A Design of a Grain Bagging Tool Using Sphiral Spring Type

Conveyor

I M. Suarta

a

, I P. G. Sopan Rahtika

b

, K. Bangse

c

, P. W. Sunu

d

, I K. Rusmariadi

and I G. B. S. W. Sandi

Department of Mechanical Engineering, Politeknik Negeri Bali, Badung, Bali, Indonesia

Keywords: Bag, Grain, Manual, Conveyor, Spiral Spring.

Abstract: With the development of human knowledge, technologies are created that make all aspects of life easier and

faster. Agriculture is no exception, which is the basic activity of human life. Various work aids have been

designed and made to make it easier and faster to do work. At this time the process of bagging grain in the

mills is done manually, namely by using a shovel, done both. To speed up the bagging process and save on

the use of employees, currently a grain bagging device uses a type spiral spring conveyor with an electric

motor drive. This tool is portable and can be operated alone so that it can speed up and save the use of labor.

The test results showed that the manual bagging rice process, which was carried out by two people, took 59.8

seconds to bag one sack of 26.4 kg of grain while using a spiral spring conveyor took 28.6 seconds for a bag

containing an average of 31.2 kg.

1 INTRODUCTION

Agriculture is a basic human job in an effort to meet

the needs of life. Rice is the staple food of people in

Asia. Due to population growth and decreasing

agricultural land, the Indonesian government

currently imports a lot of rice to meet domestic needs.

In an effort to accelerate the production process and

improve the quality of rice, innovations in

agricultural equipment must be carried out

(pertanian,2022;polbangtanyoma). To process

agricultural grain into rice, many processes are

carried out. The process includes harvesting,

transportation, drying, bagging and milling.

Therefore, the government wants to increase the

quantity and quality of rice produced by farmers. To

produce high-quality rice requires many steps that

must be taken by farmers apart from maintenance

from planting rice to harvesting. In the drying

process, which requires the grain to be completely

dry, the resulting grain is not brittle at the time of

milling. Farmers are usually overwhelmed when

inserting grain to sacks to be sent to the grinding

a

https://orcid.org/0000-0001-5715-7170

b

https://orcid.org/0000-0001-5290-6910

c

https://orcid.org/0000-0003-0220-056X

machine. Therefore, it is necessary to design a tool

inserting grain into sacks.

The grain bagging device is designed to make it

easier to inserting the grain into the sack before it is

taken to the milling machine. At this time the farmers

still use the manual method by using a shovel to

inserting the grain into the sack which takes a lot of

time and energy.

So far, the author has observed that the process of

bagging grain into sacks is done manually using only

a shovel which is very cumbersome and not

ergonomic. This process is usually done by 2 people.

This process can be seen in Figure .1 (youtube,2022)

Figure 1: Bagging grain manually.

Suarta, I., Rahtika, I., Bangse, K., Sunu, P., Rusmariadi, I. and Sandi, I.

A Design of a Grain Bagging Tool Using Sphiral Spring Type Conveyor.

DOI: 10.5220/0011972700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 959-964

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

959

The design of an ergonomically designed tool for

loading grain into sacks has been introduced by (A.

H. Pratama and H. Setiawan,2020). This “Abakan

Gadak” bagging tool can reduce muscle fatigue. The

tools introduced are still fully manual without a touch

of the machine so that it requires a lot of energy in the

bagging process. Abakan Gadak has a capacity of 25

kg in 59.12 seconds. The design model introduced

can be seen in Figure .2

Figure 2: Ergonomic manual rice bagging process.

Other designs for collecting and bagging grain

using the conveyor method have also been introduced

by (Rinanto, 2021; Prayitno, 2019). Rinanto designed

a bagging device using a screw conveyor model.

While Prayitno uses a plate belt model. The engine

capacity is 20 kg in 49 seconds. The design model can

be seen in Figure 3.

Figure 3: Belt conveyor type grain bagging device.

Another design for the bucket elevator type of

grain bagging equipment, has also been made by

(Dani Irawan,2017). The result of the design is a

prototype with a capacity of 208 lt/minute

(theoretical). The design model made is as shown in

Figure 4.

Figure 4: The prototype of the bucket bagging model.

2 MATERIAL AND METHODE

The grain bagging tool that are made today are

basically used to make it easier for farmers to bag

grain into sacks, so that they can make the farmer's

job easier to do. This tool uses a spiral spring

conveyor to pull the grain towards the guide before it

is dropped into the prepared sacks. By turning the

spring spiral to the right clockwise using the supplied

electric motor. Like picture 5.

Figure 5: Spiral spring.

The spiral spring conveyor consists of a spiral

spring that is inserted into the hose and mounted on

the shaft of an electric motor. When the shaft is

rotated, the spiral spring will rotate and pull the

material in the spiral spring.

This grain bag tool in the form of a spiral spring

conveyor serves to insert grain into sacks, which

consists of a spiral spring as a grain transfer unit, this

grain transfer tool is moved by an electric motor. In

the process of transferring the grain, the grain will be

sucked in through a flexible hose which contains a

spiral spring which is rotated by an electric motor so

1. Top cover 7. V-belt

2. Frame 8. Pully

3. Dispensing chimney 9. Sprocket

4. Adapter 10. Chain

5. Switch 11. Bucket

6. Electric motor

10

11

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

960

that the grain will move upwards.

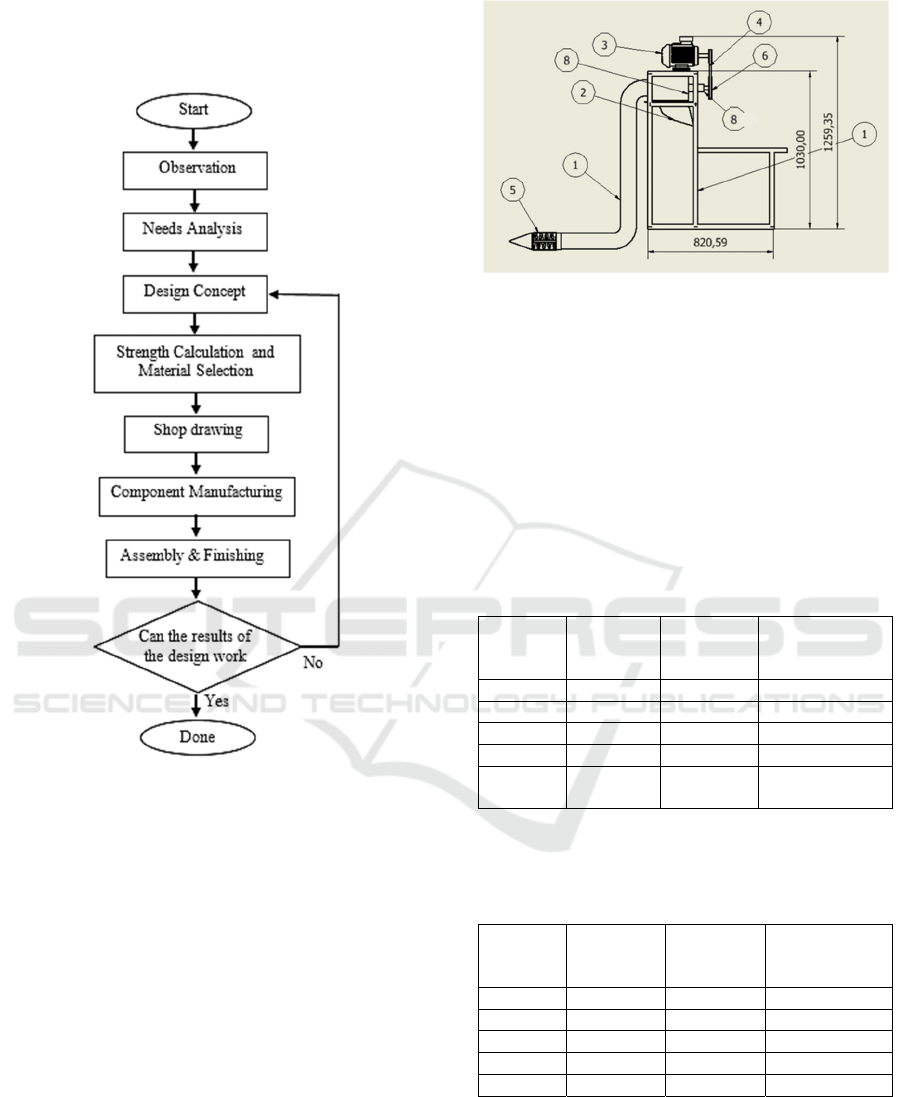

The flow diagram of the process of designing or

making grain transfer equipment can be seen in

Figure 6.

Figure 6: Flowchart of making conveyor spiral spring.

3 RESULTS AND DISCUSSION

The process of bagging the grain is currently done

manually, carried out in two as shown in Figure 1, this

process causes fatigue, because it is done by bending.

Based on these observations, the author designed a

tool that can ease the burden on workers and speed up

the work process without causing pain in the waist.

Figure 7 shows a grain bagging device using a spiral

spring conveyor.

Based on the results of the tests that have been

carried out for bagging 1 sack of grain to the

conventional grain bagging process and using a spiral

spring conveyor, significant results were obtained on

bagging speed and comfort.

Caption:

1. Frame 5. Place of entry of rice

2. Funnel out 6. Pulley

3. Electric motor 7. Axle holder box

4.V Belt 8. Axle screw holder

Figure 7: Spiral spring conveyor.

The conventional grain bagging process for one

sack of grain takes 59.8 seconds to bag one sack of

grain weighing 26.4 kg. Table 1 shows the time it

takes to bag 1 sack of grain, the testing process is

carried out 5 times.

Table 1: Manual bagging process.

Bagging

process

No.

Weight

of bagged

grain (kg)

Time

(seconds)

explanation

1 26 60 -

2 25 57 low back pain

3 28 66 low back

p

ain

4 27 59 fati

q

ue

5 26 57 pain in the

waist

The data on the grain bagging process using a

spiral spring conveyor can be seen in table 2.

Table 2: Bagging process with spiral spring conveyor.

Bagging

process

No.

Weight of

bagged

g

rain

(

k

g)

Time

(seconds)

explanation

1 27 30 no com

p

laints

2 32 29 no com

p

laints

3 31 27 no complaints

4 34 28 no complaints

5 32 29 no complaints

To make it easier to compare one by one, from the

results table a graph of the comparison of the weight

and time needed to bag the grain in one sack can be

made. Figure 8 shows the comparison of the weight

of the grain each time a bag is inserted into the sack

from the expectation to include as much as 30 kg.

7

A Design of a Grain Bagging Tool Using Sphiral Spring Type Conveyor

961

Figure 8 shows the volume obtained during the

manual bagging process. Based on the results of tests

carried out 5 times, the average weight is 26.4 kg.

Figure 8: Manual bagging process.

Figure 9 shows the weight obtained after

weighing the filling using a spiral spring conveyor.

The test results show the average mass of filled grain

is 31.2 kg

Figure 9: Conveyor spring spiral bagging process.

By comparing the manual bagging process with

bagging using a spiral spring conveyor, the graph of

the average weight filled into the sack can be seen in

Figure 10.

Figure 10: Weight comparison of the bagging process.

Based on the test results, it was found that the

weight that was filled into the manually filled sacks

was always less than the weight obtained which was

filled using a spiral spring conveyor. This is because

the workers are tired so they think the sacks are full.

Based on the results of testing the time required to

bag 1 sack of grain manually as shown in the data in

tables 1 and 2, a graph can be made as shown in

Figure 11.

Figure 11: The time it takes to deliver 1 sack of grain.

While the time needed to bag 1 sack of grain using

a spiral spring type conveyor can be graphed as

shown in Figure 12

0

5

10

15

20

25

30

35

12345

weight (kg)

nooftests

Manual bagging process

0

5

10

15

20

25

30

35

12345

weight (kg)

nooftests

Manual bagging process

0

5

10

15

20

25

30

35

12345

weight(kg)

nooftests

baggingprocess

Linear (Manual)

Linear (spiral spring conveyor)

0

10

20

30

40

50

60

70

12345

time(sec)

no.oftests

Manual bagging process

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

962

Figure 12: The time it takes to deliver 1 sack of grain.

Comparison of the time required to bagging 1 sack

of grain between the bagging process manually and

bagging using a spiral spring conveyor, a comparison

graph is obtained as shown in Figure 13.

Figure 13: Comparison of the time it takes to deliver 1 sack

of grain.

From Figures 10 and 13 it can be seen that the

comparison of the speed of the manual bagging

process with bagging using a spiral spring conveyor.

Based on the weight in one sack, it was found that the

mass of grain with the bagging process using a spiral

spring conveyor was more than the mass using the

conventional method. The average mass obtained

from the manual bagging process is 26.4 kg, while

using a spiral spring conveyor is 31.2 kg. This means

that there is an average increase of 4.8 kg or an

increase of 18.2 percent.

Based on the time required to bag 1 sack of grain

manually is 59.8 seconds, compared to using a spiral

spring conveyor is 28.6 seconds. So there is a time

savings of 51.5 percent.

4 CONCLUSIONS

Based on the design results, the dimensions of the

grain bagging device using a spiral spring conveyor

are 820.59 mm long, 600 mm wide and 1259.35 mm

high.

The bagging process using a spiral spring

conveyor has an increase in speed of 51.5 percent so

it has a very good performance.

The weight gained by bagging using a spiral

spring conveyor also increased by 18.3 percent.

ACKNOWLEDGEMENTS

The author expresses his deepest gratitude to the

Ministry of Education and Culture of the Republic of

Indonesia, Bali State Polytechnic for the financial

support. P3M Bali State Polytechnic is also grateful

for the administrative support so that this research can

be carried out.

REFERENCES

https://www.pertanian.go.id/home/?show=news&act=view

&id=2564. (2022) Accessed date 3 agustus 2022

https://polbangtanyoma.ac.id/ increase-productivity-farm

ing-use-innovation-technology/(2022)

https://www.youtube.com/watch?v=3Xqc-BUNpnY,

(2022)

Pratama A.H and Setiawan H, (2020). Design of Tools for

Inserting Ergonomic Grain Into Sacks - A Case Study

in Rice Mills. Mr. Santo. Jurnal Ergonomi Indonesia.

Vol. 06 No. 01 Juni 2020. doi: https://

doi.org/10.24843/JEI.2020.v06.i01.p05

Rinanto A et al. (2021). Innovation of Grain Collector With

Screw Conveyor. Industrial and Mechanical Design

Conference. Vol 3 th 2021.

https://publikasi.atmi.ac.id/index.php/imdecatmi/article/vi

ew/96/82

Prayitno K.A. (2019). Dry Rice Packaging Machine Design

Using DC Motor. Muhammadiyah Surakarta

University.

Irawan D. (2017) Bucket Elevator Prototype Design. Jurnal

Ilmiah Multitek Indonesia, Vol. 11, No. 1, Juni, 2017.

Achmad, Z. 2006. Design, PT. Aditya Refika. Bandung

Juhana., Ohan, Suratama., M. 2000. Drawing Mechanical

Engineering with ISO Standards. Graphic Library CV.

Bandung.

Sayuti, N.R. M, A. 2017. Design of Industrial Machinery.

CV Budi Utama. Yogyakarta.

Hush, Knneth S. 2009. Principles of Engineering Design..

Erlangga. Jakarta

Buchari, M., Z. Sentinuwo, S. R., Lantang, O. A. 2015.

Design of 3-Dimensional Vodeo Animation for Motor

‐10

10

30

50

70

12345

times(sec)

no. of tests

conveyor spring sphiral bagging

procces

0

10

20

30

40

50

60

70

12345

times(sec)

no.oftests

bagging process

Linear(Manual)

Linear(spiralspringconveyor)

A Design of a Grain Bagging Tool Using Sphiral Spring Type Conveyor

963

Vehicle Testing Mechanisms at the Department of

Transportation, Culture, Tourism. Communication and

Information. Informatics Engineering E-journal. 6(1) :

2301-8364

Nur. R., Sayuti, M, A. 2017. Design of Industrial

Machinery. CV Budi Utama. Yogyakarta.

Hush, Knneth S. 2009. Principles of Engineering Design..

Erlangga. Jakarta.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

964