Multivariate Analysis for Main Quality

Variable Control in Industry 4.0

Jorge M. de Souza

a

, Fabrício Cristófani

b

and Giovanni M. de Holanda

c

FITec - Technological Innovations, Aguaçu street, Campinas, Brazil

Keywords: Multivariate Analysis, Quality Control, Industry 4.0, out-of-Control, Out-of-Quality.

Abstract: The T

2

Hotelling one-dimensional control chart representation points out the out-of-control samples but does

not display how the secondary variables affects the primary ones considered the main quality variable. From

the same depart, the CHI squared distribution, a 2nd degree equation is derived highlighting the main quality

variable and its dependence on the secondary ones. This approach allows the identification of out-of-control

points that affects quality and require some adjustment of the secondary variables and the out-of-quality points,

which need an investigation of the root causes that lead to this undesirable output.

1 INTRODUCTION

With the technological innovations made possible by

the resources of Industry 4.0, quality control

techniques for production processes can and should

be refined to keep pace with these changes. Engineers

and manufacturing process supervisors can benefit,

for example, from clearer and more interactive

assessments of sample data generated in

manufacturing production (Godina and Matias,

2019). These issues have been presented either as a

requirement for the sustainable performance of the

industry (Foidl and Felderer, 2016) and to leverage

predictive actions resulting from a more

instrumentalized quality control–see, for example,

(Lee et al., 2019).

Indeed, in several industries, semiconductor,

metallurgy, cosmetics etc. there are one or more main

quality variables that quantify the product quality

(piston ring diameter, solution purity etc.) that are

affected by secondary ones that should be

investigated when the quality goal is not reached

(Palací-Lopez et al., 2020). These goals can be

achieved with stable and well-controlled processes. In

this sense, increased quality is defined as a reduction

in the variability of processes and products, which can

a

https://orcid.org/0000-0002-9902-6547

b

https://orcid.org/0000-0003-0142-2179

b

https://orcid.org/0000-0001-5603-2675

make of statistical methods essential in efforts to

improve processes (May and Spanos, 2006).

As each stage of the manufacturing process has a

set of variables whose measurements and control

involve a defined number of observations, statistical

models are used to monitor deviations of these

parameters and thus exercise forms of control to

detect process variability and its impact on the

product quality. In practice, many factors can

influence such a variability as improperly adjusted or

controlled machines, operator errors, different

operators crew, defective raw material, temperature

variation etc. that contribute to increase this

variability and increase the production of non-

conforming items.

The way these variables are measured is shifting

with the Industry 4.0 with the possibility to record

100% of measured data by means of IoT sensors and

wireless network (Godina and Matias, 2019). This

huge amount of data must be classified to consider the

many factors that can influence the variability as

pointed previously.

Therefore, in the context of Industry 4.0 it is

necessary the simultaneous statistical control of two

or more quality characteristics making possible to

266

M. de Souza, J., Cristøsfani, F. and M. de Holanda, G.

Multivariate Analysis for Main Quality Variable Control in Industry 4.0.

DOI: 10.5220/0011921600003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 266-272

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

control the impact of variability. In this context,

multivariate control charts (MCC) are used in the

aggregated monitoring of two or more process or

product variables. The p-dimensional points (that is,

the values of p random variables or statistics of

interest derived from them) are represented one-

dimensionally and presented in graphs similar to

Shewhart charts, simplifying the task of simultaneous

control of variables.

The paper is structured as follows: In Section 2,

the motivation for this approach is presented,

highlighting how multivariate analysis can bring new

information for process monitoring and control, and

how to specify control limits based on capability

index. Section 3 presents the ellipse control

expressions for multivariate analysis. Section 4 is

dedicated to the T

2

Hotelling approach. Finally, in the

Section 5, the method proposed is applied to three

variables highlighting the concept of out-of-control

and out-of-quality points.

2 WHY MULTIVARIATE

ANALYSIS? THE MOTIVATION

Industry 4.0 will allow at low cost a significant spread

of sensor technology on shop floors gathering a huge

volume of data. New levels of quality control have

been demanded to match the current abundance of

data and the facilities made possible by new

automation and data intelligence technologies, in a

way to extract more effective value from this new

production management potential–see, for example,

(Moyne and Iskandar, 2017), (Lee et al., 2019).

The resources of statistical process control, which

have been applied for a long time in the productive

environment, are also gaining state-of-the-art studies

and becoming more specialized to further contribute

to the quality management (Zhong et al., 2017), (Tu

et al., 2009), (Sindhumol et al., 2018). Some

approaches include cutting-edge technological

solutions, for example neural network in a system to

detect and classify fabric defects (Mahmud et al.,

2021), which even though not within the scope of

statistical control, illustrates the efforts applied to

improve quality control practices in view of the news

demands of the Industry 4.0.

When it comes to the production of

semiconductors–such as solid-state drive (SSD) and

multi-chip packages, to name a few types–, which can

involve multistage and multistep processes, many

factors can influence the quality of the production

process in an aggregated and interdependent way.

Several techniques have been used to analyze the

multiple variables acting in this process, with

approaches that try to capture the process

particularities, monitor the control limits established

for production and deepen the analyses to increase the

interpretability of the collected data.

By focusing on a timeline of the technical

literature of this century, one can observe that two

decades ago, (Skinner et al.,2002) already compared

multivariate statistical methods to analyze wafer data.

A few years later, based on multivariate analysis, (Ma

et al., 2010) extracted key variables from a broad set

of variables measured with small number of runs.

Currently, amidst the challenges of big data in

semiconductor production, (Saib et al., 2021) presents

a multivariate analysis method for large amounts of

multidimensional data. Already (Chien and Chen,

2021) developed a collinear multivariate model-

based approach to extend managerial capabilities in

intelligent semiconductor manufacturing.

In this context, there is an issue that quality

management may have multivariate quality control

tools to detect the variations among data that are not

independent. In other words, data should be jointly

considered, otherwise the quality management

analysis can lead to erroneous conclusions. Another

issue is how to show the way secondary variables

affects primary ones.

This second point is the motivation of this paper.

We propose to consider a practical example to

highlight the proposition.

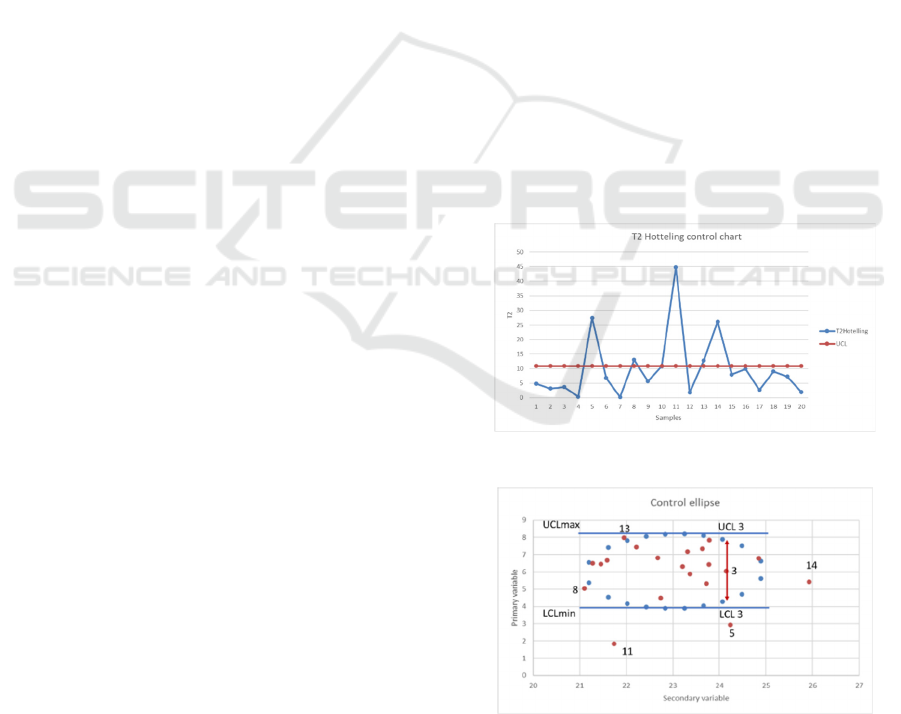

Figure 1: T2 Hotelling control chart.

Figure 2: X-Y Control ellipse. Sample 3 control limits.

Figure 1 shows the T

2

Hotelling control chart

analyzing two variables. Figure 2 displays the X-Y

Multivariate Analysis for Main Quality Variable Control in Industry 4.0

267

dispersion of the variables and the ellipse multivariate

control chart.

The samples 5, 11 and 14 are out-of-control points

but a difference can be pointed. The value of the

secondary variable of sample 14 is within the

maximum control limits of the primary variable and

can be adjusted to be inside the ellipse to ensure

primary variable control. Differently, the same does

not happen with the value of the secondary variable

of samples 5 and 11 that are out of the maximum

control limits of the primary variable directly

affecting the quality.

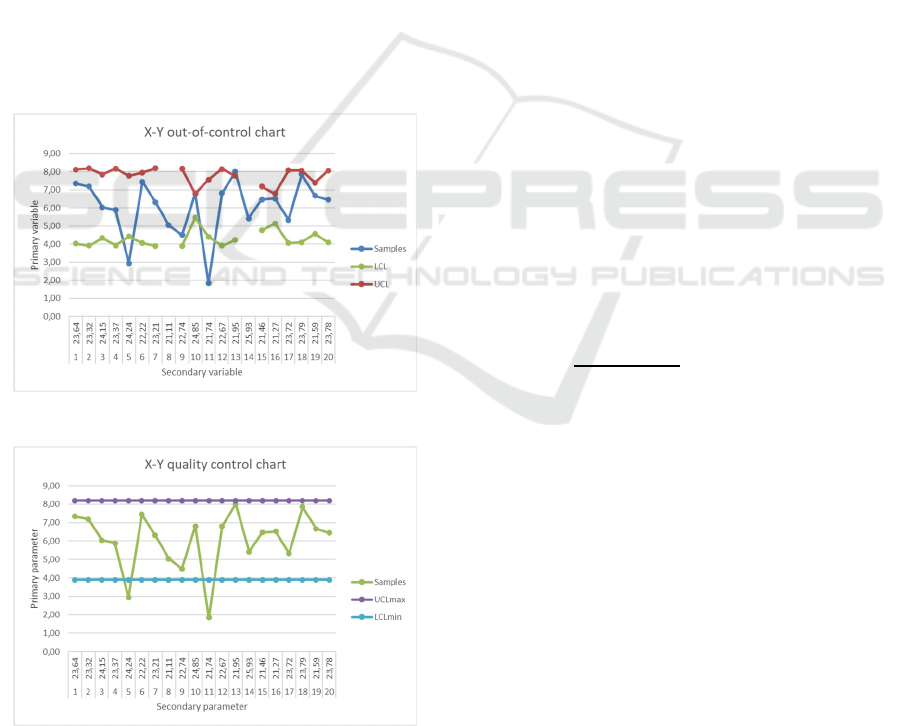

The ellipse control chart is not easily visualized

when several secondary variables are considered,

since is difficult to construct the ellipse for more than

two quality variables. It is proposed a X-Y control

chart, as illustrated in Figures 3 (a) and (b) for two

variables. The UCL, Upper Control Limit and LCL,

Lower Control Limit are the intersection of the

vertical straight-line of each sample with the ellipse

curve, changing with the time sequence of the

samples. The break of the UCL and LCL limits at

samples 8 and 14 is explained by the lack of solution

because they not vertically intersect the ellipse.

Figure 3(a): X-Y Out-of-control chart.

Figure 3(b): X-Y quality control chart.

The X-Y quality control chart points out the

samples that are not inside the quality range

delimitated by UCLmax and LCLmin, which

respectively represent the maximum of the UCL

values and the minimum of the LCL values shown in

figure 3(a)

For more than two secondary variables, the set

will be displayed by a table.

In the following sections the ideas herein

presented are developed.

3 ELLIPSE CONTROL CHART

Equation (1) is the matrix exponent of the

multivariate normal density function.

𝑋

−𝑋

𝑆

𝑋

−𝑋

(1

)

where:

𝑋

= 𝑋

,𝑋

,

...𝑋

is the mean vector of the p

variables,

𝑋

= the mean vector of means

and S the matrix of covariances.

Suppose that p quality variables are jointly

distributed according to the bivariate normal

distribution with sample averages of the quality

variables computed from a sample of size n, then the

statistics

𝜒

,

=𝑛𝑋

−𝑋

𝑆

𝑋

−𝑋

(2)

will have a chi-square distribution with p degrees of

freedom.

Let 𝜒

,

be the upper

α

percentage point of the

chi-square distribution with p degrees of freedom

For p=2 the following equations holds:

𝜒

,

=𝑛

1

𝜎

𝜎

−𝜎

𝜎

𝑣

+ 𝜎

𝑣

−2𝑣

𝑣

𝜎

(3)

𝑣

= 𝑋

−𝑋

𝜎

𝑣𝑎𝑟𝑖𝑎𝑛𝑐𝑒 𝑜𝑓 𝑖,𝜎

𝑐𝑜𝑣𝑎𝑟𝑖𝑎𝑛𝑐𝑒 𝑏𝑒𝑡𝑤𝑒𝑒𝑛 𝑖,𝑗

Equation (3) is the base of the ellipse control

example of Figure 2 taking variable 1 as primary and

2 as secondary for a given n and α.

For p variables, taking p = 1 as the primary one,

the equation (2) can be expressed as:

𝜒

,

=𝑛

𝑣

𝑉

,

𝜎

𝑆

,

𝑆

,

𝑆

,

𝑣

𝑉

,

(4)

𝑉

,

,𝑆

,

𝑠𝑢𝑏𝑎𝑟𝑟𝑎𝑦 𝑜𝑓 𝑖 𝑙𝑖𝑛𝑒𝑠 𝑎𝑛𝑑 𝑗 𝑐𝑜𝑙𝑢𝑚𝑛𝑠

Expression (4) is a 2

nd

degree equation for

variable 1.

ISAIC 2022 - International Symposium on Automation, Information and Computing

268

4 THE MULTIVARIATE

APPROACH

Generally, MCC (Multivariate Chart Control) are

used in situations where there is a significant

correlation between the variables to be monitored,

since in most of the multivariate processes the

variables interfere and suffer interference with each

other, thus having a strong correlation. In addition,

these charts are useful in cases where the variables are

not correlated, as they are capable of monitoring

processes in which there is a possibility of false

alarms when the operator finds problems in a certain

variable that is not necessarily interfering with the

process. According to (Montgomery, 2013), the

difference between univariate and multivariate

control is the increase in the complexity and levels of

automation of production processes, together with the

collaboration of growing computational support.

For (Mason and Young, 2001), a control

procedure based on Hotelling's T

2

statistics observes

the fact that a change in a variable can cause a ripple

effect throughout a system. By considering the

interrelationships between variables, the T

2

statistics

produces a powerful tool that is useful in detecting

subtle changes in the system. This fact explains the

expansion of multivariate control within industries,

simultaneously monitoring the various quality

characteristics (process variables)–see, for example,

the application of (Tavares and Ramos, 2006) in the

Brazilian aluminum industry, and (Nunes et al.,2018)

discuss the use of this and other multivariate control

charts in industrial processes with automatization and

large data volumes.

The most popular multivariate control charts are

the Chi-squared and Hotelling’s T

2

charts. They

follow the same line of the univariate Shewhart chart

and can detect large variations in the process along

with its behavior related to its mean. The Chi-squared

control chart considers that the vector of the mean of

the characteristics and the covariance matrix of the

variables involved are known. We know that in

practice this almost does not happen. Thus, in our

approach, we considered the Hotelling’s T

2

chart,

since it uses assumptions that are estimated by means

of preliminary samples collected from the process,

when it is under statistical control.

Now, we present a summary of the ideas about

Hotelling’s T

2

charts contained in (Montgomery,

2013), in order to formalize it. The T

2

chart was

developed by Hotelling in 1947, which was a pioneer

researcher on multivariate control charts. In formal

terms, to build the chart, the quadratic form expressed

in equation (5) is considered:

𝑇

=𝑛𝑋

−𝑋

𝑆

𝑋

−𝑋

(5)

Being more specific, for each line k of the sample

and each characteristic j, it is considered that

𝑋

=

1

𝑛

𝑋

(6)

𝑠

=

1

𝑛−1

𝑋

−𝑋

(7)

In both equations, (6) and (7), 𝑗=1,2,...,𝑝 and

𝑘=1,2,...,𝑚. While the covariance between

features j and h at the k-th coordinate is given by

equation (8)

𝑠

=

1

𝑛−1

𝑋

−𝑋

𝑋

−𝑋

(8)

with 𝑘 =1,2,...,𝑚 and 𝑗≠ℎ. Consequently,

𝑋

and S are obtained considering the averages

𝑋

=

1

𝑚

𝑋

,𝑗=1,2,…,𝑝

𝑠̅

=

1

𝑚

𝑠

,

𝑗=1,2,…,𝑝

𝑠

̅

=

1

𝑚

𝑠

,𝑗≠ℎ

(9)

and the matrix.

𝑆=

𝑠

̅

⋯𝑠

̅

⋮⋱⋮

𝑠

̅

⋯𝑠

̅

(10)

It is important to note that, in this case, 𝑋

represents the elements of vector 𝑋

𝑒 𝑆 represents the

covariance matrix considering the mean of the

covariance of each line of the sample.

The construction of Hotelling’s T

2

chart has two

distinct phases. Phase I consists of using the graph to

test whether the process was under control when the

first observations were extracted. In this case, the

objective is to obtain a set of data under control for

establishing the control limits. Phase II, in turn, uses

these limits to test whether the process remains under

control, when future observations are extracted.

Upon completion of the Phase I, the limits are

defined as expressed in equations (11) and (12)

𝑈𝐶𝐿 𝐼 =

𝑝

𝑚−1

𝑛−1

𝑚𝑛−𝑚−𝑝+1

𝐹

,,

(11)

𝐿𝐶𝐿 𝐼= 0

(12)

where p is the number of characteristics being

considered simultaneously, n is the size of the

subgroup, m is the total of samples and

Multivariate Analysis for Main Quality Variable Control in Industry 4.0

269

𝐹

,,

is a point of a portion of the upper

percentage of the F distribution with p and 𝑚𝑛−

𝑚−𝑝+1 degrees of freedom. For the case in which

future observations are extracted from the process, in

Phase II, the control limits are calculated via

equations (13) and (14)

𝑈𝐶𝐿 𝐼𝐼=

𝑝

𝑚+1

𝑛−1

𝑚𝑛−𝑚−𝑝+1

𝐹

,,

(13)

𝐿𝐶𝐿 𝐼𝐼= 0

(14)

where p, m and n represent the same parameters

defined previously. When a large number of samples

is considered, it is customary to use 𝑈𝐶𝐿=𝜒

,

as

the upper control limit in both phases I and II. In this

case, 𝜒

,

represents the upper percentage point of

the Chi-squared distribution with 𝑝 degrees of

freedom–see (Montgomery, 2013) for more details.

5 APPLICATIONS

A hypothetical example is considered to exemplify

the proposed multivariate analysis.

Table 1: Samples.

Sample

𝑋

𝑋

𝑋

1 23.64 7.34 5.18

2 23.32 7.18 3.78

3 24.15 6.04 5.32

4 23.37 5.88 4.72

5 24.24 2.94 4.50

6 22.22 7.44 4.24

7 23.21 6.30 6.44

8 21.11 5.04 5.22

9 22.74 4.50 4.66

10 24.85 6.80 6.04

11 21.74 1.85 5.36

12 22.67 6.81 5.06

13 21.95 8.00 3.32

14 25.93 5.42 3.78

15 21.46 6.46 3.40

16 21.27 6.51 5.20

17 23.72 5.33 5.38

18 23.79 7.85 7.46

19 21.59 6.66 5.32

20 23.78 6.44 4.46

𝑋

23.03 6.04 4.94

Table 1 shows the mean of the variables

considering n = 5, m = 20 and p = 3. Primary variable

1 is dependent of the other two secondary variables.

The T

2

Hotelling chart points out eight out-of-

control points as shown in figure 3.

Figure 4: T

2

Hotelling chart.

The X-Y chart based on equation (4) highlights

the out-of-controls points but also those that directly

affects the primary variable which measure the output

quality. The control limits UCL and LCL shown in

Figure 5 are time-varying with the sample sequence,

since they represent the intersection of the vertical

straight-line of each sample with the ellipse curve, as

explained in Section 2. In Figure 6, the X-Y quality

control chart points out the samples that are not inside

the quality range delimitated by UCLmax and

LCLmin, which respectively represent the maximum

of the UCL values and the minimum of the LCL

values shown in figure 5

Figure 5: Out-of-control chart.

Figure 6: Quality control chart.

ISAIC 2022 - International Symposium on Automation, Information and Computing

270

The control limits UCL/LCL enclose the out-of-

control points and UCLmax/LCLmin delimit the

quality control area, concerning the primary variables

whose limits are determined by the secondary ones.

Sample 14 can be considered an out-of-quality point

and Table 1 displays the values of the secondary

variables which lead to this nonconformity. In other

words, the out-of-control points need a correct setting

of the secondary variables, but the out-of-quality

points need an investigation of the root causes that

lead to this output.

6 CONCLUSIONS

In many applications concerning quality control in

Industry 4.0 there are sensors that measure the output

quality variables and those that measure the

secondary variables affecting the output quality. A

quality control analysis should take this particularity

into account.

Due to correlation between measured variables in

the industrial process Multivariate analysis is of

paramount importance because individual variable

control can lead to erroneous conclusions.

Multivariate analysis based on the T

2

Hotelling is

a one-dimensional control chart representation

pointing out the out-of-control samples but does not

display how the secondary variables affects the

primary ones, considered the main quality variables.

Based on the Chi-squared distribution, a 2

nd

degree equation is derived highlighting the main

quality variable and its dependence on the secondary

ones. This approach allows the identification of out-

of-control points that affects quality and require some

adjustment of the secondary variables and the out-of-

quality points, which need an investigation of the root

causes that lead to this undesirable output.

For further work, we planned to include data

assimilation into the statistical modelling and

consider predictive uncertainty quantification in this

approach, with the purpose of evaluating to what

extension this analytical detailing will contribute to

support more assertive decisions. Such an evaluation

might be feasible, as long as we have a significant

increase in the amount of monitored data.

ACKNOWLEDGEMENTS

The authors would like to thank the Brazilian

Ministry of Science, Technology and Innovations for

the financial support part of this project through the

PADIS (Program of Support for the Technological

Development of the Semiconductor and Displays

Industry).

REFERENCES

Chien, C.-F., Chen, C.-C. (2021) Adaptative parametric

yield enhancement via collinear multivariate analytics

for semiconductor intelligent manufacturing. Applied

Soft Computing, 108.

https://doi.org/10.1016/j.asoc.2021.107385

Foild, H., and Felderer, M. (2016) Research Challenges of

Industry 4.0 for Quality Management. International

Conference on Enterprise Resource Planning Systems,

In: Felderer M., Piazolo F., Ortner W., Brehm L., Hof

HJ. (eds) Innovations in Enterprise Information

Systems Management and Engineering. ERP Future

2015. Lecture Notes in Business Information

Processing, vol 245. Springer, Cham.

https://doi.org/10.1007/978-3-319-32799-0_10

Godina R., Matias J.C.O. (2019) Quality Control in the

Context of Industry 4.0. In: Reis J., Pinelas S., Melão

N. (eds) Industrial Engineering and Operations

Management II. IJCIEOM 2018. Springer Proceedings

in Mathematics & Statistics, vol 281. Springer, Cham.

https://doi.org/10.1007/978-3-030-14973-4_17

Lee, S.M., Lee, D. & Kim, Y.S. (2019) The quality

management ecosystem for predictive maintenance in

the Industry 4.0 era. Int J Qual Innov 5, 4.

https://doi.org/10.1186/s40887-019-0029-5

Ma, M.-D, Wong, D.S.-H., Jang, S.-S., Tseng, S.-T. (2010)

Fault detection based on statistical multivariate analysis

and microarray visualization. IEEE Transactions on

Industrial Informatics, 6 (1), 18-24. Doi:

10.1109/TII.2009.2030793

Mahmud T., Sikder J., Chakma R.J., Fardoush J. (2021)

Fabric Defect Detection System. In: Vasant P., Zelinka

I., Weber GW. (eds) Intelligent Computing and

Optimization. ICO 2020. Advances in Intelligent

Systems and Computing, 1324. Springer, Cham.

https://doi.org/10.1007/978-3-030-68154-8_68

Mason, R. L.; Young, J. C. (2001) Multivariate Statistical

Process Control with Industrial Application.

Philadelphia: Society for Industrial and Applied

Mathematics.

May, G. S.; Spanos, C. J. (2006). Fundamentals of

semiconductor manufacturing and process control.

New Jersey: Wiley-Interscience.

Montgomery, D. (2013) Introduction to statistical quality

control. New York: John Wiley & Sons.

Mottonen, M., Belt, P., Harkonen, J., Haapasalo, H., Kess,

P. (2008) Manufacturing Process Capa-bility and

Specification Limit. The Open Industrial and

Manufacturing Engineering Journal, 1, 29-36.

Moyne, J., Iskandar, J. (2017) Big data analytics for smart

manufacturing: Case studies in semicon-ductor

manufacturing. Processes 2017, 5 (39).

Doi:10.3390/pr5030039

Multivariate Analysis for Main Quality Variable Control in Industry 4.0

271

Nunes, T.F.B., Carrir, R.C., Rosa, A.F.P., Royer, R. (2018)

Parametric multivariate control charts: a review.

RAUnP, 10 (3).

https://doi.org/10.21714/raunp.v10i3.1836

Palací-Lopez, D., Borràs-Ferrís, J., Oliveria, L.T.S., Ferrer,

A. (2020) Multivariate Six Sigma: A Case Study in

Industry 4.0. Processes 2020, 8, 1119;

Doi:10.3390/pr8091119

Saib, M., Lorusso, G. F, Charley, A.-L., Leray, P., Kondo,

T., Kawamoto, Y., Ebizuka,Y., and Ban, N. (2021)

Multivariate analysis methodology for the study of

massive multidimensional SEM data. Proc. SPIE

11611, Metrology, Inspection, and Process Control for

Semiconductor Manufacturing XXXV, 116112C.

https://doi.org/10.1117/12.2583696

Sindhumol, M.R., Gallo, M., Srinivasan, M.R. (2018)

Monitoring Industrial Process using a Ro-bust

Modified Mean Chart”, Austrian Journal of Statistics,

48 (1), pp. 1-13. Doi:10.17713/ajs.v48i1-1.765

Skinner, K.R., Montgomery, D.C., Runger,G.C., Fowler,

J.W., McCarville, D.R., Rhoads, T.R., and Stanley, J.D.

(2002) Multivariate statistical methods for modeling

and analysis of wafer probe test data. IEEE

Transactions on Semiconductor Manufacturing, 15 (4),

523-530. Doi: 10.1109/TSM.2002.804901

Souza J.M., Holanda G.M., Henriques, H.A., Furukawa

R.H. (2021) Modified Control Charts Monitoring

Long-Term Semiconductor Manufacturing Processes.

In: Iano Y., Saotome O., Kemper G., Mendes de Seixas

A.C., Gomes de Oliveira G. (eds) Proceedings of the

6th Brazilian Technology Symposium (BTSym’20).

BTSym 2020. Smart Innovation, Systems and

Technologies, vol 233. Springer, Cham.

https://doi.org/10.1007/978-3-030-75680-2_11

Tavares, P.S., Ramos, E.M.L.S. (2006) Gráfico de controle

multivariado T2 de Hotelling - instrumento de análise

da qualidade numa indústria de alumínio. SPOLM

2006, 539-550.

Tu, K.K.-W, Lee, J.C.-S., and Lu, H.H.-S. (2009) A Novel

statistical method for automatically partitioning tools

according to engineers’ tolerance control in process

improvement. IEEE Transactions on Semiconductor

Manufacturing, 22 (3), 373-380. Doi:

10.1109/TSM.2009.2025812

Yang, C., Chang, C.-J., Niu H.-J.& Wu, H.-C. (2008)

Increasing detectability in semiconductor foundry by

multivariate statistical process control. Total Quality

Management & Business Excellence, 19 (5), 429-440.

Doi: 10.1080/14783360802018079

Zhong, R. Y., Xu, X., Klotz, E., Newman, S.T. (2017)

Intelligent Manufacturing in the Context of Industry

4.0: A Review. Engineering, 3, 616–630.

Doi:10.1016/J.ENG.2017.05.01

ISAIC 2022 - International Symposium on Automation, Information and Computing

272