shapes which involve two dissimilar

materials. However, it has several difficulties for the

dissimilar materials mean different properties, which

lead to the other different applied parameters in

joining processes, like temperature, pressure, and

holding time. Diffusion bonding is introduced to

solve this kind of problem when the two dissimilar

joining of materials is necessary (Akca & Gu Gürsel,

2015, Cooper & Allwood, 2014). To achieve

optimum conditions using this method, several

experimental investigations are necessary. It is well

known that experiments on advanced material science

take huge amount of cost and time, thus a few

alternatives of numerical methods are introduced.

These methods have shown promising advantages to

enhance the needs of joining dissimilar materials with

optimum condition.

Apart from the other numerical methods such as

finite element method (FEM), continuum modeling,

and Monte Carlo simulation, another numerical

method like Molecular Dynamics (MD) simulation

has shown an increasing interest by researchers

extensively, especially in joining processes

(Zaenudin et al., 2018, Zaenudin et al., 2022,

Zaenudin et al., 2020). The core idea of this method

is the solution of the Newtonian equation of motion

numerically, which runs under a particular ensemble

of atoms like microcanonical and canonical

ensemble. These equations are then numerically

integrated for a tiny range of time (about 2−3),

and through the observation of elapsed time the

equilibrium of the statistical averages is computed as

interim averages. This method offers a new way to

observe and analyze the behavior of material at

atomic scales, which nowadays become more

important due to the requirement of precision and

accuracy of the estimation properties and applied

parameters for application like joining processes.

Specific on joining process using diffusion bonding

technique, MD simulations was able to deliver

several phenomena and mechanisms that have

significance influence to the final result of the as

Zaenudin, M., Abdulrazaq, M., Al-Zubaidi, S. and Gamayel, A.

Effect of Pressure on Mechanical Properties and Structural Evolution of Diffusion-Bonded Al-Ni: Insight from Molecular Dynamics Simulation.

DOI: 10.5220/0011770300003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 337-341

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

337

welded materials, whether it is based on the structural

evolution during joining processes, diffusion

mechanism based on the self-diffusion of material, or

even the phenomena that contribute to the mechanical

properties and structural evolution of the as received

material compared to the as received material. Chen

et al. has conducted research on diffusion bonding of

Cu-Ag (Chen et al., 2005) and Cu-Al (Chen, 2007)

and has successfully investigated the dominant

mechanism during diffusion bonding. Hu et al. (2013)

have demonstrated the temperature-dependence of

the mechanical properties of diffusion-bonded Ni-Al.

The significance effect of temperature also has been

demonstrated by Zhang and Jiang (Zhang and Jiang,

2013) on the stainless-steel and pure Ni materials by

simply extracting the displacement of atoms into

calculation of mean square displacement (MSD).

Based on the broad range application of Ni-Al

materials like turbine blades (Darolia et al., 2012),

batteries (Mukherjee, 1998, Young, 2013, Young,

2013), multilayers for joining of different Ti-alloys

(

Simões et al., 2010, Simões et al., 2018), coating

with a tungsten layer (Ramos et al., 2017), and mask

absorber of extreme ultraviolet (EUV) radiation [17],

this paper presents an investigation on the effect of

applied pressure on the structural evolution and

mechanical properties of diffusion bonding between

Al and Ni. The structural analysis is obtained by

employing a vector displacement analysis tool

(Stukowski, 2010) based on its slip vector properties

(Zimmerman et al., 2001) and the other properties,

such as mechanical and physical properties, are

presented in curves and tables.

2 SIMULATION PROCEDURE

This study has been performed by using LAMMPS

software package (Plimpton, 1994). Every movement

and energy of atoms in the molecular dynamics

simulation system is defined by an interatomic

potential model, thus the importance of interatomic

potential is crucial. Embedded atom method is one of

the well-established interatomic potentials. In EAM,

the total energy of a binary system A-B is defined as:

1

2

Ф

(1)

Here Ф

is the interaction of pair potential as

a function of distance

between atoms and that

have chemical sorts

and

and

is the embedding energy of an atom of chemical

sort

as a function of the host electron density

induced at site by all other atoms in the system. The

well-established EAM developed by Mishin (Mishin,

2002) is adopted in this simulation.

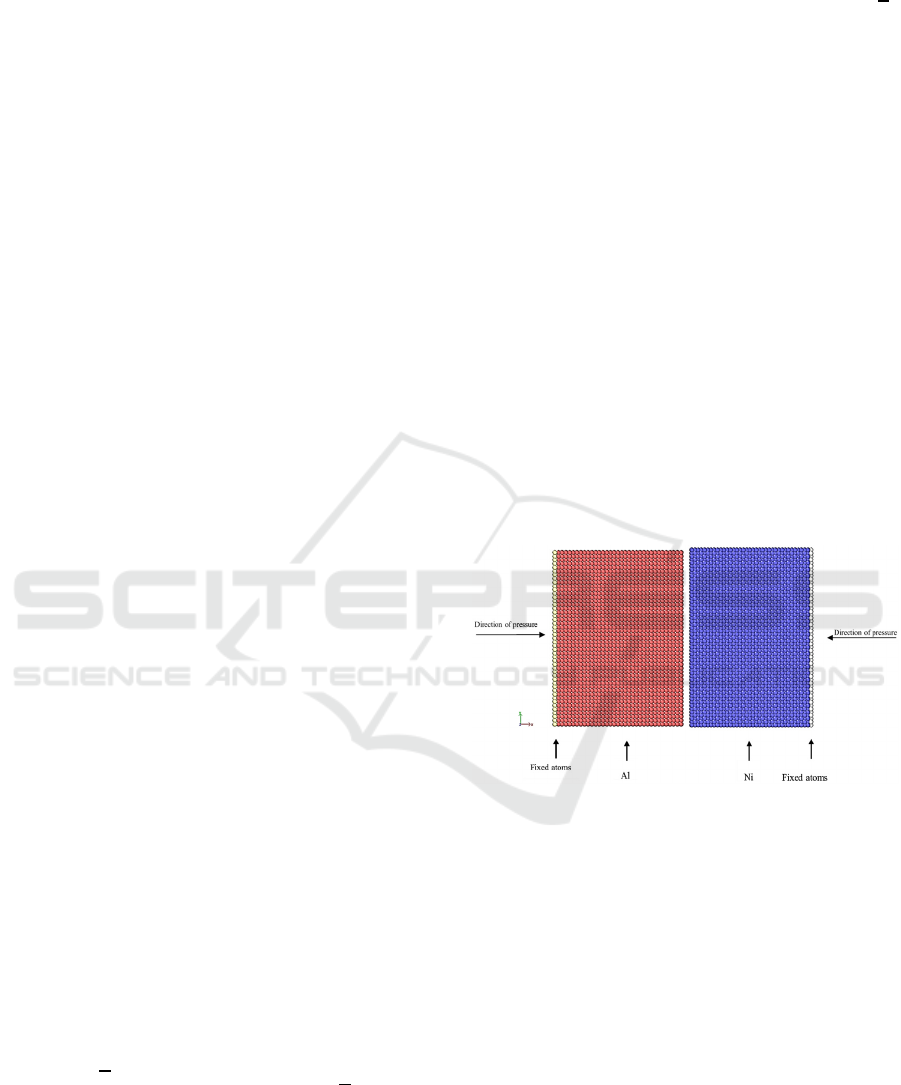

In this simulation, two slabs of Al and Ni is

deployed in this simulation with approximate

dimension of 7.29.29.2 for both Al

and Ni slabs and followed by fixed atoms in the edge

of each slab as shown in Figure 1. Lattice constant of

both monocrystalline Al and Ni slabs are 4.05 and

3.52, respectively, as reported by refs. (Mishin et al.,

2022, Mishin et al., 2004). Boundary condition is set

to periodic in all three directions , , and . This

configuration allows atoms pass through the sides of

the cell and entering on the opposite side with the

exactly with the same condition and properties such

as velocity and internal energy, and the system can

also maintain the number of atoms. In addition, each

atom in the simulation cell interacts with the closest

image of the remaining atoms. This would then avoid

the boundary effects on the simulation. Isothermal-

isobaric ensemble with Number, Pressure, and

Temperature (NPT) controlled is employed in this

simulation.

Figure 1: Planar view of simulation model of Al (red) and

Ni (blue) slabs paired with fixed atoms in each edge of the

slab.

The initialization process is started with low

temperature and pressure and maintained for 10

picoseconds. This initialization process is a key to the

achieve an equilibrated system before the production

process. Equilibrium state is indicated by the minimal

amount of potential and kinetic energy. For

production process, the temperature is designed at

500, while the pressure is set to three different

levels, they are 10, 50, 100, and

150 in direction for 200 . Finally, the

structure is cooled down from temperature of 500

to an ambient temperature to perform a tensile test

with a strain rate of 2.649/. The timestep of all

simulation process is set to 1.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

338

3 RESULT AND DISCUSSION

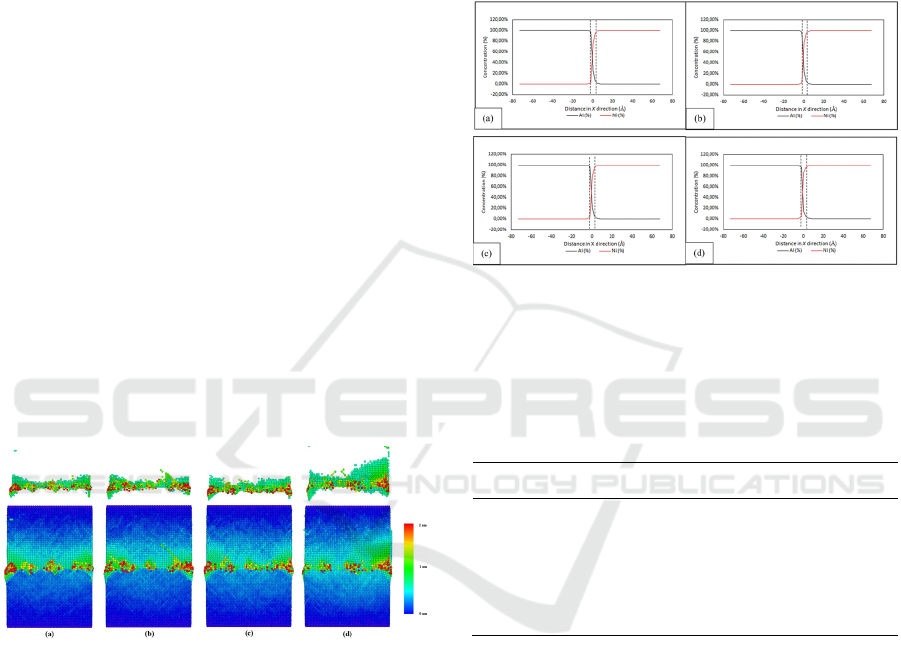

Figure 2 shows the structural evolution of diffusion-

bonded Al-Ni of four different conditions namely S1,

S2, S3, and S4. On the planar view (bottom) of the as

welded Al-Ni, it can be observed that there is no

major difference between all four different

conditions. However, at the respective diffusion

interface (above) it can be observed that the applied

pressure is shown to deform the Al slab (top) as the

pressure is increased. Even though higher pressure

influences the diffusion interface by deforming it, the

atomic exchange which is mostly shown by red-

colored atoms has no significant difference. It can be

concluded that the applied pressure (50 MPa to 150

MPa, S2-S4), instead of promoting into a better

bonding structure, mostly only deformed the Al slab

due to the lower strength of Al compared to Ni. In

addition, most of both Al-Ni slabs maintain their FCC

structure which is shown by the blue-colored atoms.

It indicates the applied pressure and temperature for

200 ps has an excellent bonding structure, except for

the highest applied pressure which can be observed

had significant defects and deformations located on

the interface. At this step, it is suggested to apply low

pressure if the temperature is high enough to allow

diffusion between two dissimilar materials to be

joined.

Figure 2: Planar view of displacement vector analysis of

diffusion-bonded between Al and Ni at temperature of

500 and hold for 200 with pressure at (a) 10,

(b) 50 , (c) 100 , and (d) 150 (upper

image) and its respective diffusion interface (lower image).

The concentration distribution curve is depicted in

Figure 3 and Table 1 shows its corresponding

interfacial region thickness. Interfacial region is

defined as the area within the diffusion zone in which

the concentration of a material is more than 5%. Table

1 is obtained from the concentration distribution data

with proper estimation. Even though the highest value

applied pressure shown has the widest interfacial

region area as listed in Table 1, the difference

between the other values of interfacial region

thickness is small. For the lowest value of applied

pressure (i.e., S1 with 10 MPa) to the highest value of

applied pressure (i.e., S4 with 150 MPa), the

difference in interfacial region thickness is only about

0.1 Angstrom. While S1 also has the highest value

among the other two conditions namely S2 and S3 (50

and 100 MPa). The applied pressure at this level of

temperature (500 K) has no significant effect on the

result of diffusion bonded Al-Ni, thus the lowest

applied pressure and vast amount of heat is suggested.

Figure 3: Curve of concentration distribution of four

different welding conditions at temperatures of 500 with

holding time of 200 and variation on pressure (a)

10, (b) 50, (c) 100, and (d) 150

referred as sample 1, 2, 3, and 4, respectively.

Table 1: Approximated interfacial region thickness of four

different conditions namely S1, S2, S3, and S4.

Condition (s) Interfacial region thickness (Å)

S1 4,485838854

S2 4,383252102

S3 4,474520861

S4 4,585924319

After the final diffusion-bonded result is acquired,

the system is then subjected to a tensile test. The

structural evolution of diffusion-bonded Al-Ni

depicted in Figure 4. The image is captured when the

as-welded Al-Ni subjected to tensile test at the time

of 25 ps, 50 ps, 75 ps, and 100 ps. At time of 25 ps,

condition S4 showed the worst behavior owing to the

huge number of defects and deformations during the

welding process and thus influencing the sample

during tensile test. While the other sample namely S1-

S3 still maintain their structure, the sample S4

deformed at the interface. This behavior proves that

during diffusion welding, the applied welding

pressure of 150 MPa is too high and is not suggested.

As the tensile test goes on to time of 50 ps to 100 ps,

sample with the lowest applied welding pressure

Effect of Pressure on Mechanical Properties and Structural Evolution of Diffusion-Bonded Al-Ni: Insight from Molecular Dynamics

Simulation

339

which is 10 MPa (S1) has the best behavior, as shown

it mostly maintain the structure and the deformation

during tensile test shown relatively small compared to

the other sample. For the tensile test result, the stress-

strain curve is presented in Figure 5. The ultimate

tensile strength is obtained from the lowest applied

pressure. The route with the lowest applied pressure

has the best results and behaviors, while the highest

one shows the worst. However, an inverted behavior

is obtained for pressures of 50 MPa and 100 MPa

which indicate the sensitivity of the system as the

pressure is increased. The behavior of the system

becomes harder to estimate as the pressure is

increased.

Figure 4: Planar view of displacement vector analysis of

structural evolution of diffusion-bonded Al-Ni with four

different welding conditions (a) S1, (b) S2, (c) S3, and (d)

S4 subjected to tensile test.

Figure 5: Stress-strain curve of as-welded Al-Ni with four

different welding conditions (S1-S4) subjected to tensile

test.

During diffusion welding, there are at least three

parameters that contribute to the result of the as

welded materials, they are temperature, holding time,

and pressure. The effect of pressure in this study

indicates significant to the performance of the as

welded material. For example, when the applied

welding pressure is too high, even before being

subjected to tensile test defects and deformations has

occurred and it has affected the lower ultimate tensile

strength during tensile test. Thus, diffusion welding

with relatively high pressure is not suggested.

Another aspect to be considered when the applied

welding pressure too high is the ability of the welded

materials to recover their structure is not utilized,

which means if defects are occur during diffusion

bonding, the structure will keep the defects or even

make it bigger and thus affecting the ultimate tensile

strength of the as welded material. Instead of applying

high welding pressure which has no significant

difference in term of benefits, applying low welding

pressure, such as 10 MPa, is suggested because it has

indicates resulting the highest ultimate tensile

strength and excellent bonding structure while

interfacial region thickness shown indication the

ability to maintain its bonding that can avoid any

dissolving phenomena. This low-pressure diffusion-

bonding could be used for nano-scale welding (Lu et

al., 2010) to macroscale. Even though the applied

welding pressure is low, the other parameters like

temperature and pressure still need to be estimated

properly. Here, at a temperature of 500 K, good joints

are achieved with a relatively wide enough interfacial

region and relatively high ultimate tensile strength.

As reported in refs. (Chen et al., 2007, Hu et al.,

2013), the influence of temperature will decrease the

ultimate strength, thus the applied heating

temperature has to be considered properly. If the

temperature is high enough to promote diffusion

between the two dissimilar materials, thus avoiding

making the temperature higher is reasonable.

4 CONCLUSIONS

This study has successfully examined the effect of

pressure on diffusion bonding between Al and Ni.

The conclusions are drawn as listed below:

1. From the concentration distribution profiles, the

welding at low pressure with high enough holding

time (200 ps) and temperature (500 K) shows

good joints and it is enough to avoid any

dissolving phenomena indicated by the high value

of thickness of the interfacial region. Instead of

performing at high pressure that shows no

significant impact, the welding of Al-Ni is better

selecting high enough temperature and long

enough holding time.

2. If the pressure is high enough to perform diffusion

bonding of Al-Ni and has shown satisfactory

results on concentration profile, it is a good

decision to consider the lowest value of pressure

to avoid deformation/defect and efficiency of

resources. Another reason to consider the lowest

possible applied pressure is that with the lowest

value, as discussed in this section, the highest

value of ultimate tensile strength is achieved.

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

0 0,05 0,1 0,15 0,2 0,25 0,3

Stress (GPa)

Strain (%)

10

Mpa

50

Mpa

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

340

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support

from Jakarta Global University and Management &

Science University throughout this project.

REFERENCES

Akca, E., & Gürsel, A. (2015). The importance of

interlayers in diffusion welding-A review. Periodicals

of Engineering and Natural Sciences (PEN), 3(2).

Liu, Z., Nouraei, H., Papini, M., & Spelt, J. K. (2014).

Abrasive enhanced electrochemical slurry jet micro-

machining: Comparative experiments and synergistic

effects. Journal of Materials Processing Technology,

214(9), 1886-1894.

Zaenudin, M., Mohammed, M. N., & Al-Zubaidi, S. (2018).

Molecular dynamics simulation of welding and joining

processes: an overview. Int. J. Eng. Technol, 7(4),

3816-3825.

Zaenudin, M., Abdulrazaq, M. N., & Al-Zubaidi, S. S.

(2022). A Review on Molecular Dynamics Simulation

of Joining Carbon-Nanotubes and Nanowires: Joining

and Properties. International Journal of Integrated

Engineering, 14(4), 137-159.

Zaenudin, M., Abdulrazaq, M. N., Al-Zubaidi, S., &

Sunardi, A. (2020). Atomistic Investigation on the Role

of Temperature and Pressure in Diffusion Welding of

Al-Ni. Journal of Engineering & Technological

Sciences, 52(2).

Chen, S. D., Soh, A. K., & Ke, F. J. (2005). Molecular

dynamics modeling of diffusion bonding. Scripta

Materialia, 52(11), 1135-1140.

Chen, S., Ke, F., Zhou, M., & Bai, Y. (2007). Atomistic

investigation of the effects of temperature and surface

roughness on diffusion bonding between Cu and Al.

Acta Materialia, 55(9), 3169-3175.

Hu, Z., Zhang, J., Yan, Y., Yan, J., & Sun, T. (2013).

Molecular dynamics simulation of tensile behavior of

diffusion bonded Ni/Al nanowires. Journal of

Mechanical Science and Technology, 27(1), 43-46.

Zhang, Y., & Jiang, S. (2018). Atomistic investigation on

diffusion welding between stainless steel and pure Ni

based on molecular dynamics simulation. Materials,

11(10), 1957.

Darolia, R., Walston, W. S., & Nathal, M. V. (1996). NiAl

alloys for turbine airfoils. Superalloys, 1996, 561-570.

Mukherjee, A. B. (1998). Nickel: a review of occurrence,

uses, emissions, and concentration in the environment

in Finland. Environmental Reviews, 6(3-4), 173-187.

Young, K. H. (2016). Research in nickel/metal hydride

batteries 2016. Batteries, 2(4), 31.

Simões, S., Viana, F., Ventzke, V., Koçak, M., Sofia

Ramos, A., Teresa Vieira, M., & Vieira, M. F. (2010).

Diffusion bonding of TiAl using Ni/Al multilayers.

Journal of Materials Science, 45(16), 4351-4357.

Simões, S., Viana, F., Ramos, A. S., Vieira, M. T., & Vieira,

M. F. (2018). Microstructural characterization of

dissimilar titanium alloys joints using Ni/Al nanolayers.

Metals, 8(9), 715.

Ramos, A. S., Maj, L., Morgiel, J., & Vieira, M. T. (2017).

Coating of Tungsten Wire with Ni/Al Multilayers for

Self-Healing Applications. Metals, 7(12), 574.

Luong, V., Philipsen, V., Hendrickx, E., Opsomer, K.,

Detavernier, C., Laubis, C., ... & Heyns, M. (2018). Ni-

Al alloys as alternative EUV mask absorber. Applied

Sciences, 8(4), 521.

Stukowski, A. (2009). Visualization and analysis of

atomistic simulation data with OVITO–the Open

Visualization Tool. Modelling and simulation in

materials science and engineering, 18(1), 015012.

Zimmerman, J. A., Kelchner, C. L., Klein, P. A., Hamilton,

J. C., & Foiles, S. M. (2001). Surface step effects on

nanoindentation. Physical Review Letters, 87(16),

165507.

Prieve, D. C., & Russel, W. B. (1988). Simplified

predictions of Hamaker constants from Lifshitz theory.

Journal of Colloid and Interface Science, 125(1), 1-13.

Mishin, Y., Mehl, M. J., & Papaconstantopoulos, D. A.

(2002). Embedded-atom potential for B 2− NiAl.

Physical review B, 65(22), 224114.

Mishin, Y. (2004). Atomistic modeling of the γ and γ′-

phases of the Ni–Al system. Acta Materialia, 52(6),

1451-1467.

Lu, Y., Huang, J. Y., Wang, C., Sun, S., & Lou, J. (2010).

Cold welding of ultrathin gold nanowires. Nature

nanotechnology, 5(3), 218-224.

Plimpton, S., & Root, J. (1994). Materials and strategies

that work in low literacy health communication. Public

Health Reports, 109(1), 86.

Effect of Pressure on Mechanical Properties and Structural Evolution of Diffusion-Bonded Al-Ni: Insight from Molecular Dynamics

Simulation

341