The Effect of Magnetic Intensity on the Characteristics of a Mixed

LPG and Gasoline + Bioethanol Engine

Tatun Hayatun Nufus

1 a

, Dianta Mustofa Kamal

2 b

and Candra Damis Widiawati

3 c

1

Program Study of Energy Conversion Engineering, Politeknik Negeri Jakarta, Jl. G. A. Siwabessy, 16425, Indonesia

2

Master in Applied Engineering Energy Manufacturing Technology, Politeknik Negeri Jakarta, 16425, Indonesia

3

Program Study of Electrical Engineering, Politeknik Negeri Jakarta, Jl. G. A. Siwabessy, 16425, Indonesia

Keywords: Bioethanol, LPG, Torque, Exhaust Emissions.

Abstract: LPG fuel has a high calorific value, is widely available in the market and has low exhaust emissions of CO,

CO2 and HC. However, NOx levels are high due to high combustion temperatures so that engine

performance decreases. To overcome this, this machine is equipped with magnets and LPG fuel combined

with a mixture of bioethanol-gasoline. The purpose of this study was to analyze the magnetic field strength

of the engine performance using a mixture of LPG and bioethanol-gasoline. The object of this research is a

gasoline engine. The composition of the bioethanol-gasoline fuel is (10:90, 15:85, 20:80). The magnet used

has a magnetic intensity of 1500 Gauss. The independent variable is the variation of the fuel mixture and

magnetic field, while the fixed variable is engine performance (exhaust emissions, power and torque). As a

result, the average engine power increases by 8-16%, engine torque increases by 5-15% and exhaust

emissions of HC, NOx and CO are reduced by 47%, 44% and 62%, respectively. In the future, LPG and

gasoline-bioethanol mixtures can be used in vehicles as an alternative to electric vehicles. The drawback,

the aesthetics of this LPG-fueled vehicle is less attractive.

a

https://orcid.org/0000-0002-5360-361X

b

https://orcid.org/0000-0001-9336-8936

c

https://orcid.org/0000-0002-7452-1074

1 INTRODUCTION

Several research results show that the use of a

magnetic field in the engine can improve

combustion efficiency and reduce emissions of

combustion products (Cetin, 2011). Increased

combustion efficiency can maintain energy security

because it can save the amount of fuel used.

Reducing emissions can make combustion more

environmentally friendly. In addition to the use of

magnets in the engine, the use of alternative fuels

such as LPG and bioethanol is one of the efforts to

improve combustion quality and environmentally

friendly exhaust emissions.

The selection of LPG fuel as one of the objects

of research is because LPG exhaust emissions are

environmentally friendly, abundant in market

availability and relatively cheap prices. The use of

LPG in engines can provide engine life up to twice

that of gasoline engines and is relatively safe (Sayin

Kul and Ciniviz, 2020). The disadvantage of LPG is

that it produces high levels of NOx because it has a

fairly high combustion temperature (Dhande, Sinaga

and Dahe, 2021). To overcome this deficiency, one

of them is mixing LPG with bioethanol. In certain

compositions, the addition of bioethanol to the

engine has been proven to not cause technical

problems and is very environmentally friendly

(Silitonga et al., 2018). The combustion temperature

of bioethanol is low so that it can neutralize NOx

formed from LPG gas. On the other hand, the

performance of engines fueled by bioethanol is

lower than that of engines fueled by LPG because

bioethanol has a low calorific value.

The description above shows the lack of these

two fuels, namely that they have not been able to

produce optimum engine performance, therefore the

presence of a magnetic field is very necessary,

because the magnetic field through the cluster-

decluster effect is proven to improve the quality of

630

Nufus, T., Kamal, D. and Widiawati, C.

The Effect of Magnetic Intensity on the Characteristics of a Mixed LPG and Gasoline + Bioethanol Engine.

DOI: 10.5220/0011860100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 630-637

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

combustion which in turn increases engine

performance. In addition, mixing the two fuels is

carried out with the aim of improving engine

performance, so the purpose of this study is to

analyze the effect of magnetic fields on engine

performance using a mixture of LPG and bioethanol.

In the future, this research will be used as an engine

model with maximum performance and minimum

exhaust emissions using environmentally friendly

fuels.

2 LITERATURE REVIEW

Excellent fuel structure for internal combustion

engine is the most challenging approach to achieve

good engine performance and lower gas emissions.

Therefore, some researchers have made efforts to

modify the characteristics of the fuel to increase

combustion efficiency and reduce pollutant products

using a magnetic field. Among the fuels structural

modification method, utilizing electromagnetic field

is one of the powerful techniques that has been used

to produce better fuel conditioning (TH. Nufus, R. P.

A. Setiawan, W. Hermawan, 2017). Strategy

facilitates the alternation of fuel properties with

changes in molecular structure. Magnetic fuel

treatment affects better atomization which reduces

the amount of HC, CO and NOx.

The study reveal that, a significant improvement

in performance of coated engine operating on dual

fuel mode (LPG-biodiesel) with additive by an

increase in efficiency of 4.5% and decrease in brake

specific fuel consumption of 4.2% at 80% of full

load, HC and CO emissions are reduced between 9%

and 12% at entire load spectrum compared to

uncoated engine operating on diesel fuel. NOx

emission is drastically reduced up to 32% for dual

fuel with additive compared to without additive in

coated engine operation and very close to diesel fuel

in uncoated engine operation (Musthafa, 2019).

In this study; an experiment was carried out to

examine the effects of LPG-ethanol fuel blends on

the emission performance of a four cylinder SI

engine.

Performance tests were conducted to determine

the correct air/fuel ratio (lambda = 1). Exhaust

emissions were analyzed for CO, CO2, NOx, HC,

O2 using LPG-ethanol blends with different

percentages of fuel blends at variable engine speeds

ranging between 1000 and 5000 rpm. It was

observed that depending on the rate of ethanol

increase in mixture, the CO2, CO, NOx and HC

emission concentrations in the engine exhaust gases

decreased (TH Nufus et al., 2020).

Automobile fuel system created with the concept

of dual fuel, which allows the car can be operated

with gasoline or LPG and bioethanol mixture

alternately. The result is the lowest CO emission is

obtained at 30% gas valve opening and 750 rpm

engine speed. The lowest HC emission is obtained at

50% gas valve opening and 3000 rpm engine speed.

Optimum torque is obtained at 50% gas valve

opening and 3000 rpm engine speed. While the

bioethanol valve opening has no significant effect

(Nibin, Raj and Geo, 2021).

The present investigation was conducted on a 4-

cylinder diesel engine fueled with either pilot diesel,

or pilot waste cooking oil biodiesel (WCOB), and

fumigated liquified petroleum gas (LPG) at three

loads. The LPG addition is expressed in terms of a

LPG power substitution percentage (LPSP), ranging

from 10 to 30% at each load. the result that both

types of dual fuel operation can lead to reduction in

both NOx and PM emissions, with LPG-Diesel

operation being more effect in reducing NOx

emissions while LPG-WCOB operation more

effective in reducing particulate emissions (Duc and

Duy, 2018).

Diesel engine using diesel/biodiesel mixture with

liquefied petroleum gas (LPG) and cooled exhaust

gas recirculation (EGR) inducted in the intake port.

The optimal operating factors for acquiring the

largest fuel consumption time, the lowest smoke and

NOX are decided for 1500 rpm and different loads.

The results display that predictions by Taguchi

method are in fair consistence with the confirmation

results, and this method decreases the number of

experimental runs in this study. The best fuel

consumption time, smoke, and NOX at each load is

acquired at a combination of B10 (A1), 40% LPG

(B3) and 20% EGR ratio (C1) (Vinoth et al., 2017).

3 RESEARCH METHODS

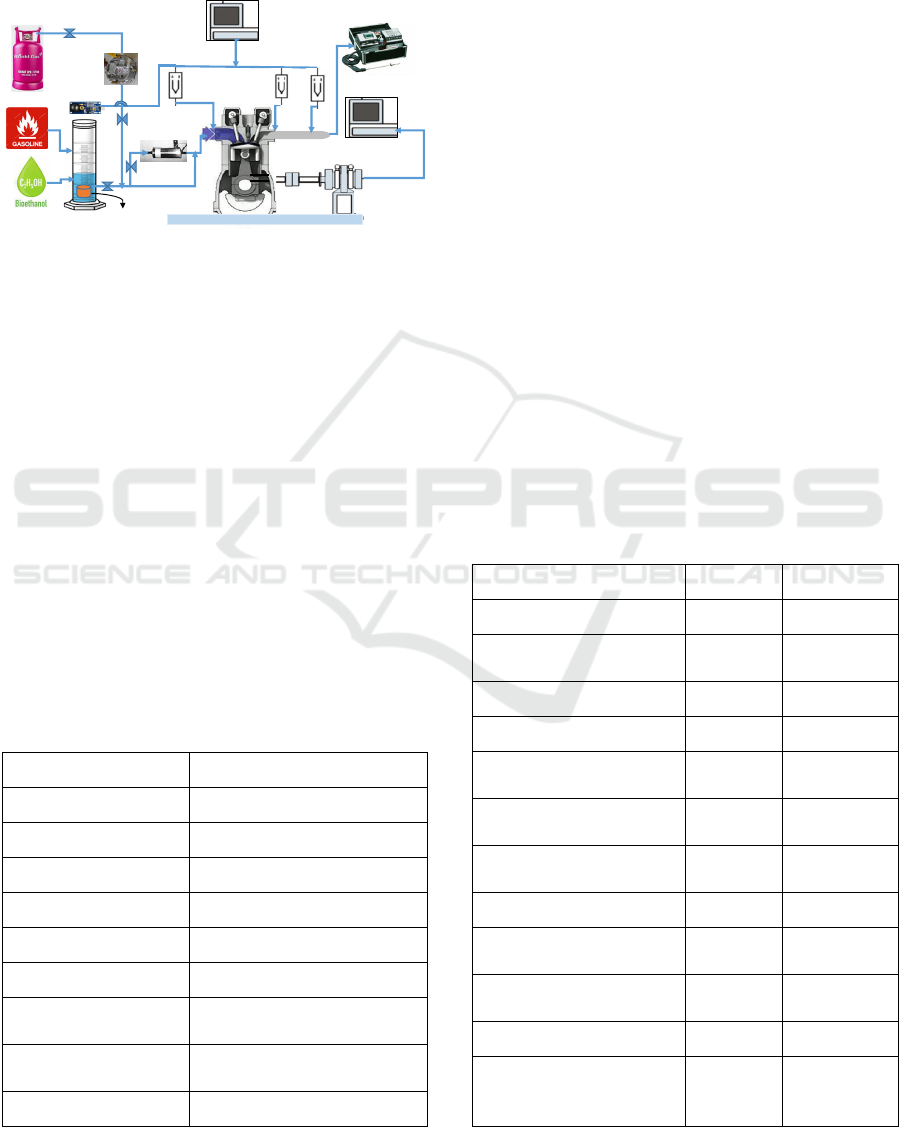

The materials used in this study were bioethanol

from cassava with a content of 98% and gasoline

with an octane number of 90 as a mixture of

bioethanol. The fuel system is made with a dual fuel

concept that can be operated with gasoline or with

fuel mixture of LPG and bioethanol alternately. the

test engine is a 125cc motorcycle. The engine

performance test is carried out using a dynamometer

with the scheme shown in Figure 1. The parameters

measured in this test are torque, engine power at

various percentages of mixtures, and exhaust

The Effect of Magnetic Intensity on the Characteristics of a Mixed LPG and Gasoline + Bioethanol Engine

631

emissions. Measurements were made in the engine

speed range of 1500-3500 RPM. The magnitude of

the magnetic field used The strength of the magnetic

field used is 1500 Gauss. As a control is an engine

without fuel magnetization.

LPG

Konveter kit

magnet

Data acquisition

Termocouple type K

Fuel pump

Engine

Data acquisition

Dynamometer

Gas analyzer

Sensor Flow

Fuel tank

Figure 1: Gasoline engine performance testing installation.

The tools and materials used in this study are

specified in Tables 1 and 2. The composition of a

mixture of gasoline and bioethanol E0, E10, E15 and

E20. other tools, namely the combustion quality

improvement device and a 12 volt battery voltage

source. Motorcycle performance testing using a

dynamometer connected to data acquisition. The

research begins with the calibration of the required

equipment, inspection of diesel engine components

such as: lubricating oil, lubricating oil filter, fuel

filter. Parameters observed are Torque, Power and

fuel consumption. The test starts by starting the

engine at 1000 rpm and then holding it for ± 10

minutes to get a normal engine working temperature.

After the machine is operating normally, data

retrieval begins. Data collection is done by looking

at the measuring instrument and taking notes on the

note sheet.

Table 1: Engine Specification (TH Nufus et al., 2020).

Parameter Value

Diameter x Stroke 52.4 x 57.9mm

Cylinder Volume 125 cc

Compression ratio 9.5 : 1

Maximum Power 7 kW / 8000 rpm

Maximum Torque 9.6 Nm / 5500 rpm

Engine oil 0.84 liter

Transmission

System

CVT Outomatic

Tipe Kopling

dry, Centrifugal

Automatic

Ignation System TCI/ Fuel Injection

Data processing

Power (break horse power) Brake horse power is the

power generated from the engine output shaft [13].

bhp = . ω.T

bhp = 2π . n . T / 746 (hp)

with:

T = Torque (N.m)

n = rotation of the waterbrake dynamometer shaft

(rps)

Fuel consumption is the amount of fuel used by

the engine for a certain unit of time. While sfc

(specific fuel consumption) is the amount of engine

fuel consumption during a certain unit of time to

produce effective power. If in the test data is

obtained regarding the use of fuel m (kg) in s

(seconds) and the power produced is bhp (hp), then

the fuel consumption per hour is: Power (end

horsepower), Brake horsepower is the power

generated of the engine output shaft. Specific fuel

consumption (specific fuel consumption)

SFC= (3600. mbb)/bhp (kg/kW.hr)

with:

mbb = fuel consumption per unit time (kg/hour)

s = fuel consumption time (seconds)

sfc = specific fuel consumption (kg/kW.hour)

Table 2: Properties of gasoline and bioethanol (Silitonga

et al., 2018).

Fuel Type Gasoline Bioethanol

Formula (liquid) C

8

H

18

C

2

H

5

OH

Molecular weight

(g/mol)

11.15 46.07

Density (kg/m3) 765 785

Viscosity (cSt) 9.792 6.891

Heat of vaporization

(kJ/kg)

305 840

Specific heat (kJ/kgK)

liquid

2.4 1.7

Specific heat (kJ/kgK)

vapour

2.5 1.93

Lower heating value 44000 26900

Stoichiometric air-fuel

ratio by mass

14.6 9

Research octane

number

92 108.6

Motor octane number 85 89.7

Enthalphy of formation

(MJ/kmol)

liquid

259.28 224.10

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

632

4 RESEARCH RESULT

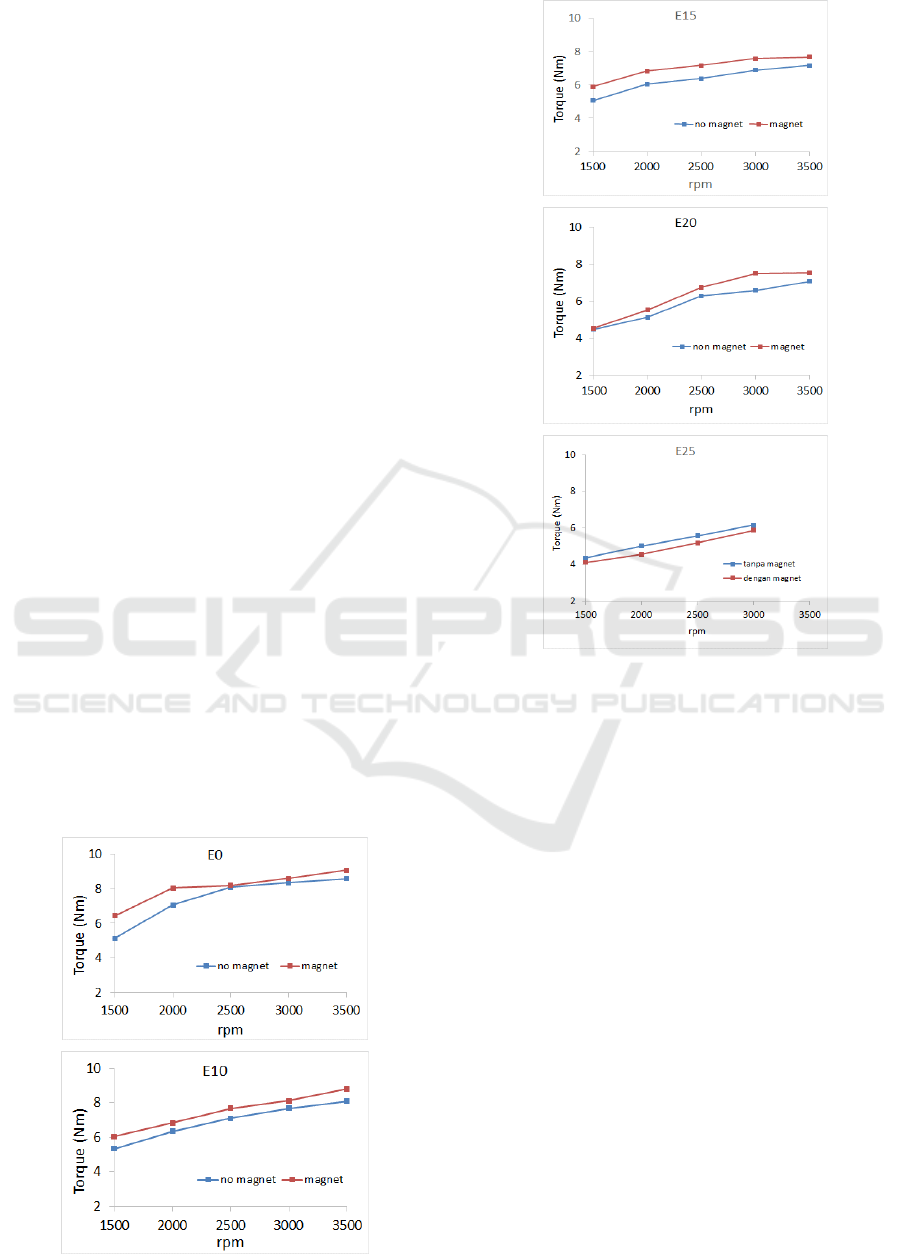

Figure 2 presents a graph of the relationship between

torque and engine torque, it appears that the increase

in torque is proportional to the increase in engine

speed until it reaches the maximum value so that the

amount of fuel entering the combustion chamber

increases as a result of which the fuel energy is

converted into the mechanical energy (torque)

generated through the combustion process is getting

bigger. After reaching the maximum value, the

torque produced by the engine decreases because the

time available for combustion at high rpm is very

short. However, in the graph above, there is no

visible decrease in torque, this is because the engine

speed has not reached a critical or maximum speed

due to the limited capabilities of the testing

equipment in the laboratory.

The torque generated by the engine with the

magnetized fuel is higher than that of the

unmagnetized fuel. For E0 fuel (100% gasoline)

there is an increase of around 6-15%. For E10 fuel,

the increase in torque is around 5-11%, for E15 fuel,

the torque increase is around 6-12%, for E20 fuel,

the torque increase is around 5-10%. The increase in

torque due to fuel magnetization is due to the

magnetic field affecting the molecular structure of

the hydrocarbons contained in the fuel causing the

breakdown of the hydrocarbon chain into smaller

parts or the fuel molecules changing from cluster to

de cluster. In addition, the arrangement of the fuel

atoms is parallel to the direction of the given

external magnetic field or the fuel molecules are

neatly arranged, so that it will be easier to react with

oxygen obtained from the outside air and produce a

more complete combustion. Complete combustion

will result in increased torque.

Figure 2: Torque testing result: a – E0; b – E10; c – E15;

d – E20, e – E25.

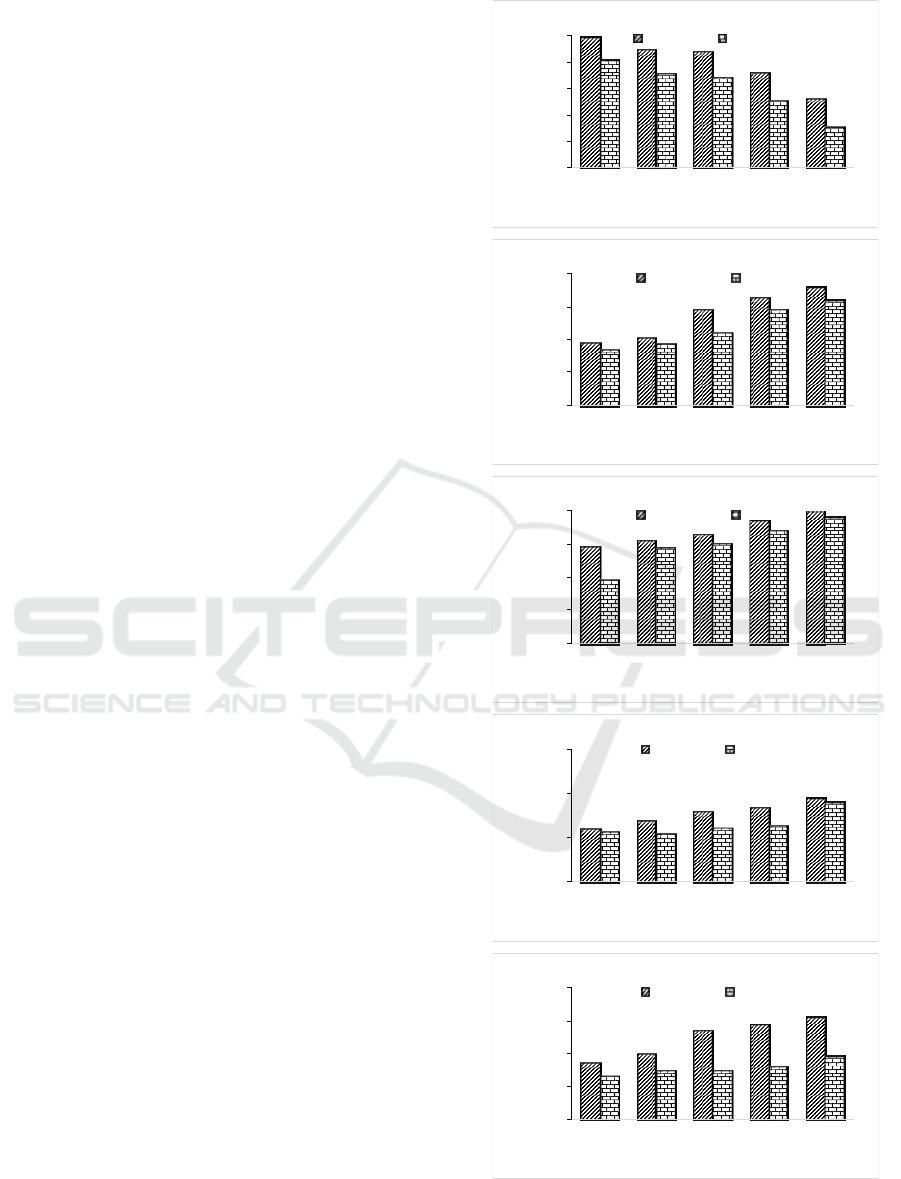

Figure 3 presents a graph of the relationship

between power and engine torque, it appears that the

increase in power is proportional to the increase in

engine speed until it reaches the maximum value so

that the amount of fuel that enters the combustion

chamber increases as a result of which the fuel

energy is converted into The mechanical energy

(power) produced through the combustion process is

greater. After reaching the maximum value, the

power produced by the engine decreases because the

time available for combustion at high rpm is very

short. However, in the graph above, there is no

visible decrease in power, this is because the engine

speed has not reached a critical or maximum speed

due to the limited capabilities of the testing

equipment in the laboratory. Figure 3 shows the

power generated by an engine with a magnetized

fuel being higher than that of an unmagnetized fuel.

For E0 fuel (100% gasoline) there is an increase in

power ranging from 8-17%. The increase in E10 fuel

is around 6-10%, E15 fuel increases in power by 5-

13%, and E20 fuel has an increase in power of 5 -

10%.

The Effect of Magnetic Intensity on the Characteristics of a Mixed LPG and Gasoline + Bioethanol Engine

633

2

4

6

8

10

1500 2000 2500 3000 3500

Power (HP)

rpm

E20

tanpa magnet dengan magnet

Figure 3: Power testing result: a – E0; b – E10; c – E15;

d – E20.

The increase in power due to fuel magnetization is

due to the magnetic field affecting the molecular

structure of the hydrocarbons contained in the fuel

causing the breakdown of the hydrocarbon chain into

smaller parts or the fuel molecule changing from

cluster to de cluster. In addition, the arrangement of

the fuel atoms is parallel to the direction of the given

external magnetic field or the fuel molecules are

neatly arranged, so that it will be easier to react with

oxygen obtained from the outside air and produce a

more complete combustion.

0

200

400

600

800

1000

1200

1500 2000 2500 3000 3500

HC (ppm)

RPM

LPG

tanpa magnet magnet

0

200

400

600

800

1000

1200

1500 2000 2500 3000 3500

HC (ppm)

RPM

E0

tanpa magnet magnet

0

200

400

600

800

1000

1200

1500 2000 2500 3000 3500

HC (ppm)

RPM

E10

no magnet magnet

0

200

400

600

800

1000

1200

1500 2000 2500 3000 3500

HC (ppm)

RPM

E15

no magnet magnet

0

200

400

600

800

1500 2000 2500 3000 3500

HC (ppm)

RPM

E20

no magnet magnet

Figure 4: Emission HC testing result: a – LNG; b – E0;

c – E10; d – E15; e – E20.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

634

Complete combustion will result in increased

torque. Based on the description above, the largest

increase in torque is experienced by gasoline fuel

compared to other fuels mixed with bioethanol,

considering that bioethanol has lower energy than

gasoline, however, bioethanol has a higher octane

value than gasoline, while a mixture of gasoline and

Bioethanol which experienced the largest increase

was E15, the same as torque.We strongly encourage

authors to use this document for the preparation of

the camera-ready. Please follow the instructions

closely in order to make the volume look as uniform

as possible (Lee and Park, 2020).

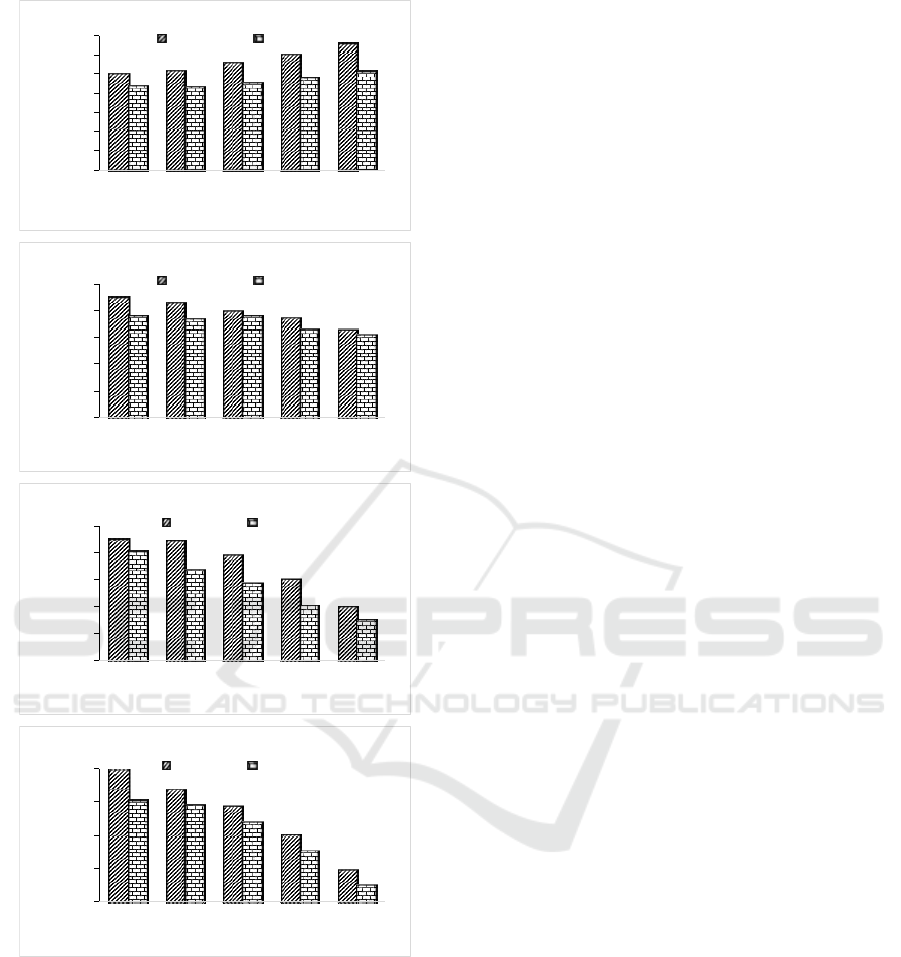

Figure 4 shows the results of the HC emission

test, it appears that the HC value in an LPG-fueled

engine is smaller than that of gasoline. This is

because LPG is an environmentally friendly gas and

the difference is around 9.43-22.04%. On the other

hand, an LPG-fueled engine when compared to a

mixture of gasoline and bioethanol, the HC level is

lower in a mixture of gasoline + bioethanol, this is

because the molecular bonds of bioethanol contain

oxygen which causes the combustion to become

more complete so that HC exhaust emissions are

reduced, the difference is around 22-46 %. The

higher the bioethanol content, the lower the HC

emission level. Likewise, if the fuel, either LPG,

gasoline or bioethanol, is passed through a magnetic

field, the HC content will be even smaller, this is

due to the cluster-decluster effect which is reduced

by up to 47%.

Air consists of 80% by volume of nitrogen and

20% by volume of oxygen. At room temperature,

there is little tendency for nitrogen and oxygen to

react with each other. Nitrogen contained in the

combustion air can be oxidized and form toxic NOx,

if the combustion process occurs at a high enough

temperature.

Figure 5. Showing the results of the NOx emission

test, it appears that the NOx value in the LPG-fueled

engine is smaller than that of gasoline. This is because

LPG is an environmentally friendly gas and the

difference is around 10-34%. On the other hand, an

LPG-fueled engine when compared to a mixture of

gasoline and bioethanol, the NOx level is lower in a

gasoline + bioethanol mixture, this is because the

molecular bonds of bioethanol contain oxygen which

causes the combustion to become more complete so

that NOx exhaust emissions are reduced, the diffe-

rence is around 9-24 %. The higher the bioethanol

content, the lower the NOx emission level. Likewise,

if this fuel is passed through a magnetic field, the

NOx content will be even smaller, this is due to the

cluster-decluster effect, which reduces to 44.61%.

0

200

400

600

800

1000

1500 2000 2500 3000 3500

CO (ppm)

RPM

E10

no magnet magnet

0

100

200

300

400

1500 2000 2500 3000 3500

NOx (ppm)

RPM

LPG

tanpa magnet magnet

0

100

200

300

400

1500 2000 2500 3000 3500

NOx (ppm)

RPM

E0

tanpa magnet magnet

0

100

200

300

1500 2000 2500 3000 3500

NOx (ppm)

RPM

E20

no magnet magnet

0

100

200

300

400

1500 2000 2500 3000 3500

NOx (ppm)

RPM

E10

no magnet magnet

Figure 5: Emission NOx testing result: a – LNG; b – E0;

c – E10; d – E15; e – E20.

The Effect of Magnetic Intensity on the Characteristics of a Mixed LPG and Gasoline + Bioethanol Engine

635

0

500

1000

1500

2000

2500

3000

3500

1500 2000 2500 3000 3500

CO (ppm)

RPM

LPG

tanpa magnet magnet

0

1000

2000

3000

4000

5000

1500 2000 2500 3000 3500

CO (ppm)

RPM

E0

tanpa magnet magnet

0

200

400

600

800

1000

1500 2000 2500 3000 3500

CO (ppm)

RPM

E15

no magnet magnet

0

200

400

600

800

1500 2000 2500 3000 3500

CO (ppm)

RPM

E20

no magnet magnet

Figure 6: Emission CO testing result: a – LNG; b – E0;

c – E10; d – E15; e – E20.

Figure 6. Showing the results of the CO emission

test, it appears that the value of CO in the LPG-

fueled engine is smaller than that of gasoline. This is

because LPG is an environmentally friendly gas and

the difference is 18-44%. On the other hand, an

LPG-fueled engine when compared to a mixture of

gasoline and bioethanol, the CO content is lower in a

gasoline + bioethanol mixture, this is because the

molecular bonds of bioethanol contain oxygen

which causes the combustion to become more

complete so that CO exhaust emissions are reduced,

the difference is around 6-47 %. The higher the

bioethanol content, the lower the CO emission level.

Likewise, if this fuel is passed through a magnetic

field, the HC content will be even smaller, this is

due to the cluster-decluster effect which is reduced

by up to 62%.

In addition, LPG's carbon-hydrogen ratio is

lower thangasoline and LPG gas state actually burns

more homogeneously mixture. As a result, CO and

HC emissions are reduced. moreover,volumetric

calorific value of LPG is lower than gasoline and

reduced energy supplied contribute to the

reductionNOx emission. In addition, the LPG.

carbon-hydrogen ratio low fuel and LPG in a

gaseous state burns effectively with a more

homogeneous fuel mixture. At low speed, when the

engine speed is increased, NOx Emissions are

gradually increasing for gasoline and LPG due to

increased of the temperature inside the cylinder; On

the other hand, HC and CO. emissions reduced as

high temperatures contribute to combustion process.

On the other hand, at high speed, restrictions in the

air line increased dramatically. This causes a

reduction in of the volumetric efficiency, so that the

combustion temperature reduced due to a decrease in

the air-fuel mixture quantity. As a result, when the

engine speed overtakes the value of speed, NOx

emissions are reduced but HC and CO. emissions

slightly increased.

The magnetic field used in the fuel, gas

emissions reduced to lesser, and the value keeps

decreasing with increasing engine speed as shown

on picture. 5. It is well known that hydrocarbon

molecules is a diamagnetic molecule. So, the

presence of magnets the field on the hydrocarbon

molecule can interfere and affect H-C bond. It can

pull and stretch the bond between molecules, even

though the bonds between the H–C atoms are not

separate from each other. Bond strength will weaken

slightly due to the stretching of the bond so

that,hydrogen and carbon atoms will be more easily

attracted into oxygen in the combustion process

(Sayin Kul and Ciniviz, 2020). Next up, gasoline

fuel is made up of molecules that are bonded to each

other long hydrocarbon chains. For this reaction to

take place simultaneously in the combustion

chamber, the first thing that all you have to do is

break the chemical bonds in the hydrocarbons [16].

Therefore, sparks are needed by spark plugs as a

spark plug external energy source to break chemical

bonds.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

636

5 CONCLUSION

At low to medium speed there is an increase in

torque and power generated by the engine from all

types of mixed fuel tested compared to gasoline fuel.

The greatest torque and power are obtained in mixed

fuels with a percentage of 15% bioethanol. The

performance of gasoline engines (motorcycles) with

a mixture of gasoline-bioethanol fuel (E0, E10, E15,

E20) and being magnetized causes

a. The average engine power increased by 8-16%,

b. Engine torque increased by 5-15%

c. HC emission levels reduced by up to 47%

d. NOx emission levels reduced by up to 44 .61%

e. CO emission levels reduced by up to 62%

REFERENCES

Cetin, M. (2011) ‘The emission of characteristics LPG

ethanol blend as a fuel in a SI Engine’, Energy

Education Science and Technology Part A: Energy

Science and Research, 28(1), pp. 151–160.

Dhande, D. Y., Sinaga, N. and Dahe, K. B. (2021) ‘Study

on combustion, performance and exhaust emissions of

bioethanol-gasoline blended spark ignition engine’,

Heliyon. Elsevier Ltd, 7(3), p. e06380. doi:

10.1016/j.heliyon.2021.e06380.

Duc, K. N. and Duy, V. N. (2018) ‘Study on performance

enhancement and emission reduction of used fuel-

injected motorcycles using bi-fuel gasoline-LPG’,

Energy for Sustainable Development. International

Energy Initiative, 43, pp. 60–67. doi: 10.1016/j.esd.20

17.12.005.

Lee, Z. and Park, S. (2020) ‘Particulate and gaseous

emissions from a direct-injection spark ignition engine

fueled with bioethanol and gasoline blends at ultra-

high injection pressure’, Renewable Energy. Elsevier

B.V., 149, pp. 80–90. doi: 10.1016/j.renene.2019.12.0

50.

Musthafa, M. M. (2019) ‘A comparative study on coated

and uncoated diesel engine performance and emissions

running on dual fuel (LPG – biodiesel) with and

without additive’, Industrial Crops and Products.

Elsevier, 128(x), pp. 194–198. doi: 10.1016/j.ind

crop.2018.11.012.

Nibin, M., Raj, J. B. and Geo, V. E. (2021) ‘Experimental

studies to improve the performance, emission and

combustion characteristics of wheat germ oil fuelled

CI engine using bioethanol injection in PCCI mode’,

Fuel. Elsevier Ltd, 285(June 2020), p. 119196. doi:

10.1016/j.fuel.2020.119196.

Sayin Kul, B. and Ciniviz, M. (2020) ‘Assessment of

waste bread bioethanol-gasoline blends in respect to

combustion analysis, engine performance and exhaust

emissions of a SI engine’, Fuel. Elsevier, 277(May), p.

118237. doi: 10.1016/j.fuel.2020.118237.

Silitonga, A. S. et al. (2018) ‘Evaluation of the engine

performance and exhaust emissions of biodiesel-

bioethanol-diesel blends using kernel-based extreme

learning machine’, Energy. Elsevier Ltd, 159, pp.

1075–1087. doi: 10.1016/j.energy.2018.06.202.

TH. Nufus, R. P. A. Setiawan, W. Hermawan, A. H. T.

(2017) ‘The Effect Of Electro Magnetic Field Intensity

To Biodiesel Characteristics’, Jurnal Pendidikan

Fisika Indonesia, 13(2), pp. 79–87. doi: 10.15294/jp

fi.v13i2.10152.

TH Nufus et al. (2020) ‘Two wheeled vehicles E20 fuel

magnetization study on exhaust gas emissions’,

International Journal of Mechanical and Production

Engineering Research and Development, 10(2), pp.

201–212. doi: 10.24247/ijmperdapr20218.

Vinoth, T. et al. (2017) ‘Experimental Investigation on

LPG + Diesel Fuelled Engine with DEE Ignition

Improver’, Materials Today: Proceedings. Elsevier

Ltd, 4(8), pp. 9126–9132. doi: 10.1016/j.matpr.20

17.07.268.

The Effect of Magnetic Intensity on the Characteristics of a Mixed LPG and Gasoline + Bioethanol Engine

637