Development of Liberica Coffee Roasting Machine Using Quality

Function Deployment (QFD) Method as the Leading Product of

Farmers of Meranti Islands Riau

Razali and Imran

Department of Mechanical Engineering Politeknik Negeri Bengkalis, Jl. Bathin Alam, Bengkalis, Indonesia

Keywords: Coffee Roasting Machine, Voice of the Consumer, House of Quality.

Abstract: Meranti Islands Regency is one of the regencies in Riau province which is famous for its Liberica coffee

production. According to the management of the Liberica Meranti Coffee Community Association (LMPK)

Al-Amin, Liberica coffee farm in Kedabu Rapat Village is currently 775 hectares and 100,000 hectares in

Rangsang Coastal area. The original Liberica coffee of Meranti is in huge demand by foreigners, especially

Malaysian. Malaysian Market demand holds up to 90% of the commodity. In order to improve the

competency, innovation will always be needed and carried out. This study conducted was to develop a

coffee roasting machine to enhance the coffee flavor by using Quality Function Deployment (QFD) method

to resolve the problems. The data obtained is in quantitative form by spreading 23 questionnaires to coffee

merchant. There were several phases conducted, which are collecting data by interviewing consumers,

compiling the house of quality matrix, and developing the concept of the tool. The data collected showed

that House of Quality requested large coffe roasting machine, while regular consumers wished to learn

coffee developement proccess. The final result of the study revealed that the design of the roasting coffee

machine proposed suits the request and needs of the users, called C concept (14 points) compared to other

concepts.

1 INTRODUCTION

Meranti Islands is one of the regencies in Riau

province which is famous for its Liberica coffee

production. Liberica is a type of coffee cultivated on

lowlands around one meter above sea level. Liberica

Coffee is currently registered as a geographical

indication at the Directorate of Intellectual Property

with application number G002014000014 by

Rangsang Meranti Liberica Coffee community

(MPKLRM). (Tiaraputri, Law, & Riau 2021).

Based on the information from the management

of the Meranti Liberica Coffee Community

Association (LMPK) Al-Amin,

Liberica coffee farm in

Kedabu Rapat Village is currently 775 hectares and

100,000 hectares in Rangsang Coastal area

, The original

Liberica coffee of Meranti is in huge demand by

foreigners, especially

.

Malaysian. Malaysian Market demand holds up to

90% of the commodity, while only 10% penetrates the

local market. In 2016, the export volume of Meranti

Liberica coffee beans to Malaysia was 71 tons or

equivalent to 800 tons of fresh beans. Each coffee

bean has different flavor, the factors that affect the

flavor of coffee are the variety of coffee beans, the

coffee growing area, the harvesting process,

fermentation and roasting. Roasting is an important

thing in processing coffee. (Novison and Sapta

2021).

Since the post-harvest coffee beans is still less in

value, those beans need to be further proccessed to

add the value to the farmers. However, during the

process of roasting, the merchant found it difficult to

determine that the beans are roasted evenly. To get

the flavor of the coffee, filling is still applied so that

the production cost and the final product can be

balanced since the price of the machine is extremely

expensive, for instance, a machine from otten coffee

with a capacity under 700 grams costs Rp. 1.8

million while large capacity machine costs up to

hundreds of millions. (Zakaria Purnama et al. 2020).

Liberica coffee beans which grows in the

lowland of Rangsang coastal area, Meranti Islands,

is one of the leading products of Meranti, which has

Razali, . and Imran, .

Development of Liberica Coffee Roasting Machine Using Quality Function Deployment (QFD) Method as the Leading Product of Farmers of Meranti Islands Riau.

DOI: 10.5220/0011899300003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 857-862

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

857

certain characteristic that cannot be found in other

coffee. Therefore, to maintain the distinct flavor, the

coffee beans should be well-roasted using proper

machine. Although the farmers need a proper

machine for roasting process, it is not affordable for

all coffee farmers and the merchants due to the

expensive price. Additionally, the farmers do not

have the required knowledge to operate the machine

or to roast the coffee beans perfectly, which affect

the flavor of the beans.

Condluding the problems mentioned above, the

author conduct a study to develop a coffee roasting

machine using Quality Function Deployment (QFD)

method which is affordable, user-friendly and high

in quality.

These are several studies related to this research

which has previously conducted.

• A study conducted by (Novison and Sapta

2021) entitled "Application of the Taguchi

Method to Determine the Quality of Liberica

Roasted Coffee Based on Roasting

Parameters". The results of the study showed

that the best roasting can be produced with

variable value ratio SN 260 °C, in 60 minutes

with 60 RPM roasting speed and the best to

method is by reducing moisture and acid level

(pH).

• Another research conducted by (Sulistyo 2020)

entitled "Design of Semi-Automatic Coffee

Bean Roasting Machine". The results obtained

from the performance of the control system on

the semi-automatic roasting machine were able

to reduce the water of 11% to 7%-5% with

light roast beans at 155 °C with an average

time of 12 minutes for heating 170 °C and 150

°C the average roasting time is 20 minutes,

medium roast at a temperature of 160 °C with

an average time of 14 minutes for heating 170

°C and 150°C, the average roasting time is 25

minutes. Semi-automatic roasting is more gas

efficient, 1 can of gas can be used to roast 6-7

times while manual roasting is only 3 times.

• A study conducted by (Arda 2020) entitled

"Design of Microcontroller-Based Smart

Coffee Roasters". The results of the automatic

research obtained the results of the coffee

roaster research with a choice of four roasting

menu options that work automatically, called

light roast, medium roast, dark roast, and set

timer. The Set timer is used when to roast the

coffee beans for a specific time by by setting

the timer

• The results of the study conducted by

(Sasongko et al. 2018) entitled "Coffee Bean

Roasting Machine With Controlled

Temperature Using Arduino Due". The results

showed that the roasted level of coffee beans

can be determined based on the final

temperature of the coffee beans, 235°C for the

medium roast level, and 240°C for the dark

roast level.

Research Objectives

The purposes of this study are:

1. Collecting House of Quality (HoQ) to get the

largest 5 weights from the QFD (Quality

Function Deployment) method.

2. Developing a coffee roasting machine design

based on concept development on the QFD

(Quality Function Deployment) method.

1.1 Product Development

a) Development Concept.

In the concept development phase, the needs of

the target market are identified, alternative

product concepts are generated and evaluated

and a concept is selected for further

development.

b) Design System.

The systems design phase includes defining the

product architecture and dividing the product

into sub-systems and components. The final

assembly scheme for a production system is

often undefined clearly during this phase.

c) Design Details.

Overall specifications are in two dimensions,

materials to be used and tolerances of all

unique product components and identification

of all standard components to be purchased

from suppliers.

d) Testing and Screening.

The testing and screening phase involves

establishing and pre-producing evaluation of

the many types of products to be developed.

1.2 Quality Function Deployment

(QFD)

QFD is a structured product planning and

development method that allows the development

team to clearly define consumer needs and then

evaluate the capacity of each proposal and product

and service systematically (AstonJones and

Cohen, 2005). According to (Djati, 2003), Quality

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

858

Function Deployment is a product development

system that starts from product design,

manufacturing processes, to delivering product to

the consumers, which is based on consumer needs.

The QFD process involves the establishment of

one or more quality matrix or tables. This matrix,

known as the House of Quality (HoQ), consists of

several parts or sub-matrix which are merged in

several ways, each of which contains related

information.

Figure 1: House of

Quality.

Part A:

Contains a structured list of consumers’ needs, the

arrangement is usually determined by conducting

market research.

Part B:

Contains three main types of information,

quantitative market data, setting strategic goals for

services and calculations for ranking consumers’

needs.

Part C:

Contains a high-level description of a product or

service that is planned to be improved, usually this

technical explanation is generated from the

consumers’ needs in part A.

Part D:

Contains the development group's consideration of

the strength of the relationship between each

element of the engineering response and each

consumer's wishes.

Part E:

Technical correlation, is the half of a square matrix,

which is separated along its diagonal and rotated 45

degrees. Since this part resembles the roof of a

house, the term 'Quality House' is used for the entire

matrix and has become the standard term for the

matrix structure. Part E contains the development

team activities to implement the correlation between

engineering response elements.

Part F:

Contains three kinds of information, ranking order,

comparative information on competitors' technical

performance and technical performance targets.

1.3 Definition of Coffee Roasting

Coffee roasting machine is a tool used to roast

coffee to seperate the coffee beans from the skin.

This machine will also grind the coffee beans into

coffee powder to be distributed to the consumers.

(Tiaraputri, Hukum, and Riau 2021) The function of

the roasting process is to bring out the original flavor

of the coffee beans and make it more delicious. The

higher the temperature and the longer the roasting

time, the more charred the beans will be. If it gets

burnt, the original character and roasting aroma will

be stronger

There are interesting percentages about the flavor

of coffee that we enjoy. Coffee farmers have a role

of 60%, 30% during roasting process, and the rest

depends on the baristas. Brewing it by yourself

means we play the remaining percentage.

2 RESEARCH METHODS

2.1 Research Design

Figure 2: Research Chat Flow.

2.2 Population and Sample

The objects of this research are Brem entrepreneurs

in Kaliabu village, Mejayan sub-district, Madiun

Regency. based on research on picnic coolers by

Development of Liberica Coffee Roasting Machine Using Quality Function Deployment (QFD) Method as the Leading Product of Farmers

of Meranti Islands Riau

859

Griffin and Houser (Eppinger & Ulrich, 1995). The

sample used was 23 respondents, to be able to

describe consumer needs up to 90%. To collect data,

questionnaires were spread to respondents to find

out their rewuirements and needs for the

development of Liberika coffee roasting machine

design.

2.3 Data Collection Technique

To involve consumers in the process of product

design and development, a data search process is

needed about the market demands. The market

demands can be found through the responds of the

consumers (merchant/coffee beans farmers). To be

able to catch consumers’ needs, a method is needed.

The methods commonly used are interviews and/or

questionnaires. Taking into account the cost and

time required, the questionnaire method was chosen

to collect data from consumers.

2.4 Data Analysis Using QFD (Quality

Function Deployment) Analysis

The data collected from the questionnaires that have

been filled out and returned, are then processed and

summarized to be used as the basis for making a

"Consumer Quality Request (CCP)" or Voice of

Consumer (VoC)". Based on the CCP that has been

obtained, it can then be used to build a House of

Quality (HoQ). The data processing steps are:

• Step 1 Collecting data based on the questionnaire

responds, called Data 1 and Data 2

• Step 2 Grouping the questionnaire data according

to the responds.

• Step 3 Grouping Consumer Quality Demand

(CCP)”

• Step 4 General Grouping Consumer Quality

Demand (CCP)”

• Step 5 Prioritizing Consumer Quality Demand

(CCP)”

• Step 6 Assessment of Consumer Quality Demand

(CCP)”

• Step 7 Preparation of Construction Quality

Performance (PKK)”

• Step 8 Structuring Construction Quality

Performance (PKK)”

• Step 9 How to Optimize and Roof Matrix

• Step 10 Comparison between CCP and PKK

• Step 11 Ranking (Weighting) of Quality Demand

• Step 12 Compilation of the House of Quality

(HoQ)

3 RESULTS AND DISCUSSION

3.1 Questionnaire Data Collection

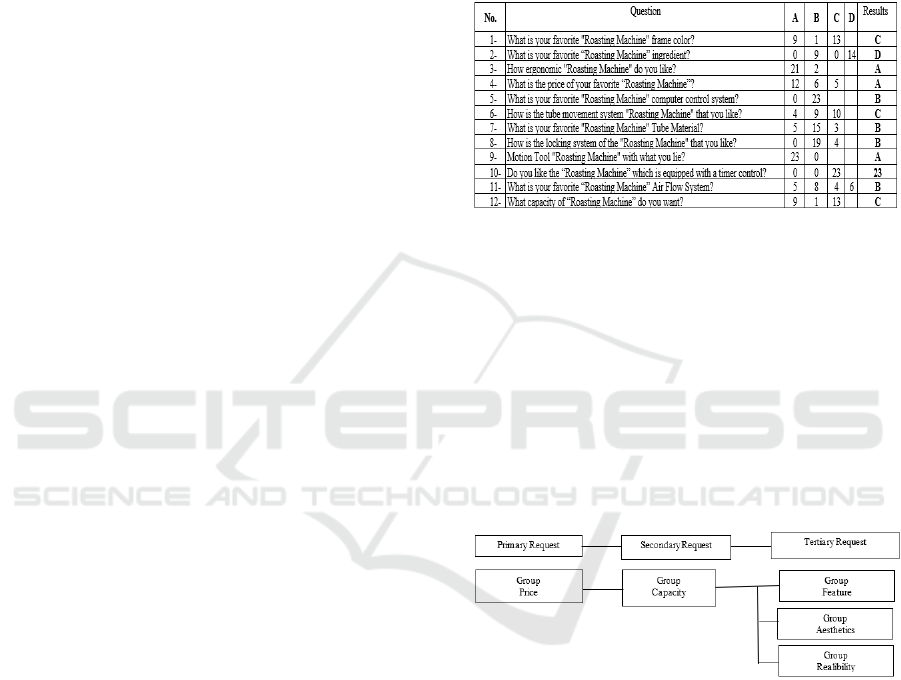

Collecting 23 questionnaire data that were returned

to the researcher and then grouped into table.

Table 1: Data.

(Source: Research Results)

3.2 Priority Setting “Consumer Quality

Demand (CCD)”

The stages after the general grouping of the data are

carried out, then at this stage is to determine the

priority of consumer quality requests by looking at

the results of the most selected questionnaires based

on the consumer's desire to determine priority on

primary requests, while for secondary requests are

data that have a moderate value. And the least

demand is tertiary.

Figure 3: Priority Setting Chart Flow.

3.3 Consumer Quality Demand

Assessment

In the following stages, a comparison will be made

between the data on consumer quality requests that

have been obtained. The assessment is done by

giving a value of 3 if the comparison result which is

deemed more important, a value of 2 if the

comparison result which is equally important and a

value of 1 if the comparison result which is less

important.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

860

Table 2: Evaluation PKC.

(Source: Research Results)

3.4 Comparison of PKC and PKK

The next step is to assess the comparison between

PKC and PKK by giving a score of 9 for a strong

correlation, a value of 3 for a moderate correlation

(medium) and a value of 1 for a weak correlation.

Table 3: Comparison of PKC and PKK.

(Source: Research Results)

description:

3.5 Preparation of House of Quality

(HOQ)

The last step is to create a House of Quality (HOQ)

which is built based on the optimization matrix and

others which have been created previously.

(Source: Research Results)

Figure 4.

3.6 Concept Development

Table 4.

(Source: Research Results)

Development of Liberica Coffee Roasting Machine Using Quality Function Deployment (QFD) Method as the Leading Product of Farmers

of Meranti Islands Riau

861

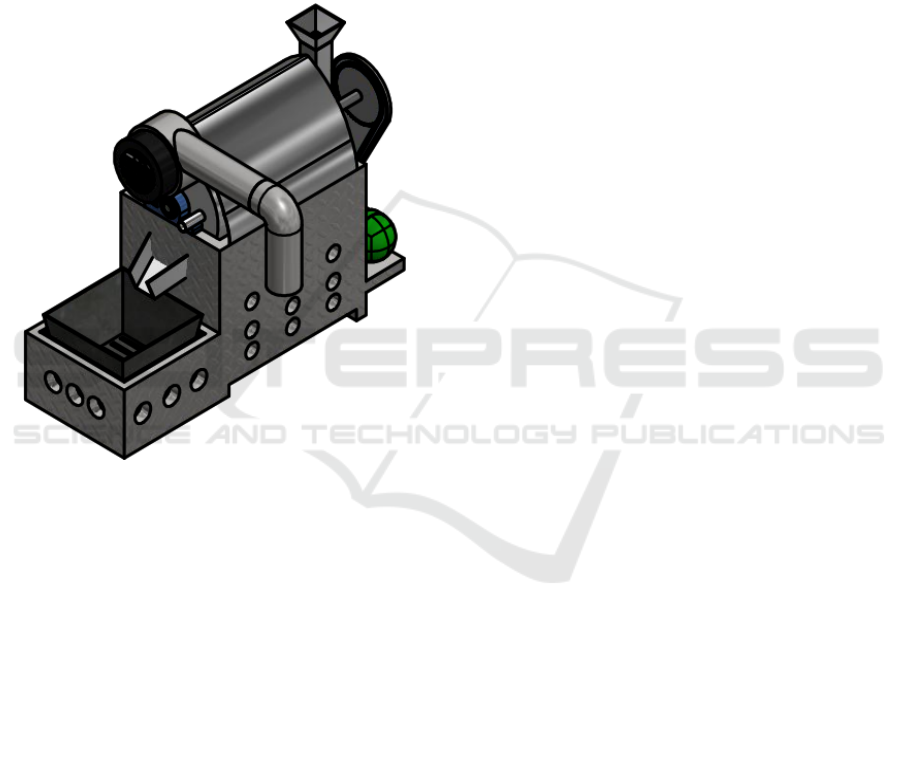

3.7 Developed Product Concept

After filtering the matrix, it is concluded that

concept C will be developed. The selection of

concept C to be developed is based on the highest

score obtained by concept C (14 points) compared to

concept B (10 points). Among 14 requested

component criteria, concept C matched the

requirements. The following is a detailed image of

the concept C machine to be developed and

manufactured.

Figure 5: Coffee roasting machine design.

4 CONCLUSION

Based on the results of the development of the

coffee roasting machine with the QFD method in

this study, the following conclusions can be drawn:

1. The data obtained and compiled through the

House of Quality resulted in 5 rankings

(weights) of the highest PKK value criteria,

which is Price Price <= 5 million with a

capacity of 30%, Air flow system with PKK

weight value of 17.6%, Tube capacity < = 5 kg

with PKK weight 14.1%, iron frame with PKK

weight 13.4%, and by using an electric motor

with PKK weight 912.0%.

2. From the discussion conducted to develop a

coffee roasting machine design using QFD

(Quality Function Deployment) analysis, the

results of the coffee roasting machine design

on concept C are obtained. The selection of the

concept C to be developed is based on the

highest score obtained by the concept C (14

points) compared to the concept B (10 points).

Of the 14 desired component criteria, all of

them are in the concept C.

REFERENCES

Arda, Abdul Latif. 2020. “Design smart coffee roasters

based on microcontroller 1.” 11(1): 57–64

Hardiyansyah, Muhammad Vikih et al. 2021. “Design of a

Temperature Control System on an Arduino-Based

Rotary Coffee Oven Machine.” 4(1): 67–76

Jatmoko Awali, Asroni. 2013. "Analysis of Shaft Failure

With Finite Element Method Approach." 1(May): 39–

44.

Sasongko, Irwan Juniar, Muhammad Rivai, A Kopi Bean,

and Coffee Bean. 2018. “Coffee Bean Roasting

Machine with Controlled Temperature Using Arduino

Due.” 7(2)

Sulistyo, Ahmad. 2020. “Final Project Report of Semi

Coffee Bean Roasting Machine.”

Tiaraputri, Adi, Faculty of Law, and the University of

Riau. 2021. “Importance Of Registration For Liberica

Coffee In Communal Intellectual District The

Importance Of Registration For Liberica Coffee In

The Regency Of Meranti Archipelago, Riau.”

unilak.ac.id/index.php/gh/ 03(02): 172–85.

Zakaria Purnama, Putra et al. 2020. “Rancang Bangun

Mesin Oven Kopi Dengan Prinsip Qfd Dan

Ergonomi.” Jurnal Mahasiswa Teknik Industri 3(2):

25–31.

Novison, R., & Sapta, R. D. (2021). Aplikasi Metode

Taguchi untuk mengetahui Kualitas Kopi Sangrai

Liberika berdasarkan Parameter Peyangraian: Taguchi.

Jurnal Elektro dan Mesin Terapan, 7(2), 89-101.

AstonJones, G., & Cohen, J. D. (2005). Adaptive gain

and the role of the locus coeruleus–norepinephrine

system in optimal performance. Journal of

Comparative Neurology, 493(1), 99-110.

Djati, S. P., & Khusaini, M. K. M. (2003). Kajian terhadap

kepuasan kompensasi, komitmen organisasi, dan

prestasi kerja. Jurnal manajemen dan Kewirausahaan,

5(1), 25-41.

Eppinger, S. D., & Ulrich, K. (1995). Product design and

development.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

862