Reliability Analysis of LCCC Leaded Solder Joints Under Thermal

Cyclic Loading Conditions

Zhang Yukun, Zhang Chun and Xu Weiling

Beijing Institute of Space Mechanics&Electricity, Beijing, China

Keywords: LCCC Package, Finite Element, Thermal Fatigue Life.

Abstract: In this paper, a finite element analysis model of the stress-strain of the solder joints of LCCC package

devices is established to analyze the stress-strain of the solder joints of LCCC devices under temperature

cyclic loading, and the effect of the substrate material on the thermal fatigue life of the solder joints is

analyzed. The results show that the use of Al

2

O

3

, the same material as the LCCC package, as the substrate

can effectively improve the thermal fatigue life of the solder joints under thermal cyclic loading conditions.

In practical applications, the Al

2

O

3

material transfer method can be used to improve the thermal fatigue life

of LCCC package devices.

1 INTRODUCTION

LCCC (Leadless Ceramic Chip Carrier) devices are

widely used in electronic products in various

industries due to their small size, high pin density,

high speed and high frequency. However, due to the

large difference in thermal expansion coefficients

between the packaging material and the FR4-based

PCB, the cyclic stress and strain on the solder joints

between the components and the PCB will be caused

under the action of high and low temperature cycles,

and when the thermal cyclic stress reaches a certain

number of times, it will cause the solder joints to

crack, which are used for mechanical support and

electrical connection in the electronic packaging

structure, and the cracked solder joints will

eventually lead to component failure. Therefore, it is

important to study the stress-strain law of LCCC

package solder joints under thermal cyclic loading.

This research has been carried out by scholars. The

stress-strain distribution of plastic ball grid array

(PBGA) devices under thermal cyclic loading

conditions has been investigated, and laminated

solder joints have been used to improve the thermal

fatigue life of solder joints under thermal cyclic

loading conditions(Wei et al., 2013). Some scholars

have analyzed the variation of thermal fatigue life

with solder joint materials by applying thermal

cyclic loads to solder joints of different materials by

experimental methods(Gao et al., 2018; Gao et al.,

2018),. Some scholars have studied the thermal

fatigue life of LCCC package devices under -30℃

~50 ℃ temperature cycling conditions based on

finite element simulation and engineering algorithm

respectively(Hou et al., 2014). The influence of filler

adhesive parameters on the reliability of lead-free

solder joints based on the Anand intrinsic model was

investigated(Zhang et al., 2000). The results showed

that the elastic modulus of the filler adhesive has no

significant effect on the thermal fatigue life of the

solder joints, while the coefficient of linear

expansion of the material has a significant effect on

the thermal fatigue life of the solder joints.

The above literature does not discuss the

influence of solder joint height and substrate

material on the reliability of LCCC packages under

temperature cyclic loading conditions. In this paper,

the stress-strain analysis of LCCC devices based on

ANSYS finite element analysis software is used to

study the effect of change in solder joint height and

substrate material on the thermal fatigue life of

LCCC devices to further improve the reliability of

the solder joints of LCCC devices.

372

Yukun, Z., Chun, Z. and Weiling, X.

Reliability Analysis of LCCC Leaded Solder Joints Under Thermal Cyclic Loading Conditions.

DOI: 10.5220/0011933300003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 372-376

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 LCCC PACKAGE THERMAL

CYCLING STRESS-STRAIN

FINITE ELEMENT ANALYSIS

2.1 Finite Element Model of LCCC

Package Solder Joints

The object of analysis in this paper is the LCCC

(leadless Ceramic Chip Carrier) package, the model

entity is derived from the CMOS image sensor

produced by BAE, the device body size is 40mm ×

50mm × 4.5mm, a total of 194 pads, pad center

spacing of 0.8mm, the bottom pad size is 1.4 mm ×

0.38mm. To reduce the impact of PCB edge stress

strain on the solder joint, the PCB size is taken to be

two times the size of the device package, the PCB

size is 80mm × 100mm × 2mm. The selected solder

joint material is Sn63Pb37 solder paste.

Considering the actual situation of the printed

circuit board on the copper wire filling glue and

other materials to establish a finite element model is

very difficult, in order to improve the efficiency of

the analysis, shorten the analysis time, the model

will do some simplification process. In this paper,

the LCCC geometric model design assumptions: 1)

ignore the printed board manufacturing process used

in the filling glue and other materials and the

influence of metal compounds between the solder

joints; 2) all parts of the model are ideally

connected, ignoring defects such as voids in the

solder joints; 3) when the ambient temperature

changes, the overall temperature of the package are

equal, there is no temperature gradient; 4) the initial

temperature of 25 ℃, the initial stress inside the

package is 0.

2.2 Material Ontology Equations and

Parameters

Due to the more obvious inelastic stress-strain

characteristics of lead-tin materials, in the finite

element analysis of the solder joints using Anand

viscoplastic instantonal equation to describe its

mechanical behaviour. Sn63Pb37 solder paste

material performance parameters are shown in Table

1. The parameters of the Anand model for Sn63Pb37

solder paste are shown in Table 2.

Table 1: Material properties of

Sn63Pb37 solder paste

.

Temp.(℃)

Elastic modulu(GPa) Poisson

-55 47.97 0.352

-35 46.89 0.354

-15 45.79 0.357

5 44.38 0.360

20 43.25 0.363

50 41.33 0.365

75 39.45 0.37

100 36.85 0.77

Table 2: Anand model material parameters for Sn63Pb37 solder paste.

S

0

(MPa)

Q /R(K

-1

)

A(sec

-1

) ξ m h

0

(MPa)

𝑠

̂

(MPa)

n

a

12.41 9400 4.0e6 1.5 0.303 1378.95 13.79 0.07 1.3

The PCB board for each anisotropic linear

elastic material, ceramic package, copper solder tray

and the rest of the parts are each homogeneous linear

elastic material. Material parameters are shown in

Table 3.

Table 3: The remaining material properties.

Materials Elastic

modulu

(GPa)

Poisson

ratio

CTE

(10

-6

1/K)

Al

2

O

3

310 0.22 7

FR-4PCB(x,

y

)35 0.12 20.6

FR-4PCB(z) 14 0.12 68.3

Solder pads 110 0.34 17

Reliability Analysis of LCCC Leaded Solder Joints Under Thermal Cyclic Loading Conditions

373

2.3 Modeling and Boundary

Conditions

The model is simplified to a quarter structure

considering symmetry, Visco107 viscoplastic solid

cells are used for the weld joint cell type, and

Solid45 solid cells are used for all other structures.

Establish the finite element analysis model and mesh

division as shown in Fig. 1 and Fig. 2. Symmetry

constraints are applied to the x-z and y-z symmetry

planes of the model, and full constraints are applied

to the symmetry center nodes on the bottom surface

of the PCB.

Figure 1: LCCC finite element analysis model.

Figure 2: Model mesh division.

2.4 Thermal Cycle Loading Condition

The thermal cycling load is applied with reference to

a standard, the initial temperature is set at room

temperature 25°C, the upper temperature 100°C, the

lower temperature -55°C, the high and low

temperature limits are insulated for 900s, the

temperature change rate does not exceed 0.17°C/s,

each cycle 3600s. The loading curve is shown in

Figure 3. The finite element analysis was calculated

using 4 temperature cycle cycles.

0246810121416

-60

-40

-20

0

20

40

60

80

100

120

temp. (

o

C)

time (10

3

s)

temp.

Figure 3: Temperature cycling condition.

2.5 Stress-Strain Finite Element

Analysis Results

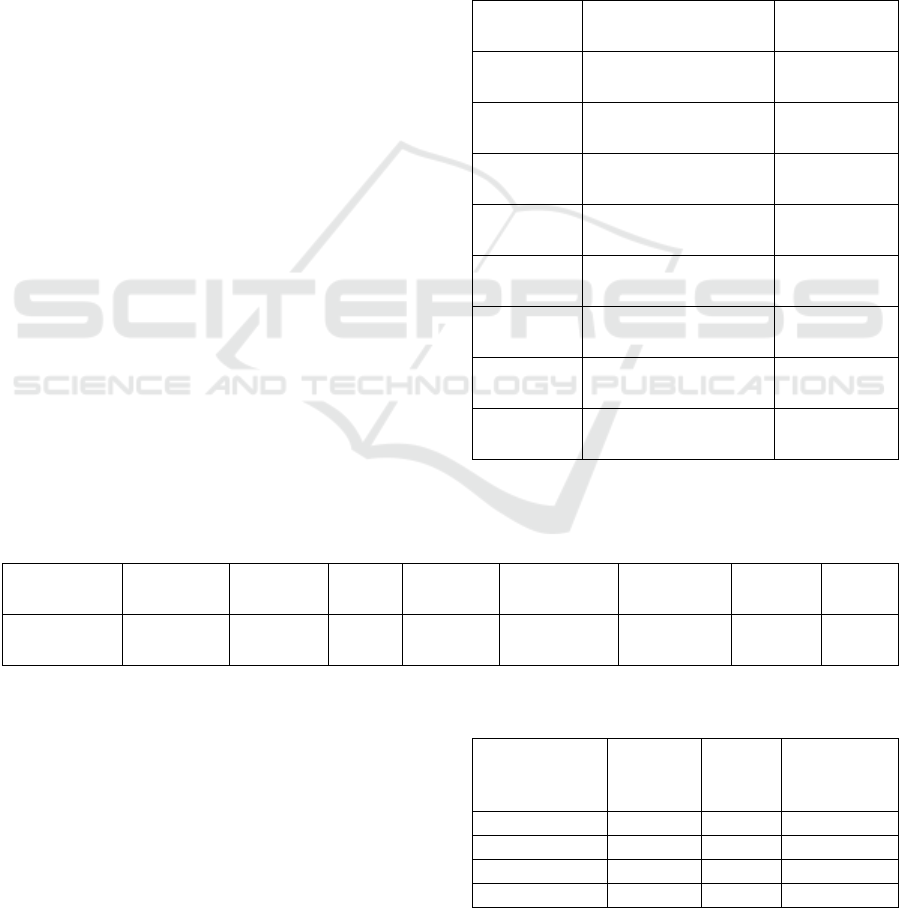

After four thermal cycles, the equivalent plastic

strain distribution in the interior of the solder joint at

the end of the fourth week of holding for Sn63Pb37

solder joints is shown in Figure 4.

Figure 4: Equivalent plastic strain distribution

The figure shows that the maximum equivalent force

and strain of the device are located at the sharp corners.

Under thermal cycling loading conditions, the solder joints

at the sharp corners of the device are critical solder joints.

The critical solder joint reaches the maximum equivalent

plastic strain at the end of the high temperature holding

period of 0.05389. The maximum strain inside a single

solder joint is located at the intersection of the bottom and

side pads of the device.

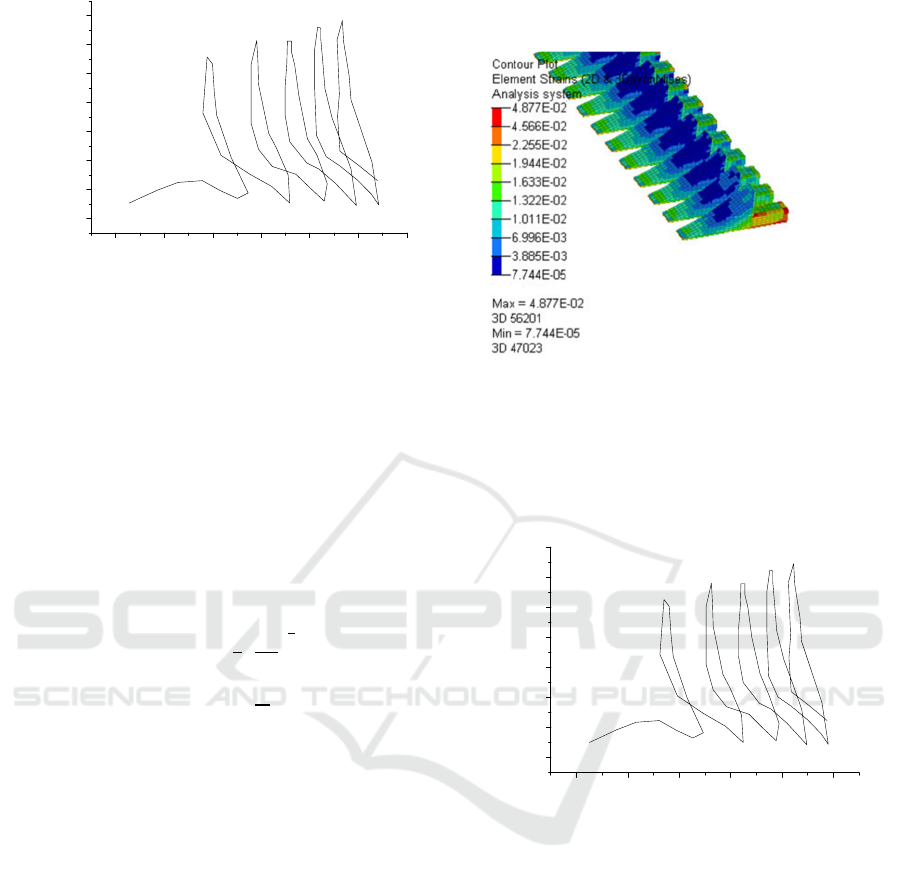

The stress-strain results of the critical weld joint were

extracted and the stress-strain hysteresis curve was plotted

as shown in Figure 5. It can be seen that the curve is

gradually converging to the hysteresis loop shape, and the

fourth cycle hysteresis loop is selected to obtain the plastic

strain range of the critical weld joint within one

temperature cycle is

∆ε = 0.0216

.

ISAIC 2022 - International Symposium on Automation, Information and Computing

374

0123456

0

10

20

30

40

50

60

70

σ(MPa)

ε(10

−2

)

Figure 5: Stress-strain curve.

3 INFLUENCE OF SUBSTRATE

MATERIAL ON THE

THERMAL FATIGUE LIFE OF

LCCC SOLDER JOINTS

3.1 Thermal Fatigue Life Prediction by

LCCC Model

Critical weld joint thermal fatigue life calculation using

Engel-maier modified Coffin-Mason equation for:

𝑁

∆

(1)

c 0.442 6 10

𝑇

1.7410

ln (1𝑓

(2)

∆γ

√

3

∆ε (3)

N

is average thermal fatigue life, ∆γ is equivalent

shear strain range; ε

is fatigue toughness coefficient

of 0.325,

𝑓

is cycling frequency of 24 weeks/day,

∆ε is equivalent plastic strain range.

The above parameters are substituted into

equation (2) to calculate c = -0.3995, and the above

parameters are substituted into equation (1) to

calculate N

≈635.

3.2 Influence of PCB Substrates on the

Thermal Fatigue Life of Solder

Joints

Considering the large stress-strain caused by the

large difference in thermal expansion coefficient

between the LCCC package material and the FR4-

based PCB, the welding substrate was replaced with

Al

2

O

3

of the same material as the LCCC package,

and the rest of the material parameters were kept

unchanged, and the corresponding finite element

model was established for analysis. From Figure 6

can be obtained from the key solder joints maximum

equivalent plastic strain maximum value of 0.04877.

Figure 6: Maximum equivalent shaping strain of ceramic

substrate.

The stree-strain curve for a solder joint with

Al

2

O

3

as the substrate is shown in

Figure 7. From the figure it

can be seen that the strain range of the solder joint within

one temperature cycle is

∆ε = 0.0192

.

012345

0

10

20

30

40

50

60

70

σ

(MPa)

ε (10

−2

)

Figure 7: Stress-strain curve.

Bring the parameters into equation (1) and the

thermal fatigue life N

≈ 852 was calculated for the

LCCC encapsulated device with Al

2

O

3

as the

substrate, which is better than the thermal fatigue

life of the LCCC encapsulated device with FR4 as

the substrate.

4 CONCLUSIONS

The results of the analysis show that the highest

stress strain is applied to the sharp corners of the

LCCC package, where the solder joints are the first

to fail.

Compared to FR4 substrate printed boards,

using Al

2

O

3

, which is the same material as LCCC

Reliability Analysis of LCCC Leaded Solder Joints Under Thermal Cyclic Loading Conditions

375

package, as the substrate can effectively improve the

thermal fatigue life of solder joints under thermal

cyclic loading conditions.

In the actual application of LCCC package

devices, the devices can be soldered to the Al

2

O

3

material adapter first, and then the adapter is

soldered to the printed circuit board with a highly

reliable connection such as through-hole soldering to

improve the thermal fatigue life of LCCC package

devices.

REFERENCES

Gao, L., Li, C., and Wan, P., (2017). A Superior

Interfacial Reliability of Fe-Ni UBM During High

Temperature Storage.Journal of Materials

Science:Materials in Electronics, 28(12):8537-8545

Gao, L., LIU, Z.and LI, C.,(2017).

Failure Mechanisms of

SAC/Fe-Ni solder Joints During Thermal

Cycling .Journal of Eletronic Materials, 46

(8):5338-5348.

Hou, C., Tong ,J. and Rong, K. , (2014).

Thermo-fatigue

life study on LCCC electronic packaging

structure.

structure & environment engineering, 41

(3):51-57.

Lall, P., Islam, M.N. , and Singh, N. (2004). Model for

BGA and CSP reliability in automotive under hood

applications. IEEE Transactions on Components &

Packaging Technologies, 27(3):585-593.

Wei, H., Huang, C., and Liang, Y. , (2013) .Reliability

analysis of plastic ball grid array double-bump lead-

free solder joint under thermal cycle. transactions of

the china welding institution, 34(10):91-95.

Zhang, X ., and Lee, S.W. , (2000) .Thermal fatigue

analysis solder joints. Journal of Electronic

Packaging, 122(3):200-206.

ISAIC 2022 - International Symposium on Automation, Information and Computing

376