Component Analyse and Carcinogenic Performance Research after

Food Material Baked to Be Roasting

Liufeige Lu

Suzhou Foreign Language School, No 201 Zhuyuan Road, Suzhou New District, Suzhou, Jiangsu Province, China

Keywords:

Component Analyse, Food Material Baked, Carcinogenic Performance.

Abstract: Food cooking include the methods such as oil frying, baking, carbon baking, stewing. Among, oil frying,

baking, carbon baking and other method cooking at higher temperature and difficult to control. High

temperature cooking will caused the foods come to be roasting, many medias reported that burned in

roasting or oil fried foods easily carcinogenic. To proof and test the reliability of this conclusion and

research the true harm of this type foods, it selects the chicken, steam bun and celery as sample, baking the

samples under different temperature and time condition, the samples happened different degree burnt. It

obtained that the food happen carbonize after foods burned in roasting, the chemical structure of protein,

starch and cellulose all are changed, generated the acrylamide and conjugate aromatic ring chemical

compounds, thus generating carcinogenic performance to human body.

1 INTRODUCTION

More and more higher opportunity catch cancer in

the modern society, according to the report from

national tumour register center in 2013, the newly

happened cancer illness case exceed 3,000,000 per

one year (Liu, 2021). Much reason of cancer, many

medias reported that, oil frying, baking, carbon

baking and other methods cooked foods easily

caused cancer. The report said that baked meats

contain strong carcinogenic performance, the meat

and fish burned in roasting contain benzopyrene, the

average catch gastric caner ratio of the crowds who

frequently eat the baked meat type foods rising

twenty times (Ye, 2016). Additionally, for the plant

food like coffee and others, the content of

benzopyrene after burned in roasting also will has

extremely rising (Yin, 1980).

Our daily foods have meat, staple food type and

vegetable type. (1) The main component of meats

are protein, protein is one type biology big molecule,

formed by 20 types different natural amino acids.

The structure of natural amino acid mainly contain

the elements such as carbon, nitrogen, oxidize,

hydrogen, etc, additionally, R-perssad of some

amino acid contain the sulphur element. The amino

acid structure of meats been damaged after baked,

the protein happen property change, and caused

possible carcinogenic. (2) The food mainly include

wheat and rice, the main component is starch. The

form of starch main are three elements carbon,

oxygen and hydrogen. The starch burned in roasting

will generate strong carcinogenic matters, the

content of carcinogenic matters will higher than

meat type and vegetable, long time eating will

caused it amass in body and carcinogenic (Yiqi W,

2021). (3) The main components of most vegetables

are cellulose, it contain the elements such as carbon,

nitrogen, oxidize, hydrogen, etc. Because fewer

carbonhydrate and fat content, so the burned

vegetable will generate polycycline carcinogenic

matters (Chu, 2021).

Based on various reports of the medias, burned

food has carcinogenic performance, but still has

many report existing contradiction. Therefore, in this

research, it selected three foods chicken, steam bun

and celery in our test, the main components are

protein, starch, cellulose and other matters, baking

them under different temperature, further more adopt

infrared spectrum (FT-IR), scan electron microscope

(SEM), UV light spectrum (UV-Vis), fluorescence

spectrum and other method to to determine and

characterize the baked foods components. Finally

researched the carcinogenic performance of baked

foods through cell toxicity test.

70

Lu, L.

Component Analyse and Carcinogenic Performance Research after Food Material Baked to Be Roasting.

DOI: 10.5220/0012001900003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 70-75

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 METHODOLOGY

2.1 Materials

The chicken, steam bun and celery all are purchased

from Suzhou HEMAXIANSHENG supermarket.

Purchased grow liquid, trypsase, Diphenyl tetrazole

bromide and glycocoll buffer liquid from Sigma

company, purchased dimethyl sulfoxide (DMSO)

from J&K scientific company.

2.2 Sample Preparation

Use knife cut the chicken, steam bun and celery into

small cube with size 1cm×1cm×1cm, use oven

(ACA TM33HT) baking them under 150℃ and

200℃ respectively, the baking time are 1 hour, 2

hours and 3 hours respectively, pick out the samples

from the oven after baked and process natural

cooling, prepare for characterize use.

2.3 Characterized Methods

(1) UV-Vis ultraviolet spectrophotometer method

Grind the baked samples to be thin and small

tiny pellets, weighing 1mg and dissolved into 10mL

deionized water and process ultrasound, convenient

to more better dissolve the samples. The dissolved

samples filtered by 0.45μm filtering film, make the

deionized water as reference ratio, use ultraviolet

spectrophotometer measure it after filtered

(Shimazu), measured wave length are 220~400nm.

(2) Fourier alternate infrared spectrum analyse

Use PerkinElmer Fourier alternate infrared

spectrum analyse instrument to process characterize

analyse (resolution ratio 4cm-1, wave length range

are 4000-400cm-1, scan 10 times).

(3) Fluorescence spectrum analyse

Use fluorescence spectrum instrument (Hitachi

F-7500), excite wave length 300nm, launch wave

length range are 220~400nm, width of excite and

launch narrow seam is 5nm.

(4) Surface pattern analyse

Adopt scan electron microscope (SEM, Hitachi

S4800) to process the surface pattern analyse the

samples chicken, steam bun and celery after baked at

different temperature, operating voltage is 1.0kV.

2.4 Cell Toxicity Test

Use foster base thinning the waiting test sample and

prepare different concentration, added into 96 holes

plate respectively, foster 24h at 37℃, then process

three times parallel determining at live cells

quantity. Then pick out empty 96 holes plate, each

one hole added 200μL foster base and 50μL MTT,

foster 4h at 37℃. Then added 200μL DMSO in each

one hole again. Finally added 25μL glycocoll buffer

liquid in each one hole, use enzyme standard

instrument record the completely absorb value at

570nm position.

3 RESULT AND DISCUSSION

3.1 Sample Preparation

The main components of chicken, steam bun and

celery are protein, starch and cellulose, put them into

oven and baking under different temperature and

time, the sample surface happened different degree

coking. It calculated the rest mass percentage after

samples baked, shown as the Table 1.

From the table it can see that, when same baking

time and temperature, the highest dewatering

quantity of celery, able to achieve 94% after baked 3

hours at 150℃, achieve 98% after baked 3 hours at

200℃, means water content of celery is the highest,

chicken at second, achieve 78% after baked 3 hours

at 200℃, lowest water content of steam bun, only

42% after baked 3 hours at 200℃. When baking at

the same temperature, example that baked at 150℃,

dewatering quantity of celery and chicken have a

certain rising along with rising baking time, but little

dewatering quantity change of steam bun. When all

samples baked at the same time, example all are

baked 3 hours, the dewatering quantity of same

sample after baked at 200℃ will bigger than

dewatering quantity after baked at 150℃.

Table 1: The dewatering quantity of chicken, steam bun and celery after baked at 150℃ and 200℃.

Dewatering quantity of different samples

baked different time at 150℃

Dewatering quantity of different

samples baked different time at 200℃

1h 2h 3h 1h 2h 3h

Chicken 70% 74% 76% 76% 78% 78%

Celery 88% 94% 94% 90% 96% 98%

Steam bun 38% 38% 38% 40% 42% 42%

Component Analyse and Carcinogenic Performance Research after Food Material Baked to Be Roasting

71

3.2 Sample Extinction Change After

UV-Vi Surface Characterize Baked

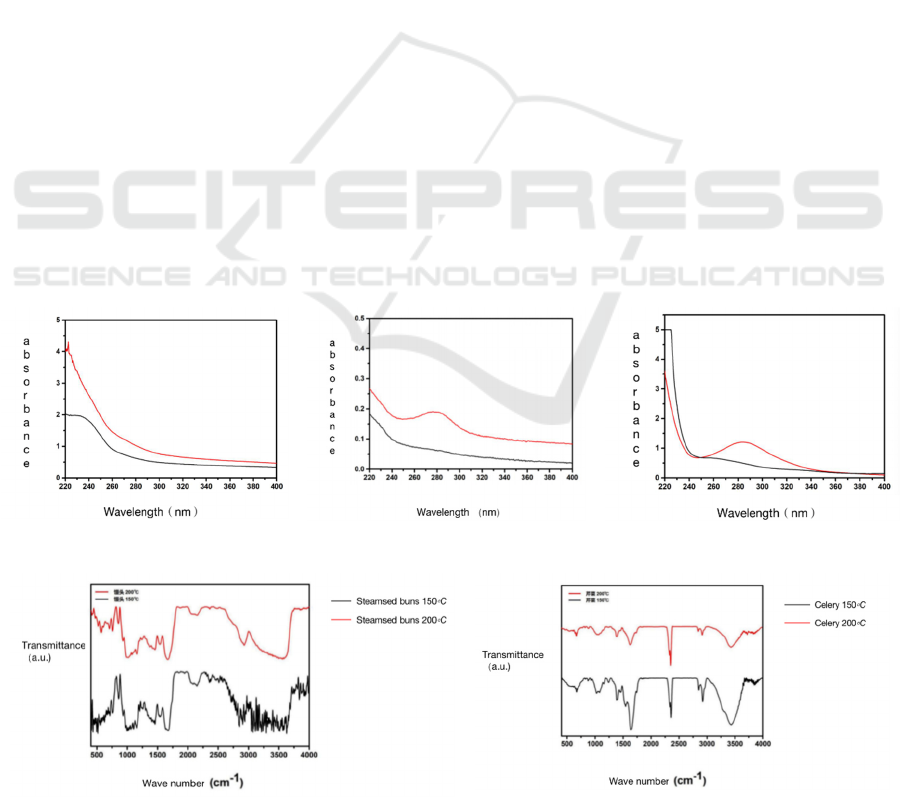

Figure 1 is the UV-Vis atlas of chicken, steam bun

and celery after baked 1h at 150℃ and 200℃

respectively. The chicken occur absorbing at

220~240nm position after baked at 150℃, occur

peak absorbing at 220nm after baked at 200℃, and

more higher peak absorbing strength, means the

generated matter quantity which able to ultraviolet

absorb increasing. The steam bun no peak absorbing

in the measured wave length range after baked, but

occur peak absorbing at 280nm position after baked

at 200℃. The celery occur one more higher peak

absorbing at 220nm after baked at150℃, but except

occur one peak absorbing at 220nm position after

baked at 200℃, also occur one absorbing at 290nm

position. The steam bun and celery all generated

absorbing at about 280nm after baked at 200℃,

generally, the absorbing at this position is the

continue conjugated alkene or aromatic chemical

compound with fewer rings. Through check the

documents, the peak absorbing of acrylamide at

280nm, means this matter maybe acrylamide (shown

as the below picture). According to report in

documents, starch and cellulose types matters easily

happen Maillard reaction under that heating under

high temperature condition and generate acrylamide

(Zhi-Jing N, 2021), through our test we found that,

the acrylamide generated by that baking steam bun

and celery at 200℃ more than baking at 150℃.

3.3 Fourier Alternate Infrared

Spectrum Characterize Result

Figure 2 is the Fourier alternate infrared spectrum of

steam bun and celery after baked 1h at 150℃ and

200℃. At the position 3500cm-1, the celery all have

one wide peak when baked 1h at 150℃ and 200℃,

this is stretch vibrating peak of oxhydryl of

glycoconjugate structure on cellulose, stretch vibrate

peak of -CH- at position 2900cm-1, stretch vibrate

peak of C=C and C=O double keys at position

1600cm-1. The function group of chemical structure

of celery baked 1h at 150℃ and 200℃ no obvious

changes. The infrared spectrum of steam bun after

baked 1h at 150℃ and 200℃ also no obvious

changes, this means the types of function group on

steam bun no changes.

3.4 Fluorescence Photometer Analyse

of Samples After Baked

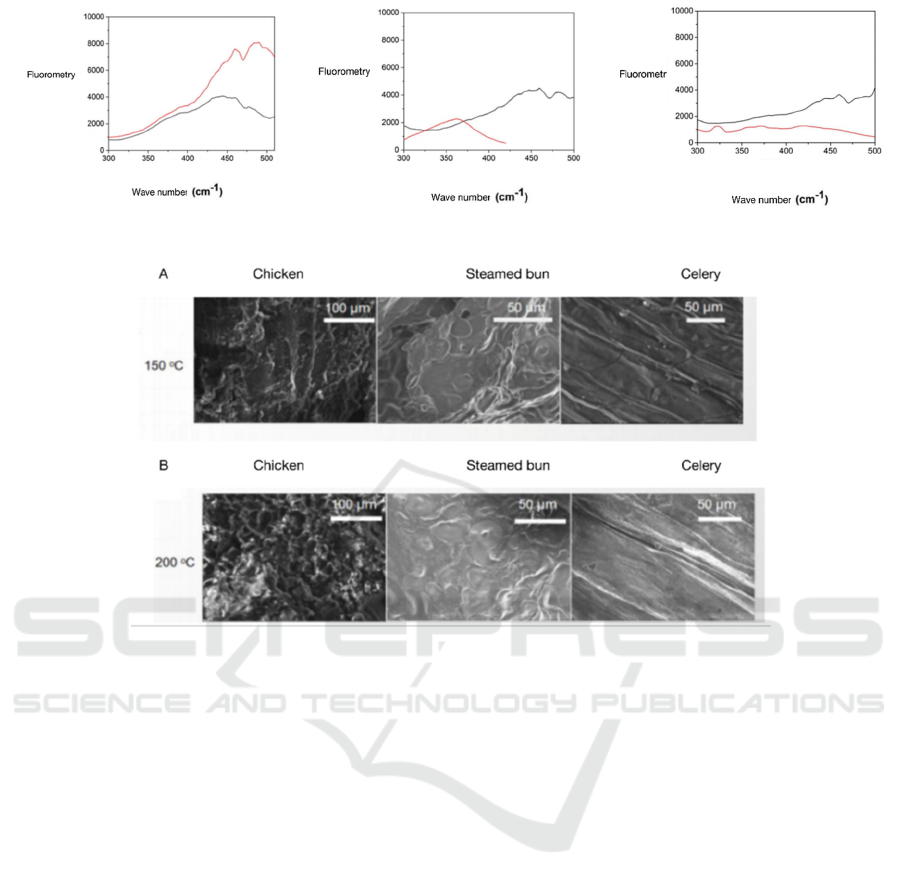

Figure 3 is the fluorescence spectrum of chicken,

steam bun and celery baked 1h at 150℃ and 200℃.

The launched fluorescence light intensity about 2

times of that baked 1h at 150℃ after the chicken

baked at 200℃. At the same time, the launched

fluorescence spectrum of chicken after baked at

200℃ happen infrared shift compare to the sample

baked at 150℃, the max fluorescence strength of

samples after baked at 200℃ about 490nm, but the

max fluorescence strength of samples after baked at

Figure 1: UV-Vis atlas of chicken, steam bun and celery after baked 1h at 150℃ (black line) and 200℃ (red line).

Figure 2: The Fourier alternate infrared spectrum of steam bun and celery after baked 1h at 150℃ and 200℃.

FSB 2022 - The International Conference on Food Science and Biotechnology

72

Figure 3: The fluorescence spectrum of chicken, steam bun and celery baked 1h at 150℃ (black line) and 200℃ (red line).

Figure 4: The SEM pictures of chicken, steam bun and celery after baked 1h at 150 and 200℃.

150℃ occur at about 445nm. Means that samples

baked at 200℃ maybe generate the related

conjugate structure. After the steam bun baked at

150℃ and 200℃, under the same excite light and

same sample concentration situation, the

fluorescence strength greatly reduced, the max

fluorescence strength of steam bun baked at 200℃

about half of chicken, at the same time, the longest

wave length of fluorescence launch spectrum also

only about 460nm. The fluorescence strength of

celery baked at 200℃ closes to the fluorescence

strength of steam bun baked at 200℃, and the

longest launch wave length of light spectrum also

closed, means the structure of celery and steam bun

baked at 200℃ are similar.

3.5 Scan Electron Microscope Observe

the Surface Structure After

Samples Baked

Figure 4 is the SEM pictures of chicken, steam bun

and celery after baked 1h at 150℃ and 200℃.

Firstly, the chicken samples occur holes after baked

at 150℃ and 200℃, especially that we can check

more bigger density of holes through scan electron

microscope after chicken baked at 200℃. Secondly,

sample surface of steam bun after baked looks more

flat, but still able to observe the celery internal fibre

tube structure of celery through SEM after celery

samples baked, this means that high temperature

baking still not destroy the internal fibre tube

structure of plant.

3.6 EDX Result of Chicken, Steam Bun

and Celery

Then it determined the EDX result of chicken, steam

bun and celery baked 1h at 150℃ and 200℃

respectively. To the chicken and steam bun, the

EDX spectrum chart after baked 1h at 150℃ and

200℃ all only contain elements C and O, and the

percentage of element C and O no obvious changes.

The component of celery baked at 150℃ and 200℃

has more obvious changes. Firstly, the celery self

contained more element types, except the elements

C and O, still contain the elements such as Na, Mg,

P, S, Cl, K and Ca, element types after baked almost

no changes, but percentage of each element has

Component Analyse and Carcinogenic Performance Research after Food Material Baked to Be Roasting

73

changes. Example, the percentage of elements C and

O a little reducing, the percentage of elements Na,

Cl and K a little rising, the reason maybe that high

temperature baked elements Na, Cl and K will not

form the volatilized matters and leave sample, so the

percentage has a little rising.

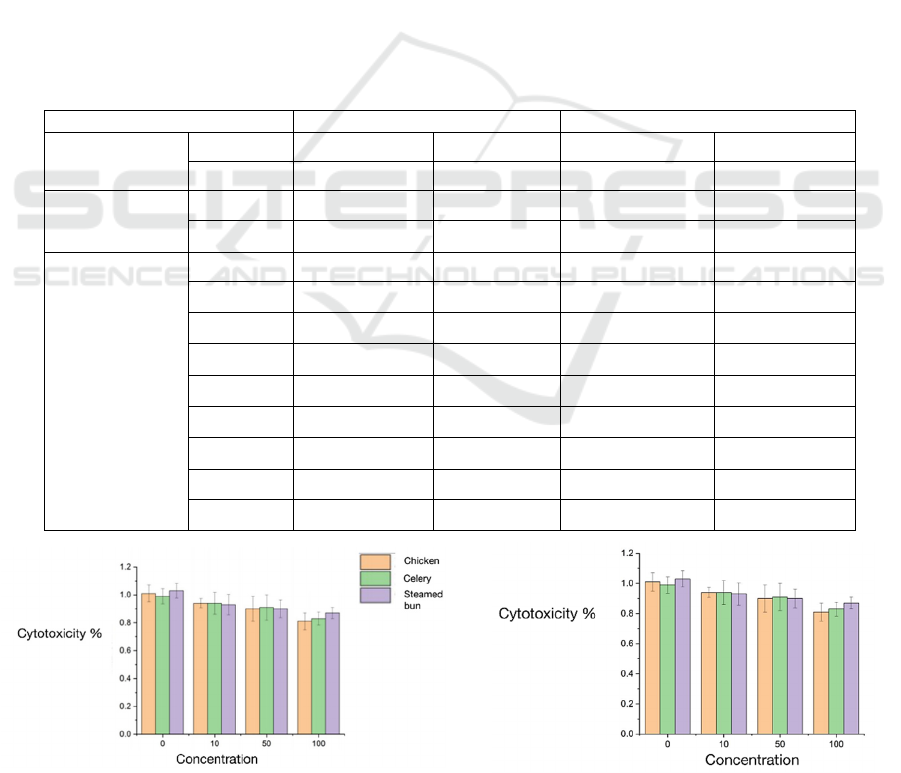

3.7 Cell Toxicity Test

Evaluating the cell toxicity of chicken, steam bun

and celery samples baked at different temperatures

and different concentration (0, 10, 50 and

100mg/mL) through MTT method. This test select

the mouse embryo fibroblast (NIH-3T3) to process

the cell toxicity test. From figure 5, we can know

that, through place the NIH-3T3 cells into sample

suspending muddy liquid and foster 2h, in

comparison, the cell toxicity of chicken, steam bun

and celery after baked at 200℃ more bigger than

samples baked at 150℃, the max cell toxicity of

samples when concentration at 100mg/mL.

4 CONCLUSION

Process characterization for the chicken, steam bun

and celery samples which baked at 150℃ and

200℃ through the test methods such as UV-Vis,

Fourier alternate infrared spectrum, fluorescence

spectrum, scan electron microscope and EDX

energy spectrum, found the foods after high

temperature baked will generate aromatic ring

chemical compound, acrylamide and other matters,

these matters all contain a certain toxicity. The cell

toxicity test result proof that, the baked foods will

generate a certain toxicity to cells under a certain

concentration. From here it can see that, no matter

meat types, starch types and vegetable types foods,

all shouldn’t be long time high temperature cooked

during the cooking process, if high temperature

cooking then will generate toxicity matters and harm

to human body.

Table 2: The EDX result of chicken, steam bun and celery baked1h at 150℃ and 200℃.

Element 150℃ 200℃

Chicken

C K 71.52 76.98 80.34 84.48

O K 28.48 23.02 19.66 15.52

Steam bun

C K 51.14 58.23 51.01 58.11

O K 48.86 41.77 48.99 41.89

Celery baked

C K 51.77 63.58 49.73 63.86

O K 31.12 28.69 25.51 24.59

NaK 02.72 01.74 05.01 03.36

MgK 00.80 00.49 00.69 00.44

P K 01.79 00.85

ClK 04.88 02.03 09.47 04.12

MoL 00.58 00.09

K K 03.59 01.35 07.35 02.90

CaK 02.89 01.06 01.66 00.64

Figure 5: The cell toxicity test of chicken, steam bun and celery samples baked 1h at 150℃ and 200℃.

FSB 2022 - The International Conference on Food Science and Biotechnology

74

REFERENCES

Chu Zhaoyin and Su Qing: the happen risk of

carbonhydrate and therioma. Shanghai medicine

science 2021, 44:286-292.

Liu Zongchao, Li Zhexuan, Zhang Yang, Zhou Tong,

Zhang Jingying, You Weicheng, Pan Kaifeng and Li

Wenqing: The globe cancer statistic report reading in

2020. Journal of Multidisciplinary Cancer

Management 2021, 7:1-14.

Ye Zhaoyu: fewer eating barbecue to prevent gastric

cancer. Food safety magazine 2016:51-52.

Yin Bing: quickly separate determine method of 3, 4-

benzopyrene in food. Oversea medicine science

(Hygiene science sub manual) 1980:53-54.

Yiqi W, Lian D, Xing Z, Yang J, Ying L, Lingling D,

Hong Y: Effect of long-term exposure to acrylamide

on endoplasmic reticulum stress and autophagy in rat

cerebellum. Ecotoxicology and Environmental Safety

2021, 224.

Zhi-Jing N, Xiang L, Bing X, Long-Teng H, Kiran T,

Zhao-Jun W: Effects of sugars on the flavor and

antioxidant properties of the Maillard reaction

products of camellia seed meals. Food Chemistry: X

2021.11

Component Analyse and Carcinogenic Performance Research after Food Material Baked to Be Roasting

75