Monitoring System of Biogas Production Volume and Digester

Pressure Control

Shalma N. Hida, Sephian Prabowo, Mukhammad Kirom and Asep Suhendi

Telkom University, Indonesia

mramdlankirom@telkomuniversity.ac.id, suhendi@telkomuniversity.ac.id

Keywords: Biogas, Biogas-Volume, Digester, IoT, Pressure-Control.

Abstract: In this paper, an IoT-based biogas production volume monitoring system and digester pressure control have

been developed. This system uses a fixed dome type digester with a semi-continuous filling method. A

mixture of stale rice and water in a ratio of 1:2 was used as a substrate with a refill time of every 2 days. The

pressure and volume of gas in the digester are measured using a pressure sensor and a flow sensor. In order

to produce optimal gas volume, the pressure in the digester is controlled using the on-off method. The biogas

pressure and volume data are displayed on the LCD screen and then sent to the IoT platform so that it can be

monitored remotely via a smart phone. Pressure in the digester can be maintained between 0.326 psi to 0.652

psi. The system that has been designed can produce an average gas volume of 10.37 liters. Data transmission

to the platform is carried out with an interval of 10 minutes with a delay in the travel time of sending data for

one transmission of 8 seconds.

1 INTRODUCTION

Biogas is one of the alternative energies that can be

used to help save petroleum energy use, because

biogas processing comes from organic matter that

does not take long to become available. Biogas is a gas

produced from the process of decomposition of

organic materials by the activity of microorganisms in

the absence of oxygen or anaerobic condition

(M. C. T.

Atmodjo, 2018)

Biogas formation process must take

place in a place that is free of oxygen, called a digester.

The shape and size of the digester can vary, according

to the needs and available materials to make the

digester (

E. Randjawali and A. Waris, 2016). In general,

biogas consists of methane (50-75%), carbon dioxide

(25-50%), as well as small amounts of other gases

such as nitrogen (0-10%), hydrogen (0-1%), hydrogen

sulfide (0-3%), and oxygen (0-2%) (S. Ford, 2007).

This gas mixture will be used as fuel.

The biogas production process involves four

successive biological processes: hydrolysis,

acidogenesis, acetogenesis and methanogenesis. If

one of these processes is negatively affected in any

way, it can affect the other process and the biogas

production process can become unstable. Process

monitoring can help to understand what's going on in

biogas installations and help keep the process stable.

The possible disadvantage is that if the biogas system

is completely damaged, it may have to be emptied and

replenished with a new substrate. This leads to time

and financial losses (B. Drosg, 2013).

Some related studies that researched to sanitize the

influence of pressure control on biogas production.

The conclusion obtained that the production of gas

produced with the largest amount is at a pressure range

of 60% of the maximum pressure (F. R. Silmi et al.,

2017). However, monitoring the parameters cannot be

remotely, it can only be seen onsite on the LCD with

volume measurements using no electronic

instruments. Another study researched to incubation

system to enhance biogas and methane production.

The conclusion obtained that the filling time of the

substrate is for two days(

F. Liberi et al., 2019).

In an on-off control system, the control signal has

only two specific positions, namely on and off or 1 and

0. On-off controllers are relatively simple and

inexpensive, they are widely used in industrial and

domestic systems (Y. Kanda, 1991). In this case, the

actuator can produce a variable value or controlled

magnitude in a state of full power or no power at all.

This research utilizes data from previous research

and is integrated into a biogas volume monitoring and

pressure control system produced on the digester by

Hida, S., Prabowo, S., Kirom, M. and Suhendi, A.

Monitoring System of Biogas Production Volume and Digester Pressure Control.

DOI: 10.5220/0011816500003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 493-498

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

493

utilizing the IoT concept as the monitoring process.

Measurement results by flow sensors and pressure

sensors will be processed and then displayed on the

LCD and delivered to the IoT platform so that gas

production can be monitored through platforms or

applications that have been connected to the system.

The pressure control process uses the solenoid valve

as an actuator with a specified pressure value range.

2 METHODOLOGY AND

SYSTEM DESIGN

2.1 System Design

The system consists of three main components,

namely digesters, panel boxes, and gas storage

containers. Digesters are used in the form of

containers with fixed dome and semicontinuous

feeding types. This digester is equipped with an open-

close valve that is above and on the bottom side, this

valve is used for the entry and output of the substrate.

The panel box serves as a placement container of

various system components. The biogas produced in

the digester will be flowed to the panel box and

measured in volume and pressure, as well as pressure

control commands sourced from this panel box. After

that, the biogas that has been measured will be flowed

and stored in plastic containers.

Figure 1: System Design.

2.2 Device Design

The hardware used to build biogas digesters includes

a ±5 liters gallon with a tap that has been installed, a

¾ inch pipe, two ball valves. The installed pipe serves

as the entrance of the substrate during the feeding

process, while the two taps attached to the pipe are

intended to hold the biogas formed in the digester so

that it is not wasted into the air when the feeding

process is carried out. The faucet that has been

installed in the lower area of the gallon is the place

where the substrate outputs.

Figure 2: Biogas Digester Design.

Electronic hardware stored in the panel box

includes arduino uno+wifi R3, LCD, RTC, SD card

module, relay, and sensor flow. While there is a

pressure sensor and a solenoid valve that is installed

outside the panel box because of its use that is closer

to the biogas digester. For online monitoring, data

processed in the microcontroller is sent to the

ESP8266 chip via serial communication. This

ESP8266 chip will read the data and then send the

data to the IoT platform, Antares. The platform is

integrated with android-based applications, so remote

monitoring can be done on the Antares platform as

well as android applications.

The program on Arduino IDE begins with the

initialization of pins connected to various

components and variables that will be processed later.

After that it is continued with the value reading for

the flow sensor and pressure sensor. For volume

readings, the accumulation of readable volumes is

carried out, while for pressure readings, accumulation

is not carried out. For volume accumulation data and

pressure values are displayed on the LCD in real time

as an onsite monitor. Data is sent to an SD card every

20 seconds as a temporary data store, and then sent to

the IoT platform every 10 minutes as an online

monitor.

Figure 3: Schematic Electronics System.

The readable pressure value is seen as a

movement parameter of the solenoid valve. Pressure

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

494

control with set point at pressure 0.652 psi and reset

point at pressure 0.326 psi, this value will be

discussed in the next chapter. When the readable

pressure is above 0.652 psi, the solenoid valve will

open, when the readable pressure is below 0.326 psi,

the solenoid valve will be closed. Meanwhile, if the

pressure value is read between the two points, then

the state of the solenoid valve depends on the

previous condition. If the previous condition is open,

it will remain open. And if the previous condition is

closed, it will remain closed.

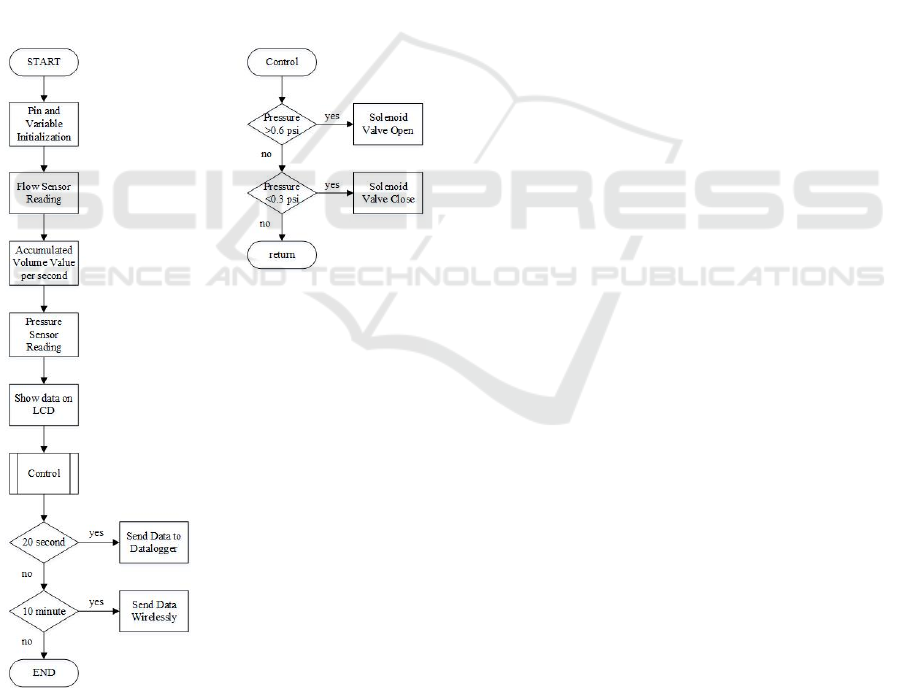

2.3 Software Design

The simple program flow of the system begins with

the readings of the volume and pressure values of

each sensor. Then the readings are distributed for

onsite monitoring on LCD, online monitoring on The

IoT platform, backup data storage on the SD card, and

determining the control of the solenoid valve.

Figure 4: Flowchart Program of Monitoring and

Controlling Biogas System.

As in Figure 4, the program begins with the

initialization of pins connected with various

components and variables that will be processed later.

After that, it is continued with the value readings for

the flow sensor and pressure sensor. For volume

readings, the accumulation of readable volumes is

carried out, while for pressure readings, accumulation

is not carried out. For accumulated volume data and

pressure values are displayed on the LCD in real time

as an onsite monitor. Data is sent to an SD card once

every 20 seconds as a temporary data store and sent

to the IoT platform once every 10 minutes as an

online monitor. The following image shows the

system software flowchart.

The readable pressure value is seen as a movement

parameter of the solenoid valve. Pressure control with

a set point at a pressure of 0.652 psi and a reset point

at a pressure of 0.326 psi, this value will be discussed

in the next chapter. When the read pressure is above

0.652 psi, the solenoid valve will open, when the read

pressure is below 0.326 psi, the solenoid valve will be

closed. Meanwhile, if the pressure value is read

between the two points, then the state of the solenoid

valve depends on the previous conditions. If the

previous condition was in an open state, it will remain

open. And if the previous condition was in a closed

state, it will remain closed.

3 RESULT AND DISCUSSION

The purpose of this study is to create a system that

can measure, monitor, and control parameters in the

biogas process with the help of IoT as its monitoring

system and solenoid valve as a control actuator.

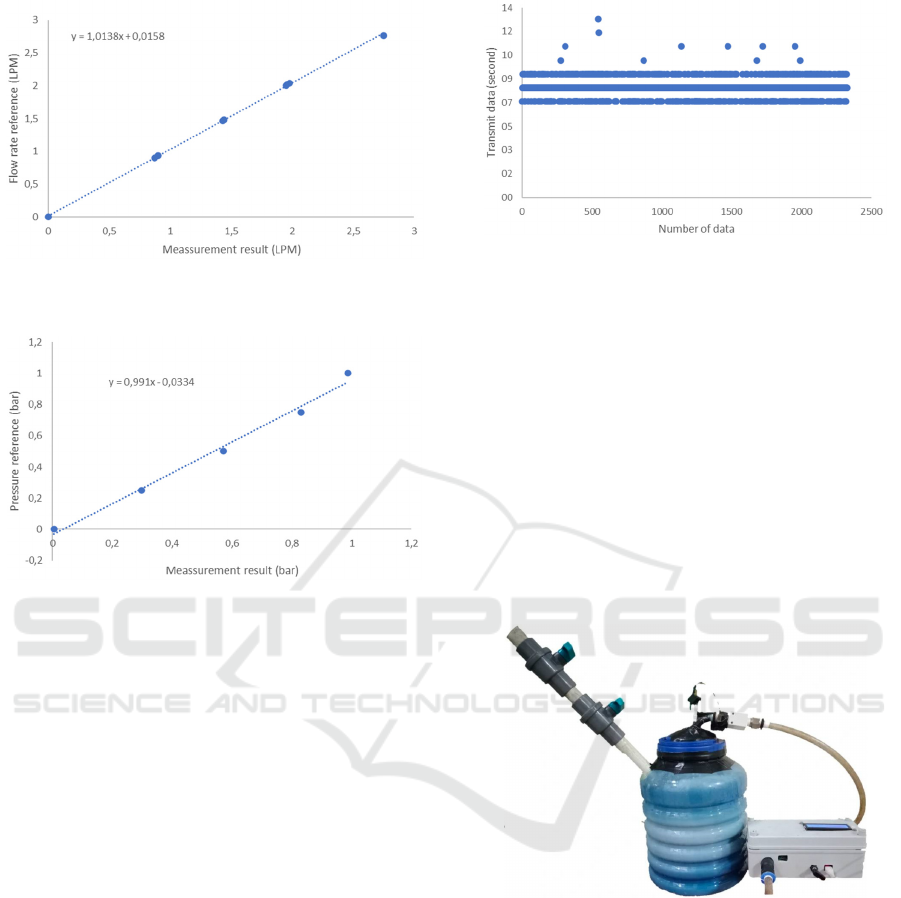

3.1 Sensor Testing

Calibration is performed to get an equation of the

relationship between the voltage emitted by the

sensor and the actual value. The readable voltage

value in the microcontroller will be compared with

the readable gas flow discharge value in the MF-5721

flowmeter. Also, when calibrating the pressure, the

voltage read in the microcontroller will be compared

with the readable pressure value in the pressure gauge.

From the results of the comparison formed a graph

and equation that states the relationship between the

two. This equation will be included in the program in

the microcontroller to calculate the appropriate

physical magnitude.

Monitoring System of Biogas Production Volume and Digester Pressure Control

495

Figure 5: Relation Between Flow Measurement Value and

Reference Value as Flow Sensor Validating.

Figure 6: Relation Between Pressure Measurement Value

and Reference Value as Pressure Sensor Validating.

Testing is done in the same scheme as when

performing calibration. The difference is the

parameters that will be compared in the actual form

with those read on the microcontroller. A comparison

of the two for sensor flow test results can be seen in

Figure 5, while the comparison for the pressure sensor

can be seen in Figure 6.

From the data on Figure 5. can be calculated

average error value of the sensor to be used 2.768%.

From the data on Figure 6., this sensor has an average

error value of 11.342%.

3.2 Communication Module Testing

Communication module testing aims to see the

required data transmission time. The test was

conducted at the Telkom University Faculty of

Electrical Engineering Building room P117 on

Monday, November 22, 2021, at 12:47:35 to 17:59:27

WIB. Data is transmitted with an esp8266 chip that

has been integrated on a microcontroller board and

will be sent to the IoT platform, Antares. Data

transmission is programmed with an interval of one

second each data. Data delivery testing can be viewed

on Figure 7.

Figure 7: Relation Between Number of Data and Time

Transmit Data as Communication Module Testing.

On Figure 7. data that can be sent as much as 2328

data. From this data obtained the average travel time

of data transmission from device to IoT platform is

eight seconds.

3.3 Device Profile

Most components are included in the 80x180x70 mm

panel box to protect against environmental

disturbances thereby reducing the risk of interference

during the reading process. Some components are not

included in the panel box because of their function

and placement more with the digester.

Figure 8: Biogas Digester and Panel Box of Electronics

System.

Measurements are carried out on biogas digesters

with a continuous filling scheme carried out in

Tegalluar Village, Bojongsoang District, Bandung

Regency. The digester used is ±5 liters that are

equipped with a faucet. The gas produced in the

biogas digester is flowed to the sensor flow sensor to

read the flow value of the gas passing through the

sensor. Then the gas is flowed to a container in the

form of plastic measuring 50x120 cm with a thickness

of 0.8 micrometers as a biogas storage area.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

496

Figure 9: Panel Box of Electronics System.

3.4 Measurement Result

Measurements were taken for 20 days from February

19, 2022, to March 10, 2022, with the initial seven

days used to determine the set point and reset point

that will be the pressure limit set on the digester. For

the first seven days there is no pressure control, with

the valve constantly closed. The pressure generated

during the first seven days can be seen in figure 10.

Figure 10: Average Pressure per Day as Deadband Value

Determination.

On Figure 10. The highest pressure for the first

seven days was 1,087. determination of the pressure

value left on the digester is 30% to 60% of the highest

pressure. Then obtained the reset point value at a

pressure of 0.3261 psi and a set point value at a

pressure of 0.6522 psi.

The control program is used after entering the set

point value and reset point that has been obtained. The

measurement process with control is carried out by

continuously replenishing the substrate for two days.

The pressure obtained until the 20th day can be seen

in Fig. 11.

Figure 11: Result of Pressure Control.

Viewed on Figure 11. When the pressure has

reached the set point value, the pressure will decrease

again. This is due to the condition of the solenoid

valve that changes. This pressure control system

produces an average error of 4.875%.

When the condition of the solenoid valve opens,

biogas will be released and passed through the flow

sensor and then measured the volume value. The

measured daily volume value of biogas can be seen in

figure 12.

Figure 12: Volume Biogas Obtained During Pressure

Control per Day.

Based on Figure 12, the volume of biogas

produced tends to increase. The accumulated value of

biogas volume produced during the control process is

as much as 10.37 liters.

3.5 Presentation of Information

Data information can be viewed or monitored directly

in real time on the LCD that has been installed panel

box such as figure 13. It can also be viewed or

monitored remotely on android-based mobile

applications or directly on the IoT platform used,

namely Antares as in Figure 14. The data displayed

online is updated every 10 minutes.

Monitoring System of Biogas Production Volume and Digester Pressure Control

497

Figure 13: Onsite Monitoring View on LCD.

Figure 14: Online Monitoring View on Android.

4 CONCLUSION

In this research, a system that can measure and

monitor the yield volume and biogas pressure has

been created in the digester. The experiment was

carried out using a digester measuring ±5 liters and

the substrate was a mixture of stale rice and water

with a ratio of 1: 2. Substrate filling was carried out

continuously every two days. The parameters

measured were volume and pressure with an average

error value of 2.768% and 11.342% for each sensor.

The volume of gas produced and the pressure in the

digester can be monitored on the LCD screen and on

the Android application and the Antares IoT platform

with data transmission times of 10 minutes. Pressure

control is carried out at the reset point and setpoint at

values of 0.326 and 0.652 psi, this pressure control

system produces an average error of 4.875%. The

total volume of gas produced for 20 days is 10.37

liters.

REFERENCES

M. C. T. Atmodjo, “The Biogas from Biomass Waste,”

International Journal of Scientific & Engineering

Research, vol. 9, pp. 706-711, 2018.

E. Randjawali and A. Waris, “Design and Testing of Mini-

size Biogas Plant,” Journal of Physics, 2016.

S. Ford, Advances in Biogas, Leatherhead: Pira

International Ltd, 2007.

B. Drosg, Process Monitoring in Biogas Plants, Austria:

IEA Bioenergy, 2013.

F. R. Silmi, M. R. Kirom and A. Qurthobi, “Analysis of the

Infuence of Internal Pressure Control to the Total Gas

Production in Anaerobic Digester,” EPIC, 2017.

F. Liberi, V. Pistolesi, et.all, “An Incubation System to

Enhance Biogas and Methane Production: A Case

Study of an Existing Biogas Plant in Umbria, Italy,”

Processes, 2019.

Y. Kanda, "Piezoresistance Effect of Silicon, Sensors and

Actuators," A Physical, vol. 28, pp. 83-91, 1991.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

498