Practical Validation on Simulation of Multi Dobot Magician

Trajectory Contour Tracking

P. Anggraeni

a

, W. A. Candra

b

, A. S. Sunarya

c

and D. Safitri

Manufacture Automation And Mechatronics Engineering Dept., Bandung Polytechnic for Manufacture, Jl.Kanyakan 21,

Bandung, Indonesia

Keywords: Manipulator, Contour Tracking, ROS, Cooperative Control.

Abstract: Manipulators are arm-like robots that have been widely used in the industry to perform repetitive work usually

performed by humans. The growing number of distributed control systems currently used by some modern

industries is evident by research on cooperative control systems (CCS) where multiple entities is two or more

things to achieve the same goal. A multi-agent system consists of many autonomous agents that can interact

with each other or with their environment. The advantages of multi-agents system compared to single-agents

are tasks that are performed more efficiently and increase the value of tolerance and flexibility in the execution

of tasks. There is a problem that is doing research to prove the advantages of the system in manipulator robots.

In this final task, a cooperative control system is performed on the manipulator robot, which is control of three

manipulator robots in a group using virtual reality simulation with leader-follower concept. The manipulator

that used is Dobot Magician which is a multifunctional robot arm for academic purposes. The platform used

is Robot Operating System (ROS) and the simulator used is Gazebo. The results of this study are the

realization of robot control through virtual reality, PID tuning with Ziegler-Nichols analysis method, precision

value of each robot when performing compound control, as well as proofed by end-effector position value of

all three manipulator robots. So the conclusion of cooperative control systems can be realized on the robot

arm and the resulting precision value can prove the effectiveness of the robot in operation.

1 INTRODUCTION

Robot is defined according to the Robot Institute

America (RIA) as a multifunctional manipulator that

can be reprogrammed and designed to move

materials, tools, parts or special devices through

programmed movement variables to perform various

tasks to help humans.

Md Rasedul Islam conducted research Cartesian

trajectory based on Dobot robot control. Thing

developed in this research, namely: use of DH

Parameters and algebraic approach back kinematics.

The controller used is PID, simulation is carried out

in the Simulink environment in where the dynamic

model of Dobot is simulated for follow the common

space and space trajectory Cartesian. The results of

this study are in the form of developing forward

kinematics and reverse kinematics of the Dobot robot

a

https://orcid.org/0000-0003-1986-272X

b

https://orcid.org/0000-0003-0888-6363

c

https://orcid.org/0000-0001-9509-0325

Magician. In this study the PID controller used to gain

joint base control Dobot Magician robot (Md Rasedul

Islam, 2019).

Qingsong Ai conducted research on the

implementation of Dobot Magician's robotic arm

trajectory control using the trajectory planning

method. The results of this study show that the robot

arm can write and draw correctly, and the upper

computer interface of the control system can display

the actual position of the arm tip in the real-time

writing process, which has real-time stability and is

good (Ai, Yang, Li, Feng, & Meng, 2018).

S Hernandez describes a concept of a Multi-

master ROS system to present a multi-robot network

system with each roscore node. This platform can

generally be applied to both mobile robots and

manipulator robots. In the ROS framework itself,

there is already a solution regarding the system,

Anggraeni, P., Candra, W., Sunarya, A. and Safitri, D.

Practical Validation on Simulation of Multi Dobot Magician Trajectory Contour Tracking.

DOI: 10.5220/0011973200003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 965-970

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

965

namely multimaster_fkie which can build a ROS

Network system configuration that involves two or

more network devices (Juan, 2015) (Anggraeni,

Defoort, Djemai, & Zuo, 2019).

Lehman (2015) explained about the introduction

of the kinematics of mobile robots and manipulators

using the features and tools found in the Robot

Operating System (ROS). This study describes the

kinematics used, such as inverse kinematics, forward

kinematics, and DH Parameters that utilize the ROS

feature (Yousuf, 2015).

The increasing prevalence of distributed control

systems that are currently used by several modern

industries, as evidenced by research on Cooperative

Control Systems (CCS) where several entities, both

two or more, do something to achieve the same goal.

A multi-agent system is a system consisting of many

autonomous agents that can interact with each other

or with their environment. An example of a

cooperative control system is a fleet of unmanned

autonomous vehicles with a general purpose, such as

reaching a target location. For example, automated

forklifts can self-regulate to provide efficient service

to machines on the warehouse floor (Monostori, et al.,

2015) (Defoort, Floquet, & Kokosy, 2008).

The advantages of a multi-agent system compared

to single-agent is tasks performed more efficiently

and improve tolerance value and flexibility in

implementation task. Based on these conclusions,

then a problem arises, namely doing research to prove

the superiority of the system on the manipulator

robot. Robots that The robot arm used is Dobot

Magician. In addition, this study used PID . control as

an end-effector position control on the robot arm.

Thus, this study able to do contour tracking using

ROS (Robot Operating System) and end-effector

position control using a leader-follower topology.

Controller PID is used on the leader robot

(Anggraeni, Defoort, Djemai, & Zuo, 2019) (Defoort,

Polyakov, Demesure, Djemai, & Veluvolu, 2015).

The rest of this paper is organized as follows. The

second section describes the mechanical specification

design of Dobot Arm manipulator robot. While Robot

Operating System (ROS) Simulator is discussed in

the third section. The fourth section addresses the

implementation validation and results. Finally, we

conclude the article in the fifth section.

2 ROBOTIC ARM

MANIPULATOR

In this section, description of Dobot Magician and

Robot Operating System (ROS) are presented to the

best illustrate the simulator.

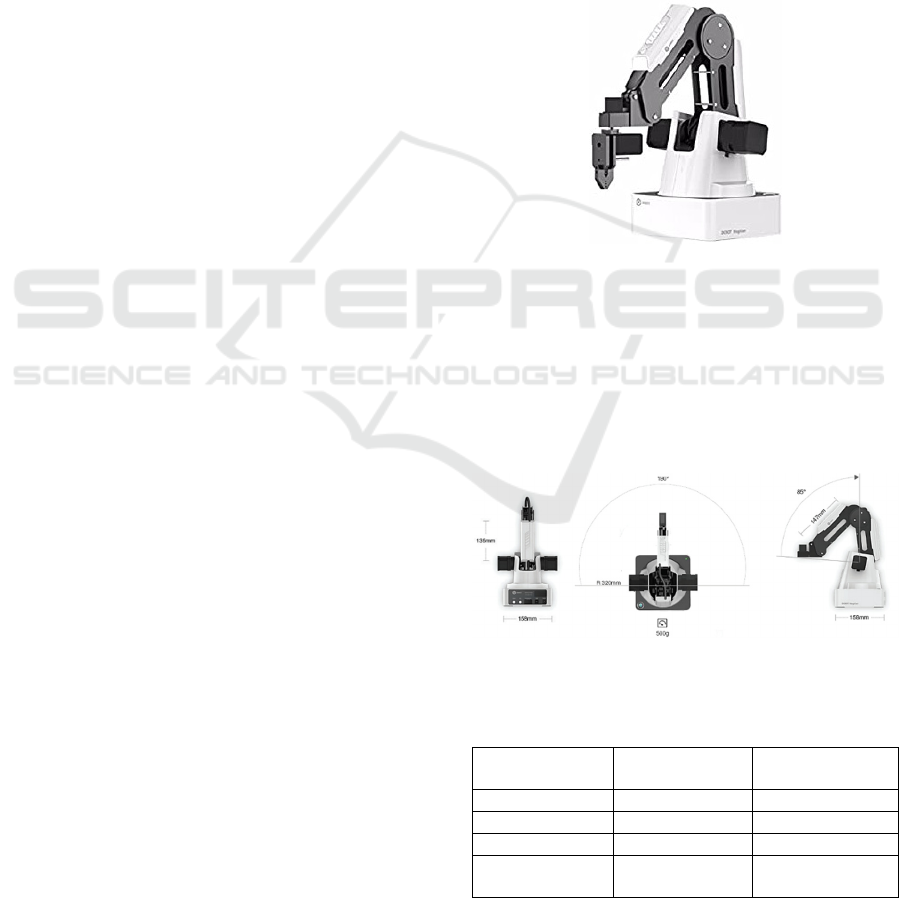

2.1 Robotic Arm Dobot Magician

The robotic arm Dobot is a 3 DoF robot that has three

stepper motors to actuate its joints (base, shoulder and

elbow) as shown in Figure 1. The basic specification

of robotic arm Dobot are shown in Figure 22.

Figure 1: Dobot Arm Robot.

The payload capacity of Dobot’s end effector is

500 gram. The end-effector uses a servo motor and a

pneumatic pump to deal with payload. The maximum

distance that can be reached by Dobot is 320 mm. It

can work under the temperature range -10°C to 60°C.

The range of motion and maximum speed of each

joints are shown in Table 1.

Figure 2: Dimension of Dobot Arm Robot.

Table 1: The Range of Motion and Max Speed of Each

Joint.

Axis Range

Max Speed

(250

g

workload)

Joint 1 base -135° to +135° 320° /s

Joint 2 rear ar

m

0° to +85° 320° /s

Joint 3 fore arm -10° to +95° 320° /s

Joint 4 rotation

servo

+90° to -90° 480° /s

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

966

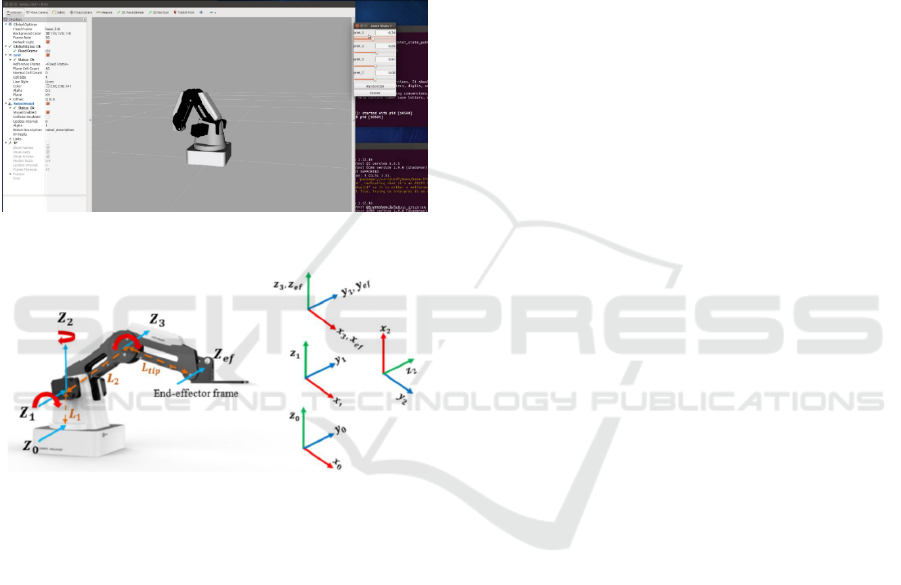

3 ROS-BASED SIMULATOR

The manipulator system simulator is developed based

on the open source ROS environment. The simulator

is called ROS Gazebo.

3.1 System Modelling and Description

This section describes multi robots model inside ROS

Gazebo Simulator. First Dobot Arm Robot profile

must be set up as showed below and all model

description stated in URDF,

Figure 3: Dobot profile in Gazebo Simulator.

Figure 4: Dobot coordinate Frame.

3.2 Multi-Robotic Arm Manipulator

Communication

To perform multi-robot movements, it requires a

Multi-master ROS as a system capable of running

Roscore more than two network devices. To use

multimaster_fkie it is necessary to perform the

installation on robot package in the following way:

git clone

https://github.com/fkie/multimaster_fki

e.git multimaster

rosdep update

rosdep install -i --as-root pip:false -

-reinstall --from-paths multimaster

In order for multimaster_fkie to be used, the mini-

PC must have pre-installed Grpcio-tools.

Multimaster_fkie consists of two nodes that are

executed master_discovery and master_sync. In

general master_discovery send a multicast message to

the network so that other ROS masters respond to

other ROS masters and examine the local roscore for

changes in the local network, and tell all other Master

ROS in the public network this change.

Then, master_sync serves to process the

information provided for the master_discovery node

to register the topic and service to the local roscore.

Information provided by the master_discovery node

is also used to update information about topic and

service. So it can be configured to select hosts, topics

and services to use or ignore. By default all the topic

and service of all hosts are synchronized, so as to

reduce the bandwidth needed to synchronize various

topic and service (Hock & Šedo, 2017).

$export ROS_MASTER_URI=http://<host

ip>:11311

ROS_MASTER_URI to determine which IP host

will be the MASTER of its network. To launch

package multimaster_fkie that need to be done is to

do roscore first on each mini-PC.

$roscore

Then, launch the master_discovery node on each

mini-PC by using the multicast _mcast_group

argument.

$rosrun fkie_master_discovery

master_discovery

_mcast_group:=224.0.0.1

After launching master_discovery followed by a

multicast sync that was covered by launching the

master_sync node.

$rosrun fkie_master_sync master_sync

After performing synchronization on each of the

mini-PCs, the master checks that have been included

in the list_masters.

Practical Validation on Simulation of Multi Dobot Magician Trajectory Contour Tracking

967

Figure 5: Multi Master Lists.

Here is the result of the Rqt-graph on ROS Multi-

master:

Figure 6: Rqt-Graph of Multimaster.

This rqt-graph shows the communication network

established for multi robot application.

3.3 Robotic Arm Manipulator Contour

Trajectory

The contour tracking involved follower 1 and

follower 2. The executed followers is a topic that

accepts positions based on the orders sent by the

leader. Figure 7 shows a chart of contour trajectory:

Figure 7: Calculation of publisher movement in xy graph.

Followers track the spiral contour tracking

utilizing the X and Y coordinates. While Z is in static

condition. The following is the calculation of the

movement:

𝑥

𝑙𝑡

𝑋 cos

𝑡

200

𝑦

𝑙𝑡

sin𝑡 90

𝑧30

(1)

The value of t is a change or time increase. In this

case t increased by about 0.1 seconds so that if done

rosbag file or recorded data, then it can be seen that

the increase of time is followed by the subsequent

movements.

Leader (Dobot 1) defined the contour trajectory

and send the information of trajectory to follower 1

(Dobot 2) and follower 2 (Dobot 3). In order for the

Masters of follower 1 and follower 2 to receive the

information of trajectory from Leader, the use of ROS

Multi-Master for Leader, follower 1 and follower 2 is

connected to each other. Multi-robot contour

trajectory has been conducted using Multi-Master

ROS system.

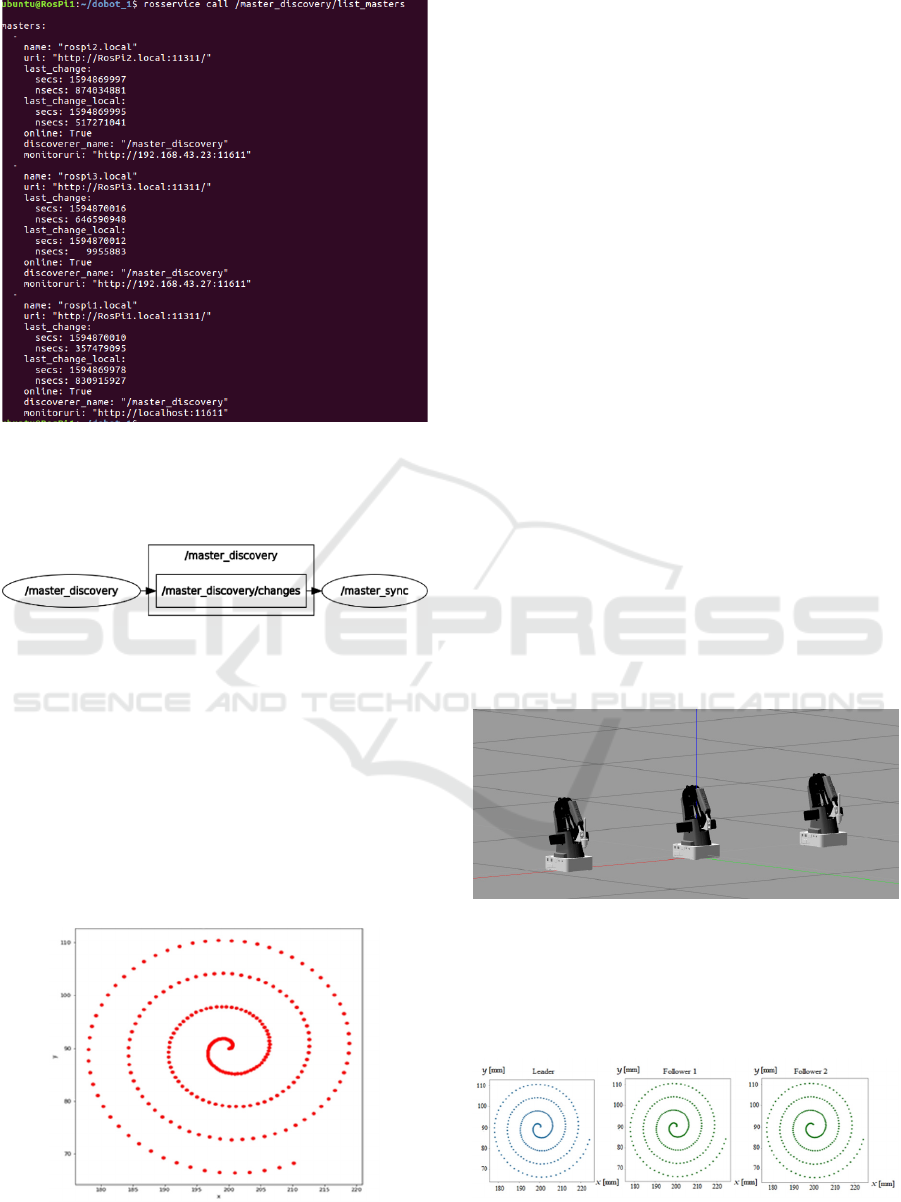

4 IMPLEMENTATION

VALIDATIONAND RESULTS

The simulation is a movement of a robot using a

kinematics program for the 3 DoF robots and a new

Gazebo movement limited to the joint movement.

Figure 8: Simulation of Multiple Dobot.

Controlling the robot arm with PID tuning

produces an ideal wave signal and the resulting value

is the position value of the end-effector robot based

on the coordinates achieved.

Figure 9: Lead-Follower Contour Tracking.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

968

The following are the results of the movement of

the three robots with Dobot 1 as the master which

produces a certain contour trajectory, while Dobot 2

and Dobot 3 as followers follow the contour.

Table below shows the movement precision of

each robot with X

1

, X

2

, X

3

as Dobot 1, Dobot 2 and

Dobot 2 movement in X axis respectively. As well as

Y

1

, Y

2

, Y

3

as Dobot 1, Dobot 2 and Dobot 3

movement in Y axis respectively.

Table 2: Precision Result in percentage (%) of Robot

Movement.

T(s) X

1

Y

1

X

2

Y

2

X

3

Y

3

0

0,085

0,390

0,083

0,315

0,049

0,371

0.1

0,074

0,417

0,064

0,335

0,062

0,390

0.2

0,060

0,434

0,090

0,347

0,106

0,401

0.3

0,043

0,442

0,128

0,350

0,172

0,402

0.4

0,025

0,439

0,187

0,346

0,240

0,394

Avg

0,058

0,424

0,110

0,339

0,125

0,392

Based on the data presented below, it is concluded

that by using PID, the movement of the arm joint of

the Dobot Magician robot is smoother but takes

longer to reach steady state. It can be seen from the 1

axis Y joint, using PID control, the resulting system

response is ideal. And if you pay attention to the three

curves in one graph, robot 1 precedes the two robots

that act as followers.

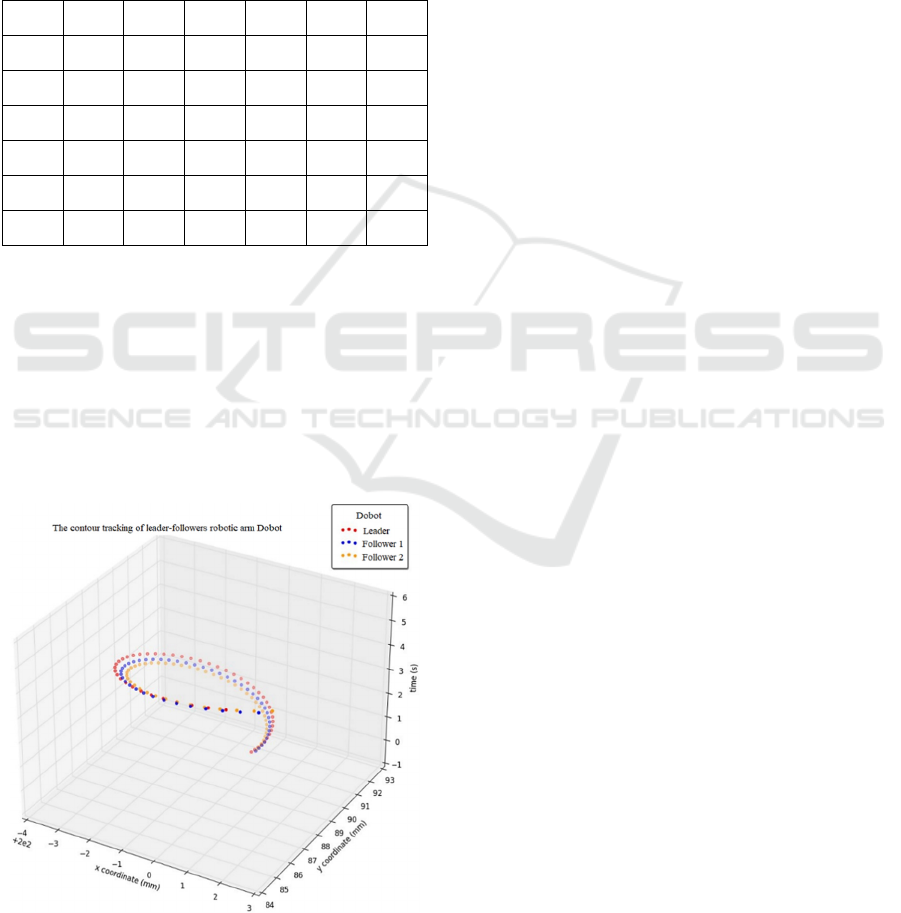

And the 3D contour tracking for all robots show

as follow:

Figure 10: Lead-Follower 3D Contour Tracking.

5 CONCLUSIONS

The application of the Multi-Agent on the Dobot

Magician robot arm produces movement with the

concept of a leader-follower and the positioning

accuracy and effectiveness in carrying out the work is

precise as long as the movement carried out is still

within the scope of the work area of the Dobot

Magician robotic arm.

To control the robotic arm of Dobot Magician, the

simulator used is the Gazebo Sim. So that the physical

dynamics of the robot is also taken into account. The

end-effector conditions in URDF are dummy or fixed.

The precision of the end-effector position on the

Dobot Magician robot arm when doing contour

tracking, it can be concluded that Robot 1 has a

precision of 0.057% at the X coordinate and 0.42% at

the Y coordinate, Robot 2 has a precision of 0.11% at

the X coordinate and 0.424% at the Y-coordinate

0.338%, and then Robot 3 to its precision of 0.1257%

at the X-coordinate and 0.39% at the Y-coordinate.

ACKNOWLEDGEMENTS

This work has been supported by Laboratory of

Robotic, Automation Engineering Technology and

Mechatronics Department, Bandung Polytechnic for

Manufacture under the Polman Bandung Internal

Research Project.

REFERENCES

Ai, Q., Yang, Q., Li, M., Feng, X., & Meng, W. (2018).

Implementing Multi-DOF Trajectory Tracking Control

System for Robotic Arm Experimental Platform. 2018

10th International Conference on Measuring

Technology and Mechatronics Automation (ICMTMA)

(pp. 282-285). Changsha, China: IEEE.

Anggraeni, P., Candra, W. A., Defoort, M., & Djemai, M.

(2019). Experimental Implementation of Fixed-Time

Leader-Follower Axial Alignment Tracking. 2019

International Conference on Mechatronics, Robotics

and Systems Engineering (MoRSE) (pp. 86-91). Bali:

IEEE.

Anggraeni, P., Defoort, M., Djemai, M., & Zuo, Z. (2019).

Control strategy for fixed-time leader–follower

consensus for multi-agent systems with chained-form

dynamics. Nonlinear Dynamics, 2693–2705.

Defoort, M., Floquet, T., & Kokosy, A. (2008). Sliding-

mode formation control for cooperative autonomous

mobile robots. IEEE Transactions on Industrial

Electronics, 3944-3953.

Practical Validation on Simulation of Multi Dobot Magician Trajectory Contour Tracking

969

Defoort, M., Polyakov, A., Demesure, G., Djemai, M., &

Veluvolu, K. (2015). Leader-follower fixed-time

consensus for multi-agent systems with unknown non-

linear inherent dynamics. IET Control Theory &

Applications, 2165-2170.

Hock, O., & Šedo, J. (2017). Forward and Inverse

Kinematics Using Pseudoinverse and Transposition

Method for Robotic Arm DOBOT. In E. G. Hurtado,

Kinematics (pp. 75-94). Rijeka: Intech.

Juan, S. H. (2015). Multi-master ros systems. Barcelona,

Spain: Institut de Robotics and Industrial Informatics.

Md Rasedul Islam, M. A.-u.-Z. (2019). Cartesian

Trajectory Based Control of Dobot Robot. Proceedings

of the International Conference on Industrial

Engineering and Operations Management Toronto (pp.

1507-1517). Toronto: IEOM Society International.

Monostori, L., Valckenaers, P., Dolgui, A., Panetto, H.,

Brdys, M., & Csáji, B. C. (2015). Cooperative Control

in Production and Logistics. Annu. Rev. Control, 12-29.

Yousuf, A. L. (2015). Introducing kinematics with robot

operating system (ROS). 2015 ASEE Annual

Conference & Exposition (pp. 26.1024.1 - 26.1024.18).

Seatle, Washington: ASEE.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

970