The Implementation of Eco-Design Through Group Tool Design for

Reinf-FR Towing Pipe Products

Hanif Azis Budiarto

a

, Yuliar Yasin Erlangga, Sidik Permana and Gheiska Amelia Wardhana

Department of Design Engineering, Bandung Polytechnic for Manufacturing, Bandung 40135, West Java, Indonesia

Keywords: Green Manufacturing, Eco-Design, Group Tool, Press Tool, Reinf-FR Towing Pipe.

Abstract: Green manufacturing is a process or system that does not have a negative impact on the environment.

However, in Indonesia, four-wheeled vehicles are still the most popular mode of transportation. With high

demand, car production and the number of components are also increasing. Improving the efficiency of the

tools and machines is necessary for the stamping process. One vehicle component with several process

stages during stamping processes is the Reinf-FR Towing Pipe. Four stages of the process are required to

manufacture the Reinf-FR Towing Pipe components. Eco-design can help to reduce or eliminate the

negative effects of manufacturing on the environment. To implement green manufacturing, a group tool has

been designed using VDI 2222 methods and ISO 14006:2011. By grouping multiple processes into one tool,

only one machine is required.

a

https://orcid.org/0000-0002-1983-3032

1 INTRODUCTION

Four-wheeled vehicles are still the most popular

mode of transportation in Indonesia. This can be

seen in Indonesia, which became Southeast Asia's

country with the highest car sales throughout 2021.

Sales reached 887,202 units, an increase of 66.8%

compared to 2020 (Kurniawan, 2022). In addition,

the issue of the Abolition of Luxury Goods Sales

Tax (PPnBM) is also one of the triggers for people

to buy new cars (Doni, 2021). With high demand,

car production is also increasing. Total car

production in Indonesia during 2021 was 1,121,967

units, an increase of 62.6% from the previous year

(Kurniawan, 2022).

Each car unit consists of many constituent

components. The number of components in the

vehicle causes the need for many tools to produce a

car. Several stages of the process need to be done to

make one vehicle component so that the number of

tools required to make one component can be more

than one. The more tools used, the more machines

required. One vehicle component with several

process stages during manufacture is the Reinf-FR

Towing Pipe.

Figure 1: Reinf-FR Towing Pipe Component.

Figure 1 shows the Reinf-FR Towing Pipe

component. This component is one part of the

bumper beam. The bumper beam itself has a

function as a protector of vehicle components such

as engine parts and oil tanks in the event of a major

collision due to accident. Four stages of the process

are required to manufacture the Reinf-FR Towing

Pipe components.

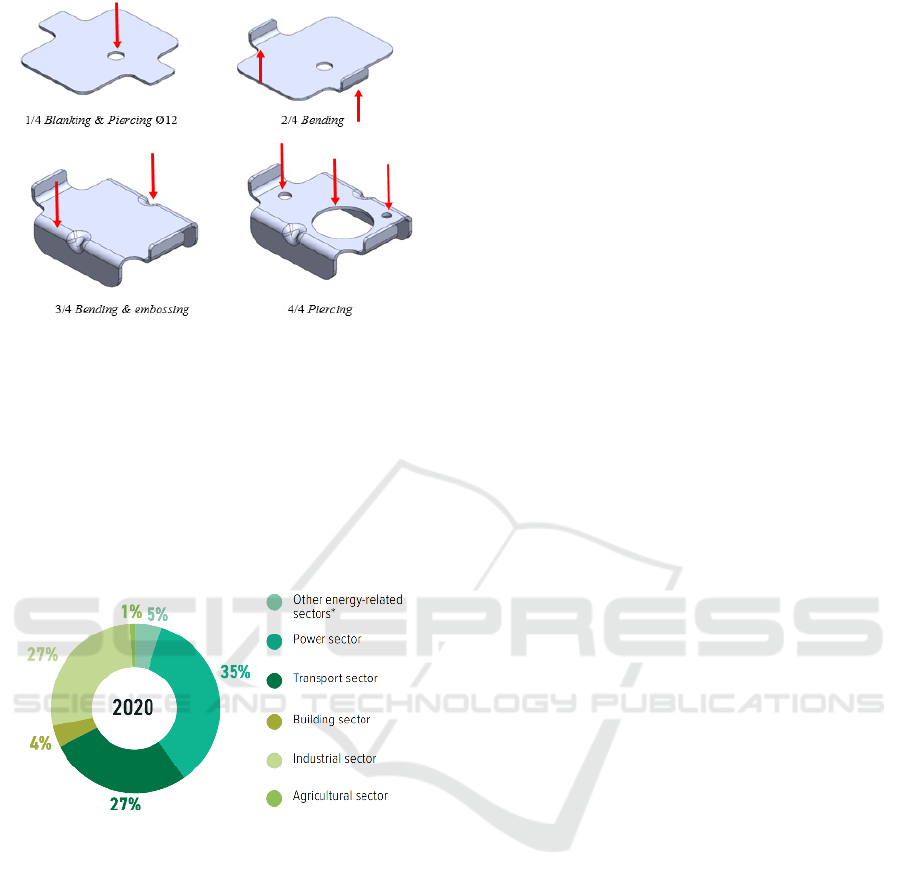

Figure 2 shows the stages of the manufacturing

process for the Reinf-FR Towing Pipe component.

The four stages of the process carried out in the

manufacture of Reinf-FR Towing Pipe components

are blanking & piercing, bending, bending &

embossing, and piercing. The four processes are

carried out using four different single tools, so four

machines will be used for each tool.

942

Budiarto, H., Erlangga, Y., Permana, S. and Wardhana, G.

The Implementation of Eco-Design Through Group Tool Design for Reinf-FR Towing Pipe Products.

DOI: 10.5220/0011966400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 942-946

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 2: Stages of the process of making the Reinf-FR

Towing Pipe component.

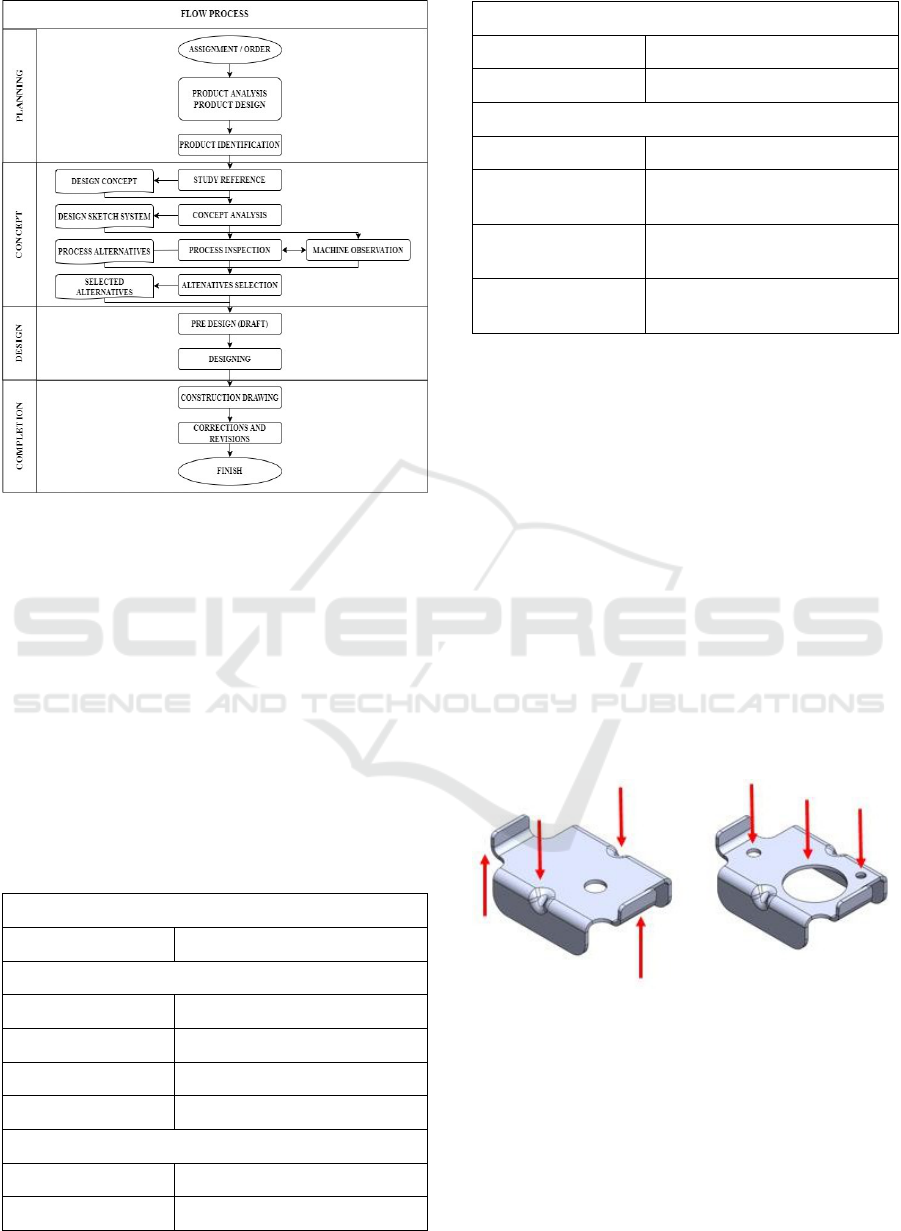

Figure 3 shows a graph of the contribution of

various sectors to the amount of CO

2

emissions from

fuel combustion in Indonesia. The industrial sector

is in the top three positions, contributing the most

CO

2

emissions, 27%. This is related to the large

number of machines used in the industry. To

overcome this, the concept of green manufacturing

is needed.

Figure 3: CO2 emissions from fuel combustion by sector

in Indonesia (Climate Transparency, 2021).

Green manufacturing is a process or system that

does not have a negative impact on the environment

(Dornfeld, 2013). To reduce or eliminate the

negative effects of the manufacturing process, lean

manufacturing can be done. Lean manufacturing is

streamlining the production process by considering

all resource expenditures to produce products with

economic value without waste (Sundar et al., 2014).

It is considered to be the most influential in

manufacturing as empirical evidence that enhances

organisational competitiveness (Ikatrinasari et al.,

2018). Eight things cause production wastage:

transport, inventory, motion, waiting,

overproduction, over-processing, defects, and

unutilised talent (Leksic et al., 2020).

Improvement tools for manufacturing vehicle

components can reduce the eight wastes in the

manufacturing process. Eco-design is one way to

implement green manufacturing. Casamayor and Su,

(2021) assessed each LED lighting production

process. One of the processes that implement eco-

design on products is optimising the amount of

material used via simulation and optimisation, in

that case, using SolidWorks simulation. Using the

eco-design concept, the production process of

vehicle components also can be faster and reduce the

use of raw materials for tool making and press

machines. Therefore, a tool improvement design was

carried out to manufacture a Reinf-FR Towing Pipe

using the tool group. It combines 2-3 types of work

on a single die set, single operation. Usually, this

tool group has no more of the two operations

(Budiarto, 2012). Tool build, cost calculation, and

tool life are not discussed. Currently, three machines

are needed to produce the Reinf-FR Towing Pipe.

By grouping multiple processes into one tool, only

one machine is required.

2 METHODS

The VDI 2222 (Verein Deutsche Ingenieur) and ISO

14006:2011 methods are used to design a group tool

because this method is suitable for the product

development process based on eco-design. By using

this method, scrap and cycle times are expected to

be reduced. (Budiarto et al., 2022; Navajas et al.,

2017). By reducing cycle time, energy consumption

is also reduced. This method consists of 4 main

stages, planning, conceptualising, designing and

completion. Figure 4 shows the flow process of VDI

222.

In the planning stage, the first step is to analyse

and identify the product so that a product

requirement is generated (Sianipar et al., 2013). As a

result of the product analysis, the cutting-forming

process stages will be determined to produce

products according to the specifications on the

product working drawings. Tool design was

developed using the layout process design for each

function part of the tool. After the layout process is

completed, a draft will eventually be detailed into an

Assembly drawing and components drawing.

Finally, the cycle time of the product production

process is investigated to ensure that the design

made is an eco-design.

The Implementation of Eco-Design Through Group Tool Design for Reinf-FR Towing Pipe Products

943

Figure 4: VDI 2222 Methods.

3 RESULTS AND DISCUSSIONS

3.1 Planning

Eco-design must be employed in the development of

the tool designed. It is expected to reduce cycle time

and production costs without compromising product

quality. The production costs can be reduced by

minimising the number of operators and machines.

Table 1 shows the list of design requirements that

have been compiled.

Table 1: Design Requirements.

Design Requirement

Demands Qualification

Product

Product dimension According to the 3D model

Thickness 2.3 mm

Grade SAPH440-P

Tensile Strength 440 N/mm²

Tool

Assy Process Easy for maintenance

Clamping System Strap clamp

Design Requirement

Demands Qualification

Standard Components MISUMI

Machine

Machine capacity Min. 120% of tool Force

Ram Dimension

Min. equal with an upper plate of

the tool

Bolster dimension

Min. equal with a lower plate of

the tool

Die height

Min. equal to a total height of the

tool

3.2 Concepting

A construction design concept is developed based on

the design requirements. The punch forming and

piercing are located in the upper assembly of a push-

through design, while the die is located in the lower

assembly. Considering the limited space in this

construction, no button die is used in the piercing

process. A push-through mechanism is used to

ensure scrap falls to the lower plate (Budiarto et al.,

2022).

The process involves merging the same two

processes in one station and creating a tool group

consisting of two stations. The first station is used

for u-bending and embossing, while the second

station is used for piercing. Figure 5 shows the

process from each station.

(a) (b)

Figure 5: (a) Station 1: u-bending and embossing (b)

Station 2: piercing.

As part of the process layout, a punch is also

used as a blank holder to hold the material flow rate.

The punch will form the U-bend first and then, when

bottoming, act as a stripper for the second bending

and embossing (Patriatna & Budiarto, 2015). Figure

6 shows the design construction from the front and

side views.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

944

(a)

(b) (c)

Figure 6: Design construction (a) front view of station 1

(left) and station 2 (right); side view (b) station 1 (c)

station 2.

3.3 Design Calculation and Control

Processes

3.3.1 Blank Calculation

SolidWorks software was used to perform a blank

calculation using the K-factor and neutral axis

settings. Figure 7 shows the blank from the software

calculation.

Figure 7: Blank from Software calculation.

3.3.2 Press Tonnage Calculation

Machine control calculations are performed to

ensure that the force required by the tool is

consistent with the machine being used. Table 2

shows the press tonnage calculation.

Table 2: Press tonnage calculation (Budiarto, 2012; Heinz

Tschaetsch, 2015; Rahmi, 2021).

Parameter Equations Result

Piercing Force = 0.8 · l · s · Rm 127.1 kN

Bending Force

= (1.7 · B · s

2

· Rm) / L

5.7 kN

Embossing Force = A proj . Kr 92.2 kN

Penetration = (1 ~ 3) · s 3,5 mm

Stripper Forming

Force

= 10% · F Process

9.68 kN

Stripper Piercing

Force

= 10% · F Process

12.71 kN

Pad Force

= (30 ~50) % (Fb + W)

0.342 kN

Total Tool Force 247.68 kN

Clearance = s · c

0.15 mm/

side

Machine capacity

= 120% · F tool

29,7 Ton

The press machine used is AIDA NC 1-1500 (2)

E, one of the references in selecting the minimum

press machine that can be used is the machine

tonnage based on calculations. Once the tonnage of

the press machine has been calculated based on the

required machine force, the dimensions of the ram

and bolster should be examined. The die height of

the machine must be taken into consideration if the

dimensions of the ram and bolts have been met.

Completion. The draft that has been made is then

converted into a 3d model and developed into an

Assembly drawing and parts. Figure 8 shows the 3D

model of the group tool for the Reinf-FR Towing

Pipe.

Figure 8: 3D model of group tool Reinf-FR Towing Pipe.

The Implementation of Eco-Design Through Group Tool Design for Reinf-FR Towing Pipe Products

945

3.4 Cycle Time Investigation

Further, the estimated processing time is calculated

to predict the products that can be completed in one

cycle. Table 3 shows the results of the cycle time

comparison.

Table 3: The comparison of cycle time.

Type of Tool

Cycle

Time

(seconds)

Setting

time

(seconds)

Time

Process +

Time

setting

Single tool 1 8 3.600 3.608

Single tool 2 12 3.600 3.612

Single tool 3 8 3.600 3.608

Total 10.828

Group Tool 15 3.600 3.615

Reduction Time (second) 7.213

Based on the calculation of processing time,

group tool can reduce the processing time by almost

66%. Furthermore, efficiency can also be measured

by the number of machines used. The existing

process requires three machines to produce the same

product, but only one machine will be required if

this tool is used. The reduction of the number of

machines and the cycle time of the process will also

reduce the electrical energy consumption.

4 CONCLUSIONS

A 260 mm x 386.3 mm x 550 mm tool group has

been produced for Reinf-FR Towing Pipe

components considering VDI 2222 methods and

eco-design. The group tool is designed using a push-

through system, station 1 forming (bending and

embossing), and at station 2 a piercing process, then

processed by an AIDA NC 1-1500 (2) Press

Machine. Moreover, with this group tool design, the

processing time can reduce almost 66%.

REFERENCES

Budiarto. (2012). Press Tool 1-3. Polman Bandung.

Budiarto, H. A., Permana, S., Yuliar, Y. E., & Hasyim, A.

P. (2022). Analisis produk dan perancangan

combination tool pada produk jam souvenir Polman

Bandung. Dinamika Teknik Mesin, 12(1), 66–77.

https://dinamika.unram.ac.id/index.php/DTM/article/v

iew/511/pdf

Casamayor, J. L., & Su, D. (2021). Investigation of a

process to eco-design led lighting products.

Sustainability (Switzerland), 13(8).

https://doi.org/10.3390/su13084512

Doni. (2021). Kebijakan PPnBM Dongkrak Penjualan

Otomotif Hingga Lebih Dari 60 Persen. KOMINFO.

https://www.kominfo.go.id/content/detail/38166/kebij

akan-ppnbm-dongkrak-penjualan-otomotif-hingga-

lebih-dari-60-persen/0/berita

Dornfeld, D. (2013). Green manufacturing: Fundamentals

and applications. Green Manufacturing: Fundamen-

tals and Applications, 9781441960160, 1–289.

https://doi.org/10.1007/978-1-4419-6016-0

Heinz Tschaetsch. (2015). Metal Forming Practice. In

Syria Studies (Vol. 7, Issue 1). https://www.research

gate.net/publication/269107473_What_is_governance/

link/548173090cf22525dcb61443/download%0Ahttp:/

/www.econ.upf.edu/~reynal/Civilwars_12December20

10.pdf%0Ahttps://think-asia.org/handle/11540/8282%

0Ahttps://www.jstor.org/stable/41857625

Ikatrinasari, Z. F., Hasibuan, S., & Kosasih, K. (2018).

The Implementation Lean and Green Manufacturing

through Sustainable Value Stream Mapping. IOP

Conference Series: Materials Science and

Engineering, 453(1). https://doi.org/10.1088/1757-

899X/453/1/012004

Kurniawan, R. (2022). Penjualan Mobil Indonesia

Terbesar di ASEAN Sepanjang 2021. Kompas.Com.

https://otomotif.kompas.com/read/2022/02/10/120200

715/penjualan-mobil-indonesia-terbesar-di-asean-

sepanjang-2021?page=all

Leksic, I., Stefanic, N., & Veza, I. (2020). The impact of

using different lean manufacturing tools on waste

reduction. Advances in Production Engineering And

Management, 15(1), 81–92. https://doi.org/10.14743/

APEM2020.1.351

Navajas, A., Uriarte, L., & Gandía, L. M. (2017).

Application of eco-design and life cycle assessment

standards for environmental impact reduction of an

industrial product. Sustainability (Switzerland), 9(10).

https://doi.org/10.3390/su9101724

Patriatna, E., & Budiarto, H. A. (2015). Perancangan

Combination Tool Proses Cutting Dan Forming Pada

Pembuatan Alumunium Cup. Jurnal Politeknik

Manufaktur Negeri Bandung, 2(1).

Rahmi, M. (2021). Comparative Analysis of Press Tool

Design for Seat Lock Patch of Mobilio Car with

AutoForm Technology.

208(Icist 2020), 316–320.

Sianipar, C. P. M., Yudoko, G., Dowaki, K., &

Adhiutama, A. (2013). Design methodology for

appropriate technology: Engineering as if people

mattered. Sustainability (Switzerland), 5(8), 3382–

3425. https://doi.org/10.3390/su5083382

Sundar, R., Balaji, A. N., & Satheesh Kumar, R. M.

(2014). A review on lean manufacturing implemen--

tation techniques. Procedia Engineering, 97, 1875–

1885. https://doi.org/10.1016/j.proeng.2014.12.3 41

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

946