Effect of Hydroxyl Aluminum Ratio on Preparation of PAC from

Aluminum Ash

Yikun Zhao

1

, Hui Yuan

1

, Yongdong He

1

and Changke Cheng

2

1

College of Physical Science and Technology, Xinjiang University, Urumqi, Xinjiang, China

2

Xinjiang Zhonghe Co., Ltd., Urumqi, Xinjiang, China

Keywords: PAC; CaO; Al

13

Molecule; Hydroxy Aluminum Ratio; Phase Transformation.

Abstract: The oligomeric polymeric aluminum chloride prepared from secondary aluminum ash was used as raw

material, and hydrolytic polymerization was carried out with different ratios of calcium oxide, and the

structure and phase transformation process of the polymeric aluminum chloride produced by hydrolytic

polymerization were characterized by XRD and infrared spectroscopy. The results showed that at the

hydroxyl-aluminum ratio of 0.25, the phases of hydrolysis polymerization products were Al(OH)

3

, AlOCl,

AlCl

3

-6H

2

O, Ca

3

Al

2

(OH)

12

; at the hydroxyl-aluminum ratio of 0.5, the main phases were Al(OH)

3

, AlO(OH),

AlCl

3

-6H

2

O, Ca

3

Al(OH)

7

-3H

2

O, Ca

3

Al

2

(O

4

H

4

), the main phase is AlCl

3

-6H

2

O,

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

when the hydroxyl-aluminum ratio is 0.75, and the polymeric

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

molecules account for 70.4%, When the hydroxy-aluminum ratio is 1, the

main phase is indeterminate; A large amount of OH- appears in the prepared high polymer polyaluminum

chloride molecule, and the peak height of the absorption peak of Al-OH-Al can also indicate that there are a

large number of Al-OH-Al bonds in the sample, which proves that the polyaluminum chloride contains a large

number of Al-OH-Al bonds. There are ((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

molecules.

1 INTRODUCTION

By the end of 2021, China produced 60.9 million tons

of aluminum, depending on the raw material, each ton

of aluminum produces raw material feeding amount

ranging from 0.3% to 10% aluminum ash, and the

disposal fee of 2000-4000 RMB/ton is required to be

paid for the disposal of aluminum ash. The new

environmental protection law in April 2014 requires

that enterprises must dispose of hazardous waste

generated from electrolytic aluminum according to

the hazardous waste disposal requirements. China

included aluminum ash in the National Hazardous

Waste List in 2016. Nitrides and carbides in

aluminum ash hydrolyze when exposed to moisture,

emitting strong irritating gases, and fluoride pollutes

soil and groundwater resources and causes fluorosis

to human and animal bones.

China relies on imported bauxite resources, while

the electrolytic aluminum industry consumes more

than 100 million tons of bauxite resources annually.

Secondary aluminum ash is a mixture of metallic

aluminum, alumina, aluminum nitride and salt

solvent with 50%-80% aluminum content, which is a

high-quality secondary aluminum resource, so it is

significant to realize the effective recycling of

secondary resources of aluminum ash.

Polymeric aluminum chloride is a kind of water-

soluble inorganic polymer with a wide range of

applications. The preparation of polymeric aluminum

chloride using

aluminides in aluminum ash leached

from hydrochloric acid is an effective way to

realize the resource

utilization of secondary

aluminum ash from hazardous waste. Kefeng Du et al.

experimentally studied the preparation of

polymerized aluminum chloride from aluminum ash

residue and waste hydrochloric acid. The degree of

polymerization of aluminum chloride affects its

physicochemical properties, application areas and use

effects, and according to the degree of polymerization,

aluminum chloride is divided into monomer (Al

3+

,

Al(OH)

2+

), dimer (Al

2

(OH)

2

4+

), trimer

(Al

3

(OH)

3

(H

2

O)

9

6+

), and hyperpolymer (Al

13

, Al

30

),

etc. Al

13

is considered the best among PACs because

of its large charge and molecular weight, it is easy to

bond and bridge in water and form flocs, thus Al

13

is

considered the best component in PAC, and the more

Al

13

content proves the higher quality of its PAC.

Yuan Huizhou

[11]

et al. prepared polyaluminum

solutions with different degrees of alkalinity by

106

Zhao, Y., Yuan, H., He, Y. and Cheng, C.

Effect of Hydroxyl Aluminum Ratio on Preparation of PAC from Aluminum Ash.

DOI: 10.5220/0011918300003536

In Proceedings of the 3rd International Symposium on Water, Ecology and Environment (ISWEE 2022), pages 106-110

ISBN: 978-989-758-639-2; ISSN: 2975-9439

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

controlling the amount of alkali addition to explore

the effect of pH on polyaluminum morphology. Lv

Jianxiao et al. explored the effect of total aluminum

concentration on the distribution of Al morphology in

polymerized aluminum chloride, and high aluminum

concentration is more likely to form products with

high polymerization, but too high aluminum

concentration will produce aluminum hydroxide

precipitation, which affects the coalescence effect.

Liu, Liang et al. explored the effects of total

aluminum concentration, alkalinity, reaction

temperature and alkalinity rate on the content of the

generated Al

13

.Yaneth Cardona

et al. studied the

formation pattern of Al

13

molecules and Al

30

molecules。

Regarding the structure and phase transformation

process of polymeric aluminum chloride generated by

the hydrolysis and polymerization of calcium oxide

and oligomeric PAC, there are few relevant studies in

China. This paper adopts the method of CaO

regulation of oligomeric PAC hydroxyaluminum ratio

(-OH to Al ratio) to study the structure and phase

transition law of polymerized aluminum chloride

generated by hydrolysis polymerization. It provides

technical support to explore the comprehensive

utilization of high value of high purity aluminum ash

residue.

2 EXPERIMENTS AND

MATERIALS

Xinjiang Zhonghe Co., Ltd. with particle size less

than 425 μm, deionized water, 35% hydrochloric

acid (analytically pure) and CaO (analytically pure)

were used as raw materials, and the aluminum ash

was washed and dried in acid solution. Take 150 g of

the dried acid solution powder, add 875 ml of

deionized water to a constant temperature water bath

at 80℃, and under the effect of mechanical stirring,

add CaO according to the hydroxy-aluminum ratio of

0, 0.25, 0.5, 0.75, 1.0, respectively, and wait for the

reaction for 4h, then cool to room temperature and

leave for 24h, followed by drying the polymeric

aluminum chloride solution using an electric

thermostatic drying oven at 75℃, and wait for the

appearance of a large number of The solid-liquid

separation was carried out when a large number of

crystals appeared; the physical phase changes and

molecular structure of the prepared polymeric

aluminum chloride were analyzed by X-ray

diffraction (XRD) and infrared spectroscopy.

3 EXPERIMENTAL RESULTS

AND ANALYSIS

3.1 Preparation of Low Hydroxyl Ratio

Oligomeric Aluminum Chloride by

Acid Leaching Method

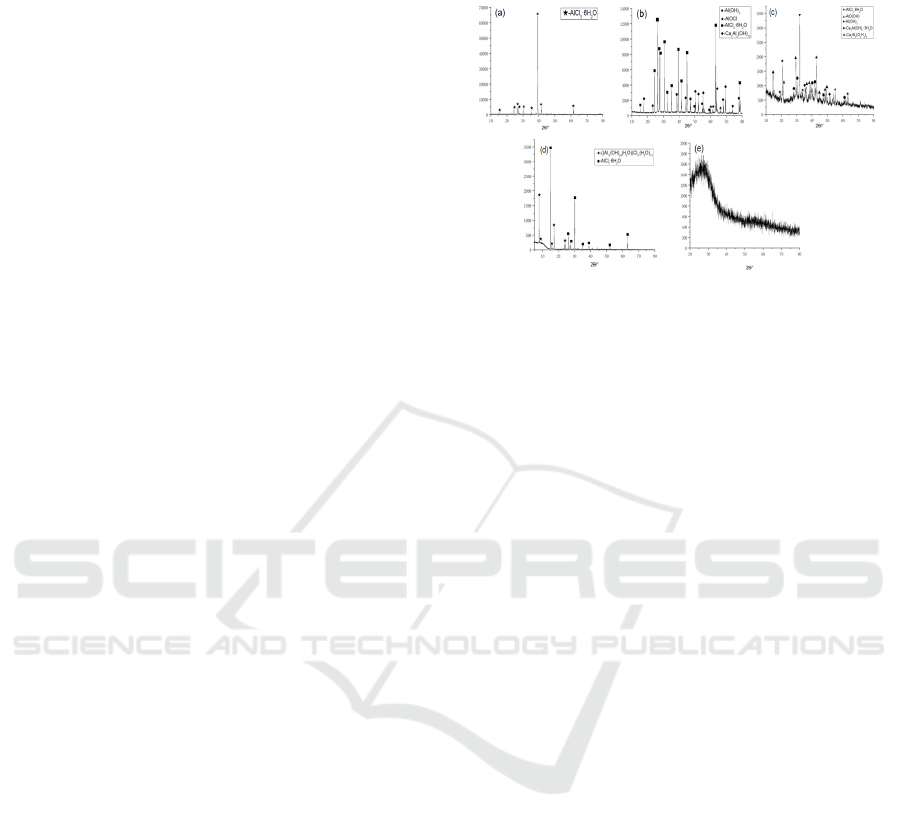

Figure 1: XRD analysis of polymeric aluminum chloride

prepared by acid leaching method

As shown in Figure 1, the XRD pattern of

polymeric aluminum chloride prepared by acid

leaching method. From Fig. 1, it can be seen that the

material phase obtained after acid dissolution of high

purity aluminum ash is relatively single with less

impurities. The aluminum ash can be obtained as

relatively pure AlCl

3

-6H

2

O after acid washing. the

polymerization degree of AlCl

3

-6H

2

O prepared

directly by acid leaching method is low, and the water

purification effect of this low hydroxyl ratio low

polymerization degree aluminum chloride is poor.

High polymerization contains a large number of

hydroxyl groups, and the hydroxyl groups, because

they can form hydrogen bonds in water, prompt the

polymerization of aluminum chloride molecules and

adsorption of impurities in water, so improving the

polymerization degree of polymerized aluminum

chloride can improve the water purification effect of

polymerized aluminum chloride.

In order to improve the polymerization degree of

polymerized aluminum chloride and strengthen the

water purification effect, the polymerized aluminum

chloride prepared directly by acid leaching method is

adjusted by adding CaO.

3.2 Analysis of the Effect of Different

Hydroxy-Aluminum Ratio

Adjustment on the Physical Phase

of PAC

From Fig. 2(a), the XRD spectrum of

hydroxyaluminum ratio of 0 shows that there is no

significant change in the structure of the PAC

Effect of Hydroxyl Aluminum Ratio on Preparation of PAC from Aluminum Ash

107

prepared without the addition of CaO hydrolysis

polymerization product (PAC) and acid leaching,

indicating that the aluminum chloride polymerization

reaction is not obvious. From Fig. 2(b), the XRD

spectrum of hydroxyaluminum ratio of 0.25 shows

that the composition of the physical phase is Al(OH)

3

,

AlOCl, AlCl

3

-6H

2

O, Ca

3

Al

2

(OH)

12

, and the

appearance of Ca

3

Al

2

(OH)

12

indicates that the PAC

polymerization increases when the hydroxyaluminum

ratio is 0.25. From Fig. 2(c), which shows the XRD

spectrum of the hydroxyaluminum ratio of 0.5, it can

be seen that the composition of the phases are

Al(OH)

3

, AlO(OH), AlCl

3

-6H

2

O, Ca

3

Al(OH)

7

-3H

2

O,

Ca

3

Al

2

(O

4

H

4

), from which it can be seen that the

diffraction peak of AlCl

3

-6H

2

O is weakened and the

appearance of the dimeric phase with higher

polymerization Ca

3

Al

2

(O

4

H

4

), indicating that the

degree of PAC polymerization continued to increase

when the hydroxyl-aluminum ratio was 0.5, but the pH

remained low due to the addition of less CaO, less

Ca(OH)

2

was generated, and thus no polymers

appeared in the physical phase. Fig. 2(d) shows the

spectrum of hydroxyl-aluminum ratio of 0.75, and the

XRD results show that the composition of the physical

phase is AlCl

3

-6H

2

O,

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

, and it can be seen

from the figure that the polymeric phase

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

appears in the

physical phase, and the PAC polymerization further

increased. Fig. 2(e) shows the XRD spectrum of

hydroxyaluminum ratio of 1. The XRD results

indicate an indefinite phase. In summary, the

polymerization degree of PAC increased with the

increase of the hydroxyaluminum ratio from 0 to 0.75,

and the indefinite phase was formed when the

hydroxyaluminum ratio was 1. This indicates that the

increase of CaO is too large, which will make the

polymeric phase ((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

hydrolyze and polymerize to form the indefinite

aluminum phase, but the phase will directly

polymerize to form the indefinite phase in the later

The reaction will directly polymerize to form

indefinite Al(OH)

3

, which will affect the water

purification effect of PAC.

Due to the high degree of polymerization of the

generated PAC in Fig. 2(d), cell refinement and

quantitative analysis were performed using JADE

software, and the results showed that

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

in the prepared

polymeric aluminum chloride accounted for 70.4% of

the total amount and the structure was highly

polymeric aluminum chloride cluster structure, and

the cell parameters of the generated Al13 molecules

were a = 13.9859, b = 23.4673, c = 22.3724, α = 90°,

β = 91.05°, γ = 90°, and the molecular radius is 1.08

nm.

Figure 2: Analysis of the influence of CaO content on

phase.

3.3 High Polymeric Aluminum

Chloride Molecular Infrared

Spectrum Analysis

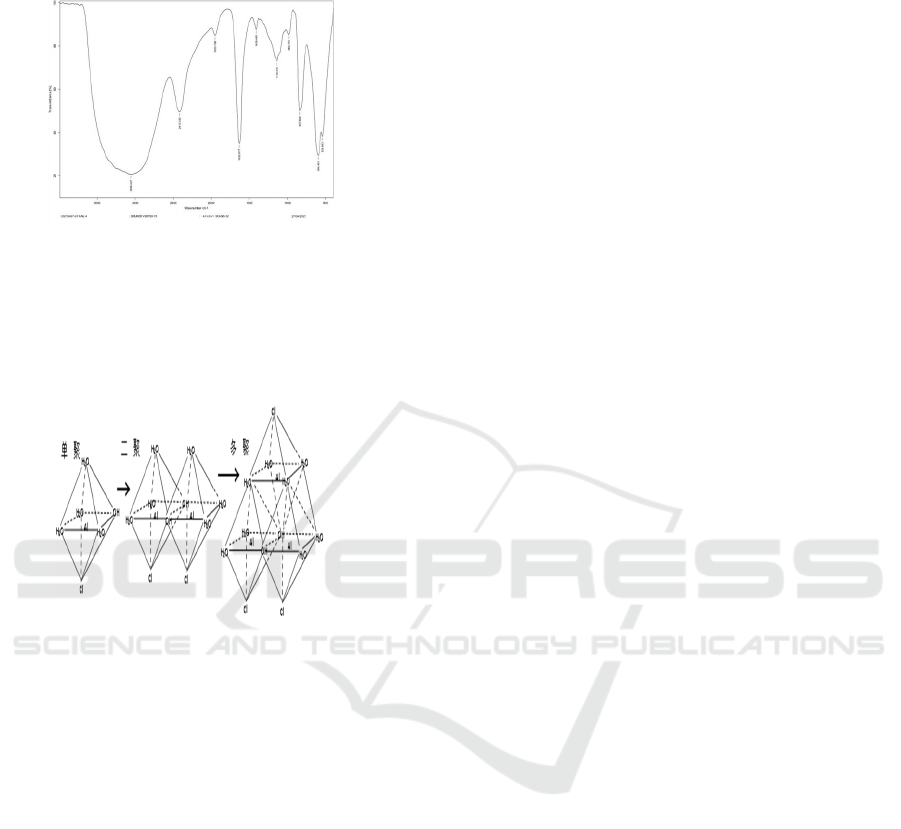

Fig. 3 shows the results of infrared spectrum analysis

of the prepared PAC when the hydroxyl-aluminum

ratio is 0.75. From Fig. 3, it can be seen that the

prepared PAC has a strong and wide absorption band

at 3058.427 cm

-1

, and the absorption band is located at

3600-2800 cm

-1

, where the absorption peak is

generated by the stretching vibration of the -OH group

in the PAC connected with the aluminum ion and the

-OH group in the adsorbed water molecule, indicating

the presence of a large number of -OH groups in

polymeric aluminum chloride. A sharp peak at

1632.877 cm

-1

, which is an absorption peak generated

by the bending vibration of H-O-H of bound water in

the Al

13

molecule, indicating that the prepared

polymeric aluminum chloride contains a large amount

of bound water. The absorption peaks appearing at

1138.840 cm

-1

, 837.896 cm

-1

are in-plane bending

vibration absorption peaks produced by Al-OH-Al,

the intensity of which can indicate the number of

bonds, and the reaction aluminum chloride

polymerizes between Al atoms during hydrolysis by

Al-OH-Al bond bridging to form polymeric aluminum

chloride. The two sharper absorption peaks at 596.463

cm

-1

and 538.643 cm

-1

are the bending vibration peaks

of Al-OH, and there are components of the

polymerization state in the reaction PAC; the peak at

2413.293 cm

-1

is the peak caused by atmospheric CO

2

.

From the infrared spectrogram, it can be seen that

a large number of -OH groups appear in the PAC

prepared with a hydroxyl aluminum ratio of 0.75, and

the peak height of the absorption peak of Al-OH-Al

can also indicate the presence of a large number of Al-

OH-Al bonds in the prepared PAC, which can indicate

ISWEE 2022 - International Symposium on Water, Ecology and Environment

108

that ((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

is indeed

present and the content very high.

Figure 3: Infrared spectrum analysis of polyaluminum

chloride molecule with high ratio

4 DISCUSSION

Figure 4: The phase transformation law of polyaluminum

chloride molecules

CaO adjusts the PAC hydroxy-aluminum ratio, and

its phase change pattern is shown in Fig. 4.

Aluminum chloride molecules ionize Al

3+

in water,

Al

3+

will spontaneously carry out hydrolysis reaction

with H

2

O molecules to form octahedral Al(OH)

2

+

with Al

3+

as the core, octahedral Al(OH)2+ will

hydrolyze with OH- in solution again to Al(OH)

4

-

,

Al(OH)

4

-

is the precursor for the formation of

polymer molecules.

Al

H

O→Al

OH

1

AlOH

OH

→AlOH

2

When CaO is added to the PAC solution, CaO will

first react with H

2

O to form Ca(OH)

2

. The presence

of Ca(OH)

2

will cause the pH of the solution to rise,

which will further accelerate the hydrolysis reaction

of Al

3+

and increase the amount of octahedral

Al(OH)

2

+

, and the octahedral Al(OH)

2

+

with Al

3+

as

the core will polymerize through the Al-OH-Al bond

to form dimer Al

2

(OH)

2

4+

, but due to the strong

acidity of the solution, the amount of OH- is low,

forming monomeric Al(OH)

4

-

, Al(OH)

2

+ and dimeric

Al

2

(OH)

2

4+

in smaller amounts, preventing the

formation of polymeric molecules.

CaO H

O→Ca

OH

3

AlOH

H

O→Al

OH

4

As CaO increases and the pH continues to rise,

forced hydrolysis of Al

3+

occurs, resulting in an

increase in Al(OH)

4

-

molecules. Al(OH)

4

-

will use ion

bridging to aggregate octahedral Al(OH)

2

+

monomers

and dimeric Al

2

(OH)

2

4+

to form Al

13

molecules with

Al(OH)

4

-

as the core, and Al

13

can decompose to Al

3+

,

again or form [Al

13

]n by physical aggregation and ion

bridging.

AlOH

Al

OH

AlOH

OH

→

Al

OH

5

With further increase of CaO, the amount of

Ca(OH)

2

formed by reaction with H

2

O is also

increasing, and the pH of the sample is increasing, the

content of Al

13

will also increase, and subsequently,

Al

13

will be transformed into [Al

13

]n, and then Al

13

will be bonded with the transformed [Al

13

]n under the

effect of ion bridging. The strong electrostatic

adsorption ability of [Al

13

]n allows a large amount of

Al

13

to be deposited on the [Al

13

]n molecule, forming

a gel-like indefinite solid phase. When an excessive

amount of CaO is added, these indefinite solid phases

are transformed into amorphous Al(OH)

3

, which

makes the purification effect of PAC poor.

Al

OH

OH

H

O→Al

OH

6

5 CONCLUSION

(1) The degree of polymerization of aluminum

chloride can be adjusted by adding a certain amount

of CaO, but the addition of excessive CaO will form

an indefinite form of Al(OH)

3.

(2) When the hydroxyl-aluminum ratio is 0.25, the

phases of hydrolysis polymerization products are

Al(OH)

3

, AlOCl, AlCl

3

-6H

2

O, Ca

3

Al

2

(OH)

12

; when

the hydroxyl-aluminum ratio is 0.5, the main phases

are Al(OH

)3

, AlO(OH), AlCl

3-

6H

2

O, Ca

3

Al(OH)

7

-

3H

2

O, Ca

3

Al

2

(O

4

H

4

). At the hydroxyl aluminum ratio

of 0.75, the main phases were AlCl

3

-6H

2

O,

((Al

13

(OH)

24

(H

2

O)

24)

)Cl

15

(H

2

O)

13

, and the polymeric

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

molecules

accounted for 70.4%, and at the hydroxyl aluminum

ratio of 1, the main phases were indefinite phases

(3) The presence of a large amount of OH- in the

prepared polymerized aluminum chloride molecules

in the polymerized state and the peak height of the

absorption peak of Al-OH-Al can also indicate the

presence of a large amount of Al-OH-Al bonds in the

Effect of Hydroxyl Aluminum Ratio on Preparation of PAC from Aluminum Ash

109

sample, which proves the presence of

((Al

13

(OH)

24

(H

2

O)

24

))Cl

15

(H

2

O)

13

molecules in the

polymerized aluminum chloride.

ACKNOWLEDGMENTS

This work is supported by Major R & D Projects

Xinjiang by the Office of Science and technology

(2020B02007) ;Supported by the National Natural

Science Foundation of China (51861033).

REFERENCES

Yongdong He, Chunrong Jin , Zhichen Sun, et al. Study on

the dissolution behavior and phase transformation

pattern of high purity aluminum ash[J]. Special Casting

and Nonferrous Alloys, 2021,41(10):1204-1209.

Chao He, Yongdong He, Yikun Zhao et al. Study on the

synthesis of calcium aluminate from secondary

aluminum ash and its physical phase change[J]. Special

Casting and Nonferrous Alloys,2021,41(11):1436-1440.

Yujing OU , Xiaolong LI, Pengguo ZHI et al. Recovery

process of Al2O3 from aluminum ash[J]. Chemical

Technology,2018,26(06):31-36.

Yong ZHANG,Zhaohui GUO,Ziyu HAN et al.Effects of Al

N hydrolysis on fractal geometry characteristics of

residue from secondary aluminium dross using

response surface methodology[J] The Chinese Journal

of Nonferrous Metals,28(2018) 2574-2581.

Tripathy A K,MahalikS,Sarangi C K,etal.A pyro-

hydrometal-lurgical process for the recovery of alumina

from waste aluminium dross[J].Minerals

Engineering,2019,137:181-186.

Cao Y.Multi-stage electrostatic separation for recovering of

aluminum from fine granules of black dross[J].Journal

of Wuhan University of Technology-

Mater.Sci.Ed.,2019,34(4):925-931.

Yanling Li, Yongdong He, Xiaohan Sun et al. Study on the

effect of wet process on the harmless denitrification of

secondary aluminum ash [J] Special Casting and

Nonferrous Alloys,2020,6.

Yangmin Zhou, Gang Xie et al. Preparation of aluminum

hydroxide by alkali sintering of aluminum ash[J] Light

Metals, 2015,No.9,12-14

Lingling Li, Ming Song, Qiang Jin. Research progress on

recycling of aluminum ash [J] Inorganic Salt Industry,

2018,Vol.50,No.8,6-10.

Kaifeng Du, Xingxing Wang, Hongjun Ni, et al. Progress in

the preparation of polymeric aluminum chloride from

aluminum-containing resources and its process

research[J] Modern Chemical Industry,

2018,Vol.38,No.8,48-51.

Huizhou Yuan, Shuizhou Ke, Jiayong Tu et al. Effect of pH

on the distribution of polymeric aluminum morphology

and coagulation effect[J]. Industrial Water

Treatment,2016,36(04):50-53.

Jianxiao Lv, Ying Cui. The effect of total aluminum

concentration on the distribution of Al morphology in

polymeric aluminum chloride[J]. Journal of Henan

Institute of Science and Technology (Natural Science

Edition),2015,43(01):34-36.

Liang Liu, Hailin Yao , Zheng Lu et al. Experimental study

on multi-factor optimization of Al137+ content of

thirteen polyalumina based on orthogonal experimental

design[J]. Science Technology and

Engineering,2017,17(29):174-179.

Shota Suzuki, ReikoMurao, RaykoSimuraet al. Crystal

structure of tridecaaluminium

tetra(nickel,ruthenium),Al13Ni1.26Ru2.74 [J].

Zeitschrift fur Kristallographie. New crystal

structures,2012,227(1)

ISWEE 2022 - International Symposium on Water, Ecology and Environment

110