Performance of the Prototype Furnace Evaporator with PLC Control

Tossin Alamsyah

1

, Bagas Aji Rotama

2

, Eri Catur Rahmad

2

and Muhammad Mukhbi

2

1

Lecturer of Applied Electrical Engineering Magister Program, Politeknik Negeri Jakarta, Indonesia

2

Electronic Engineering Study Program, Department of Electrical Engineering Politeknik Negeri Jakarta, Indonesia

Keywords: Furnace, Evaporator, Heater, Programmable Logic Controlled (PLC).

Abstract: Furnace Evaporator (FE) is an instrument that has two (2) functions as a furnace and evaporation, in an effort

to increase the capacity of the material both activities are needed. The Furnace Evaporator was first patented

by Pierce, James Louis, in 1917, using an energy source from gas, used for processing natural materials. This

Furnace Evaporator (FE) is designed to use a heat energy source (heater) from electricity, to later become a

prototype FE with a working temperature of 50°C-900˚C, and heat control based on Programmable Logic

Control (PLC). The FE prototype has two horizontal and vertical doors, with a combustion chamber area of

about 36 cm3. Prototype has accuracy in generating heat, the temperature value on the HMI monitor screen

when compared to a measuring instrument has a chi square (R2) value of 0.995. Operational testing was

carried out in three (3) conditions, namely when the prototype hood was closed (C1), half closed (C2) and

open (C3), the results had different temperature resolution responses, namely, 2.14 V/s, 1.25 V/ s and 0.83

V/s. If the three parameters are combined, they have a non-linear relationship with a chi square (R2) value of

0.9939, which means that they are significantly related.

1 INTRODUCTION

Furnace is an instrument that has the function of

heating materials / materials with a heater. Furnace

can be used in sintering and calcining processes.

Sintering process is a process of heating the material

not to exceed the melting point in order to improve

the structure and quality of the material. Calcination

is the process of heating solids in the absence or with

very little supply of air or oxygen to carry out thermal

decomposition.

Evaporator is an instrument that functions to

change part or all of a solvent from a solution from a

liquid to a vapor. Evaporators have two basic

principles, to exchange heat and to separate the vapor

formed from the liquid. Furnace Evaporator (EF) is

an instrument that has two (2) functions as a material

furnace and chemical evaporation. This tool was first

patented by Pierce, James Louis, in 1917 with Patent

No. 1,228,240, 1917. This prototype Furnace

Evaporator (FE) is gas-fueled, fuel is injected into the

chamber at the top to form a vortex fire inside. This

Furnace Evaporator (FE) is designed to use a heat

energy source (heater) from AC electricity. heater

used has a capacity of 300°C-1200˚C. This tool is

used as a support in the design of Gas sensors with

Si

(1-x)

Al

(x)

O3 substrates, this tool functions as a

furnace for the calcination process (furnace) and an

evaporator when the chemical liquid process is

evaporated to the sensor cover.. The prototype of the

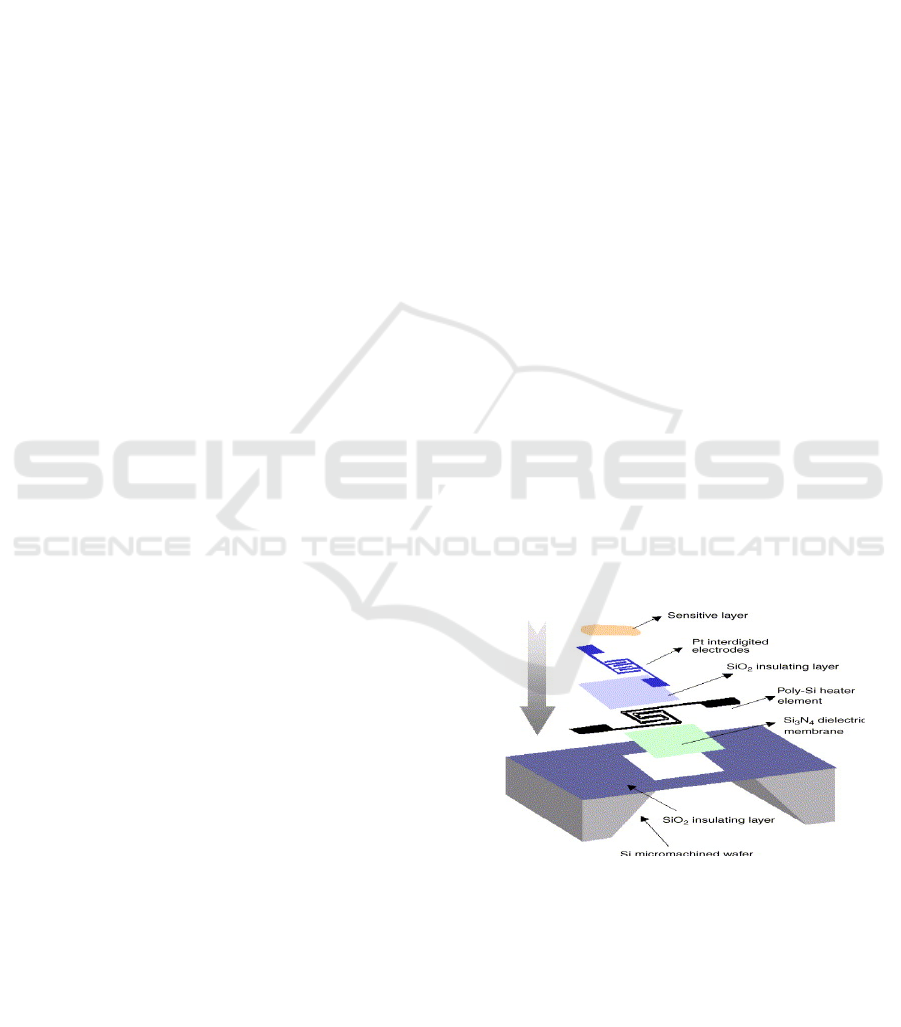

sensor design in question can be shown in Figure 1,

Figure 1: Sensor prototype.

Sensitive layer is a chemical material as a sensor

cover that functions to respond to the gas to be

detected. The evaporation temperature for chemical

liquids ranges from about 90

0

C to 200

0

C, depending

on the melting point.

The higher the heating temperature with the

longer coating time, the thicker the layer thickness on

the sensitive layer (cover sensor). The coating

Alamsyah, T., Rotama, B., Rahmad, E. and Mukhbi, M.

Performance of the Prototype Furnace Evaporator with PLC Control.

DOI: 10.5220/0011861200003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 651-655

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

651

thickness setting can be adjusted based on the rotation

time and speed if the material is placed on a swivel

stand. The results of the study [2] with SnO material

as the sample showed that at a heating temperature

of 100 °C - 200 °C, the thickness of the coating

attached to the substrate ranged from 83.8 to 80.9 nm.

The higher the annealing temperature, the lower the

refractive index of the thin film, that is, at a heating

temperature of 100°C, the refractive index is higher.

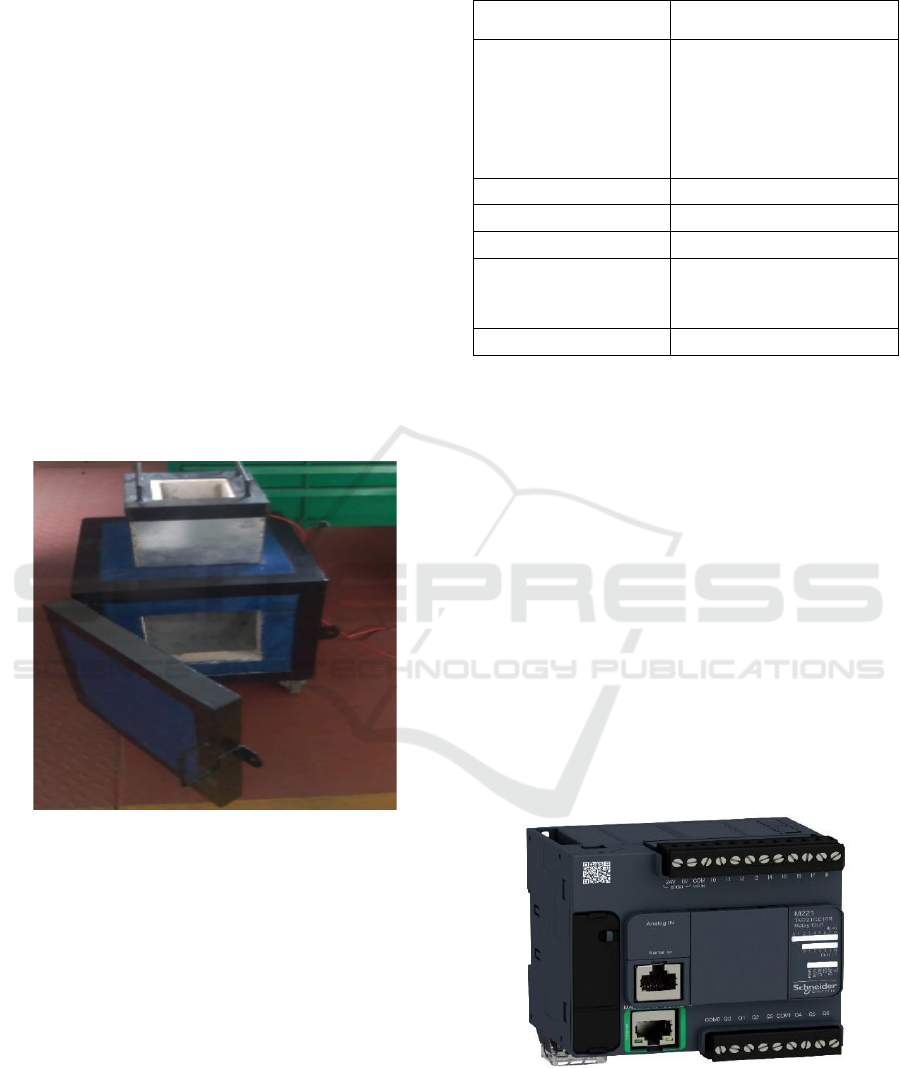

The three (3) dimensional shape of the prototype

Furnace Evaporator (FE) that has been designed can

be shown in Figure 2. There is a hole above it which

is intended to regulate the air in the combustion

chamber inside. The condition of C1 when the hole is

closed, so that the combustion chamber does not

come into contact with the outside air.

The condition of C2 when only a small gap is

given, so that the combustion chamber is in contact

with the air and in the condition of C3, the hole is not

closed, it means that the combustion chamber is in

contact with the outside air.

Figure 2: Photo Furnace Evaporator (FE).

Figure 2 shows a photo Furnace Evaporator (FE),

frame made of steel with walls made of calcite,

refractory brick. Above it is a hole intended to

regulate air when operated or also needed when

cooling. Physical dimensions of 41 cm x 41 cm x 75

cm with a volume of space is 36 cm

3

(30 cm x 30 cm

x 40 cm), the overall weight is about 12.5 Kg.

This tool has several electrical components,

including, Table 1.

Table 1.

Name of Tool Specifications

PLC Modicon

TM221CE16R

16 digital I/O, 2 analog

inputs

1 Serial port, 1 Ethernet

port

220-250 VAC power

suppl

y

, 24 VDC ou

t

Heater 1500 WATT

Solid State Relay 5A

MCB 16 A

Transmitter

Thermocouple

0-16 V

Temperature range -100–

1000 C

NYAF CABLE 2.5 mm, 0.75 mm

2 PLC Modicon TM221CE16R

Programmable Logic Controlled (PLC) used in this

tool is Modicon M221 is one of the products that

issued by Schneider Electric. This M221 PLC can be

programmed using software provided for free by

Schneider Electric, namely SoMachine Basic. PLC

M221 has 16 Digital I/O ie 9 inputs and 7 outputs and

also 2 Analog inputs, with a power supply of 100-240

Vac, with an ethernet port and also some LED

indicators. Figure 3 below shows the physical form of

the TM221CE16R PLC.

This PLC uses SoMachine Basic software, which

is PLC software that is used to configure,

communicate all devices connected to these devices,

including the Human Machine Interface (HMI)

system and networks related to automation functions.

Figure 3: PLC TM221CE16R.

2.1 HMI and SCADA

Vijeo Citect is one of the software used in the

creation, programming, and application software

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

652

SCADAVijeo Citect can be applied to handle various

cases in industries such as wastewater treatment, food

and beverage production, mining, automobile

assembly, metal casting, transportation, aerospace,

defense systems, security, etc.

software consists of four main applications, namely

Vijeo Citect Explorer, Vijeo Citect Project Editor,

Vijeo Citect Graphic Builder, and Vijeo Citect

Runtime.

1) Vijeo City Explorer is an application that is at the

top level of Vijeo Citect applications that

functions in programming and system

configuration. In figure 2.4 is the view of Vijeo

City Explorer which used for:

a) Starting and stopping the Citit Project Editor and

the Citit Graphics Builder.

b) Selecting and managing Projects

c) Create projects, delete, backup and restore

projects

d) Run other applications, such as Cicode Editor.

e) Explore and access the components of the

software being worked on.

2) Configuring Software Vijeo Citect

Before creating a layout in the software, it is

necessary to set up or initialize the project to be

created. The things that must be set are clusters and

servers, communication parameters, variable tags,

trend tags, IO devices, alarms, roles and users. All

these settings are done using the Vijeo City Project

Editor software. However, for Vijeo Citect Version

7.5, the only parameter that must be configured is the

IO Device. The other parameters are already

configured (default from Citit). However, if you use

a client and server network system, it needs to be

reconfigured.

3 METHODOLOGY

This applied research uses experimental methods,

designs and builds to produce a prototype. The level

of Technology Readiness is at levels 5 and 6, namely.

The validation, Prototype and or a collection of

Prototype in the relevant environment and

Demonstration of System/Subsystem Models or

Prototypes in the relevant environment.

Planning and design is carried out at the Electrical

Engineering Laboratory of the Politeknik Negeri

Jakarta and some mechanical work is carried out in a

private mechanic workshop around Depok.

Some of the materials needed are as follows;

a) Input Prototype;

Thermocouple Sensors and Transmitters,

b) the Output Prototype;

Heater and some Relay Contacts Multiple

Indicator Lights.

c) Control Prototype,

PLC Modicon TM221CE16R With

specifications of 16 digital I/O, 2 analog inputs

1 Serial port, 1 Ethernet port 220-250 VAC

power supply, 24 VDC out

4 RESULTS AND DISCUSSION

Results Thermocouple sensor readings from the FE

combustion chamber are sent to the transmitter to be

amplified voltage as input from PLC (Programmable

Logic Controlled). Furthermore, this data will be

changed by the PLC into BCD and processed by the

PLC program to control the Actuator (Heater),

through Solid State Relay (SSR).

The control and monitoring system uses

HMI/SCADA with the Vijeo City Project Editor

software. The connection from the FE Module to the

Laftop as a monitor uses from a PLC using TCP/IP

communication, which is connected by an Ethernet

cable. Some of the tests carried out were

a) Measurement of the EF prototype Thermocouple

and Display in Monitor.

To take measurements, it is necessary to prepare

this thermocouple which has been added a meter to

measure temperature, in the EF Prototype combustion

chamber. Then the results are compared with the

readings on the HMI, which are displayed on the

laptop/PC.

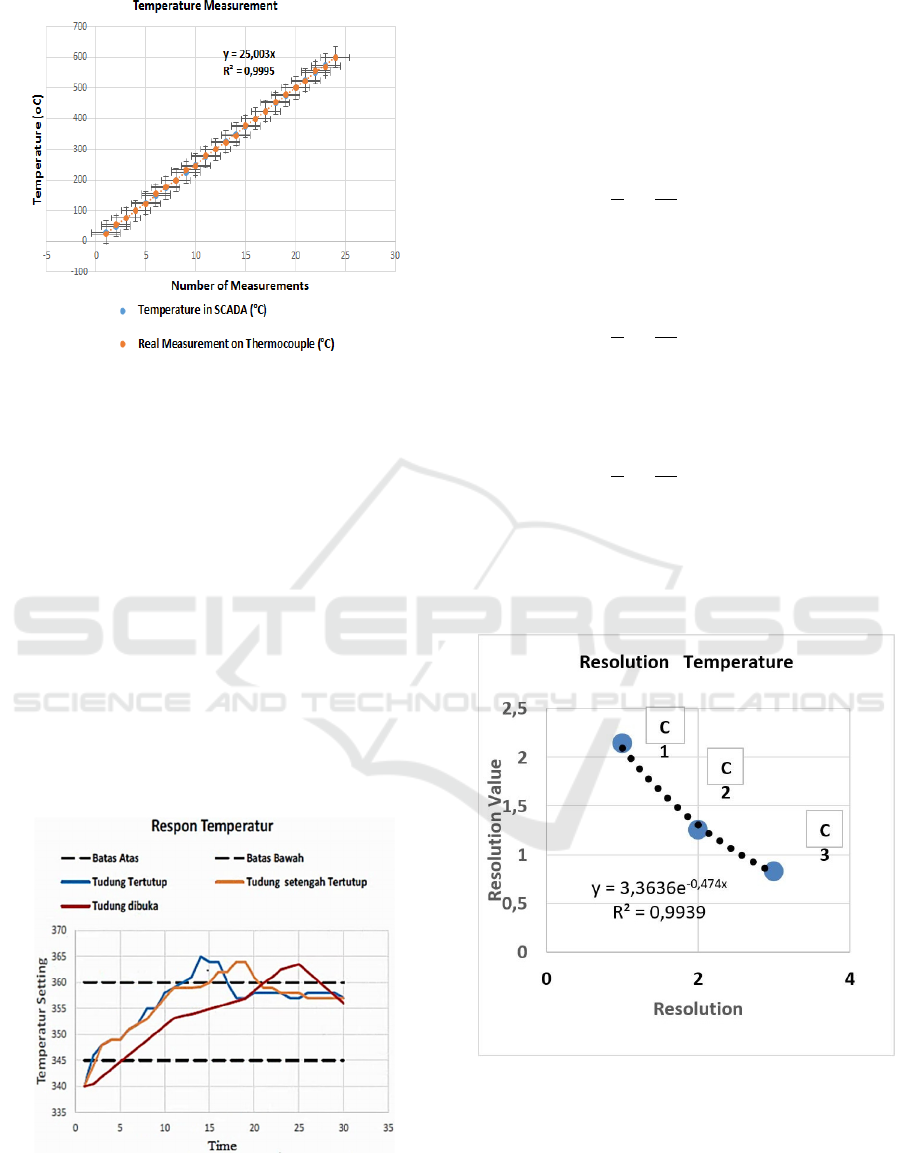

The results can be shown in the diagram shown in

Figure 4, below.

From the picture, the readings on the HMI / Scada

are almost the same as the readings with a

temperature meter using a thermocouple in Figure 4.

From the picture, the readings on the HMI / Scada

are almost the same as the readings with a

temperature meter using a thermocouple.

Notation R2 is useful for testing the relationship

or effect of two nominal variables and measuring the

strength of the relationship between one variable and

another nominal variable (C = Coefficient of

contingency). From the explanation and the R2 ;

0.9995

, it shows that the generated by this EF

Prototype can be stated as accurate and reliable.

Performance of the Prototype Furnace Evaporator with PLC Control

653

Figure 4: Temperature measurement.

b) EF Prototype Responsive Testing.

There are three (3) patterns in this test, namely;

The first test when the hood of the EF prototype is

closed. This test is intended so that the combustion

chamber does not come into contact with air, in this

condition the EF Prototype is used as a Furnace for

Calcination activities. The second and third

conditions are when the hood is half opened and fully

opened.

The temperature on the EF set at a lower

temperature of 345

o

C and an upper temperature limit

of 360

o

C. The Prototype's Temperature Response will

work between these temperatures. Then in the

observed conditions the response of temperature to

the increase in time (in second) is /∆𝑡 , when the hood

is closed, half opened and opened. Figure 5, shows

the EF performance for the three conditions.

Figure 5: EF Temperature Response for the three

conditions.

The diagram above shows a comparison of

performance responses when the hood is closed (C1),

half closed (C2) and open (C3).

EF Temperature Response when the hood is

closed (C1), thus the combustion chamber is not in

contact with outside air,

S or Resolution can be stated (R1)

𝑅1

𝑉

𝑡

15

7

2.14 𝑉/𝑠

(1)

Then for Temperature Response when the hood is

opened halfway (C2) has a resolution or temperature

response (R2) of;

𝑅2

𝑉

𝑡

15

12

1.25 𝑉/𝑠

(2)

Then for the Temperature Response when the

hood is fully opened (C3) has a resolution or

temperature response (R3) of:

𝑅3

𝑉

𝑡

15

18

0.83 𝑉/𝑠

(3)

Figure 6 shows a diagram of the Temperature

Resolution value for the three conditions, if the three

conditions are connected to each other then it has a

non-linear relationship with the chi square value

(

)

R2of 0.9939.

Figure 6: Temperature Resolution.

5 CONCLUSION

From the results of the discussion it can be concluded

that;

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

654

The prototype Furnace Evaporator (FE) which is

designed to have an accuracy in generating heat,

displays the temperature value on the HMI monitor

screen (laftpo) when compared to a measuring

instrument with a Thermocouple meter with a chi

square value (R2

)

of 0.995. The test was carried out

under three (3) conditions, namely when the

prototype hood was closed (C1), half closed (C2) and

open (C3). The three have different temperature

resolution responses, namely, 2.14 V/s, 1.25 V/s and

0.83 V/s. If the three parameters of the Temperature

Resolution Response are connected, all three have a

non-linear relationship with the chi square value (R

2

)

0.9939 which means it has a significant relationship.

ACKNOWLEDGMENTS

We would like to thank the Director of DRPM

Kemenristek Dikti, who has provided this Higher

Education Excellence Research grant (PUPT).

REFERENCES

Woolley, WJ (1951).US Patent No. 2,557,042.

Washington, DC: US Patent and Trademark Office.

Qina Sun a , Jun Hu a , Jianlong Wang a,b,*, 2014

“Optimization of composite admixtures used in

cementation formula for radioactive evaporator

concentrates.” a Laboratory of Environmental

Technology, INET, Tsinghua University, Beijing

100084, China b Key Laboratory of Advanced Reactor

Engineering and Safety, Ministry of Education,

Tsinghua University, Beijing 100084, China. journal

homepage: www.elsevier.com/locate/pnucene

Jong-Soo Leea , et all , 2003, “ZnO nanomaterials

synthesized from thermal evaporation of ball-milled

ZnO powders” a Department of Electrical Engineering,

Korea University, Seoul 136-701, South Korea bSeoul

Branch, Korea Basic Science Institute, Korea

University Campus, Seoul 136-701, South Korea c

Department of Electronics Engineering, Korea

University, Seoul 136-701, South Korea

dRadioisotopes and Radiation Application Research

Team, Korea Atomic Energy Research Institute,

Taegeon 305-353, South Korea, Journal of Crystal

Growth 254 (2003) 423–431

Grassi, E., & Tsakalis, K. (2000). PID controller tuning by

frequency loop-shaping: application to diffusion

furnace temperature control.IEEE Transactions on

Control Systems Technology,8(5), 842-847.

YV Pavan Kumar, Arvapalli Rajesh, Sadhu Yugandhar,

Viswaraju Srikanth, 2013 “Cascaded PID Controller

Design for Heating Furnace Temperature Control”,

IOSR Journal of Electronics and Communication

Engineering (IOSR-JECE) e-ISSN: 2278-2834,p-

ISSN: 2278-8735.Volume 5, Issue 3 (Mar. - Apr. 2013),

PP 76-83 www.iosrjournals.org

Zenghuan Liu Likong L, Lu Wen Guangxiang He, 2009”

Analysis of Heating Furnace Temperature Control

System Based on Expert Fuzzy Control”, 2009

International Conference on Measuring Technology

and Mechatronics Automation

Wiranto, G., Idayanti, N., Tayubi, YR, & Batara, DS

(2016). Design and Fabrication of Low Cost Thick Film

pH Sensor using Silver Chlorinated Reference

Electrodes with Integrated Temperature Sensor.

InMATEC Web of Conferences(Vol. 40, p. 01001).

EDP Sciences.

Zola, M., Cahyadi, L., & Alamsyah, AT (2018). Cooler Box

With Thermoelectric Cooler With Labview And Iot

Based Temperature Monitoring.Journal of Poly-

Technology,17(2).

Yulianto, T., Alamsyah, T., & Rusadi, B. (2018). Design of

Batch System Investigation Software based on Visual

Studio.ISSN 2302-786X, 77.

Nugraha Heri. 2016. Design of Computer Based Laboratory

Furnace Temperature Monitoring System.

Metallurgical research center-LIPI, Puspitek area Gd.

470 Serpong, Tangerang 15314 Indonesia.

https://www.researchgate.net/publica- tion/269098450.

Susprastiyo Haris, et al. 2017. Manufacture Electric

Furnace of Microcontroller-BasedMuhammadiyah

University of Sidoarjo. https://ojs.umsida.ac.id/

index.php/re m [

Tossin Alamsyah, et al, 2019 " Extraction of Local Mining

Materials, especially silicate sand (sillicond sand) as

substrate material on Gas Sensors and Their

Derivatives” PUPT Research Report First Year P3M

Politeknik Negeri Jakarta.

Performance of the Prototype Furnace Evaporator with PLC Control

655