HDPE as a New Alternative Material for Small Vessel Boat Strength

Topan Firmanda, Sony Anggara, M. Rizqi Hariadi and Akbar Rakanda Prakasa

PT. Biro Krasifikasi Indonesia, Indonesia

Keywords: HDPE, Small Vessel, Classification, FEM.

Abstract: In the last decade, the use of HDPE as an alternative material for boat is increasingly. At least there are several

reasons for using HDPE as substitute for FRP material, from zero corrosion, marine growth resistance, and

the most important is the issues of environmentally friendly (recyclable). However, the use of HDPE as boat

structures must meet shipbuilding standards, which are regulated in Classification rules, and Biro Klasifikasi

Indonesia (BKI) as the only national class does not yet have detailed rules regarding of HDPE. The study was

conducted to see the feasibility of HDPE as boat structures, starting from rules gap analysis (ISO 12215-5,

IRS polyethylene rules, BKI rules small vessel), verification of the strength of boat construction and the effect

of thermal on HDPE sheet using Finite Element Method by commercial software. The results showed that

HDPE as an alternative material can be used as a boat/small vessel with the global stress results in test model

at 15 MPa in transverse structures and 8 MPa in longitudinal structures (allowable stress 0.8Fy) both sagging

and hogging conditions. As for thermal effects, HDPE panels are tested up to 70°C and produce elastic

deformation up to 50mm for 1m frame spacing.

1 INTRODUCTION

Polyethylene is one of the simplest and most

preferred polymers, and also most widely used

polymeric raw material for plastics around the world.

Polyethylene is generally divided into three

categories based on density: Low density

polyethylene (LDPE), Medium density polyethylene

(MDPE), and High density polyethylene (HDPE).

High density polyethylene (HDPE), as well as the

grades of polyethylene processed from it, are used in

places where more mechanical, physical or thermal

properties are required (Mikko, 2015).

Compared to other types of plastic, HDPE has

mechanical properties that allow it, to further utilized

in the field of Engineering (Prihatmoyo P.E. et.al,

2018). By increasing the density, the yield strength,

toughness, modulus of elasticity, hardness and heat

resistance of polyethylene can be increased.

Increasing the density also reduces solubility and

swelling, gas permeability, and impact strength

(Nuryosuwito N. et.al., 2019)

In the last decade, the use of HDPE as an

alternative material for boat/small vessel is

increasingly, especially for professional use. At least

there are several reasons for using HDPE as substitute

for FRP or wood material, from durable against

material aging, zero corrosion, marine growth

resistance (Wahyudin et.al., 2021), lighter vessel

weight (up to 30% compared to wood (Wilma A.,

2019)), easier to assemble, UV and fire resistance,

and the very most important is the issues of

environmentally friendly (100% recyclable) (Jamal,

2015). There are two main types of materials that can

be used as a boat or small vessels, HDPE plastic in

the form of plate-shaped and powder or pellets

(Siswandi, 2016), HDPE with base material shaped

like grains as shown in Figure 1 and in the form of

plate-shaped as shown in Figure 2.

Figure 1: Grain of plastic HDPE (Siswandi,2016).

Firmanda, T., Anggara, S., Hariadi, M. and Prakasa, A.

HDPE as a New Alternative Material for Small Vessel Boat Strength.

DOI: 10.5220/0011814700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 473-477

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

473

Figure 2: Plate-shape of plastic HDPE (Wahyuddin et.al.,

2021).

However, the use of HDPE as boat structures

should meet shipbuilding standards which are usually

regulated in the Classification rules, therefore the

government oblige classification for several type of

vessels sailing in Indonesia waterways (Perhubungan

P.M., 2019), and Biro Klasifikasi Indonesia (BKI) as

the only national class in Indonesia does not yet have

detailed regulation regarding of HDPE, BKI rules

only regulates vessels with metal, wood, FRP and

composite materials (Indonesia, B.K, 2021).

The study was conducted to see the feasibility of

HDPE material as boat/small vessel hull, and will

focus on the strength aspect of vessel construction

made of HDPE plate-shape / HDPE sheet, and not

discuss the stability, seakeeping or material quality

aspects..

2 METHODOLOGY

The study methodology to see the feasibility of HDPE

as boat/small vessel structures, starting from rules gap

analysis and perform manual calculations according

to the respective reference rules, followed by

verification of the strength of boat/small vessel

construction and also thermal effect on HDPE sheet

using Finite Element Method by commercial

software.

2.1 Rules Gap Analysis

Rules gap analysis is carried out to see the different

requirement given by each rule, then reconciled with

some adjustments. HDPE vessel models with lengths

of 14m and 17m (Class Approved) as structural

geometry assumptions and verification of manual

calculations supplied by one of the HDPE shipyards.

The standard/rules that will be used as a manual

calculate comparison and gap analysis are:

BKI rules for small vessels up to 24m (BKI,

2021)

ISO 12215-5 Small craft - Hull construction

and scantlings (ISO, 2008)

Class Partner Indian Register Shipping

Guidelines on Hull Structure of Thermoplastic

Vessels (IRS, 2021)

Other Class Partner rules like Turk Lloyd

Tentative Rules for Polyethylene Crafts (TL,

2014) and Det Norske Veritas Standard for

certification no.2.21 (Veritas, D.N., 2010) are

exactly same as IRS guidance mentioned

before.

2.2 Numerical Verification

Numerical verification is needed as an additional

analysis after the rules gap, because the existing rules

do not consider the global strength or longitudinal

strength of small vessels, furthermore the facts

regarding the effect of solar heat will also be

simulated numerically using the commercial software

Poseidon and ANSYS.

3 RESULTS AND DISSCUSION

IRS Thermoplastic vessels guidelines provide only

the requirements for hull bottom and side thickness as

following:

t = kꞏs [P

F

/(6.7L)]

0.5

ꞏ (14+3.6L) (mm) (1)

where:

k = 0.72 for HDPE; s = stiffener spacing (m); PF =

Pressure factor and L = vessels length (m)

And the requirement of thickness for inner hull

shall not be less than 0.8t from eq.(1). However,

vessel constructions are complex structures, many

part have not been covered in those guidance

therefore the other rules will be used to cover this

shortfall.

Assumption to calculate the strength of HDPE

small vessels structure is with Aluminium material

approach, because although they are different in

terms of metallic types, but in terms of mechanical

properties both of these materials have same patterns,

even in ANSYS software these two materials belong

to one family of linear elastic isotropic materials as

shown in Figure 3.

3.1 Rules Manual Calculation

Before calculating the local structural strength,

design stress adjustments are made for each rule

based on aluminium material, in general the basic

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

474

design stress used in several standards / rules follows

the mechanical properties of HDPE stated in IRS

Guidelines, finally the adjustments of rules as shown

in Table 1 below.

Figure 3: Material Properties Comparison of HDPE and

Aluminium.

Table 1: Design stress adjustment for several rules.

BKI ISO IRS*

Rp

0.2

17 MPa

Rm 24 MPa

k 15,5

SF

plate

17 MPa

SF

stiff

15,4 MPa

Yield 17 MPa

Break 14 MPa

Ultimate 24MPa

*All in Tensile

Table 2: Manual calculation vs actual.

Ite

m

BKI ISO IRS Actual

Bottom

p

late 18.74 14.6 19.50 15

Side Plate 13.47 9.22 16.03 10

Deck Plate 10.8 - - 10

Bulkhead P. 4.04 9.22 15.6 12

Bar Keel 52x340 - - 40x250

Rect. Ste

m

42x302 - - 40x250

Floo

r

393 - - 360

Centre Girde

r

393* - - 360

Side Transv. 150 - - 360

Deck Transv. 67.3 - - 73.5

* BKI requires the fitted a centre girder for vessels

above 15 m with aluminium material, with a beam

deflection approach (ML/(8EI)) then a new criterion is

obtained, "All HDPE craft shall have a centreline

g

irder "

Manual calculation is carried out for each

standard/rules. Regulations that cover almost all parts

of the ship are BKI rules, but some results exceed

actual conditions, while the ISO standard provides

requirements of hull plate thickness that are very

close to actual, while IRS Guidance provides the

greatest requirement. Therefore, combining several

standards/rules is the aim of this study. The results of

local strength calculations can be seen in Table 2

below.

3.2 Numerical Calculation

3.2.1 Global Strength of Midship

When the vessels sails, it will receive loads due to

waves (sagging and hogging) in addition to the loads

due to hydrostatic pressure and cargo. This wave load

has not been considered in the previous rules/

standards, and is used to calculate the longitudinal

strength of vessels, especially the influence of centre

girder on global strength. The midship section model

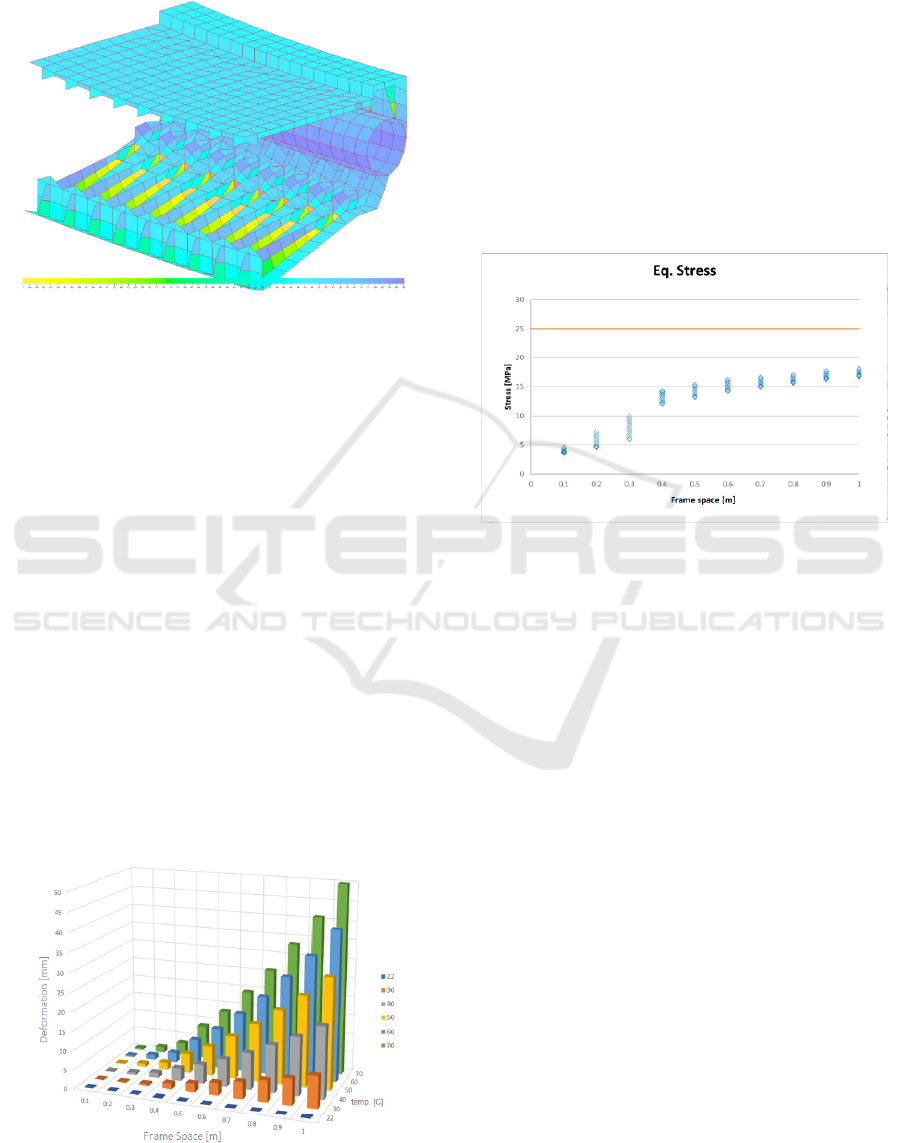

can be seen in Figure 4 below:

Figure 4: Midship cross section.

The assessment of the longitudinal strength of this

HDPE vessel uses Poseidon commercial software,

with the following input parameters:

Length of model 3.2 m (fr.15~fr.23)

E 1.08E+6 kN/m

2

dan F

y

25 MPa

Bending load 391 kNm (BKI, 2022)

The results of numerical analysis as shown in

Figure 5, and show that the total stress (vonmiss) in

the longitudinal structure is 8 MPa and in the

transverse structure is 15 MPa, while the allowable

stress is 19MPa (0.8Fy) given by Standard For

Certification Craft (Veritas D.N., 2010). This analysis

proves that the centre girder installation reduces stress

of the transverse structure significantly by dividing

the floor in two equal length, however the assessment

of global strength of the longitudinal structure is not

HDPE as a New Alternative Material for Small Vessel Boat Strength

475

required for vessels under 24m due to the stress in the

longitudinal structure is less than half the allowable

stress.

Figure 5: Vonmiss stresses in Sagging condition.

3.2.2 Thermal Effect on HDPE

Thermal analyses were carried out to relate the

behaviour of HDPE sheets in areas of the ship's

structure that are frequently exposed to the sunlight

(eg. decks and superstructures), and also based on

information from builders who stated that HDPE

vessels decks which exposed to sunlight often

deformed, but returned to normal at night.

This analysis uses ANSYS commercial software,

with the following input parameters:

Model consist of 9 panel (3x3)

Variation of plate thickness 5 ~ 15mm

Variation of frame space 0.1 ~ 1 m

Variation of thermal load 22~70 °C

Film coefficient 5E-6 W/mm

2

°C

The results of the analysis can be seen in Figure 6.

The greater frame space as the thermal load increases,

will increase the total deformation, and maximum

deformation of 50 mm is obtained with a combination

of 70°C thermal load and 1 m frame space of stiffener.

Figure 6: Deformation of HDPE sheet.

IACS provides a deformation tolerance limit, for

stiffener with 1 m of frame space will give maximum

allowable deformation limit of 3 mm (IACS rec.47,

2013), so by this standard, assuming an average

temperature at sea level is 30°C, then only 0.3 m of

frame space or less can meets the criteria.

However this deformation not only related to

material safety, but also related to passenger/crew

safety. For material safety, the analysis will be

continued until the material stress limit is obtained.

The analysis results are shown in Figure 7, and show

that the deformation that occurs is entirely elastic

deformation, which is indicated by the stresses that

never exceeds the yield of HDPE material.

Figure 7: Thermal stress versus yield material.

4 CONCLUSIONS

Recommendations for the development of BKI

HDPE regulation regarding vessels strength are to

combine several standard/rules and some methods

with the following details:

Calculation of shell (bottom and side) and

transverse bulkhead thickness according to IRS

Guidelines

Other structural calculations using BKI Rules

for small vessels using aluminium formulations

with adjustment of design stress Rp

0.2

17 MPa,

Rm 24 MPa and k 15.5

Additional requirement as follows "All HDPE

craft shall have a centreline girders"

Other part that are not regulated by the two

references above can be solved numerically

with an acceptance criterion limit of 0.8F

y

It is recommended to take the smallest elastic

deformation (see Figure 6) for passages way

area and also for the area of equipment whose

performance will be impaired due to such

deformation.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

476

ACKNOWLEDGEMENTS

Acknowledgments are conveyed to PT. Iqra Visindo

Technology which has shared technical drawings of

HDPE vessels

REFERENCES

Perhubungan P.M. (2019). PM 61 Kewajiban Klasifikasi

bagi Kapal berbendera Indonesia pada Badan

klasifikasi

BKI (2021). BKI Rules for small vessel

BKI (2022). BKI Rules for hull

ISO (2008). 12215-5 Small craft - Hull construction and

scantlings

IRS (2021). IRS Guidelines on Hull Structure of

Thermoplastic Vessels

Loydu, T. (2014). Tentative Rules for Polyethylene Crafts

Veritas, D.N (2010). Standard for certification no.2.21

IACS (2013). IACS Rec. no.47 Shipbuilding and Repair

Quality Standard

Mikko M. (2015). Structural dimensioning of polyethylene

boat, urn.fi/URN:NBN:fi:amk-201505086920

Prihatmoyo P.E., et.al. (2018). Rancang Bangun Mesin

Destilator Pengubah Limbah Plastik Menjadi Minyak.,

In Proceedings Conference on Design Manufacture

Engineering and its Application (Vol. 2, No. 1)

Nuryosuwito, N., et.al. (2018). Pengaruh Campuran

Sampah Plastik dengan Katalis Alam terhadap Hasil

Produk Pyrolisis. Rekayasa Mesin, 9(2), pp. 85-91

Wahyuddin et.al, (2021). Material Cost Analysis for 35 GT

Passenger Ships with High Density Polyethylene

Materials, Repository.unhas.ac.id.

Wilma A. (2019). Analisa Teknis Ekonomis Penggunaan

Kulit Plastik HDPE Sebagai Pengganti Kulit Kayu Pada

Lambung Perahu Katamaran, Kapal: Jurnal Ilmu

Pengetahuan dan Teknologi Kelautan

Jamal (2015). Strength Evaluation of Pompong Structure

Made from High Density Polyethylene Plastics as Basic

Materials, The 4th International Seminar on Fisheries

and Marine Science

Siswandi (2016). High Density Polyethylene (HDPE)

Vessel of Pompong as a Fishing Vessel for Bengkalis

Fisherman, The 2nd International Seminar on Science

and Technology.

HDPE as a New Alternative Material for Small Vessel Boat Strength

477