Making a Disc Mill Machine Design Using the Autodesk Inventor

Application

Ferdi Fathurohman

1,2

, Adhan Efendi

1,2

and Ridwan Baharta

1

1

Agroindustry Department, Subang State Polytechnic, Arif Rahman Hakimt, Subang, West Java, Idonesia

2

Mechanical Engineering Department, Subang State Polytechnic, Arif Rahman Hakimt, Subang, West Java, Indonesia

Keywords: Corn Cob, Disc Mill Machine, and Ruminant Feed.

Abstract: Process of making animal feed at the People's Husbandry Center (SPR) Subang Regency is one of the

producers of ruminant animal feed for cattle. The ruminant feed is distributed to cattle breeders in Subang

Regency. Ruminant feed is made from corncob waste. The manufacture of animal feed made from corn cobs

is still done conventionally, so that the fulfillment of ruminant feed needs is often hampered. This study aims

to design a disc mill machine that is used to crush corn cobs. The research method starts from observing,

sketching, making 2D and 3D designs, and conducting expert validation. Based on the research, it can be

concluded that the design made has been declared valid with a score of 87% or is in the proper category.

Further recommendations that the design is feasible to proceed to the manufacturing process.

1 INTRODUCTION

Since 2005, the Indonesian government has planned

to be self-sufficient in beef, namely imports of no

more than 10% of the total national consumption.

However, beef self-sufficiency has not yet been

achieved with various problems faced. The

alternative choice to meet the needs of beef

consumption is through imports, but the import price

is cheaper than the price of local beef, making it a

tough competitor for farmers as the main producers

of local beef.

More than 90% of local beef supply comes from

small-scale small-scale farms, so production

efficiency is low or the cost per unit of production is

high. If the amount of imports is not controlled, it will

result in the price of local beef in the market being

depressed with cheap import prices so that farmers

lose out. If this happens in the long term and with

limited capital, it will make farmers not eager to do

beef cattle business (Widianti, 2014).

The development of cattle in quantity has been

able to have a very real impact on increasing people's

income in improving their welfare. The development,

which is currently still based on the strength of

people's livestock, has made this business managed

traditionally. The purpose of maintenance which is

still used as a side business from farming activities

has caused market demand to have not become the

main consideration for livestock business. In this

condition, it is very difficult to encourage the

community to achieve an economic scale of business

in the livestock business (Fathurohman, 2016).

The People's Animal Husbandry Center (SPR)

which was launched in early 2016 is expected to make

Subang district a national and regional beef supporter,

according to the Decree of the Minister of

Agriculture. In West Java Province, out of 27

regencies/cities only four regencies are the sites for

SPR. Of the four districts, in Subang there are two

SPRs and three other areas one SPR each. Two SPRs

in Subang, namely Kasaliang, cover the areas of

Kasomalang, Cisalak, Tanjungsiang. Then SPR

Cinagara Bogo covers the Cipunagara and Cibogo

areas.

SPR Cinagarabogo produces ruminant feed which

is then sold publicly to farmers in Subang Regency.

This feed is made manually with corncobs as the main

ingredient. Generally, the use of a disk mill machine

can help the process of making ruminant feed. The

disc mill machine has the main function of chopping

and crushing grains into flour (Adhan and Roni,

2018). Added by the components of the disk mill

machine has several main components, namely (1) a

hopper, made of iron plate in the shape of an inverted

pentagon measuring 27 x 20 x 21 cm, (2) a shell / cage

consisting of four rotating blades with a size of 3 x 2

x 2 cm, eight cylindrical knives with a diameter of 1.5

Fathurohman, F., Efendi, A. and Baharta, R.

Making a Disc Mill Machine Design Using the Autodesk Inventor Application.

DOI: 10.5220/0011966600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 947-950

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

947

cm, and 24 static knives measuring 2 x 2 x 1.5 cm, (3)

one channel for dispensing flour from an iron plate

measuring 15 x 6 cm, (4 ) a three-phase drive engine

with a power of about 2.2 kw, and (5) a transmission

system using a belt (Adil et all, 2012).

The use of disc mill machines is very useful in

agriculture and plantations (Asep et all, 2020). Added

by Oduntan and Omitoyin (2015) disc mill machines

are very suitable for crushing foodstuffs in a finer

form. The performance of the cutting knife can make

the process of refining corncobs more effective for

ruminant feed (Kruszelnicka, 2021). Fulfilling the

target of making feed for all cattle breeders in the

Subang area makes it necessary to design a disc mill

machine to assist the process of making ruminant feed

at SPR Cinagarabogo.

Irzad, Faoji, and Syarfidudin (2021) added that

the design is the beginning before the tool enters the

manufacturing process. added by Gede and Chintya

(2020) that the design can be started from a hand

sketch which is then described in the autodex inventor

application so that an image with 2D and 3D schemes

is found. The results of previous research, from Tri

and Supriono (2019), concluded that design and

manufacturing are very much needed in the process

of making an effective corncob crusher machine in

agriculture.

2 METHOD

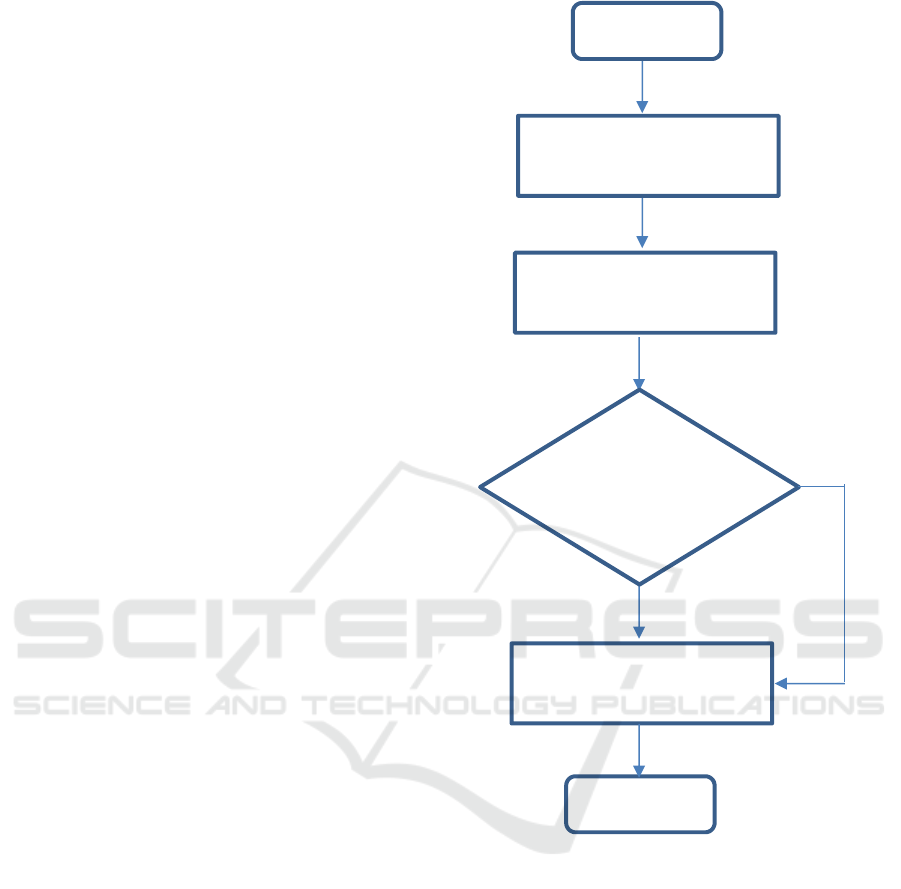

This research is a type of development research. Data

collected through observation and documentation

methods. The data were then analyzed descriptively

qualitatively. The stages of the research are as in

figure 1. The research stages started from collecting

data related to the disc mill machine, which was

followed up with observations at SPR Cinagarabogo,

then the research team made 2D and 3D sketches

through the autodeks inventor application, image

validation was carried out by experts, then entered the

data analysis stage.

3 RESULT AND DICUSSION

3.1 Study Literature and Observation

The literature study was carried out by the research

team in collecting several publications regarding the

design of a disc mill machine for corn cobs. Then

continued with observations at the People's

Husbandry Center (SPR) Cinagarabogo. Interviews

Figure 1: Research Stages.

were conducted with the head of the SPR to seek

information regarding the need for tools that can

assist the process of making ruminant feed there.

3.2 Study Literature and Observation

This stage is the first step in making tool designs

which will later provide a clear picture for the

manufacturing department in making the

conceptualized machine. This design describes the

size, type of material and working procedures. The

design process uses the autodex inventor application.

This design is in accordance with the needs obtained

during an interview with the head of the People's

Livestock Center (SPR) Cinagarabogo.

Start

Study Literature and

Observation

Design 2D and 3D Disc

Mill

Validation

Finish

Manufaktur

No

Yes

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

948

Figure 2: Disc Mill Design 2D.

In the process of making 2D sketches, it was

found that some components were made of stainless

steel. This is because based on the needs analysis, the

machine will be used to crush corn cobs in ruminant

feed, so a strong machine is needed in the process.

Figure 3: Disc Mill Design 3D.

In the next stage, the research team created a 3d

image of the disc mill machine. Also made a detailed

description of each component in the disc mill

machine. Drawings of components and types of

materials used will facilitate the manufacturing

process in making machine prototypes.

3.3 Validation

Validation was carried out by Mr. Agus Haris Abadi,

M.Pd. as a lecturer who has a BNSP competency

certificate at the Subang State Polytechnic Campus.

Validation adjusts the drawing rules, selection of

materials and sizes, as well as the suitability of

punctuation in 2D designs. The validation results

state that the image gets a score of 87% or is in the

proper category

3.4 Manufacturing

In this stage, researchers carry out the manufacturing

process. This process begins with the process of

measuring, cutting, welding and assembling. Making

machines based on validated drawings. The tool

making process guide uses work preparation as a

reference in the stages of making a disk mill machine.

Figure 4: Disc Mill Machine.

Performance tests showed that the machine can

crush corncobs for the manufacture of ruminant feed

with a capacity of 25 kilograms corncobs/1 hour.

4 CONCLUSION

Based on the research, it can be concluded that the

design made has been declared valid with a score of

87% or is in the proper category. Further

recommendations that the design is feasible to

proceed to the manufacturing process.

PARTS LIST

DESCRIPTIONPART NUMBERQTYITEM

Stainless steel

Hopper11

Steel GalvanizedTutup Mesin12

Steel Mild

Mata Pisau1

3

Steel GalvanizedRumah Mata Pisau

14

Steel GalvanizedRangka1

5

Motor BakarSistem Penggerak

16

MESIN DISK MILL

POLITEKNIK NEGERI SUBANG

A4

Skala

Digambar

Diperiksa

Waktu

Dilihat

06-06-20

Adhan.E

0,08 : 1

NO. 01

1

3

4

5

2

6

Making a Disc Mill Machine Design Using the Autodesk Inventor Application

949

ACKNOWLEDGEMENTS

Thank you to all those who have helped in carrying

out this research. This paper is the output of an

internal research at the Subang State Polytechnic

Campus.

REFERENCES

Adhan Efendi dan Roni Suhartono. (2018) Perbaikan dan

Pemeliharaan Mesin Disc Mill Bongkol Jagung. Jurnal

Rekayasa mesin, Volume 13, No.3, Desember, 2018.

ISSN 1411-6863. Hal. 97-104

Adil, et all. (2012). Uji Performansi Mesin Penepung Tipe

Disc (Disc Mill) untuk Penepungan Juwawut (setaria

italica (l.) P.Beauvois). Bogor: Institut Pertanian Bogor

Asep Bayu, et all. (2020). Mechanical Impact in Disk Mill

for Producing Controlled Rice Husk Particle Size by

Changing Impactor Shapes and Disk Rotation Speeds.

Sains Malaysiana 49(12)(2020): 2927-2940

Fathurohman, F. (2018). Model Bisnis Kawasan

Peternakan Kabupaten Subang. Jurnal Ilmiah Ilmu Dan

Teknologi Rekayasa, Vol.1. Politeknik Negeri Subang.

I Gede Eka Lesmana and Shania Chintya Candida. (2019).

Perancangan Mesin Pemotong Dan Penepung Tipe

Disk Mill Untuk Ubi Kayu. Semrestek. 2019.

O.B. Oduntan and B.O. Omitoyin. (2015). Wear of disc mill

hammer in wet grinding processes on groundnut cake

for fish feed production. Journal Res. Agr. Eng. Vol.

61, 2015 (4): 162–169.

Muhamad Irzad Nauval, Ahmad Faoji, Syarifudin. (2021).

Perancangan Alat Penggiling Biji Jagung Menjadi

Tepung Mesin Disk Mill Tipe Ffc 15. Tugas Akhir:

Politeknik Harapan Bersama.

Tri Mulyanto and Supriyono. (2019). Design of corncobs

Grinder Machine. Jurnal ASIIMETRIK: Jurnal Ilmiah

Rekayasa & Inovasi. Volume 1.1, JANUARI 2019.

Widianti, R. (2014). Membangun Industri Peternakan Sapi

Potong Rakyat dalam Mendukung Kecukupan Daging

Sapi. Wartazoa.Vol.24.

Weronika Kruszelnicka et all. (2021). Study of the

Relationships between Multi-Hole, Multi-Disc Mill

Performance Parameters and Comminution Indicators.

Journal Sustainability 2021, 13, 8260.

https://doi.org/10.3390/su13158260.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

950