CAD & CAM Design System of 3D Concrete Printing Machine for

Building

Nandang Rusmana

a

, Heri Setiawan

b

and Muhammad Ghizar Muttaqien Nadhif

Manufacture Engineering Department, Bandung Polytechnic of Manufacturing, Jl. Kanayakan No. 21, Bandung, Indonesia

Keywords: Computer Aided Design (CAD) & Computer Aided Manufacturing (CAM) System, 3D Concrete Printing,

Mach3 CNC Controller, SketchUp, 3D Slicer Ultimaker Cura.

Abstract: CAD & CAM system is a computer-aided software tool that can simplify the process of 3D printing of

buildings, this CAD & CAM serves as a tool that bridges the 3D design of building models with the 3D

printing manufacturing process. Based on the results of the CAD & CAM system design on a 3-dimensional

building concrete casting machine, the system tends to be almost the same as 3D Print FDM in general but is

adjusted to the object to be printed, namely the building. The process of making a 3D CAD design of a

building construction model using the SketchUp 2014 software tool, then the 3D building model is converted

into a G-Code program using the help of the CAM 3D Slicer Ultimaker Cura v3.5.1 software with the machine

parameter approach that is on the 3-dimensional building concrete casting machine. From the results of a

simple trial of inputting the G-Code program generated by 3D Slicer Ultimaker Cura on a computer-based

Human Machine Interface (HMI), namely Mach3. The tool-path generated on Mach3 is in accordance with

that generated from the slicing process by Ultimaker Cura and the G-Code program can also be scanned and

read by Mach3 although further testing is needed to adjust the movement of control components controlled

by Novusun NVUM 6 Axis Mach3 CNC Controller so that the parameters previously set on Ultimaker Cura

can run according to the printing process.

1 INTRODUCTION

Along with the times, the manufacturing industry is

always developing continuously so that advances in

manufacturing technology can simplify and speed up

the manufacturing process, as well as civil technology

that applies Additive Manufacturing technology by

means of 3D Print for building construction.

According to the international standard ISO/ASTM

52900, Additive Manufacturing (AM) is defined as

the process of combining materials to make a certain

part of the 3D model data, which is carried out layer

by layer (Paolini et al, 2019). Thus, the construction

of buildings can be operated by 3D Prints. The

processing time is relatively faster than the

manufacture by human labor.

This 3D Print building or 3-dimensional building

concrete machine (3D Concrete Printing Building)

has a standard function that is very similar to the

standard Fused Deposition Modeling Printer (FDM

a

https://orcid.org/0000-0001-8772-5626

b

https://orcid.org/0000-0001-8767-1429

Printer) (Jay et al, 2019), where the building to be

printed can be formed by adding concrete layer by

layer through a nozzle whose movement is operated

by the program. 3D Print this building requires a

computer programming system that is able to act as a

bridge between the 3D design of the building

construction model and the manufacturing process, so

a CAD & CAM system is needed with computer-

aided software tools that can simplify the 3D printing

process of the building.

CAD is a technology related to the use of

computer systems to assist in the creation and

modification of designs, while CAM is a technology

related to the use of computer systems to plan,

manage, and control manufacturing operations (Lee,

1999). The computer system used is in the form of

software.

The software used in CAD is SketchUp software,

which is one of the popular CAD software used by

architecture that can make it easier to make 3D design

Rusmana, N., Setiawan, H. and Nadhif, M.

CAD & CAM Design System of 3D Concrete Printing Machine for Building.

DOI: 10.5220/0011816700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineer ing Science (iCAST-ES 2022), pages 499-506

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

499

of a building models and in operation it is also lightly

processed by computers. In CAM, the software used

is the 3D Slicer Ultimaker Cura which is generally

used in making FDM 3D Printing processes and its

intuitive interface makes it easy to use.

Thus, this study is intended to explain how the

CAD & CAM system is used in a 3-dimensional

building concrete casting machine (3D Concrete

Printing Building) which in the system explains how

the compatibility of the CAD & CAM software

available with the machine, how to describe the CAD

manufacturing process. & CAM with a parameter

approach on a 3-dimensional building concrete

casting machine, and how the output on the system is

in the form of a G-Code program so that it can be read

by the machine controller.

2 METHOD

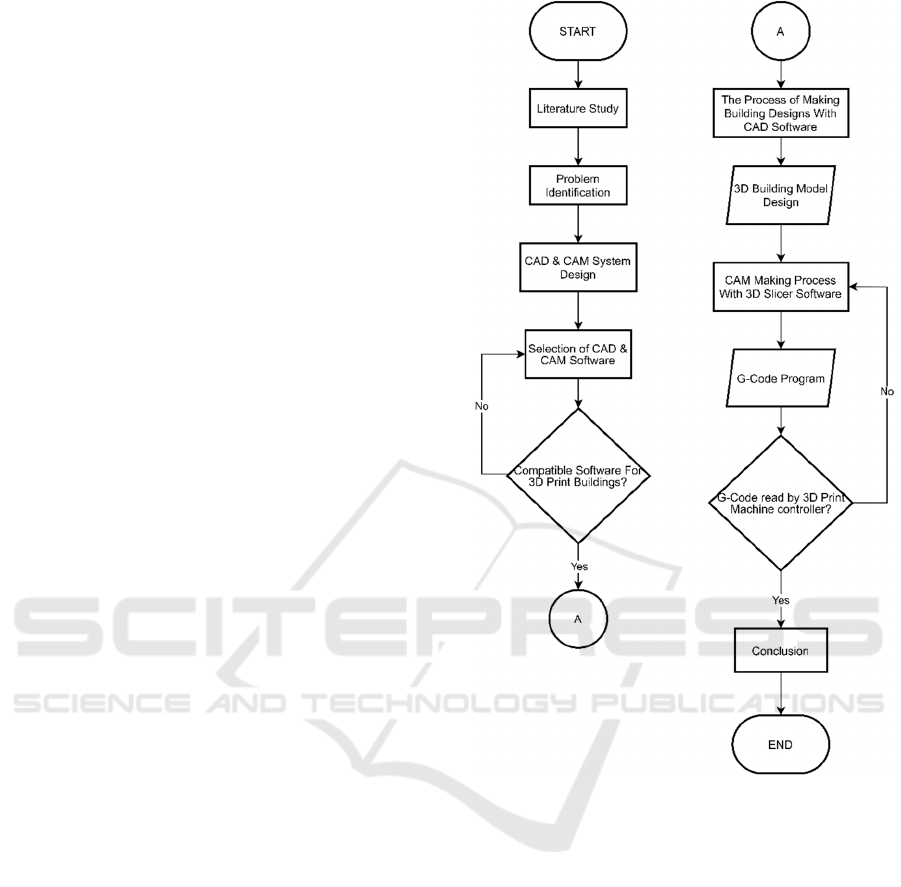

In this method of completion, it begins by looking for

references regarding the control system for 3D Print

in general and its relation to the CAD & CAM process

in 3D Concrete Printing. From the references

obtained, it turns out that the working principle of 3D

Print is generally the same as 3D Concrete Printing,

it's just that there is a development in the control

system and there are also adjustments to the CAM

process.

The problem was then identified in the CAD &

CAM system, where the CAM software available in

general is for 3D Print Fused Deposition Modeling

while on the 3D Print machine the building uses a

Mach3 CNC Controller so it is necessary to adjust the

machine parameters so that the resulting G-Code can

be read by the controller and works fine.

With the problem identified, the system is then

determined so that CAD & CAM can be suitable for

the building's 3D Print machine. One of the system

designs is made as an illustration of how an activity

or process of a CAD & CAM system will run on a

building 3D Print machine.

This CAD & CAM system is a computer software

so it is necessary to find an alternative to CAD &

CAM that is compatible with the three-dimensional

printing process of the building. The selection of

CAD software used was based on consideration of

features that matched the building construction model

to be printed and for CAM software was chosen based

on the consideration of software compatibility on the

Mach3 controller firmware.

Figure 1: Method Flowchart.

CAD & CAM software needs to be checked first

for compatibility of the software used for 3D Print

buildings. The pre-determined software options are

checked for specifications whether they are suitable

and compatible with the control system to be used.

An overview of the CAD process is explained so

that the system created can describe the process of

making building construction designs with CAD

SketchUp 2014 software. Creating a design process

with building construction that is designed as much

as possible is still within the scope of the building's

3D Print machine capabilities.

The description of the process of making CAM is

also explained, this CAM uses 3D Slicer Ultimaker

Cura software. The process is carried out using a

machine parameter approach in the 3D Slicer

software that is used so that the resulting G-Code

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

500

program can be read by the building's 3D Print

machine controller.

The resulting G-Code program needs to be

checked for readability with the Mach3 controller. If

it is not readable, it is necessary to return to the CAM

manufacturing process to analyze the problem. If the

CAM manufacture still gets results that cannot be

read by the controller, it is necessary to re-select the

CAM software used so that it can be compatible with

the machine controller.

3 RESULT AND DISCUSSION

3.1 Design of CAD & CAM System for

Building 3D Printing Machine

The CAD & CAM system on the building 3D Print

machine, was designed based on existing software

tools for most FDM 3D Print machines because there

is no software specifically for the building 3D Print

machine so it is necessary to adjust the machine

parameter approach so that it can be processed by the

building 3D Print machine well.

The output generated by this system will be in the

form of a G-Code program. The program can instruct

the building 3D Print machine control so that the

movement of the nozzle can be in accordance with the

desired 3D printing process based on what has been

set on the CAM.

Figure 2: G-Code Program Input Flow.

Description:

[1 & 2] Z Axis Pillar Slider Motor

[3 & 4] Y Axis Pillar Slider Motor

[5] X Axis Pillar Slider Motor and Nozzle

[6] Human Machine Interface Mach3

The G-Code program is inputted through the HMI.

HMI integrated with the Novusun NVUM 6 Axis

Mach3 CNC Controller will process the G-Code

program and then send signals to control components

such as the motor on the slider and the extruder motor

on the nozzle. The control components are active and

move according to the program instructions on the

controllers.

3.1.1 3D Print Concrete Building CAD

System

The CAD system used in the 3D printing process of

this building uses CAD software tools to facilitate the

3D design process of building models that are usually

used by architecture so that it can facilitate the design

of special building designs that will be printed later.

The default CAD file format saved by CAD software

is usually different, therefore it needs to be converted

to another standard format such as STL or OBJ that is

compatible with the CAM software used.

Figure 3: CAD System Flowchart.

3.1.2 3D Print Concrete Building CAM

System

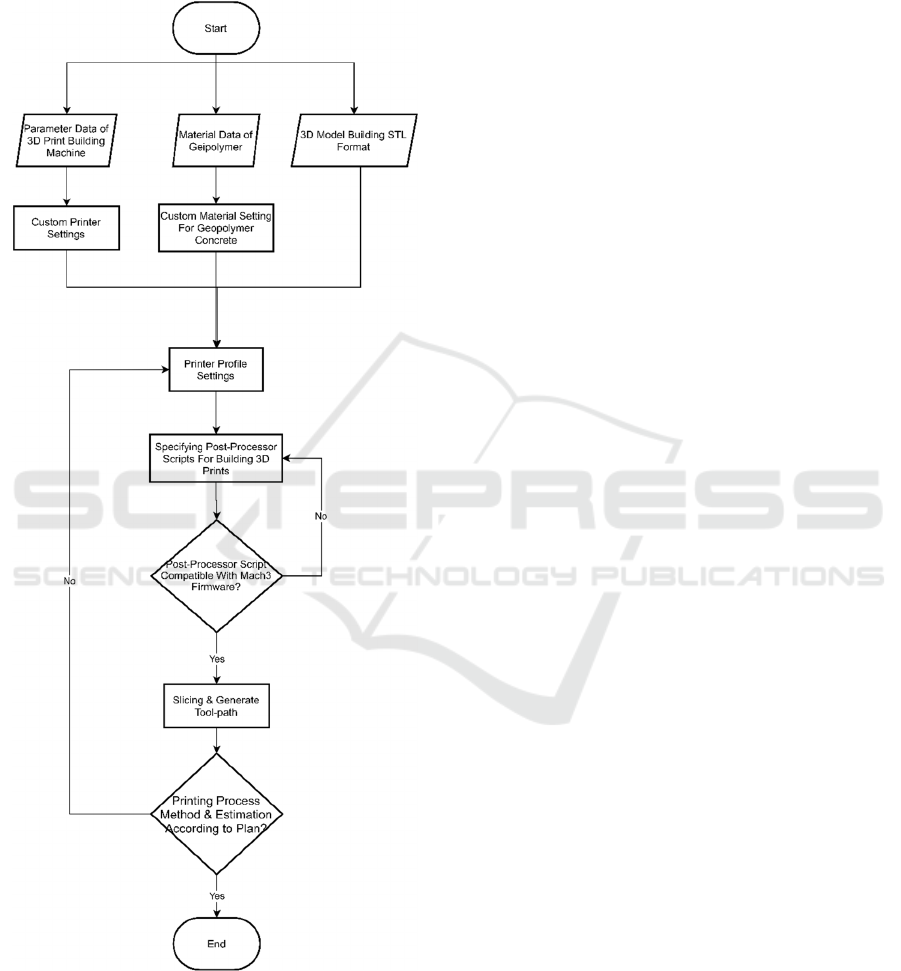

The CAM system in this building's 3D Print process

includes making special settings for Custom Printers,

Custom Materials, and Custom Profiles. Special

arrangements need to be made because this CAM

software that is available is generally made for 3D

Print FDM, where the extruded material is

thermoplastic so that there are some parameters that

will not be used and some must be added in order to

CAD & CAM Design System of 3D Concrete Printing Machine for Building

501

adapt to the building's 3D Print machine. For

example, there is a heating temperature parameter in

the nozzle area to melt thermoplastic filaments, while

printing with this geopolymer material basically does

not require a melting process.

Figure 4: CAM System Flowchart.

This CAM is also programmed to produce

standard 3D Print G-Code, while the controller used

in this 3D Print machine is CNC Mach3. Thus, there

will be a slight difference in the G-Code program read

by the machine controller and cause some G-Code

programs to malfunction or be ignored. Even so, the

program can continue to run until the end. As for the

post-processor script which is needed to facilitate

special work on the building printing process, the

post-processor script itself is programming code that

reads the G-Code generated by the CAM when slicing

the model and modifies it to the desired result before

Cura sends the final result to 3D printers.

3.1.3 Selection of CAD & CAM Software

CAM computer software for the 3D printing process

is generally available only for thermoplastic Fused

Deposition Modeling 3D Printers, so this selection is

necessary so that the CAM software used can be

compatible with the 3D Print machine for the building

to be made. In general, there are many choices of

software in CAD for various engineering fields, as

well as in CAM software so that it needs to be

narrowed back to its application function. 3D Print of

a building is a job whose application is more directed

at the realm of civil engineering because the object it

prints is a building construction, therefore, for the 3D

CAD model design process, CAD software is needed

that is able to support building construction design

work.

3.1.4 CAD Software

SketchUp 2014 was chosen as computer CAD

software for making 3D models of building

construction on a 3D Print machine because it is easy

to use and the computer specifications required are

not too high. But in reality all these CAD software are

the same depending on what they are applied for, the

convenience of the user, and the capabilities of the

computer they are using. So that the choice of CAD

software for a building 3D Print machine can be said

to be relative as long as the most important thing is

that the stored 3D CAD digital design file must be in

STL file format so that it can be compatible with

many 3D print CAM software.

3.1.5 CAM Software

In practice, this CAM serves as a bridge between the

construction of a digital 3D model (which is created

through CAD) and a manufacturing process system

by translating the digital 3D object model into a

program of instructions to be executed by the

machine. However, most of the 3D printing

technology process is not carried out with the term

CAM software but with 3D Slicer software, where the

3D Slicer is not categorized as a CAM in general even

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

502

though it performs the same function so that in

subsequent writings will use the term 3D Slicer as a

CAM 3D Print (Grames, 2021). This 3D Slicer

software is compatible with 3D print technology in

general because of the features in it that support

Printer Fused Deposition Modeling (FDM)

parameters, similar to those in 3D Print buildings.

Ultimaker Cura version 3.5.1 was chosen as 3D

Slicer software because, Cura's interface is intuitive

and user-friendly for beginners, but there are more

complete settings if needed so that it can be adapted

to the 3D Print engine building. Compatible with

many 3D Printer machines, especially on firmware

other than 3D Print machines, namely Mach3 CNC

Controller. Compatible with various types of 3D

CAD file formats. There is a custom post-processor

script on Cura that can be used for the construction

process on the overhang of the building. The version

chosen is 3.5.1 because in another version there is a

bug in the G-Code flavor Mach3 so it is not

compatible with 3D Print building controller.

3.2 CAD Process on 3D Printing

Building Machine

The CAD process of the 3D Print building machine is

the creation of a 3D model of building construction

with the help of CAD software. From what has been

determined previously, the CAD software used is

SketchUp. Before entering this process, some

information data is needed in advance about building

construction as an example of the CAD

manufacturing process, including:

1) The available working area is 5 x 4.5 x 3 meters

with an offset of 0.5 meters as a safe distance for

the printhead nozzle with X, Y, and Z pillar

construction. After an offset of 0.5m is made from

the working area the size of the house to be printed

becomes 4m x 3.5m x 2.5m.

2) The 3D model objects created in CAD are

building constructions that will only be printed by

geopolymers, which are mostly walls.

3) The building construction to be printed is a

building in the form of a non-standard house (not

based on the standard type of house in Indonesia)

which only has one floor level because it is limited

by the working area of the building's 3D Print

machine.

4) The house building consists of one main room and

one bathroom.

5) The thickness of the walls of the house is 15 cm.

6) There is one main door, two main windows, and

one bathroom door.

7) With its non-standard type, the building of this

house is more like a premium boarding room with an

attached bathroom which is suitable for the upper

middle class.

3.3 Export CAD File into STL

CAD files need to be saved or exported into STL files

because they are easy to manipulate in the process

planning system (Zhou, 2005) (CAM), especially in

the slicing process by 3D Slicer Ultimaker Cura

software. without showing color, texture, and other

general attribute models so that it is quite simple to

process in the slicing process.

(a) (b)

Figure 5: (a) 3D CAD Model (b) 3D CAD Model After

Converting to STL.

3.4 CAM Process with Ultimaker

Cura Software

The process of making CAM on the 3D Print building

machine is carried out with the 3D Slicer Ultimaker

Cura software, this process begins with making

special settings for the printer machine, special

settings for materials, special settings for printer

profiles, and in addition to setting post-processor

scripts. Thus, although this Ultimaker Cura 3D Slicer

is not intended for 3D printing with geopolymer

materials, it can be adjusted by making profile

settings that are close to the parameters of the 3D

Print building machine.

3.4.1 Custom Printer Settings on Ultimaker

Cura

This custom printer setting is made in such a way

because Cura defaults machine profile is unavailable

for a building 3D printer, this building 3D Printer

machine is a machine made in the final project at the

Bandung Polytechnic of Manufacturing and is not

commercially available.

Information on building 3D Print engine

parameter data is required, which include:

CAD & CAM Design System of 3D Concrete Printing Machine for Building

503

1) The available working area is 5 x 4.5 x 3 meters

with an offset of 0.5 meters as a safe distance for

the printhead nozzle with X, Y, and Z pillar

construction.

2) The working area is square.

3) The controller uses CNC Mach3, so the G-Code

flavor used is Mach3.

4) It only has one extruder on the nozzle.

5) The height of the gantry or the distance between

the base of the working area and the construction

of the X pillar is assumed from the height of the

working area plus the thickness of the X pillar,

which is about 3m + 0.5m = 3.5m.

6) Because the material to be printed uses a

geopolymer, the compatible filament diameter

material is the same as the nozzle hole diameter.

7) Start and End G-Code are left default.

From the data above, it can be input to the custom

printer machine settings in Settings → Printer → Add

Printer → Custom FFF Printer.

3.4.2 Custom Material Setting for

Geopolymer

Ultimaker cura does not provide material profiles for

types of materials that are cement or mortar such as

geopolymers, so it is necessary to add special settings

in the Material Settings section. Geopolymers have

material properties as shown in the following table:

Table 1: Geopolymer Concrete Material Properties

(Meng et al, 2019).

Properties Geopolymer Concrete

Mass density 2,40 g/cm³

Poisson’s ratio 0.21

Bending strength 10.1 Mpa

Compressive Strength 93.6 Mpa

The material properties for this custom material

setting are only the mass density, so other information

is ignored. For settings, it can be done by selecting

Settings → Extruder 1 → Materials → Manage

Materials.

3.4.3 Custom Printer Profile Settings

Before specifying the custom printer profile settings,

first import or enter the object to be printed by

selecting File → Open File(s) and then selecting the

3D CAD file of the building to be printed in STL or

OBJ form. Then readjust the size and scale of the

object, also adjust the position of the object so that it

loads the working area properly and correctly.

Custom printer profile settings are settings for the

printing process method which can affect the nozzle

movement pattern as well as what instructions are

needed so that the machine can print objects

according to what has been designed. Therefore, the

resulting output will be in the form of a G-Code

program. These settings include:

3.4.4 Layer Height

Determining the layer height can affect the quality of

print detail that will be obtained. The smaller the

height resolution of each layer, the better the surface

detail obtained but the longer the printing process

(Grames, 2021). The layer height in the 3D Print of

the building is assumed to be 1 inch or 25.4mm. The

height is uniform with the hole inside the nozzle

diameter.

3.4.5 Shell

The shell is the outline or the outer boundary of each

layer of the object to be printed (Wobith, 2019). This

shell can affect the stability of the model. In

determining the parameters of this shell, there are

several settings in it, namely the thickness of the shell

wall (wall thickness), the number of layers of the shell

wall (wall line count), and the thickness of the

top/bottom thickness (top/bottom thickness).

In setting the shell for 3D Print printing of

buildings, from many video references on the internet

that most house walls are printed with a shell wall as

thick as a nozzle diameter that is 25.4mm in this case

and there is only one layer of wall so that it will

produce a cavity in the wall of the house which has a

thickness of 15cm. The cavity will later be filled with

infill with a certain pattern and density to strengthen

the building construction.

3.4.6 Infill

The arrangement of this section plays an important

role in influencing the strength and weight of the

building construction to be printed (O’Connel, 2022).

There are two important parameters in the infill

setting, namely the infill density and the infill pattern.

Fill density for standard printing is around 15% -

50% with simple patterns such as Grid patterns, too

dense infill and too complex patterns can cause the

printing process to be very long and increase the

complexity of nozzle movement so it is not

recommended for home wall printing. The infill

density is sufficient at 20% to speed up the printing

process but is still quite sturdy.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

504

3.4.7 Printing Speed and Flow Rate

Printing speed and flow rate can also affect the

quality, accuracy, and even the strength of the

construction to be printed. Too fast causes inaccuracy

of the dimensions of the printed object and can also

reduce the quality of object details.

Printing speed and flow rate for building 3D Print

is in the range of 60 mm/s to 120 mm/s and 37,9 ml/s

to 51,3 ml/s, respectively. The printing speed and

flow rate refers to the research conducted by Daniel

Tay et al. in 2019. Where in this range, the prints tend

not to break and do not experience cracks so that the

prints will be better and stronger. The fastest printing

speed is selected, which is 120 mm/s with flow rate

51,3 ml/s so that the printing process time is shorter.

3.4.8 Travel

Travel is a setting in Cura to control nozzle traffic at

the time of printing. This setting contains several

important parameters, including Combing Mode,

Avoid Printed Parts, Avoid Supports, and Z Hop

When Retracted (Anon, 2022).

Combing Mode functions in reducing the

possibility of defects on the outer surface of the mold

by recalculation of all traveling nozzle movements so

that they remain within the mold limits. Avoid Printed

Parts and Avoid Supports if enabled will make the

printhead avoid parts that are printed while the nozzle

is traveling, assuming the safe distance is one nozzle

diameter which is 25.4mm. While Z Hop When

Retracted allows the printhead to move over the print

without the nozzle touching it, but this parameter is

not really necessary because it will increase the

printing process time.

3.4.9 Post-Processor Script Setup for

Building Printing Process

Post-processing scripts in the 3D Print process of

buildings are needed because they can be used as a

method that can facilitate the installation of manual

support on the overhang section of building

construction. The post-processing script is “Pause At

Height”. The method the script will use is to read all

the G-Code lines, then detect the G-Code at which the

printer will reach the desired height, and add a pause

G-Code, such as the M0 (Unconditional Stop)

command.

To install the Post-processing script this plugin

can be done by selecting Extensions → Post

Processing → Modify G-Code → Add a script →

Pause at height. After that, the Post Processing Plugin

window will appear and the parameter fields that

must be filled in.

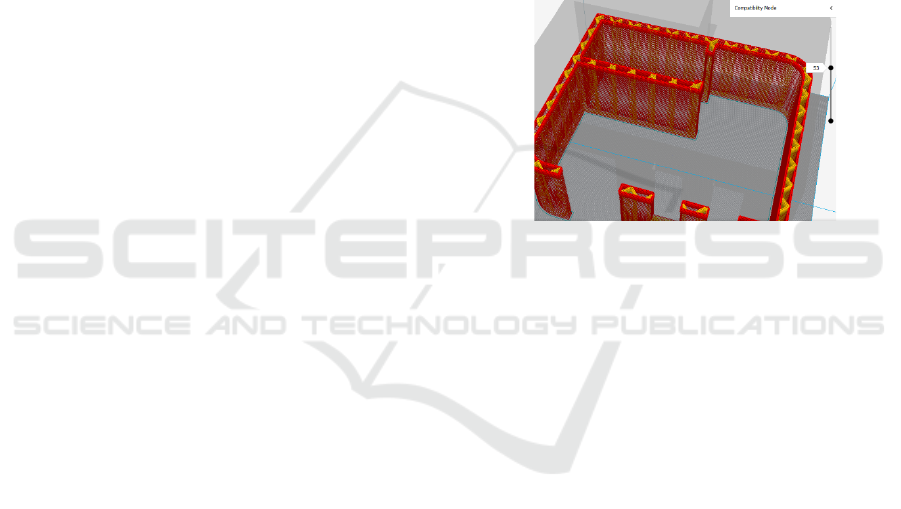

3.4.10 Slicing on Building Objects to Be

Printed

The object that is ready will then be sliced into several

layers, after which the tool-path line and its layers

will appear, so you can see if the nozzle movement

path is in accordance with what was planned.

The display in Figure 4 is an overview of the tool-

path on layer 52 out of a total of 100 layers. You can

see the red lines that show the nozzle movement path

in the formation of the shell wall and the yellow lines

that show the nozzle movement path in the formation

of the filling.

Figure 6: Layer View and Slicing Tool-path Pattern.

3.5 Simple Testing of G-Code

Program on Mach3

This simple test simply checks the G-Code program

whether it can be read by Mach3 and the resulting

tool-path is exactly the same as that produced by

Cura's Ultimaker CAM 3D Slicer. The G-Code

program is inputted through a computer-based

Human Machine Interface (HMI), namely Mach3.

After that Mach3 will scan the loaded G-Code

program before it can be executed.

When the scan is complete, Mach3 will display

tool-path lines on the Display indicating that the next

G-Code program can be executed. However, if after

scanning there are no tool-path lines on the Display,

it means that an error has occurred in the G-Code

program.

G-Code programs that do not experience errors

after being scanned can be seen for their detailed tool-

paths in the Display section, so that it can be easily

checked whether the tool-paths represent the G-Code

programs that have been loaded.

The tool-paths previously generated from the

CAM 3D Slicer Ultimaker Cura process with Tool-

paths displayed on Display Mach3 have similarities,

CAD & CAM Design System of 3D Concrete Printing Machine for Building

505

(A) (B)

Figure 7: Tool-path view (A) Top and (B) Isometric.

but there are limitations to the Display Mach3 feature

which cannot display tool-paths in more detail. Even

so, the G-Code program can still be read by Mach3,

it just needs further testing to adjust the movement of

the control components controlled by Mach3 so that

the previous parameters set on the CAM 3D Slicer

can run according to the printing process.

It is proven that Ultimaker Cura 3D Slicer

software is compatible with Mach3 CNC controllers,

so that the software can be used in a 3D Print

approach to the 3D printing process.

4 CONCLUSIONS

The CAD & CAM system on the building 3D Print

machine is almost the same as the FDM 3D Print in

general. The process of making a 3D CAD design of

a building construction model using the SketchUp

software tool, then the 3D building model is

converted into a G-Code program using the help of

the CAM 3D Slicer Ultimaker Cura software with a

3D Print machine parameter approach of the building.

SketchUp software compatibility meets STL and

OBJ standard file storage, while Ultimaker Cura 3D

Slicer software can be compatible with Mach3 CNC

controllers on building 3D Print machines.

The CAD process in the 3D Print of the building

begins with the creation of a 3D design of the building

construction model and the process of exporting the

file into STL type format with SketchUp software.

The CAM process in the 3D concrete printing

building process consists of making custom settings

for custom printers, custom materials, and custom

printer profiles.

The G-Code program generated by 3D Slicer

Ultimaker Cura can be read by Mach3 CNC

controller.

If using open-source software such as Ultimaker

Cura, pay attention to the updated version. In some

versions there are bugs in the Mach3 firmware that

have not been fixed by the software developer so that

the resulting G-Code program is not compatible.

Overall, using this software produces

performance for 3D building concrete casting with

good execution speed.

REFERENCES

Paolini, A et al (2019). Additive manufacturing in

construction: A review on processes, applications, and

digital planning methods, Additive Manufacturing, 30.

2.

Jay G, S et al (2019). 3D Concrete Printing for

Construction Applications, 3D Concrete Printing

Technology. 4.

Lee, K. (1999) Principles of CAD/CAM/CAE Systems,

Boston: Addison Wesley Publishing Co.

Carolo, L. (2020). What Is a 3D Slicer? – Simply Explained.

From https://all3dp.com/2/what-is-a-3d-slicer-simply-

explained. (Accessed 2022-05-23).

M.Y.Zhou. (2005). STEP-based approach for direct slicing

of CAD models for layered manufacturing,

International journal of production research, 43(15), pp.

3273-3285.

Meng, Q et al (2019). Experimental and numerical

investigation of blast resistant capacity of high

performace geoplymer concrete panels, Composites

Part B: Engineering, 171. 5.

Grames, E. (2021). 3D Printing Layer Height: How Much

Does It Matter?. From https://all3dp.com/2/3d-printer-

layer-height-how-much-does-it-matter. (Accessed 20

22-06-25).

Wobith, E. (2019). 3D Printing Shells – All You Need to

Know. From https://all3dp.com/2/3d-printing-shells-

all-you-need-to-know/. (Accessed 2022-06-24).

O’Connel, J. (2022). 3D Printing Infill: The Basics Simply

Explained. From https://all3dp.com/2/infill-3d-

printing-what-it-means-and-how-to-use-it/ (Accessed

2022-06-26).

Daniel Tay, Y.W et al (2019). Effect of printing parameters

in 3D concrete printing: printing region and support

structures, Materials Processing Technology, 271. 14-

16.

Anon. (2022). Travel Settings. From https://support.

ultimaker.com/hc/en-us/articles/360012611299-Travel

-settings. (Accessed 2022-06-26).

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

506