Implementation of Particle Swarm Optimization (PSO) Method in

Minimum Quantity Lubrication (MQL) Optimization to Obtain

Optimal Machining in CNC Milling Machine

Yogi Muldani Hendrawan, Faza Husnan Anshori, Andri Pratama, Herman Budi Harja, Pandoe

and Akil Priyamanggala Danadibrata

Department of Manufacturing Engineering, Manufacturing Polytechnic Bandung, Jalan Kanayakan No. 21, Dago,

Coblong, Bandung, 40135, Indonesia

herman@polman-bandung.ac.id, pandoe@polman-bandung.ac.id, akil_pd@polman-bandung.ac.id

Keywords: Minimum Quantity Lubricant, Particle Swarm Optimization, CNC Milling Machine, ISO 14001, Regression.

Abstract: One of the machining processes used is the milling process with CNC milling machines equipped with cutting

fluid to reduce the impact of the cutting process. One of the techniques of cutting fluid is to use MQL

(Minimum Quantity Lubricant) as an application of ISO 140001 in reducing coolant waste in the environment

which has the advantage of being more economical in reducing friction between the tool and the workpiece,

thereby reducing the temperature rate in the cutting tool. The CNC tool machine of Politeknik Manufaktur

Bandung is equipped with MQL (Minimum Quantity Lubricant) with Arduino control which has no

parameters for optimum coolant discharge during the machining process.

In this study, the Particle Swarm Optimization (PSO) method was used, which is one of the optimization

methods for making decisions used in the manufacturing process by looking for a minimum value. There

sulting from the milling process becomes a response in the process on CNC milling machines to obtain the

characteristics of an effective discharged lubricant discharge. Some parameters such as cutting depth and

feeding speed for aluminum and steel materials St37 were identified as experimental data for response. The

data was searched for equations with regression, so in this study a polynomial regression model was chosen

that could describe the data value better than linear regression.

Polynomial equations are calculated with the Particle Swarm Optimization (PSO) algorithm to find the

optimum flowrate. So that the minimum discharge obtained on aluminum material for a feeding depth of less

than 0.85 mm is 25ml/h, and more than 0.85mm is 85ml/h. while for St.37 material the feeding depth of less

than 0.35 mm is 25ml/h, and more than 0.35mm is 85ml/h.

1 INTRODUCTION

One of the machine tools that uses automation

systems that are commonly used by industry today is

CNC (Computer Numerical Control) machines. In the

machining process, it cannot be separated from the

use of coolant or coolant to clean and cool the

workpiece and cutting tools. Related to

environmental issues regulated in ISO 140001 on

recommendations for reducing coolant waste in the

machining process. Therefore, a method is needed by

using a coolant that is as minimal as possible with

more environmentally friendly materials. One of the

methods used is minimum quantity lubricant (MQL).

Related to environmental issues regulated in ISO

140001 on recommendations for reducing coolant

waste in the machining process. Therefore, a method

is needed by using a coolant that is as minimal as

possible with more environmentally friendly

materials. One of the methods used is minimum

quantity lubricant (MQL).

Be advised The development of POLMAN CNC

machine tools already has a cooling system by

installing a minimum quantity lubricant (MQL)

method cooling system with Arduino control on a

MINI CNC Milling machine made by POLMAN.

However, the Minimum Quantity Lubricant (MQL)

does not yet have an optimum discharge. The Particle

Swarm Optimization (PSO) method is used as one of

the optimization algorithms that can solve complex

optimization problems if solved in an exact manner.

Hendrawan, Y., Anshori, F., Pratama, A., Harja, H., Pandoe, . and Danadibrata, A.

Implementation of Particle Swarm Optimization (PSO) Method in Minimum Quantity Lubrication (MQL) Optimization to Obtain Optimal Machining in CNC Milling Machine.

DOI: 10.5220/0011891500003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 821-827

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

821

2 THEORY AND RESEARCH

METHODS

The machining process is the process of removing

material parts (removal of material) with the help of

cutting tools on the machine. The machining process

aims to achieve the desired. geometry, size, surface

smoothness, and function of the workpiece in the

process.

The principle of the machining process is that the

part of the workpiece that is not needed will be

removed by means of a cutting process using a cutting

tool with a rotating or shifting motion. Here are the

five elements of the machining process, namely

(Rochim, 1993):

1) cutting speed: v (m/min);

2) feeding speed: vf (mm/min);

3) depth of cut: 𝑎 (mm);

4) cutting time: tc (min);

5) rate of metal removal: z (cm3 /min);

2.1 Wet Machining

Figure 1: Wet machining.

Wet machining method is the use of coolant in the

machining process aimed at cooling the cutting tool

used. According to how coolant is given to the Wet

Machining method, it can be divided into three types

of cooling processes, namely: flooded to the

workpiece (Flood application), sprayed (Jet

application fluid) and atomized (Mist application

fluid).

The use of this many coolants in the machining

process can accelerate the rate of cooling that occurs.

With the material studied is the steel type AISI 422

states that, for wet engine temperatures are in the

range of 26-30 °C, which is the temperature spreading

throughout the cutting surface with pressure from the

engine pump, and absorbing the temperature from the

tool, workpiece and furious (Glanis, 2008). In this

study, synthetic fluids were used, synthetic fluids

consisted of a mixture of organic and inorganic

alkaline materials and added with additives to ward

off corrosion. This liquid has the best cooling

capacity when compared to other coolants.

2.1.1 Minimum Quantity Lubrication

Minimum quantity lubrication (MQL), using a very

small amount of liquid for the machinery process in

the form of an aerosol formed from a mixture of

coolant and air using a venturi working insert. The

pressure difference between the air pressure channel

in and output through the nozzle is lower pressed so

that the coolant enters the mist lubrication spray

system.

MQL has two types of coolant supply, namely

External MQL Supply and Internal MQL Supply. The

application of MQL although the provision of a

minimum coolant but is able to produce better tool

life, better surface finish, better furious shape,

reduced cutting power and on the workpiece, cutting

tools and parts affected by the coolant will provide

resistance to oxidation, providing environmental

friendliness

Minimum quantity lubrication (MQL) is a total-

loss lubrication method, which means using new and

clean lubricants only one-time use. But as a general

rule, 25-85 ml / hour on a cutting tool less than 40 mm

in diameter,

2.2 Particle Swarm Optimization

(PSO)

The PSO algorithm was invented by Kennedy and

Eberhart in 1995, mimicking the behavior of a flock

of seagulls that fly together to forage or nest. Pso

algorithms can easily reach global and optimal points

because of their ease of application to solve problems

and have consistent performance, so that PSO

algorithms are good and effective for solving

optimization problems.

The PSO algorithm, birds are represented as

"particles", where each particle represents a possible

solution to an optimization problem. The word

"particle" denotes an individual, where each

individual is connected using their own intelligence

(Intellegence) and influences the behavior of their

group. Thus, if one of the particles finds the fastest

Figure 2: Minimum quantity lubrication type.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

822

and right path to the food source then the rest of the

other group can immediately follow the path even

though the location of the member is far from the

group.

2.2.1 PSO Algorithm Structure

There are several components in the PSO Algorithm

including the following:

1. Swarm, which is the number of particles in

a population in an algorithm. The size of the

swarm depends on how complex the

problem is. In general, the swarm size in

PSO algorithms tends to be smaller

2. Particle, is an individual in a swarm that

represents the solution of solving a

problem. Each particle has a position and

speed determined by the representation of

the solution at that moment.

3. Personal best (pbest), is the best position

that a particle has ever achieved by

comparing fitness in the current particle

position with before. Personal best is

prepared to get the best solution.

4. Global Best (gbest), is the best position of

particles obtained by comparing the best

fitness values of all particles in the swarm.

5. Velocity (velocity), v is a vector that

determines the direction of displacement of

the particle's position. Velocity changes are

made each iteration with the aim of

correcting the original particle position.

6. Inertial weight (inertia weight), w is used to

control the impact of the velocity change

given by the particle.

7. Acceleration coefficient, is the controlling

factor of the extent to which particles move

in one iteration. In general, the values of the

acceleration coefficients c1 and c2 are the

same, namely in the range of 0 to 4.

Nevertheless, the value can be determined

by yourself for each different study

2.3 Mathematical Equations with

Regression

The term regression according to statisticians applied

to almost all areas of science, to estimate or foresee

the value of one variable based on another variable

whose value has been known, and both variables have

a functional or causal relationship with one another.

Before creating a regression equation it is necessary

to determine the form of the data distribution. So it is

better to make it in a scatter diagram or scatter

diagram and then look at the regression equation that

is closest based on the number of data distribution so

that the deviation that occurs can be as small as

possible.

There are two types of regression sought in this

study:

Multiple linear regression equation

𝑌̂ = 𝑏0 + 𝑏1 𝑋1 + 𝑏2 𝑋2

(1)

Ý = function value (bound variable)

b0 = constant value

b1 = partial regression coefficient of X1 b2 = coefisen

partial regression of X2

Polynomial regression equation

𝑌 = 𝑎 + 𝑏𝑋 + 𝑐𝑋2 (2)

Y = function value (bound variable) a = constant

value

b = the value of the coefficient constant X c =

coefficient constant value X2

X = free variable value

In this study the search for regression equations was

carried out with the help of matlab software and IBM

SPSS.

2.3.1 Normality Test

Parametric statistical analysis is an analysis used to

test population parameters through statistical analysis

or test population size through sample data. In order

for the data to be tested for parametric analysis, it is

required that the data must be normally distributed

(Widana,2020).

Figure 3: Normal distribution chart.

A data will form a normal distribution curve with

the shape of the bottom open curve or resemble a bell

with two parameters, namely average and standard

deviation. The shape of the normal distribution curve

can be seen in the figure below:

Normality tests can also be performed by plotting

probability plots. Where a data in the regression

model is said to be normal if the plotting data (dots)

depicting the actual data follows a diagonal line

(Widana,2020).

Implementation of Particle Swarm Optimization (PSO) Method in Minimum Quantity Lubrication (MQL) Optimization to Obtain Optimal

Machining in CNC Milling Machine

823

2.3.2 T Test (Partial)

Partial tests are used to show how much influence an

independent variable or free variable has on a

dependent variable or bound variable.

Step-by-step in performing partial testing on data

(Nuryadi, 2017):

1.

Determine the significance value of the α (the value

used α = 0.05).

2.

Looking for the calculated value of t

3.

Comparing the calculated t value with t table (α/2

; n-k-1)

If:

Sig value. > α significantly different (no relationship)

Sig value. < α does not differ significantly (there is a

relationship)

t count < t the table differs significantly (there is no

relationship)

t count > t the table does not differ significantly

(there is a relationship)

2.3.3 F Test (ANOVA)

The F test or Analysis Of Variance (ANOVA) is one

of the tests in test statistics used to test the distribution

or variance means in variables simultaneously or

together (Nuryadi, 2017).

Steps in conducting the F Test used (Nuryadi, 2017):

1 Specifies the significance value of the α (the

value used α = 0.05).

2 Looking for the calculated F value.

3 Comparing F count with F Table (k ; n-k) If:

Sig value. > α significantly different (no relationship)

Sig value. < α does not differ significantly (there is a

relationship)

F count < F the table differs significantly (there is no

relationship)

F count > F the table does not differ significantly

(there is a relationship)

2.4 Research Methods

In this study, an experimental method was used,

namely a method by testing the Minimum Quantity

Lubricant (MQL) with quality controlled based on

predetermined parameters. These parameters are

Depth of Cut (DoC), the composition of the lubricant

flowrate, RPM and feeding that have been

determined.

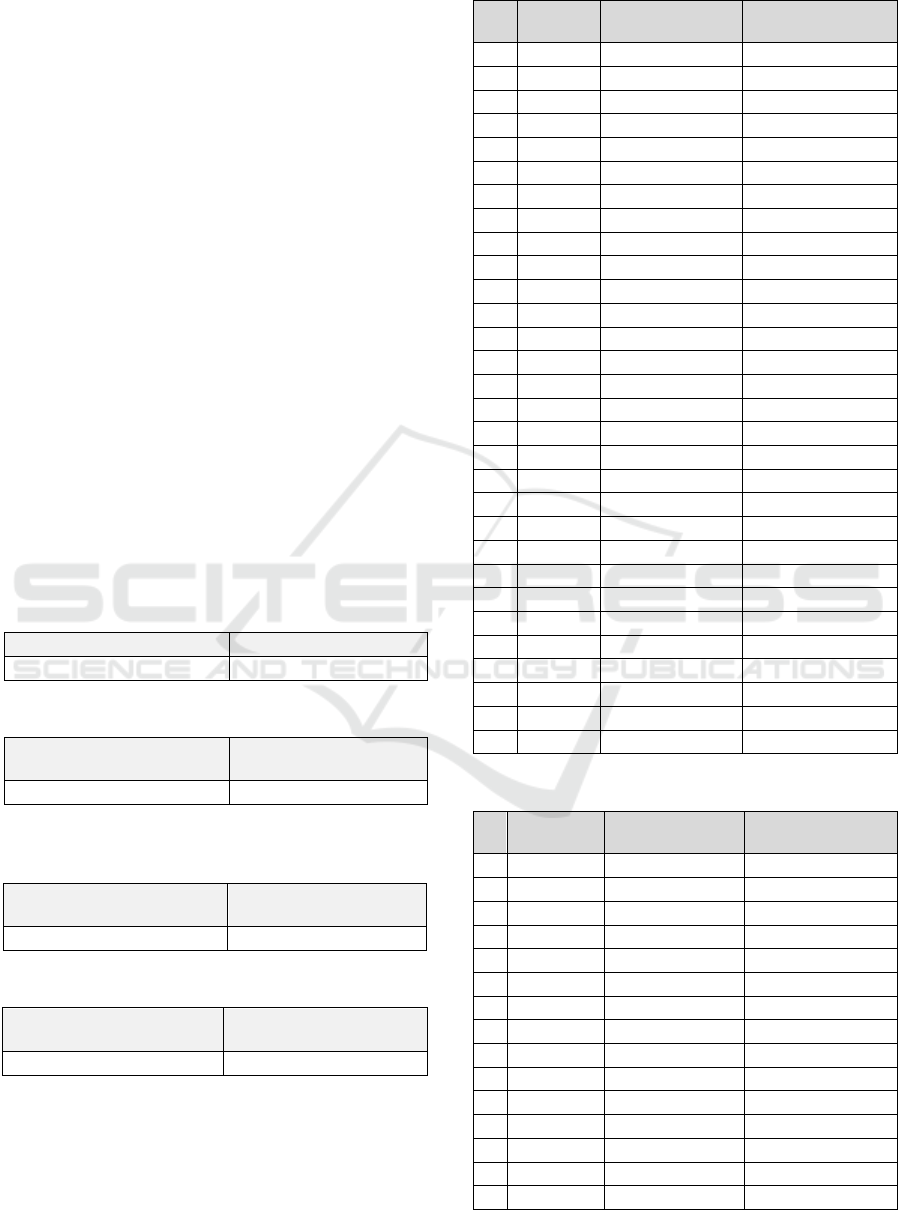

Figure 4: Research method flow chart.

2.4.1 Activity Flowchart

Flowchart planning activities optimization minimum

quantity lubricant on CNC machines, consisting of

pre-research activities, data retrieval, PSO analysis,

and implementation and testing.

2.4.2 Experiment Strategy

Strategic planning in conducting minimum quantity

lubricant (MQL) optimization experiments in

accordance with the selected parameters. The

activities on the experimental strategy can be seen in

the flow chart below:

Figure 5: Experiment strategy flow chart.

2.4.3 Machining Parameters

Here is the determination of the parameters for

aluminum and St.37 materials:

1. Aluminium

Vc aluminium = 80 m/mnt

Feed per teeth= 0.02

𝑅𝑝𝑚 =

1000 𝑥 80

𝜋 𝑥 10

= 2546.47 ≈ 2500 rpm

𝑓𝑒𝑒𝑑𝑖𝑛𝑔(𝑠) = 2500 × 0.02 × 4 = 200 𝑚𝑚/𝑚𝑖𝑛

2. St.37

Vc St.37= 20 m/mnt

Feed per teeth = 0.02

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

824

𝑅𝑝𝑚 =

1000 𝑥 20

𝜋 𝑥 10

= 636.61 ≈ 650 rpm

𝑓𝑒𝑒𝑑𝑖𝑛𝑔(𝑠) = 650 × 0.02 × 4 = 52 𝑚𝑚/𝑚𝑖𝑛

To obtain the data is carried out machining process

with predetermined parameters. The following is a

flow chart of the process of machining activities for

data collection:

Figure 6: Machining experiment flow chart.

The optimization process is carried out with the

model of mathematical equations obtained so that the

optimum value of the flow rate of the corresponding

machining process is obtained. The Optimization

process is carried out according to the flow chart of

the algorithm starting from the initialization of the

position, the initial speed, the maximum iteration.

then, calculate the value of each

particle through the

value of the function to determine

the initial Pbest and

Gbest. after that, do an update of position and speed.

recalculates the fusion value based on the new

position up to the specified iteration limit, and then

sorted to find the minimum solution.

3

RESULT

3.1 Research Methods

The data taken is the influence into the feeding and

flowrate on the temperature response that occurs

during the machining process. So that data for

aluminum and St.37 were obtained as follows:

Table 1: Alumunium experiment result, n=2500 rpm,

feeding=200 mm/min.

No

DoC [mm]

Flow Rate

[ml/h]

Temperature

[

o

C]

1

0.25

25

24.9

2

40

24.9

3

55

24.3

4

70

24.5

5

85

26.4

6

0.5

25

26.9

7

40

27

8

55

27.2

9

70

27.4

10

85

27.4

11

0.75

25

28.4

12

40

28.8

13

55

28.4

14

70

28.5

15

85

28.1

16

1

25

29.2

17

40

28.8

18

55

30

19

70

29.8

20

85

28.9

21

1.25

25

31.1

22

40

31.6

23

55

32.4

24

70

32.4

25

85

31.8

26

1.5

25

33.3

27

40

33.1

28

55

32.9

29

70

32.1

30

85

30.1

Table 2: ST37 experiment result, n = 650 rpm, feeding = 32

mm/min.

No

DoC [mm]

Flow Rate

[ml/h]

Temperature

[

o

C]

1

0.1

25

25.8

2

40

26.5

3

55

26.2

4

70

26.1

5

85

26.4

6

0.2

25

27.1

7

40

27.1

8

55

27.7

9

70

27.7

10

85

27.4

11

0.3

25

28.1

12

40

28.3

13

55

28.1

14

70

27.9

15

85

27.8

16

0.4

25

28.3

17

40

28.2

18

55

28.3

19

70

28.2

20

85

28.2

21

0.5

25

29

22

40

29.1

23

55

29.2

24

70

28.5

25

85

28.6

26

0.6

25

28.9

27

40

29

28

55

28.8

29

70

29.1

30

85

28.9

Implementation of Particle Swarm Optimization (PSO) Method in Minimum Quantity Lubrication (MQL) Optimization to Obtain Optimal

Machining in CNC Milling Machine

825

3.2 Regression Equation Results from

Experiments

The linear regression equations from the experiment

obtained using IBS SPSS is:

𝑌1 = 23,98 − 0,002 𝑋1 + 5,879 𝑋2

𝑌2 = 26,147 − 0,001 𝑋1 + 5,240 𝑋2

The polynomial regression equations from the

experiment obtained using Matlab is:

𝑌1 = 21,42 + (0,06564 × 𝑥1) + (7,819 × 𝑥2)

− (0,0003333 × 𝑥12)

− (0,03528 × 𝑥1 × 𝑥2)

𝑌2 = 24,81 + (0,006444 × 𝑥1) + (13,47 × 𝑥2)

− (0,02 × 𝑥1 × 𝑥2) − (10.18 × 𝑥22)

Information:

Y1 = Suhu Aluminium Y2 = Suhu St.37

x1 = Flowrate

x2 = Depth of Cut

3.3 Comparison of Linear Regression

Equations and Polynomials

To see the regression equation that is suitable for

processing with PSO, the role of regression equation

is carried out

Table 3: Comparison of the coefficient of determination of

aluminum regression.

Multiple Linear Regression

Polynomial Regression

0,916

0,9327

Table 4: Comparison of aluminum regression errors.

Multiple Linear

Regression

Polynomial

Regression

0,577942

0,501499

Table 5: Comparison of regression coefficients of

determination St.37.

Multiple Linear

Regression

Polynomial

Regression

0,865

0.9404

Table 6: Comparison of St.37 regression errors.

Multiple Linear

Regression

Polynomial Regression

0,288933

0,202568

3.4 PSO Algorithm Calculation Results

Here are the results of the pso algorithm optimization

calculation through Matlab software:

Table 7: Alumunium PSO algorithm results.

No

DoC

[mm]

PSO Flow Rate

Results [ml/h]

Best Fitness PSO

Results [

o

C]

1

0.05

25

23.1995

2

0.1

25

23.5464

3

0.15

25

23.8932

4

0.2

25

24.2401

5

0.25

25

24.5869

6

0.3

25

24.9338

7

0.35

25

25.2806

8

0.4

25

25.6275

9

0.45

25

25.9743

10

0.5

25

26.3212

11

0.55

25

26.668

12

0.6

25

27.0149

13

0.65

25

27.3617

14

07

25

27.7086

15

0.75

25

28.0554

16

0.8

25

28.4023

17

0.85

85

28.6885

18

0.9

85

28.9295

19

0.95

85

29.1705

20

1

85

29.4115

21

1.05

85

29.6525

22

1.1

85

29.8935

23

1.15

85

30.1345

24

1.2

85

30.3755

25

1.25

85

30.6166

26

1.3

85

30.8576

27

1.35

85

31.0986

28

1.4

85

31.3396

29

1.45

85

31.5806

30

1.5

85

31.8216

Table 8: Alumunium PSO algorithm results.

No

DoC [mm]

PSO Flow Rate

Results [ml/h]

Best Fitness PSO

Results [

o

C]

1

0.05

25

25.5942

2

0.1

25

26.1663

3

0.15

25

26.6875

4

0.2

25

27.1579

5

0.25

25

27.5773

6

0.3

25

27.9459

7

0.35

85

28.2302

8

0.4

85

28.4369

9

0.45

85

28.5928

10

0.5

85

28.6977

11

0.55

85

28.7518

12

0.6

85

28.7549

13

0.65

85

28.7072

14

07

85

28.6085

15

0.75

85

28.4590

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

826

Table 8: Alumunium PSO algorithm results (cont.).

No

DoC [mm]

PSO Flow Rate

Results [ml/h]

Best Fitness PSO

Results [

o

C]

16

0.8

85

28.2585

17

0.85

85

28.0072

18

0.9

85

27.7049

19

0.95

85

27.2728

20

1

85

26.9477

3.5 Implementation on Arduino

Implementation of optimization results in the form of

a data base on the Arduino from the optimum flowrate

results for feeding recommendations. The add-on

program to MQL is a new menu for recommendations

of MQL optimum values. Flowrate recommendation

menu display:

Table 9: Arduino menu display.

3.6 Results Test and Validation Results

The test results are carried out to validate the results

of the optimization data calculated using the PSO

method, by testing the feeding in accordance with the

optimum flowrate obtained. here are the results of

MQL testing with optimization results with Particle

Swarm Optimization.

Table 10: Validation of optimum flowrate comparison

(Alumunium).

DoC

Temp

with MQL

Temp without

MQL

PSO Measure.

Temp.

0.15

24.8

25.8

23.89

0.25

25.9

26.4

24.58

0.35

26.3

26.8

25.28

0.5

27.2

28.1

26.32

0.85

28.8

30.8

28.68

Table 11: Validation of optimum flowrate comparison

(ST37).

DoC

Temp

with MQL

Temp without

MQL

PSO Measure.

Temp.

0.2

27.8

30.9

27.17

0.25

28.5

31.5

27.57

0.3

28.9

31.9

27.94

0.35

29.3

32.7

28.23

0.4

29.8

33.2

28.43

4 CONCLUSIONS

To obtain the optimal lubricant discharge in MQL,

data collection is carried out with depth of cut and

flowrate parameters. so that the results of the data will

be processed to obtain the regression equation. The

Regression Equation will be calculated through the

PSO algorithm and the results will be obtained:

In aluminum materials the discharge of lubricant

for a depth of less than 0.85mm is 25 ml/h.

Meanwhile, more than 0.85 ml/h is 85 ml/h.

In St.37 materials the discharge of lubricant for

depths of less than 0.35mm is 25 ml/h. Meanwhile,

more than 0.35 ml/h is 85 ml/h.

REFERENCES

Cholissodin, I. Swarm Intellegence (Teori & Case Study).

Malang: Fakultas Ilmu Komputer Universitar

Brawijaya, 2016.

Dhanasaputra, N., & Santosa, B. Pengembangan algoritma

cat swarm optimization. Jurnal ITS, pp 3, 2010.

Erny. "Optimasi Pola Penyusunan Barang Dalam Peti

Kemas Menggunakan Algoritma Particle Swarm

Optimization," Skripsi,. Makasar: Universitas

Hassanudin, 2013.

Glanis, N. I., Manolakos, D. E., & Vaxevanidis, N. M. .

Comparison Between Dry and Wet Machining of

Stainles steel. Proceedings of the 3rd International

Conference on Manufacturing Engineering (ICMEN),

91-98, 2008.

Ihsyani, T. A. "Pembuatan Sistem Minimum Quantity

Lubrication (Mql) Dengan Kontrol Arduino Pada Mesin

CNC." Tugas Akhir Diploma, Bandung: Jurusan Teknik

Manufaktur Politeknik Manufaktur Bandung, 2021.

Nuryadi, Astuti, T. D., Utami, E. S., Budiantara, M. "Dasar-

dasar statistic penelitian

.", Yogyakarta: SIBUKU

MEDIA, 2017.

Rochim, T. "Teori dan teknologi Permesinan

.", Bandung: ITB

Press, 1993.

Widana, W, Muliani, P. L. "Uji persyaratan analisis

.",

Lumajang: KLIK MEDIA, 2020.

Implementation of Particle Swarm Optimization (PSO) Method in Minimum Quantity Lubrication (MQL) Optimization to Obtain Optimal

Machining in CNC Milling Machine

827