The Effect of Paint Thickness Coating on Power Radiated in Above

Ground Carbon Steel Pipe for Fire Hydrant System

Ni’matut Tamimah

1 a

, Ika Erawati

1

, Dianita Wardani

1 b

, Pekik Mahardhika

1 c

and Aslam Chitami Priawan Siregar

2 d

1

Department of Marine Engineering, Politeknik Perkapalan Negeri Surabaya, Sukolilo, Surabaya, Indonesia

2

Department of Physics, Institut Teknologi Sepuluh Nopember, Sukolilo, Surabaya, Indonesia

aslamsiregar01@gmail.com

Keywords: Coating, Thickness, Power Radiated, Carbon Steel, Fire Hydrant.

Abstract: Corrosion is a primary cause of material failure, especially in the fire hydrant system that uses carbon steel

placed above ground. Corrosion protection is performed on the pipeline to prevent or reduce the occurrence

of corrosion. The most common method for corrosion protection is coating with a layer protective.

Corrosion is applied to the entire panel with a primer coat of red epoxy resin before assembling to pipes. In

this research, the variable coating thickness of the paint used was 150, 200, 250, 300, 350, and 400 μm. The

result showed that the highest radiation occurred at the 200 μm of coating thickness and the lowest radiation

was 350 μm. It can be concluded that 350 μm coating thickness was the lowest absorbed by the material.

Therefore, it was better to be applied to protect the carbon steel pipe for fire hydrants system from

corrosion.

a

https://orcid.org/0000-0002-5234-2737

b

https://orcid.org/0000-0001-6465-0086

c

https://orcid.org/0000-0002-5239-9741

d

https://orcid.org/0000-0003-4972-5769

1 INTRODUCTION

Coating is one of the methods to resist the materials

from corrosion. Coating is also applied as a

decorative, protective, and some others specific

purposes (Wicks, 2007). The first attempt to control

corrosion in pipelines is to use coating materials.

Corrosion can be prevented as the pipeline metal can

be isolated from the contact with the natural

environment. Moreover, the coating can be as an

effective protection against corrosion because it is an

effective electrical insulator and it can be applied

without any damage and will be easily to repair.

(Peabody, 2001).

For the protection of a fire hydrant system that

uses Carbon Steel Pipe on the ground surface which

may daily exposed to sunlight and other

environmental factors, protection in the form of a

coating is needed (Maulana, 2020). However, the

optimum thickness that can be applied to reach the

best performance and without incurring the

excessive costs for coatings are required.

In this study, the thickness using FDTD (Finite

Difference Time Domain) method of the pipe

coating was varied. The optimum thickness with low

power radiated was also obtained to increase the

protection of carbon steel pipes that were used for

the fire hydrants which placed above ground.

2 MATERIALS AND METHODS

2.1 Materials

In this study, corrosion-resistant metals such as

Carbon Steel ASTM A53 gr A with NPS 4" Sch 40

for fire hydrants were used to reduce the corrosion

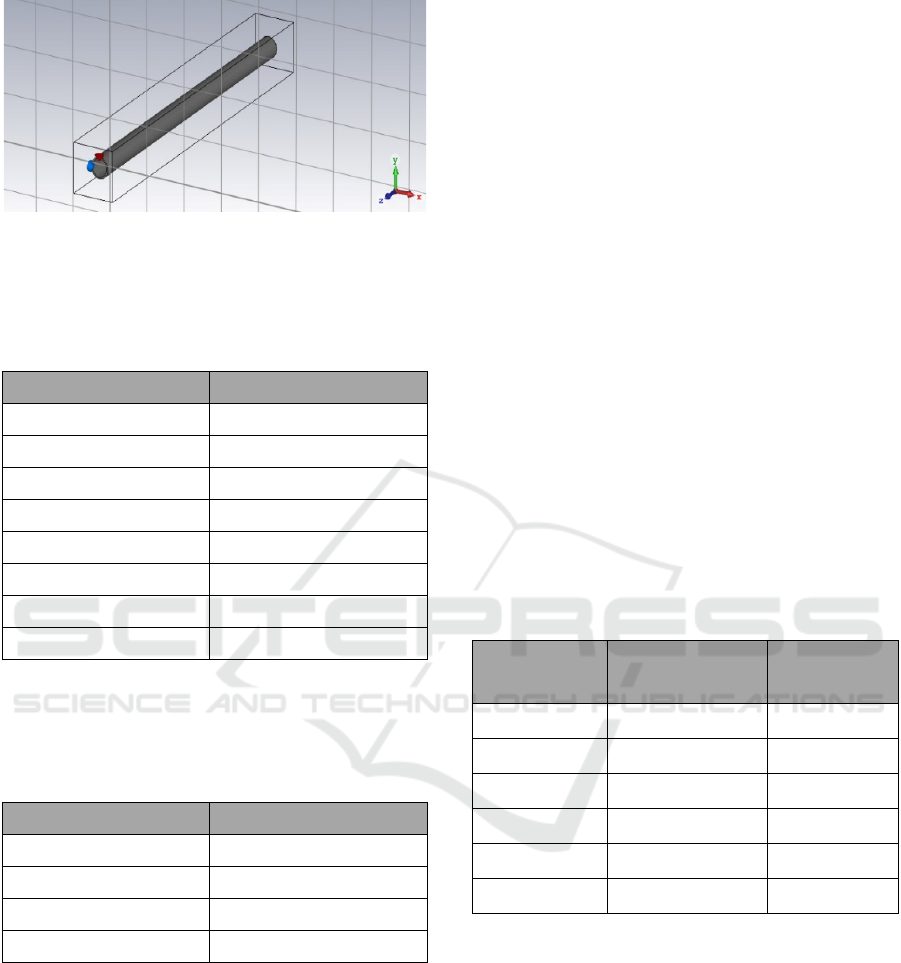

rate. Figure 1 below shows the simulation of carbon

steel pipe with 4 m length.

434

Tamimah, N., Erawati, I., Wardani, D., Mahardhika, P. and Siregar, A.

The Effect of Paint Thickness Coating on Power Radiated in Above Ground Carbon Steel Pipe for Fire Hydrant System.

DOI: 10.5220/0011811900003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 434-436

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Carbon steel pipe simulation.

While the material specifications of carbon steel

pipe used in the simulation are shown in the Table 1.

Table 1: Carbon steel material specifications.

Specification Value

Electric cond. 6.993e+06 [S/m]

Density 7870 [kg/m^3]

Thermal cond. 65.2 [W/K/m]

Heat capacity 0.45 [kJ/K/kg]

Diffusivity 1.84103e-05 [m^2/s]

Young's modulus 205 [kN/mm^2]

Poisson's ratio 0.29

Thermal expand 13.5 [1e-6/K]

On the other side, a red epoxy resin material was

used as the protective layer of coating paint. The

epoxy resin specifications are shown in the Tabel 2.

Table 2: Epoxy resin material specifications.

Specification Value

Density 1500 [kg/m^3]

Thermal cond. 0.2 [W/K/m]

Young's modulus 13 [kN/mm^2]

Poisson's ratio 0.45

2.2 Methods

FDTD (Finite Difference Time Domain) is a

differential numerical method that is often used in

simulation of electromagnetic waves (Siregar, 2021).

The FDTD method uses a differential approach in

the spatial domain explicitly and a differential

approach in the time domain implicitly. First

introduced by Yee, the FDTD method has been used

in a variety of application problems (Gregory, 1999).

The algorithm used is quite simple in numerical

approximation of Maxwell's equations of differential

form.

Then, an electric field grid (E) and magnetic

field (H) intermittent in space and time were used,

so that computation can be done by calculating the

field equation as a function of the previous field.

The basis of the Yee algorithm is approximation

with a second-order Taylor expansion in space and

time. Numerical dispersion and lattice-induced

errors Irregularity can be minimized by giving the

number of lattice spaces per unit length appropriate

wave (Pozar, 2005).

3 RESULTS

The energy of sunlight received by a surface on the

earth is about 1000W/m

2

. It means that each location

of 1 m

2

has the potential to generate 160-200W of

solar electricity. Therefore, this study used 200 W

for solar electricity lighting in simulation. The result

of simulation showed that the addition of a paint

coating could affect to the power of sunlight

reflected on the pipe.

Table 3: Irradiation simulation results on carbon steel

pipe.

Thickness

(μm)

Power Radiated

(10

-5

W)

Frequency

(GHz)

150 0.27 1

200 0.46 1

250 0.33 1

300 0.31 0.921

350 0.22 1

400 0.35 1

Based on Table 3 above, the reflected power of

sunlight was affected by coated pipe (the thickness).

Most coated pipe received normal energy absorption

(1 GHz) although they were varied in value of power

radiated. The greatest energy absorption happened at

the 300 μm paint coating. It occurred at a frequency

of 0.921 GHz which was in the same phase with the

wave of sunlight on the carbon steel pipe affected.

Here, the thickness of the coated was able emit

electromagnetic waves at the UHF (Ultra High

Frequency). Means here, the 300 μm has fast

responses for sunlight irradiated compared to others.

The Effect of Paint Thickness Coating on Power Radiated in Above Ground Carbon Steel Pipe for Fire Hydrant System

435

Figure 2: Graph between thickness of coating pipe and

power radiation.

While in the Figure 2, it can be shown that the

highest radiation occured at the 200 μm coating

thickness and the lowest radiation was at 350 μm.

The higher power radiated value indicated that there

was more sunlight absorption into the material. In

other hand, the lower power radiated value indicated

less sunlight absorption into the material.

From the Figure 2, it also can be indicated that

350 μm coating thickness was the lowest sunlight

absorption by the materials. Less sunlight absorption

also indicated low of corrosion rate. Therefore, the

350 μm was better applied to protect the carbon steel

pipe for fire hydrants system from corrosion.

4 CONCLUSIONS

Based on the research result, the best coating

thickness to protect carbon steel pipe for fire

hydrants was the coating thickness which had the

minimum power radiated value. Furthermore, with

the appropriate coating thickness applied to the

materials, it could minimize the corrosion rate which

later it also could affect to the lifetime of the

materials.

ACKNOWLEDGEMENTS

We thank to Allah SWT, the almighty, who has

granted us countless blessings, knowledge, and

opportunity to finish this research.

REFERENCES

Gregory M. T., & Christos C. (1999). FDTD Analysis of

Phased Array Antennas. IEEE Transactions on

Antennas and Propagation, (Vol. 47, No. 4)

Maulana, R. E., & Poernomo, H. (2020). Pemilihan Jenis

dan Spesifikasi Pompa Pada Desain Sistem

Firefighting Jenis Hydrant, Sprinkle dan Fire Monitor

Pada Pabrik Gula. In Proceedings Conference on

Piping Engineering and its Application (Vol. 5, No. 1,

pp. 146-151).

Peabody, A. W. (2001). Control of Pipeline Corrosion.

Texas, NACE International the Corrosion Society.

Pozar, D.M. (2005). Microwave Engineering Third

Edition. US, John Wiley & Sons, Inc.

Sullivan, D. M. (2000) Electromagnetic Simulation Using

The FDTD Method, IEEE Press.

Siregar, A. C. P., Yudoyono, G., & Pramono, Y. H.

(2021). A Study of Silicon Effect as a Switch on Folded

Dipole Antenna (No. 6970). EasyChair.

Wicks Jr. Z. W, Joes F. N. Pappas S. P. and Wicks D. A.

(2007). Organic Coatings Science and Technology.

US, John Wiley & Sons Inc.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

436