Progressive Hybrid Stamping Tool Development on Automotive

Components Stay Headlight Material SPC270C

Aida Mahmudah

a

, Metha Islameka

b

, Rofan Yulian Romansyah

c

and Sigit Permana

Design Engineering Department, Politeknik Manufaktur Bandung, Jl. Kanayakan No. 21, Bandung, Indonesia

Keywords: Progressive Hybrid Tool, Stay Headlight, SPC270C.

Abstract: Stay headlight component is a product that requires several stages in its manufacture. The production process

used one compound tool and one group tool mounted on two different press machines. Progressive hybrid

tools can be used to reduce the number of operators, press machines, and speed up processing times. A

progressive hybrid tool is a stamping tool used to produce components from sheet metal materials. In

progressive hybrid tools, the combined process consisting of cutting and forming processes occurs

continuously. In this study, the initial development of a progressive hybrid tool was carried out to produce a

stay headlight component that functions as a vehicle headlight holder. The material used is SPC270C, with a

thickness of 1.6 mm. The design method used is VDI 2222 (Verein Deutsche Ingenieure 2222), which consists

of 4 main stages: planning, conceptualising, designing, and finishing. This early-stage development results in

a progressive hybrid tool design consisting of 11 process stations with a material efficiency of 57.6%. The

tool's dimensions are 845 mm long, 640 mm wide, and 370 mm high. The total force required on this tool is

64.86 tons.

1 INTRODUCTION

The automotive industry is one of the main sectors

contributing to the national economy. The automotive

industry is currently experiencing an increase. This is

in line with the development of technology and

components in vehicles. The development of

manufacturing processes to improve the efficiency of

the production process has become a necessity for the

industry as an active player in manufacturing

activities. The stamping process is one manufacturing

process to produce components from sheet metal

materials, for example, automotive components,

medical equipment, household equipment, and so on

(Thomas et al., 2000; Su et al., 2022). Automotive

components are the most needed stamping products

with a wide variety of materials, shapes, and

dimensions. So that the development of process

quality and production acceleration is necessary in

line with the increasing demand for components

(Silva et al., 2021). The development of precision tool

technology is an alternative solution that can be done

to increase production efficiency without reducing

a

https://orcid.org/0000-0002-7124-0824

b

https://orcid.org/0000-0003-4578-8850

c

https://orcid.org/0000-0001-9216-785X

the quality of the resulting product (Shakkarwal et al.,

2021).

The stay headlight component is one of the

components on the front of the vehicle that functions

as a vehicle headlight holder. This component is made

of SPC270C material with a thickness of 1.6 mm.

This product goes through several process stages:

cutting, forming and bending. The process is carried

out using two stamping tools, the compound tool

(cutting process) and the group tool (forming and

bending process). Both tools are installed on two

different press machines with two operators.

Furthermore, based on the analysis of the stay

headlight product, the result is that the product can be

formed with a continuous process stage using one

tool, namely the progressive hybrid tool. Progressive

hybrid tools are often recommended for mass

production of stamped parts requiring complex press

operations (Karimov, 2021). By using one tool, the

number of press machines and operators needed is

reduced. This, of course, can also reduce energy

consumption and production process costs (Gen and

Yunong, 2020). Therefore, an initial step is necessary

Mahmudah, A., Islameka, M., Romansyah, R. and Permana, S.

Progressive Hybr id Stamping Tool Development on Automotive Components Stay Headlight Material SPC270C.

DOI: 10.5220/0011806400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 375-380

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

375

for developing the tool that will be used to produce

the stay headlight component, namely the design of a

progressive hybrid tool consisting of a combination

of cutting and forming processes which are carried

out gradually and continuously. The design method

used is VDI 2222 (Verein Deutsche Ingenieure 2222),

which consists of four main stages: planning,

conceptualising, designing and finishing. The design

of a progressive hybrid tool equipped with technical

documents for each component to be fabricated as

well as machine specifications following the tool

geometry and machine tonnage required were carried

out in this study.

2 MATERIAL AND METHOD

2.1 Stay Headlight

The stay headlight product functions as a headlight

holder for two-wheeled motorised vehicles. This

product is made of SPC270C material with a

thickness of 1.6 mm and has Rm 270 N/mm

2

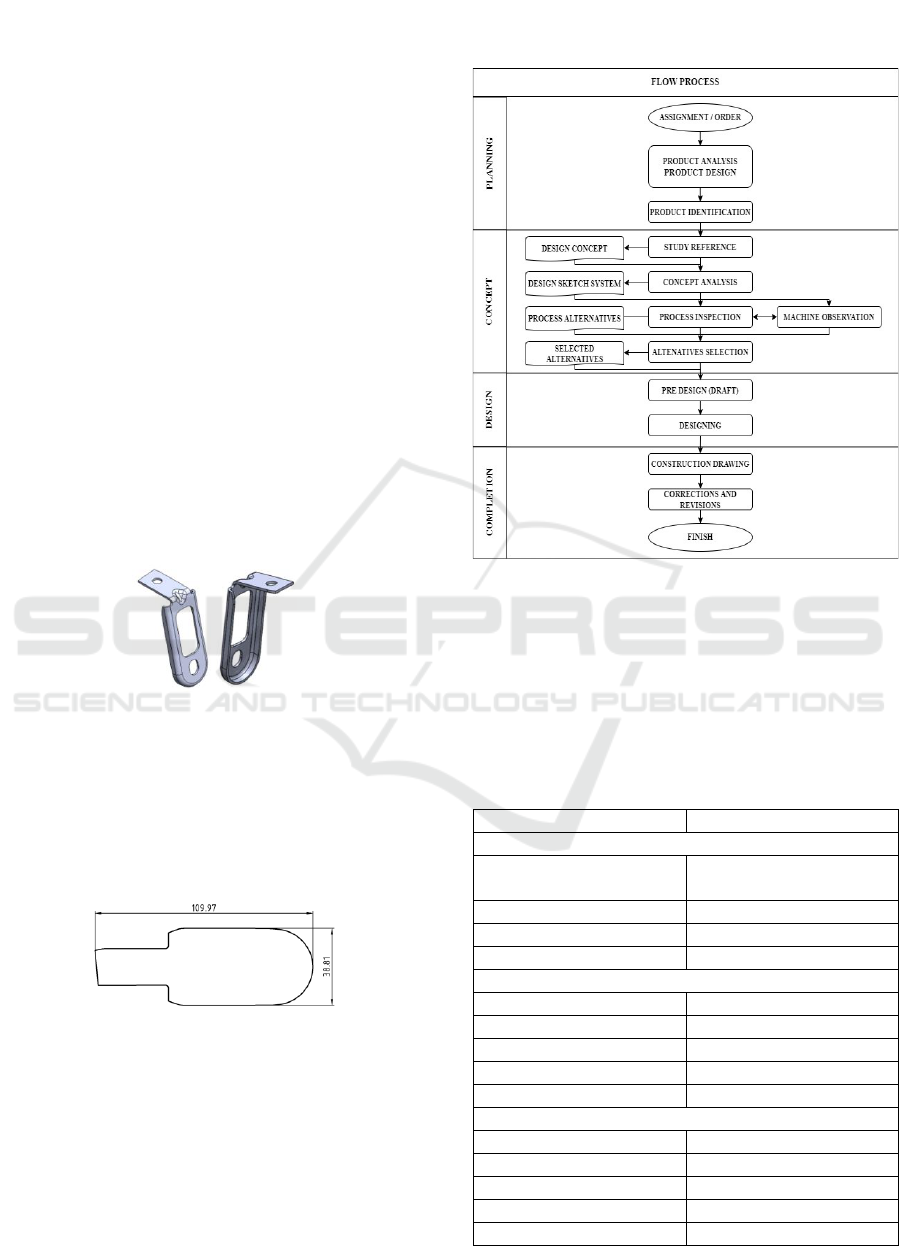

. Figure

1 shows the shape of the stay headlight product.

Figure 1: Stay headlight.

Product shape analysis is carried out to obtain a

fully defined product shape and size. Furthermore,

with the help of modelling software, the shape and

size of the stay headlight product are obtained. Figure

2 shows the flattened shape and the size of the stay

headlight product before it is formed.

Figure 2: Flattened shape.

2.2 Design Method

The method used in the design process of the

progressive hybrid tool for the stay headlight BEJ/AT

is VDI 2222 (Verein Deutsche Ingenieure).

According to VDI 2222, the design flowchart is

divided into four major parts: planning,

conceptualising, designing and completing. Figure 3

shows the VDI 2222 flowchart used.

Figure 3: Design method VDI 2222.

2.2.1 Design Parameters

The design parameters are used as a reference to

achieve the given requirements. Table 1 shows the

design parameters for the developed progressive

hybrid tool.

Table 1: Design parameters.

Demand

Qualification

Product

Dimension

According to the working

drawing

Product thickness

1.6 mm

Material

SPC270C

Tensile stress

270 N/mm

2

Press Tool

Tool assembly process

Easy to install and maintain

Tool clamping

T-slot bolt

Use of standard components

Misumi

Die height

340-450 mm

Tool safety

Miss feed sensor

Machine

Machine type

AIDA A-04

Press machine capacity

200 tons

Slide adjustment

110 mm

Upper bolster dimension

1850 × 650 mm

Lower bolster dimension

2420 × 680 mm

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

376

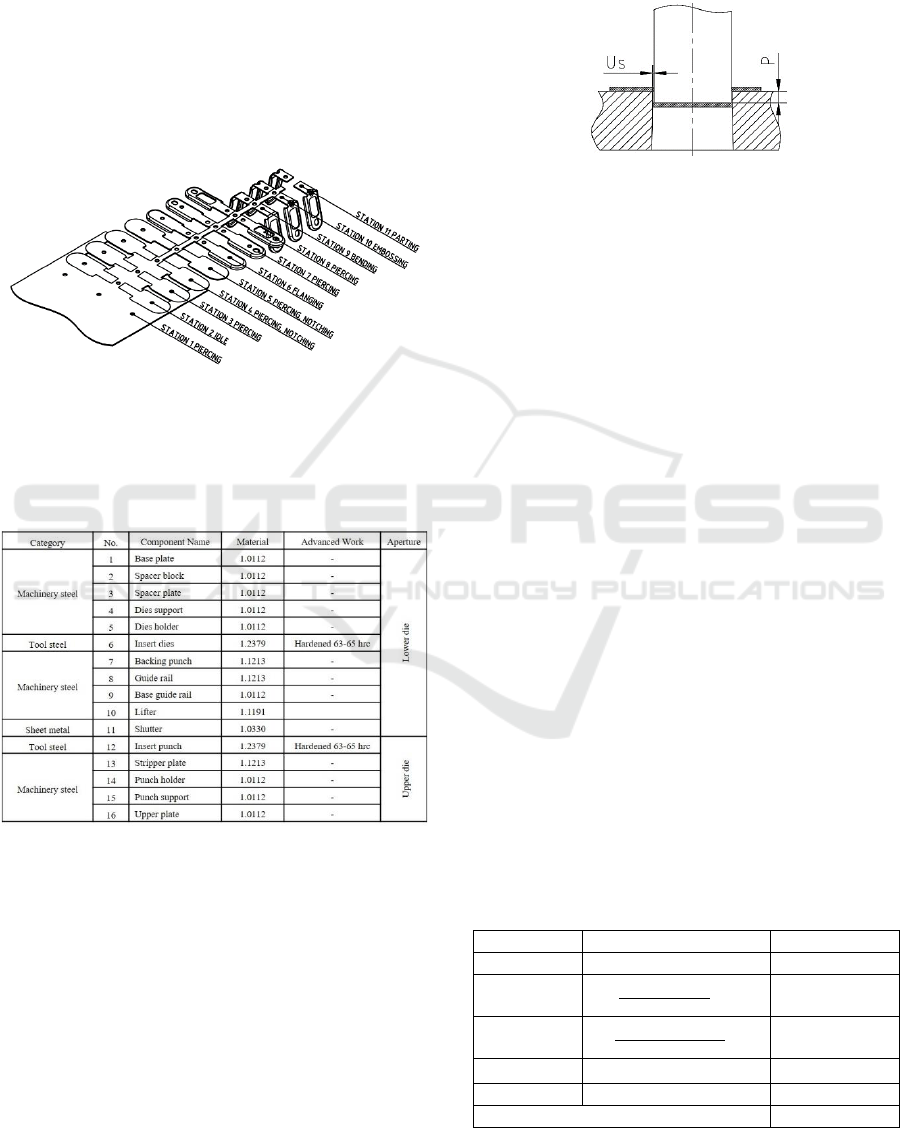

2.2.2 Design Concepting

The design concept consists of several stages: making

the layout and selecting materials for the main

components. Figure 4 shows the planned progressive

process layout. The process layout consists of 11

process stations, namely 4 piercing process stations,

2 piercing notching processing stations, 1 flanging

process station, 1 bending process station, 1

embossing process station, 1 parting process station

and 1 idle station.

Figure 4: Process layout.

Materials for the main components of this

progressive hybrid tool are shown in Table 2.

Table 2: Material of tool’s component.

2.3 Tool Design

At this stage, a tool design construction calculation is

carried out, which will determine the tool's

performance and the quality of the resulting product.

This construction calculation consists of calculating

the clearance between the punch and the die cutting,

the penetration length of the punch to the die, the

stamping force, the stripper force, and the process’s

center of gravity to result in the pre-design of a

progressive hybrid tool.

2.3.1 Cutting Clearance

Calculation of cutting clearance refers to the analysis

and table of standard MISUMI clearance selection.

Figure 5 shows the cutting clearance.

Figure 5: Cutting clearance.

Us = T × c%

(1)

Where Us is the clearance, T is the material thickness,

and c is the working factor. The working factor is

selected to be 6% for the category of extra soft

clearance on steel material. So, the cutting clearance

is 0.1 mm/side.

2.3.2 Die Penetration

Dies penetration is the penetration of the punch from

the thickness of the material strip and pushes the scrap

out of the die. Equation (2) shows the calculation of

the penetration of the die.

L

die penetration

= 1 to 3 × T

(2)

Where L

die penetration

is the length of the die

penetration. So, the die penetration is 1.6 mm to 4.8

mm. The die penetration length for this progressive

hybrid tool design is 3 mm.

2.3.3 Stamping Force

The stamping force is calculated based on the type of

process that occurs in the tool. The calculation of the

stamping force on this progressive hybrid tool is

shown in Table 3.

Table 3: Stamping Force calculation (Budiarto, 2009;

Luchsinger, H R.,198)).

Process

Equations

Force [N]

Cutting

= 0.8 . l . s . Rm

399,164.58

Flanging

=

B×s×Rm

3

× n

20,691.18

Bending

=

b × T × Rm

3

× n

2.631.10

Embossing

F

Embossing

=Ae x Kr x n

44,278.92

Stripper Force

= 10% . F Proses

46,700.66

Total Tool Force

538,082.62

Progressive Hybrid Stamping Tool Development on Automotive Components Stay Headlight Material SPC270C

377

Table 3: Stamping Force calculation (Budiarto, 2009;

Luchsinger, H R.,198))(cont.).

Process

Equations

Force [N]

Minimal

Machine

capacity

= 120% . F tool

648.624,19

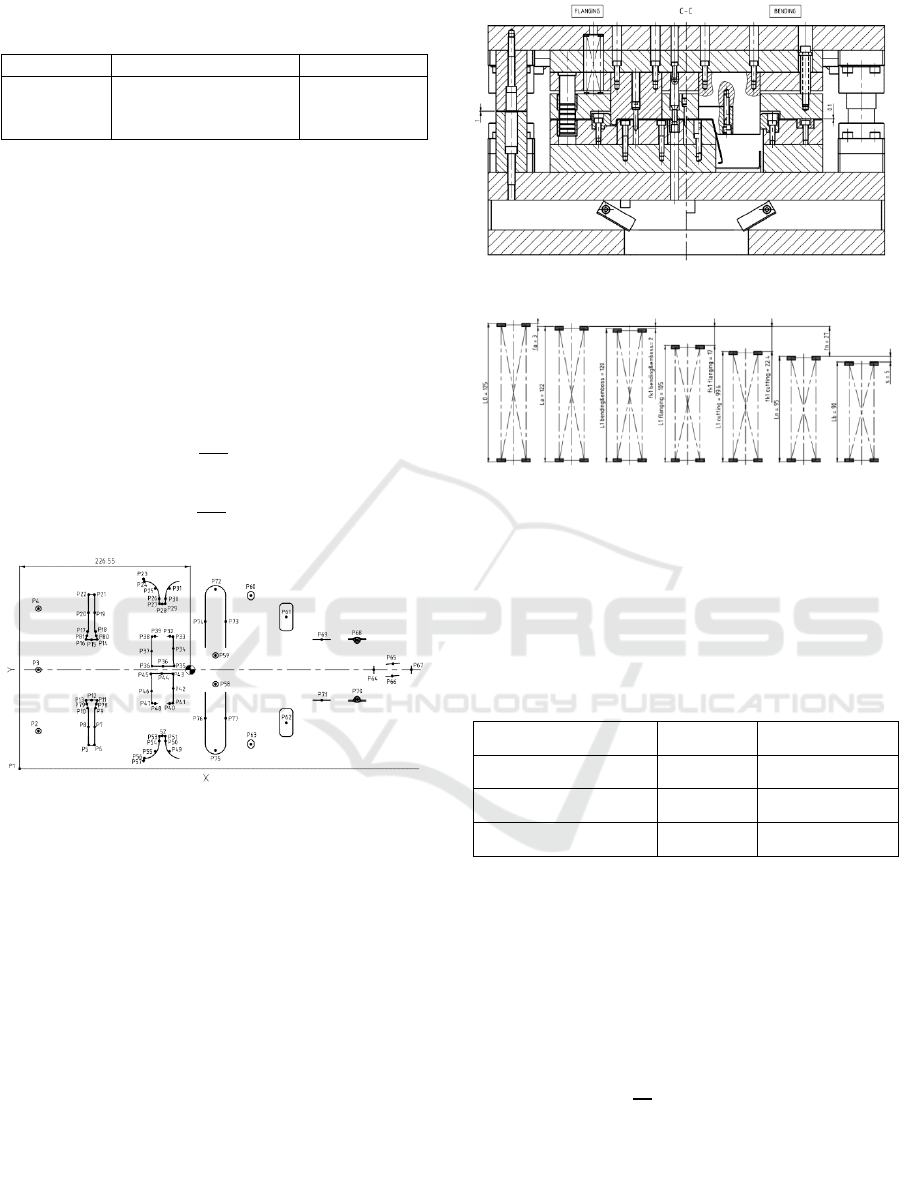

2.3.4 Center Gravity of Tool

The position of the center of gravity of the tool is

important in determining the placement of the tool on

the press machine. The calculated center of gravity is

the position of the center of gravity of the process and

is usually indicated by the installation of the shank

component. The position of the center of gravity of

this progressive hybrid tool is shown in Figure 6. This

data is poured into a pre-design, as shown in Figure

7.

x =

Lx

L

(3)

y =

Ly

L

(4)

Figure 6: Center gravity of tool.

3 RESULT AND DISCUSSION

The pre-design obtained results in a tool with

dimensions of 845 mm in length, 640 mm in width,

and 370 mm in height. The minimum machine

capacity required is 64.86 Tons. The specifications of

this tool meet the machine specifications specified in

Table 1.

Validation of tool construction is carried out

through construction inspection calculations,

including spring components and punch components.

The performance of spring components must be

carried out to ensure the spring can work properly.

Figure 8 below shows the spring step diagram.

Figure 7: Pre-design.

Figure 8: Spring step diagram.

The spring used must fulfil its function as a stripper

or lifter where the selected spring force must be

greater than the required force. The results of the

inspection calculations are shown in Table 4, where

all the springs used can meet the required spring

force.

Table 4: Spring performs validation.

F

Stripper

or F

Lifter

[N]

F

Spring

[N]

Conclusion

F

Stripper 1

= 26,895.63

31,363.9

Well performed

F

Stripper 2

= 19,805.03

31,363.9

Well performed

F

Stripper 1

= 90.04

91,2

Well performed

The reaction force of the punch shall not exceed

the allowable stress of the upper plate component

material in direct contact with the top surface of the

punch. Suppose the reaction force exceeds the

allowable pressure of the material. In that case, it is

necessary to add an insert plate of a material with a

higher hardness level so that the upper plate

components are not damaged.

p =

Fs

A

≤p allow

(5)

Where p is the surface pressure, A is the punch head

cross-sectional area, Fs is the processing force, and p

allow is the allowable surface pressure. The allowable

surface pressure for unhardened steel with impact

loading mode is 40 N/mm

2

(Budiarto, 2012). From

the calculation of the surface pressure at each punch

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

378

that cuts the strip of material, it is found that most

piercing process stations need an insert plate.

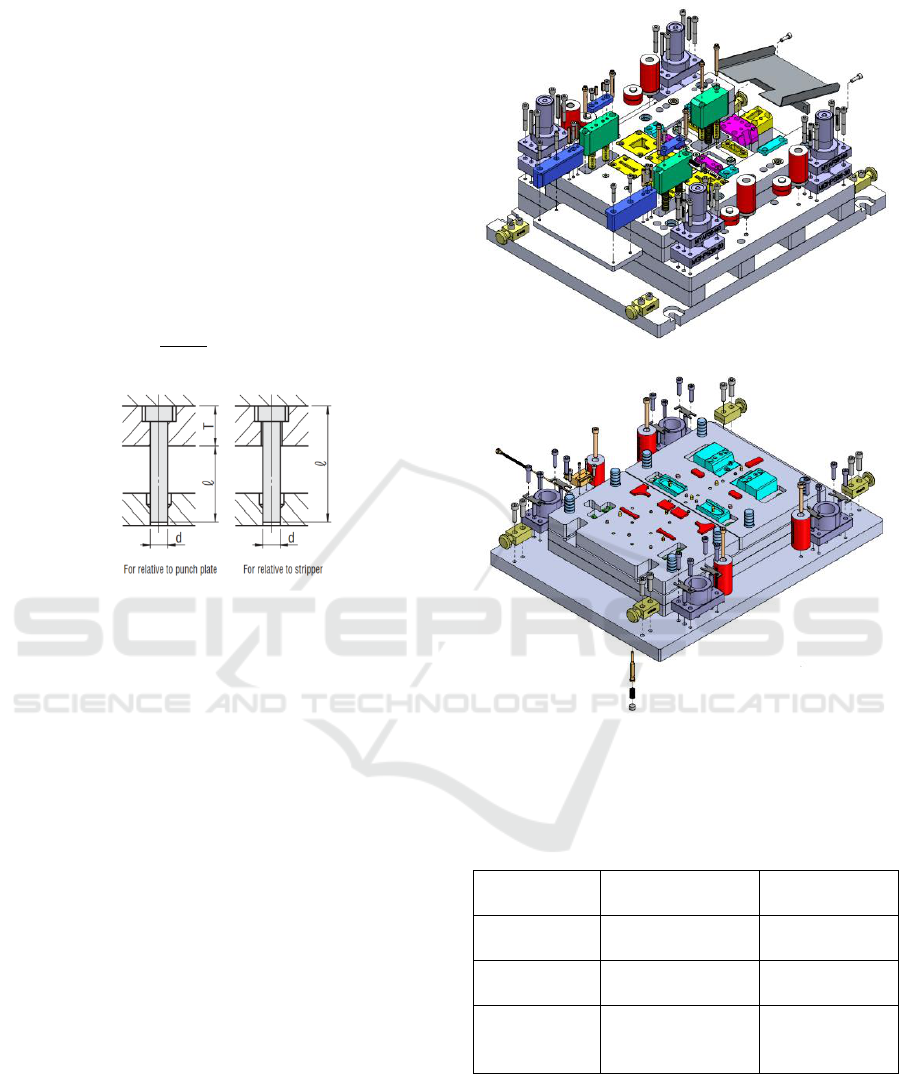

In addition, to examine the punch construction

based on surface pressure, the punch buckling

phenomenon was also checked. Buckling is

instability that leads to failure, caused by a structure’s

inability to maintain its original shape so that it

changes form to find a new balance. In this case, the

processing force that occurs in the punch (F

process

)

must be less than the force that will cause buckling in

the punch (F

buckling

). The magnitude of this buckling

force is strongly influenced by the free length of the

punch in the punch mounting construction model, as

shown in Figure 9.

𝐹

𝑏𝑢𝑐𝑘𝑙𝑖𝑛𝑔

=(

π

2

×E×I

l

2

) ÷ Sf ≥ 𝐹

𝑝𝑟𝑜𝑐𝑒𝑠𝑠

(6)

Figure 9: Free length of punch.

Considering the punch construction that has the

most potential for buckling, piercing the slot shape at

station 7, it is found that the force that will cause

buckling, F

buckling

= 2,321,081.56 N, while the process

force that occurs at the station is 11,567.24 N. Thus,

it can be seen that the punch will not undergo

buckling during the cutting or forming of the product.

Construction validation carried out on spring and

punch components can meet the construction

requirements of the designed progressive hybrid tool,

which is then tested after the tool fabrication is

completed. The overall tool design can be seen in

Figure 10.

The results of this progressive hybrid tool design

contribute to the use of the press machine and the

number of operators. In addition, increasing the

amount of production in one manufacturing process

because with the layout process applied to this tool,

two products are obtained in 1 stamping process. The

following Table 5 shows a comparison of the

production process of stay headlight components

using the previous tool and the progressive hybrid

tool.

(a)

(b)

Figure 10: Progressive hybrid tool (a) top opening and (b)

lower opening.

Table 5: The comparison of stay headlight production

process.

Comparison

Compound tool

& group tool

Progressive

hybrid tool

Number of

machines

2

1

Number of

operators

2

1

Number of

products

in one stroke

1

2

4 CONCLUSION

The development of a stamping tool for the

production process of stay headlight components has

resulted in a progressive hybrid tool with 11 process

Progressive Hybrid Stamping Tool Development on Automotive Components Stay Headlight Material SPC270C

379

stations. Tool dimensions are 845 mm long, 640 mm

wide, and 370 mm high. The force required on this

tool is 64.86 Tons and can be used on the press

machine AIDA A-04 engine with a capacity of 200

tons. By using a progressive hybrid tool, the number

of machines and operators can be reduced, and even

the production speed can be increased by increasing

the number of products produced in one stamping

process.

REFERENCES

Budiarto (2009). Presstool 1. Bandung. Politeknik

Manufaktur Bandung.

Budiarto. (2009). Presstool 2. Bandung. Politeknik

Manufaktur Bandung.

Gen, Y., & Yunong, W. (2020, August). Progressive

stamping process and die design of high strength steel

automobile structural parts. In Journal of Physics:

Conference Series (Vol. 1605, No. 1, p. 012063). IOP

Publishing.

Hakim, Adies Rahman. (2005). Kekuatan Bahan Dasar.

Bandung. Politeknik Manufaktur Bandung.

Karimov, R. (2021). PLANNING OF BELT BRIDGE FOR

UNSYMMETRICAL PROGRESSIVE STAMPING.

Scientific progress, 2(2), 616-623.

Luchsinger, H R. (1984). Tool Design 2. Zurich. Swiss

Technical Cooperation and Swisscontact.

Shakkarwal, P., Kumar, R., Sindhwani, R. (2021).

Progressive Die Design and Development Using

AutoCAD. In: Joshi, P., Gupta, S.S., Shukla, A.K.,

Gautam, S.S. (eds) Advances in Engineering Design.

Lecture Notes in Mechanical Engineering. Springer,

Singapore. https://doi.org/10.1007/978-981-33-4684-

0_54

Silva, J. C., da Silva, F. J. G., Campilho, R. D. S. G., de Sá,

J. C. V., & Ferreira, L. C. R. N. P. (2021). A model for

productivity improvement on machining of components

for stamping dies. International Journal of Industrial

Engineering and Management, 12(2), 85.

Su, T., He, T., Yang, R., & Li, M. (2022). Topology

optimization and lightweight design of stamping dies

for forming automobile panels. The International

Journal of Advanced Manufacturing Technology,

121(7), 4691-4702.

Thomas, W., Oenoki, T., Altan, T., (2000). Process

simulation in stamping – recent applications for product

and process design. Journal of Materials Processing

Technology. Volume 98. Issue 2. Pages 232-243. ISSN

0924-0136.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

380