Design of Tool Elasticity of Compressed Springs Tester with the

Variable Value of the Force and Spring Constant Through a Load

Cell and a Millimeter Scale Reading Method

Meri Rahmi

1a

, Rachmatullah

2b

, Aida Mahmudah

1c

and Yuliar Yasin Erlangga

1d

1

Teknik Perancangan Manufaktur, Politeknik Manufaktur Bandung, Jl. Kanayakan No. 21, Bandung, Indonesia

2

Teknik Mesin, Politeknik Negeri Indramayu, Indramayu, Indonesia

Keywords: Spring Elasticity, Spring Force, Spring Tester, Load Cell, Millimeter Scale.

Abstract: This study aims to design a tool for testing the elasticity of compression spring that often used in strippers in

press tool design. The elasticity spring is the ability of the spring to return to its original shape when the

external force is removed. The process of loading and unloading compressed springs uses a hydraulic system.

The method for reading the value of spring elasticity at the time of measurement on the tool is by using a load

cell measuring instrument and a millimeter scale. Design of tools from being a tool for reading the spring

elasticity value it can also be used as a tool to install and ensure that the spring is attached to the stripper. The

design method refers to VDI 2222 which consists of planning, concept, design process, and finishing. The

results obtained are the tester design of the test equipment with a maximum capacity for four springs, with a

total load that can be accommodated 180 kg. The results of calculations and simulations using Solidworks

software show that the frame and base are safe because they can withstand a pressure with a safety factor

value of 2.

1 INTRODUCTION

One part of the press tool construction is the stripper

plate. The stripper plate is a part that can moves freely

up and down along with a spring attached to the bolt

holder. This plate functions as a material clamping

plate during the process and so as to avoid the

occurrence of defects in the formation of the

workpiece surface such as wrinkles and folds, as well

as a punch guide. One of the components to help the

movement of the stripper plate is the stripper spring.

The stripper spring serves to maintain the position of

the stripper, return the punch position to its initial

position, and provide a compressive force on the

stripper so that it does not shift when subjected to

cutting and shaping forces.

Springs are objects that have elastic properties to

a certain extent. The elasticity's spring is the ability of

the spring to return to its original shape when the

a

https://orcid.org/0000-0002-9379-3083

b

https://orcid.org/0000-0002-8579-721X

c

https://orcid.org/0000-0001-5865-6895

d

https://orcid.org/0000-0001-6677-6133

external force was removed. However, several

obstacles that still encountered in the determination

and selection of springs, one of which is the absence

of tools to ensure and test the condition of the spring

and its elasticity properties, especially the

compressed spring for the stripper on the press tool.

The problem of testing the compressive elasticity of

the stripper for the press tool is still not widely studied

and researched, especially on the education scale. It

can also be used as practicum material for students to

test the elastic properties of springs.

The problem of testing the compressive elasticity

of the stripper for the press tool is still not widely

studied and researched, especially on the education

scale. It also can be used as practicum material for

students to test the elastic properties of springs.

According to (Yakin, et al., 2020) in their research

stated that the results of the spring constant analysis

using the conventional method showed that the

horizontal and vertical soil spring constant values for

Rahmi, M., Rachmatullah, ., Mahmudah, A. and Erlangga, Y.

Design of Tool Elasticity of Compressed Springs Tester with the Variable Value of the Force and Spring Constant Through a Load Cell and a Millimeter Scale Reading Method.

DOI: 10.5220/0011964200003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 937-941

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

937

clay soils were the same as those for sandy soils with

the same N-SPT value. Budi research, et al., (2020),

only discusses the nature of the spring constant and

the modulus of elasticity with the conclusion that two

identical springs have different spring constant

values. While the value of the spring constant is

directly proportional to the value of the modulus of

elasticity but inversely proportional to the length of

the material. The results of the design and simulation

of the spring constant test equipment for a capacity of

50N/mm, able to withstand a maximum static load of

2000N or 203.94 kgf with a safety factor of 1.1

(Pratama and Fitri, 2021). Research by (Djaja and

Hatuwe, 2015), states that there is a decrease in the

spring caused by cyclic loads, minimum loads

(preload) the number of revolutions caused by diesel

motors. However, this decrease in spring force is still

in the safe category from several parameters.

Several studies have discussed the design of

spring constant test equipment. The design of the

spring constant test tool that has been carried out by

Chaudhary (2018) states that the tool in the form of a

spring rolling machine is very simple in operation

using a microcontroller with a digital display.

Meanwhile, (Jadhav., et al, 2015) in a hydraulic

spring stiffness testing machine made a tool using two

cylinders with different diameters connected by the

same fluid. Rahat, et al., (2015) performed spring

compression on a spring constant testing machine

using a combination of direct shear loads and

torsional loads. Saha, et al., (2018) for a spring

stiffness measuring apparatus tool using a pneumatic

system the air cylinder is clamped perfectly to the

equipment frame. So, this machine uses wind power

from the compressor. While the spiral spring

deflection test tool Martias's (2018) research uses a

mass placed on top of the spring to be tested.

Based on the exposure of several studies above,

several tests of spring constants and spring elasticity

properties have been carried out, as well as several

forms of test equipment that have been made for

certain needs with several methods. It is still difficult

to find research that discusses how to check and test

springs that have been installed and have been used

in the production process several times, especially for

stripper springs used in press tools. The purpose of

this research is to design and manufacture a tool for

testing the elasticity properties of the compressed

spring with the method of reading the value of the

variable force and spring constant through a load cell

and a millimeter scale for tools that install springs on

a stripper for press tools with a hydraulic system in

previous studies.

2 METHOD

2.1 Design Method

The design method will follow the VDI 2222 method

to design tools according to several types of springs

with different press tool shapes. The VDI 2221

method is a “Systematic Approach to Design for

Engineering Systems and Engineering Products”

described by (Pahl, et al., 2007) in his book,

Systematic Approach to The Design of Technical

Systems and Products. This method is very suitable

for designing the test equipment because there are

problems faced also systematic in the steps of the

process. Tools designed, able to adjust the shape of

the press tool. The experimental method is carried out

by performing the Finite Element Method (FEM)

using supporting analysis software that can analyze

well to analyze the shape of the tool design. The

design stages for this tool which refers to the VDI

2222 method are:

1. Planning

At this stage, identification of the requirements

required for testing aids carried out. A spring

tester is needed to test the spring deflection and

the maximum spring load on the existing

component catalogue with actual readings. In

addition, a spring tester can be used to check the

quality of springs that are old but still fit for use.

Because there is a need, a solution is made that

will later meet that need.

2. Concept

At the conceptualizing stage, a list of

requirements is made as a reference in making

the design. Based on this list of requirements,

the most optimal design concept for the

assessment of technical aspects will be made. In

addition, the search for data and information

about the test equipment that will be made starts

from the shape of the frame to the sensors that

will be used.

3. Design

This stage can be done when it’s have

determined the chosen alternative design, which

alternative has met the design requirements for

the customer. The design made is in the form of

a 3D modeling design using Solidworks

software.

4. Finalization

At the final stage in the design process, it

produces a complete working drawing of the

part drawing, but in the design of this spring

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

938

tester, it has only arrived at the stage of making

the 3D modeling design.

2.2 Product Analysis

The requirements for a spring tester can be seen in

Table 1. This tool is designed for testing the elasticity

of a compressed spring with a force that reaches 180

kg Regarding the page layout, authors should set the

Section Start to Continuous with the vertical

alignment to the top and the following header and

footer:

Table 1: Design List Demand.

Requirements Quantity

(

Unit

)

Press Type Hidraulic Hand Pump 1

Load Cell Type Compression Load Cell 1

Display Type Digital 1

S

p

rin

g

T

yp

e S

p

rin

g

Coil 4

3 THE RESULT

3.1 Design Alternative

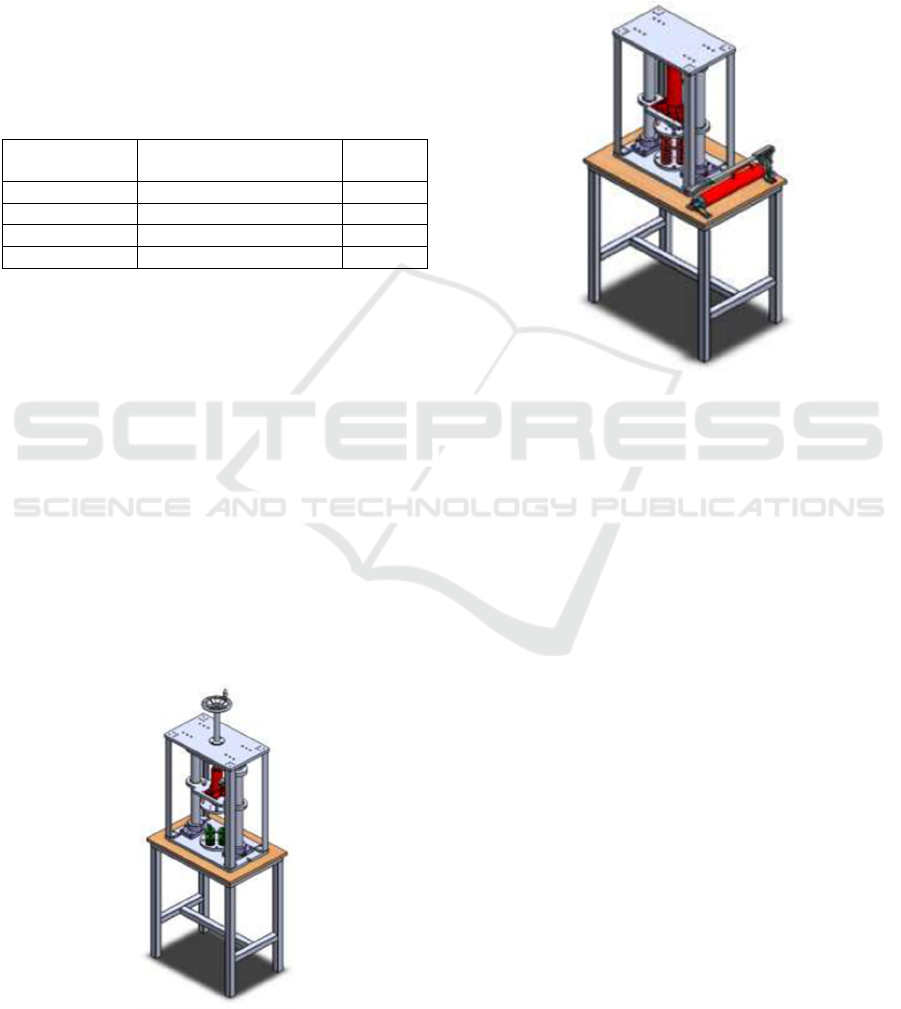

Based on the stages in the design, the obtained two

alternative designs of tools for testing the elasticity

properties of the compressed spring with the method

of reading the value of the force variable and spring

constant through a load cell and a millimeter scale.

The form of 3D models for these two alternatives can

be seen in Figure 1 and Figure 2. These two

alternatives can accommodate the integrity or

requirements must be as a spring elasticity testing

tool. Each alternative has advantages and

disadvantages.

Figure 1: 3D Alternative Model 1.

The advantage of the first alternative design is that

the tool operating system is easier. Because the

moving side process can be adjusted by adjusting the

height (adjustable). The operation process is also

facilitated by the presence of a handle wheel. Another

advantage is the relatively smaller dimensions of the

tool. However, the first alternative has a drawback,

namely, the number of components used is more.

Figure 2: 3D Alternative Model 2.

The second alternative design is the opposite of

the first alternative design. These two alternative

designs can accommodate the needs and requirements

as a tool for testing the elasticity of the compressed

spring.

Based on the consideration of the two alternative

designs for testing the elasticity properties of the

compressed spring using the method of reading the

value of the force variable and spring constant

through a load cell and a millimeter scale, the design

chosen is the first alternative design because of the

ease of operation and smaller dimensions of the tool.

The framework used in the first alternative is the L

profile and is used as a reference in calculation and

simulation analysis using Solidworks software.

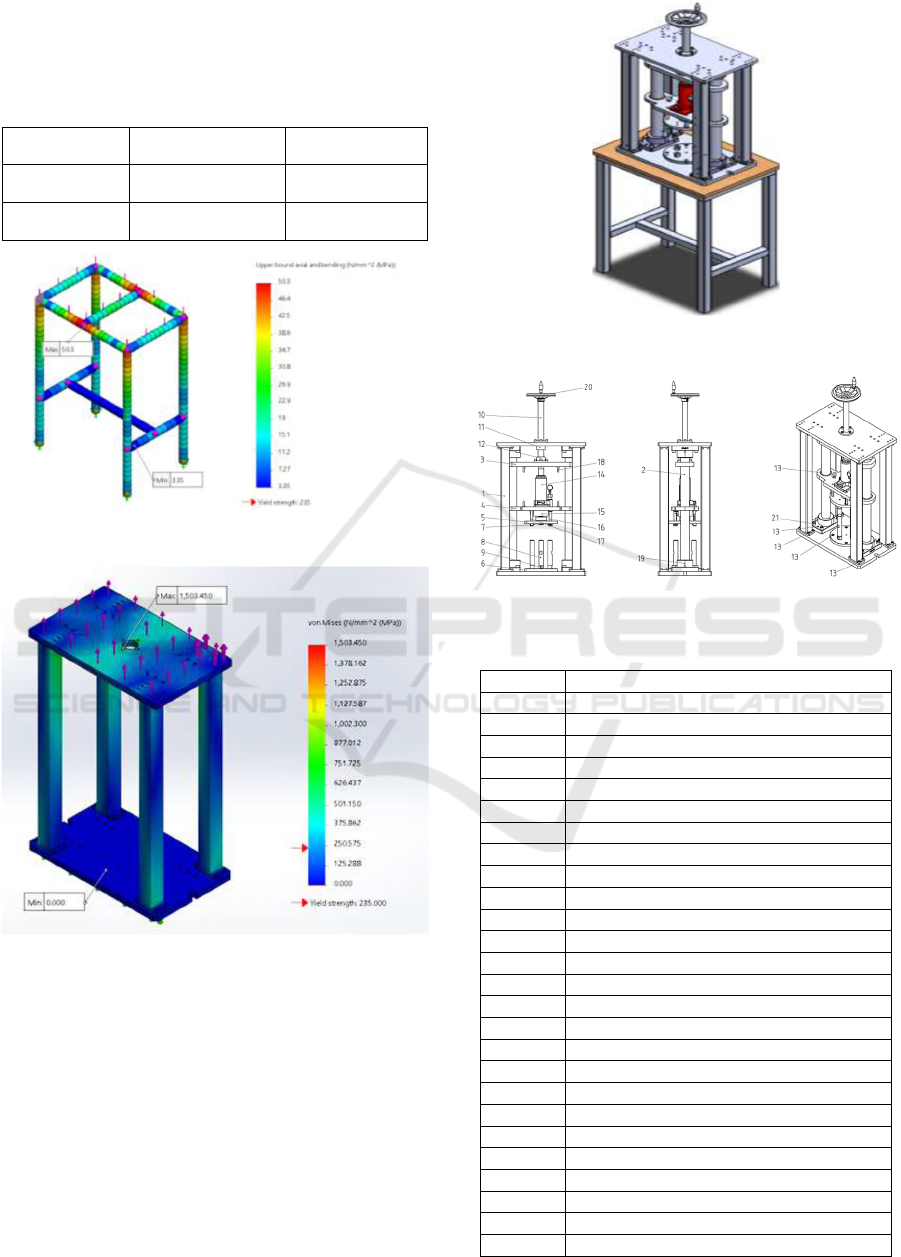

3.2 Design Calculation

The calculation was carried out on the chosen

alternative design, namely the first alternative which

can be seen in Figure 1. The critical parts that need to

be analyzed and simulated are the frame and upper

plate because they get greater pressure during

operation. The safety factor used in the calculation is

2. This is because this tool was included in the

category of dynamic loading, known materials, and

environmental conditions of fixed and easily

Design of Tool Elasticity of Compressed Springs Tester with the Variable Value of the Force and Spring Constant Through a Load Cell and a

Millimeter Scale Reading Method

939

determined loads and stresses. The simulation results

using Solidworks can be seen in Figures 3 and Figure

4.

Table 2: Pressure Calculation Results

Plane Pressure Value Unit

Frame 0.02 N/mm

2

Upper Plate 2.67 N/mm

2

Figure 3: Frame Simulation Results.

Figure 4: Upper Plate Simulation Results.

From the results of calculations and analysis, the

frame used is recommended to be replaced the

minimize damage that occurs. The recommended

frame profile is using a square tube profile. Based on

the calculation results and recommendations, the

finalization of the design was carried out by changing

the L profile to a square tube profile which can be

seen in Figure 5. While the working drawing without

a framework that will be used as a reference in

making the product can be seen in Figure 6. The part

descriptions can be seen in Table 3.

Figure 5: 3D Final Model.

Figure 6: Final Drawing.

Table 3: Drawing Part.

No. Part Name

1Frame

2 Guide Shaft

3 Indexing Plate

4H

y

draulic Base Plate

5 Base S

p

rin

g

U

pp

e

r

6 Base S

p

rin

g

Lowe

r

7SringHolder Uppe

r

8 Spring Holder Lowe

r

9 Extension Shaft

10 Ad

j

uster Shaft

11 Screw Bush Ad

j

uster Shaft

12 Adjuster Shaft Holde

r

13 Insert Bush Hydraulic Base

14 Hydraulic

15 Load Cell

16 Guide Pin

17 Stri

pp

er Bolt

18 Lifting Eye Bolt

19 Guide Shaft Holde

r

20 Handle Wheel

21 L-Bolt M12x40

22 L-Bolt M8x25

23 L-Bolt M6x16

24 Pin Bolt M8x10

25 Silinder Pin dia 10x35

26 Silinder Pin dia 6x20

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

940

4 CONCLUSIONS

A tool for testing the elastic properties of compressed

springs using the method of reading the value of the

force variable and spring constant through a load cell

and a millimeter scale, consisting of the frame and

base, and the system. The use of a hydraulic jack as a

spring press. When the spring is pressed, the length of

the spring will change. This process continues until

the maximum working condition of the spring.

Changes in the length of the spring will be read on the

millimeter scale measuring instrument. Meanwhile,

elasticity is measured with a load cell. Tests were

carried out for a maximum of four springs, with a total

load that can be accommodated 180 kg.

The results of calculations and simulations using

Solidworks software show that the frame and base are

safe because they can withstand a safety factor of 2.

However, it is recommended to use square tube

profile steel. However, this still needs further research

to compare in terms of costs.Words like “is”, “or”,

“then”, etc. should not be capitalized unless they are

the first word of the subtitle.

ACKNOWLEDGEMENTS

Thank you to those who have helped to carry out the

analysis, especially to Politeknik Manufatur Bandung

with this collaboration. And thank you to Politeknik

Negeri Indramayu for financing this research so that

it can be implemented well. We hope that paper can

be used for knowledge and study in vocational

university to improve the students sklills.Please note

that the name of each author must start with its first

name.

REFERENCES

Bhandari, V.B. (1994). Design of Machine Elements. India:

Tata McGraw-Hill International Book Company.

Boljanovic, Vukota. 2004. Sheet Metal Forming Processes

and Die Design. United States: Industrial Press

Budiarto. (2001). Press Tool 3 (Proses Drawing). Bandung:

Politeknik Manufaktur Negeri Bandung.

Budynas dan Nisbett. (2006). Mechanical Engineering.

United States of America: Mc-Graw-Hill International

Book Company.

Deutschman, A. (1975). Machine Design Theory and

Practice. New York: Macmillan

Dharmika, P. Adhi. 2013. Rancang Bangun Load Cell

(Sensor Gaya) Berkapasitas 10 kN untuk Uji Tekan

Material. Jurusan Studi Fisika, FST, UIN.

Djaja, Y., & Hatuwe, M.R (2015). Uji “Ketahanan Lelah

Dan Penurunan Gaya Pegas “Katup Kompresi Akibat

“Beban Operasi” Pada Katup Motor Diesel Output

Rated 400 Kw.11(02), 205–212

Hayes, M. (2006). Compression Spring Equipment, Design,

and Non-Axial Performance. Springs, 45(4), 63-64.

Idiar. 2016. Rancang Bangun Cetakan Deep Drawing Cup

Silindris untuk Selongsong Peluru Kaliber 20

Milimeter. Jurusan Teknik Mesin FTI ITS.

Jadhav, A. R., Pol, G. J., & Desai, A. A. S (2015). Design

and Manufacturing of Hydraulic Spring Stiffness

Testing Machine. 4395 (October 2014), 184–190.

Khurmi RS Gupta, JK., (2005). TextBook of Machine

Design Eurasia, Publising House ltd Ram Nagar, New

Delhi.

Manullang. (2020). Analisa Gaya Tekan Mesin

Pembentukan Logam Pada Pembuatan Tutup Mangkok

Dengan Bahan Aluminium Menggunakan Instrumen

Load Cell. Jurusan Teknik Mesin, FTI, UMSU.

Martias, H. D. (2018). Perancangan Dan Pembuatan Alat

Uji Defleksi Pegas Spiral. 1, 1–7.

Muller, I. Brito, R.M.d, Pereira, & Brusamarello, V. (2010).

Load Cells in Force Sensing Analysis – Theory and a

Novel Application. IEEE. Instrumentation &

Measurement Magazine

Naik, S., & Kumbhalkar, S. B. J. S. S. (2018). Design &

Analysis of Helical Spring Testing Machin: A Review.

6(01), 1059–1060.

Pahl, G., Beitz, W., Feldhusen, J. and Grote, KH.,

Engineering design – a systematic approach, Translated

and Edited by Wallace, K., Blessing, L., 3rd ed (2007),

pp. 125-436, Springer-Verlag, London

Pollack, Herman W. 1988. Tool Design Second Edition.

United States: Prentice Hall

Pratama, Zizka Moch dan Fitri, M. (2021). Desain

Komponen Utama Alat Uji Konstanta Pegas Untuk

Kapasitas 50 N/mm. Jurnal Teknik Mesin, Vol.10. No.1

Publishing Co., IncWidhi Artha, Gandhi. (2015).

Perancangan Die Set untuk Proses Ironing Selongsong

Peluru Kaliber 20 Milimeter. Jurusan Teknik Mesin

FTI ITS.

Setiahardja, T.S. (2010). Pengembangan Alat Ukur

Berbasis Load Cell Untuk Pengujian Tahanan Model

Kendaraan Tempur Amphibi. Jurnal Wave. Vol 4 (02),

66–70

Sularso, Kiyokatsu Suga, (2004). ”Dasar Perencanaan dan

Pemilihan Elemen Mesin”. Jakarta: Pradya Paramita

Togotorop. 2017. Rancang Bangun Alat Ukur Konstanta

Pegas Menggunakan Arduino Uno Dan Sensor

Ultrasonik Hc-Sr04. Jurusan Teknik Eelektro, FT,

UMA.

Yakin, Y. A., Pratiwi, D. S., & Bilaldy, B. F. (2020).

Analisis Konstanta Pegas pada Fondasi Tiang (Studi

Kasus: Gedung Type B DPRD Surabaya). Jurusan

Teknik Sipil Itenas, 42-53.

Yuliafif, Afrizal (2017). Rancang Bangun Cup Ejector Pada

Proses Deep Drawing Cup Selongsong Peluru Kaliber

20 Mm. Jurusan Teknik Mesin FTI ITS.

Design of Tool Elasticity of Compressed Springs Tester with the Variable Value of the Force and Spring Constant Through a Load Cell and a

Millimeter Scale Reading Method

941