Development of Cloud Based Production Card Process

for Manufacturing

Haris Setiawan, M. Yazid Diratama

a

and Malfin

Politeknik Manufaktur Bandung, Jl. Kanayakan No.21, Dago, Bandung, Indonesia

Keywords: PPC, Production Planning, Monitoring, Web Designing, PHP.

Abstract: Process card is an important piece for monitoring a production scheduling. Process cards are issued by the

PPC (production planning control) unit in the Manufacturing Engineering department Polman Bandung.

Process cards are issued for each part with information such as process sequence, processing date, and

processing time. Currently the process card is issued by the PPC software for production scheduling in the

PPC unit. The PPC software can only be accessed on Windows 7 and is not yet cloud-based, so the software

needs to be developed to be more accessible in every device include smartphone. This study aims to develope

the process card so that it can be accessed via a web browser with local network access to increase the

accessibility of using process cards for planning and monitoring the production activity. The developed starts

with analyzing the data needed before starting software design. The design of this software is done on HTML

pages with PHP in order to be able to run SQL commands through web pages. The final result is a process

card and a schedule in the form of a gantt chart.

1 INTRODUCTION

The main purpose of the PPC unit at Polman Bandung

is to receive and carry out tasks from UPM to get an

estimate of the time and price of an order, as well as

to plan and control the schedule for the execution of

the order project such as molds, press tools, and

mechanical parts.

A PPC software designed by Polman itself and

used as a production management that used to help

the PPC unit to control and manage the production

activity. The software can do a several task like select

and write materials, select work processes and

workers, planning machining operation and assembly

operation. Another function is used to estimate

quotation price for some projects begin from material

costs until process cost. This software was

programmed by using internal storage on Polman

database to store important information used for

estimation calculations and production control.

The production cards process is used for the

machinist or operators in Polman workshop as a guide

line for the manufacturing process sequence. The

process cards issued by PPC softawre by input some

of the data like number order, name order,

a

https://orcid.org/0000-0002-9514-4335

manufacturing process sequence, process time, and

operators. But, the production card process still in

paper form and has not been in digital form so the

documentation process is still difficult to do and

difficult to transfer the manufacturing information

process as fast as possible for planning and

monitoring activity.

Noviasari (2018) made production design and

control system more interactive and computerized so

that it is easier and faster to process and produce

information. Dhuha et al. (2017) produced class

diagrams, sequence diagrams, physical data models,

component designs, and interface designs with budget

management, procurement, and issue ticket functions

that can be used by project managers in managing

project costs, and other functions such as viewing

project reports can be used by directors to supervising

and as a reference in making decisions related to the

project.

The goal of this research is to develop the clous

based production card process for used on job shop-

based production activity using a cloud system in

order to issue digital process cards and replace the

current paper-shaped process cards for production

activities in the manufacturing department as a

Setiawan, H., Diratama, M. and Malfin, .

Development of Cloud Based Production Card Process for Manufacturing.

DOI: 10.5220/0011955300003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 903-908

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

903

function for planning and monitoring.

2 SOFTWARE DEVELOPMENT

Cloud-based production cards process software is run

on a web browser via the same local internet network

as the host server PC (Personal Computer). This

system is referred to as a client-server system. The

development of production card process software is

carried out in several stages as described in the

following stages.

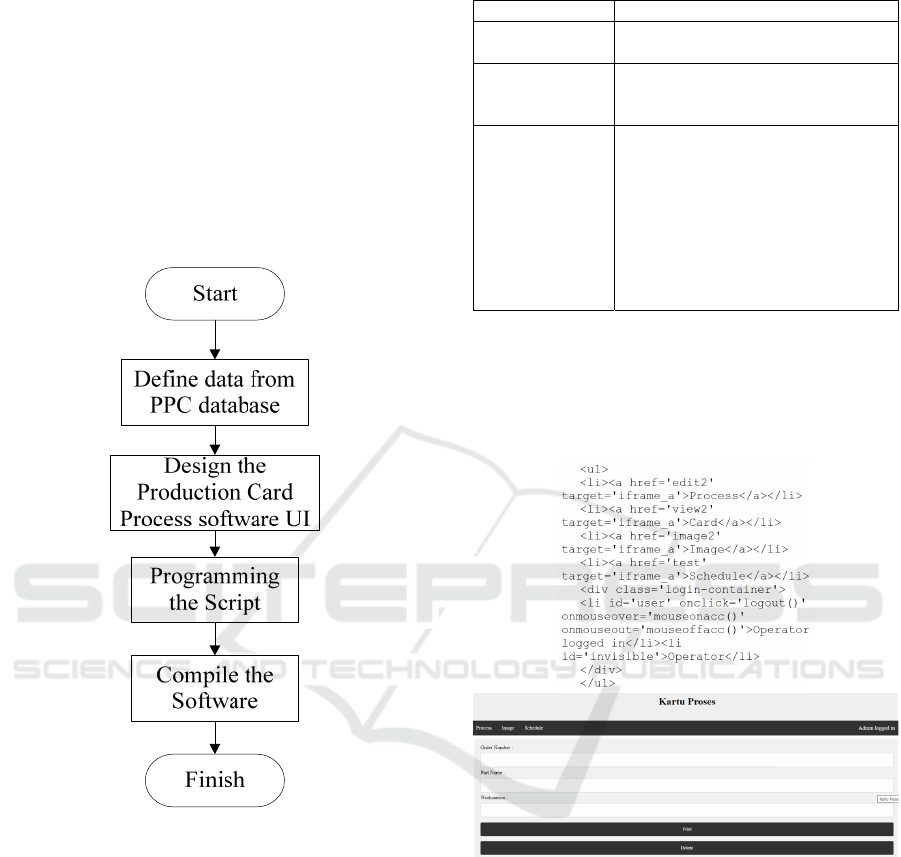

Figure 1: Development steps.

2.1 Define Data from PPC Database

The data like Number order, Part Number, and

Workstation is stored into the PPC database on the

host PC and can be accessed through the server PPC

application.

In the production process card software, the data

needed from PC database consist of three data that

retrieved using SQL commands like shown in table

below.

Table 1: Data and SQL Command.

Data name SQL command

No Order

“SELECT OrdNumber FROM

dbo.Orders”

Part Number

"SELECT PartName FROM

dbo.Parts where

OrdNumber='$OrderN'"

Workstation

"SELECT WCName FROM

dbo.WorkCenters WHERE

WCID in (select WCID

from dbo.Operations

where PartID in (select

PartID from dbo.Parts

where

OrdNumber='$OrderNum'

and PartName='$PartN'))"

2.2 Design the UI

The production process card software has three main

menus there are process, image, and schedule. The

script and the UI is shown below.

Figure 2: UI for production card process software.

Access to software is divided into operators,

workshop heads, and PPC. If the user has not logged

in either as an operator, workshop head, or PPC

admin, then the user cannot access the software

functions at all and can only access the main page

with a blank display where the software functions

should be located.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

904

Figure 3: Script for account access.

2.3 Program the Script

The production process cards using PHP

programming language to be able to make

connections and run SQL commands on software web

pages. The PHP programming language allows web

pages to make connections and execute SQL

commands. PHP writing is done with notepad and the

SQL management software used is SQL Server 2019

from microsoft. Main menu in production process

card software consist of three main menu they are

process menu that two sub menu, image menu that

have two sub menu, and schedule.

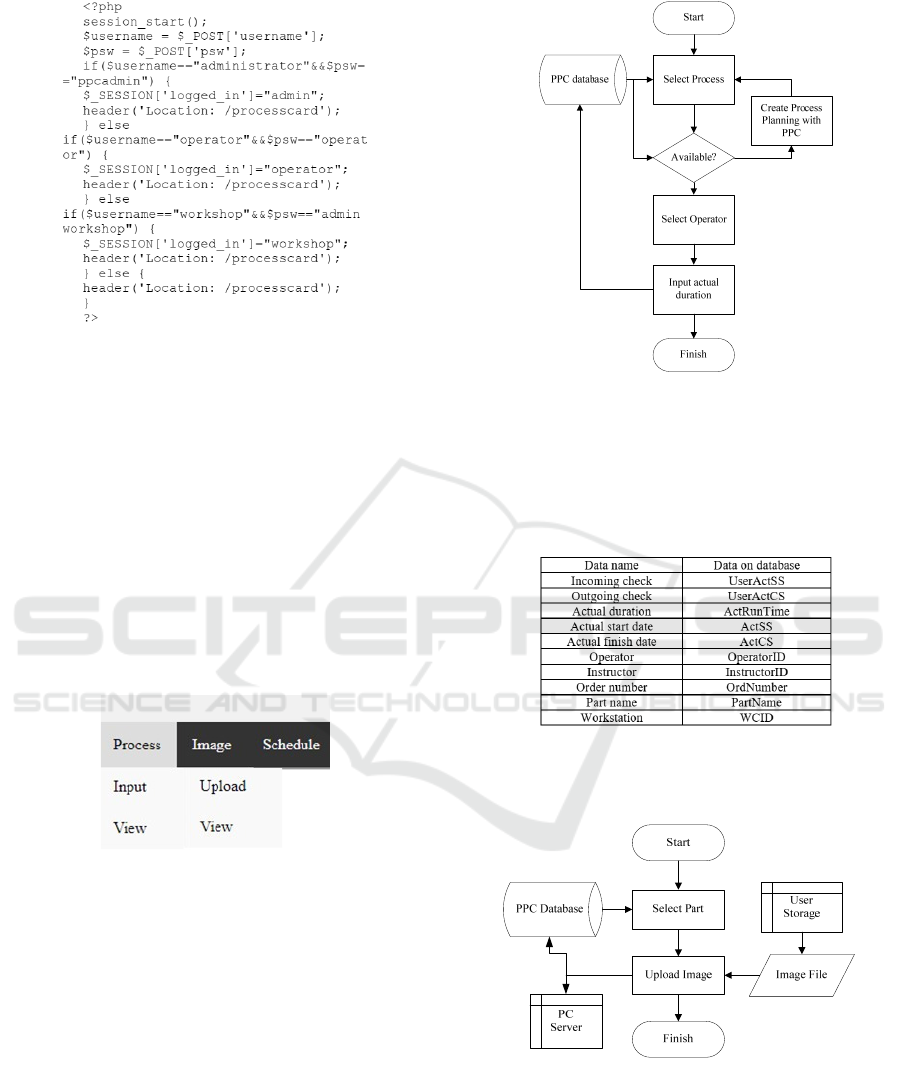

Figure 4: Three main menu and sub menu.

Process input menu have funtion to create,

modify, or delete data or records of a process for a

part in an order.

Figure 5: Flowchart for Process input.

Process card view have function to output any

data that has been written from the process card input

for all processes in a part of an order.

Table 2: Data on the input process.

Uploading images have function to upload

working images both by PPC and by the head of the

workshop for operators to work on.

Figure 6: Flowchart of the process of uploading an image.

Image view have function to view the uploaded

work images from image uploads.

Development of Cloud Based Production Card Process for Manufacturing

905

Figure 7: Flowchart to select a part on View Process.

Schedule is have funtion to issue a work schedule

for an order in the form of a Gantt chart.

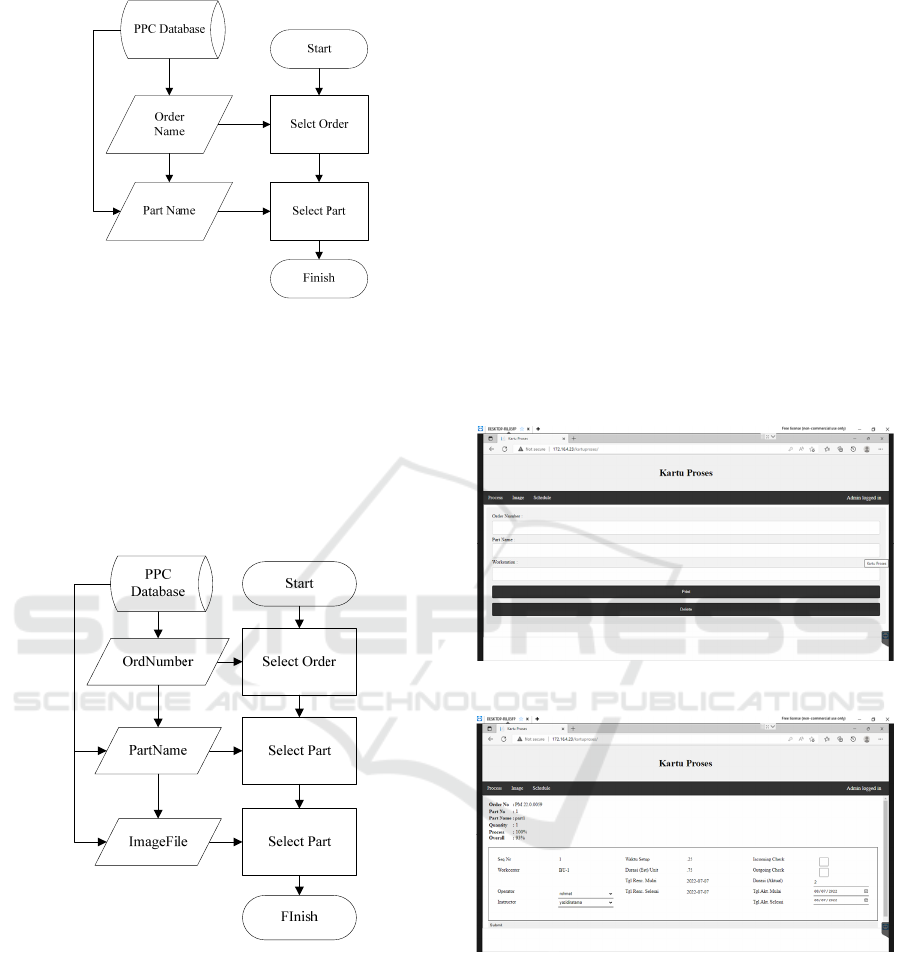

2.4 Software Compiling

After the user interface has been created and the

scripting has been programmed for the PPC software,

the next step is to run and test it.

Figure 8: Display the process selection interface.

3 IMPLEMENTATIONS

After all the planning has been completed on the PPC

software, starting from part planning to assy and

scheduling, with the kartuproses software, the head of

the workshop selects an operator and instructor for

each operation on the workstation for each process

and part.

The workshop head can also upload working

drawings for operators to work on in the drawing

section.

The operator fills the part of the kartuproses

software with operator access to enter the actual time

and date that the operator is working on. Operators

can view working drawings uploaded by the head of

the workshop in the drawing section. The end result

of this whole process is a process card that contains

all the processes for a part in sequence.

3.1 Software Test

After the user logs in, the user can choose part or

process depending on what is selected. If the user

selects an input process, an interface will appear to

select a process. If the user selects view process, an

interface will appear to select a part.

Figure 9: Display process selection interface.

Figure 10: Display the program input process interface.

Selecting and uploading technical drawings by

uploading and viewing images is the same as the view

process, an interface will appear to select a part. It's

just that in the upload image there is a section where

the user can choose a technical drawing to upload and

then view it in the view image. In the image view

there is also a section where the user can select the

previously uploaded image.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

906

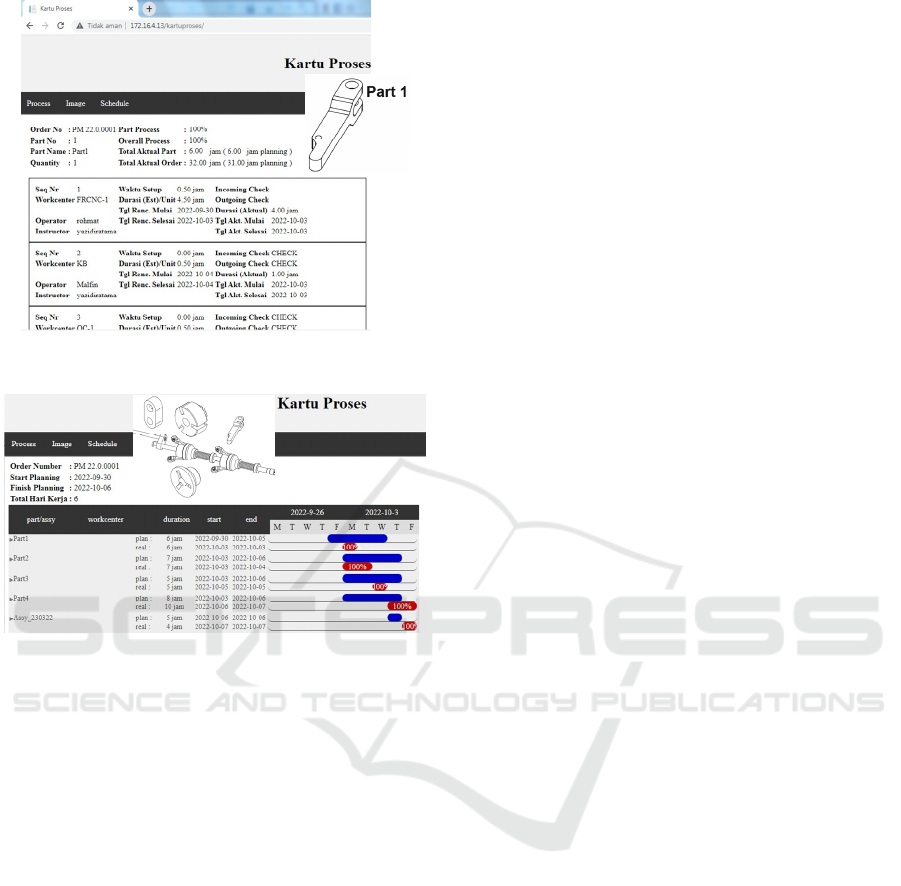

Figure 11: Display of the results of the view process of a

part.

Figure 12: Interface for uploading images.

Figure 13: Interface for image views.

The scheduling section is a section for viewing the

schedule of each process on an order in the form of a

gantt chart. In it there is a section where the user can

select the order number or job number from the

database.

Figure 14: Interface for schedule.

Figure 15: Result of schedule view.

3.2 Software Trial

An example component will be used to trial the

production process card. The component is a general

mechanics type that consist of four part with number

order PM 22.0.0001.

Part 1

Part 2

Part 3

Part 4

Figure 16: example component PM 22.0.0001.

A manufacturing sequence for these four

component of Tripod shown by table below.

Table 3: Manufacturing sequence for component in Tripod.

Parts Manufacturin

g

Sequence

1 2 3 4

1 Mill Workbench Qc

2 Turnin

g

Mill Workbench Qc

3 Turnin

g

Mill Workbench Qc

4 Mill Drill Workbench Qc

These manufacturing sequence the stored into

PPC software for every Tripod component. If we call

the order number PM 22.0.001 in process card

software, it will show the detail data about the

process, it’s sequence, process time, operators, actual

time, planning time, etc like shown below.

After input the process time and delivery time for

the project (in this example is Tripod), then we can

see the ganchart schedule with actual and planning

time for the project like shown below.

Development of Cloud Based Production Card Process for Manufacturing

907

Figure 17: manufacturing sequence for part 1.

Figure 18: Manufacturing schedule process for Tripod

component.

4 CONCLUSIONS

From the development of this cloud-based Production

Cards Process software, two conclusions can be

drawn as:

1 The software developed has succeeded in issuing

process cards as a function of monitoring the work

process as well as gantt charts from the schedule

as planning and monitoring the entire process on

an order.

2 The process card software workflow works with

two types of users with different access, namely

operators and workshop heads. The workshop

head appoints an operator and instructor for an

operation, and the operator fills in the actual

duration and actual date of a process. The third

account in the form of a PPC admin can access

everything that the operator and the head of the

workshop can access.

REFERENCES

Noviyasari, C. (2011). Simulation of Production Planning

and Control Systems in Manufacturing Companies.

Journal of Informatics Management (JAMIKA), 1(2).

Dhuha, AR, Pradana, F., & Priyambadha, B. (2017).

Development of a Web-Based Project Management

Application System (Case Study: PT. Swadaya Graha).

Journal of the Development of Information Technology

and Computer Science E-ISSN, 2548.

Yeager, NJ, & McGrath, RE (1996). Web server

technology. Morgan Kaufmann.

Kurniawan, E. (2015). Application of Cloud Computing

Technology at the University Case Study: UKDW

Faculty of Information Technology. Journal of

Exploration of Information Systems and Science, 8(1).

Nuryana, M., & Sulistiyono, S. (2014). Analysis and

Design of Hotel Front Office Systems at Pt Ratu Hotel

Bidakara Serang. ProTekInfo (Research Development

and Observation of Informatics Engineering), 1, 48-54.

SQL Server Programming 2019. (2021). (np): Elex Media

Komputindo.

Puspitasari, D., Watequlis, Y., & Asmara, RA (2017). The

Use of Tansact SQL (T-SQL) in the Development of

Web-Based Database Management Applications.

Simantec Journal, 6(2).

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

908