Technical and Economical Study of Using Used Oil as Fuel for

Aluminium Smelting Furnace

Teguh Suprianto, Muhammad Kasim, Darmansyah and Muhammad Hasbi

Departmnt of Mechanical Engineering, Politeknik Negeri Banjarmasin, Kayutangi, Banjarmasin, Indonesia

Keywords: Used Oil, Oil-Fired Furnace.

Abstract: Used oil is liquid waste generated from the use of vehicle and industrial engines. Waste oil can be used as a

fuel in metal smelting. This study discusses the technical aspects and costs of using used oil as fuel for

Aluminium smelting furnaces. This research uses a spray gun to mix used fuel oil and air. The mixed fuel and

air are then burned in a nozzle burner to melt 3 kg of Aluminium. As a comparison, experiments with LPG

fuel were also carried out. Temperature and flame measurements were carried out in this study. The burner

flame fuelled by used oil produces a higher maximum temperature than the LPG flame, which is 950 and

1100 C, respectively. From the results of the study, the comparison of the cost of smelting 3 kg of Aluminium

using used oil is 0.12 USD while the cost of smelting with LPG is 0.6 USD.

1 INTRODUCTION

Waste is the residue of a business and/or activity.

Meanwhile, Hazardous and Toxic Waste is the

residue of a business and/or activity containing

Hazardous and Toxic Materials. Hazardous waste is

known because its nature, concentration, or amount,

either directly or indirectly, can pollute and damage

the environment, and endanger health. It also

endangers the survival of humans and other living

things. Used Oil or Used Lubricating Oil is a type of

dangerous waste that is commonly found around us.

Used oil waste is generally generated from the use of

lubricating oil or oil. Lubricating oil is generally used

by equipment that is moving, or machines, or

motorized vehicle engines such as motorcycles, cars,

trucks and electric generator engines. The ever-

increasing use of motorized vehicles will cause the

amount of used oil to also increase and the potential

for pollution to also increase

Used engine oil, however, has a relatively high

calorific value so that it is interesting to be used this

waste as a renewable fuel for heat generation. One

alternative that can be used as fuel in the metal casting

process is used oil (Osarenmwinda, 2015). Used oil

can be obtained from motorcycle and car repair shops.

So far, used oil has not been widely used and the price

is cheap. This has the potential to be used as a

substitute for metal casting fuel.

Many previous studies have used oil as a fuel.

Study conducted by Tamaki made a high effective

and stable combustion of waste oil combustor design

which was achieved with low energy (Tamaki, 2003).

Another study stated that the combustion zone of the

two-stage burner was higher than those in the single-

stage type as a result of a better mixing of air and fuel

(Lekpradit & Namkhat, 2017). Study by Elnajjar, Al

Omari, Hamdan, Ghannam, & Selim, 2021) showed

better combustion quality with the addition of diethyl

ether additive.

One of the most popular types of metal casting is

aluminium casting. Aluminium casting is used by the

community and small industry to make household

appliances, ship propellers and so on. (Yulianti &

Wahdah, 2019).

So far, many small industries use LPG (Liquified

Petroleum Gas) as fuel for aluminium smelting. This

is because it tends to be easy to obtain and easy to use

even though the price is expensive.

The use of used oil, in addition to utilizing waste,

is also to look for cheaper alternative fuels so as to

reduce casting production costs. Research on used oil

fuels has often been done, but it is still rare to show a

comparison of costs with other fuels. This research

intends to design an aluminium smelting tool fuelled

by used oil and carry out a cost comparison study

between using used oil and LPG.

Suprianto, T., Kasim, M., Darmansyah, . and Hasbi, M.

Technical and Economical Study of Using Used Oil as Fuel for Aluminium Smelting Furnace.

DOI: 10.5220/0012002100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 1001-1005

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1001

2 METHODOLOGY

2.1 Experiment Setup

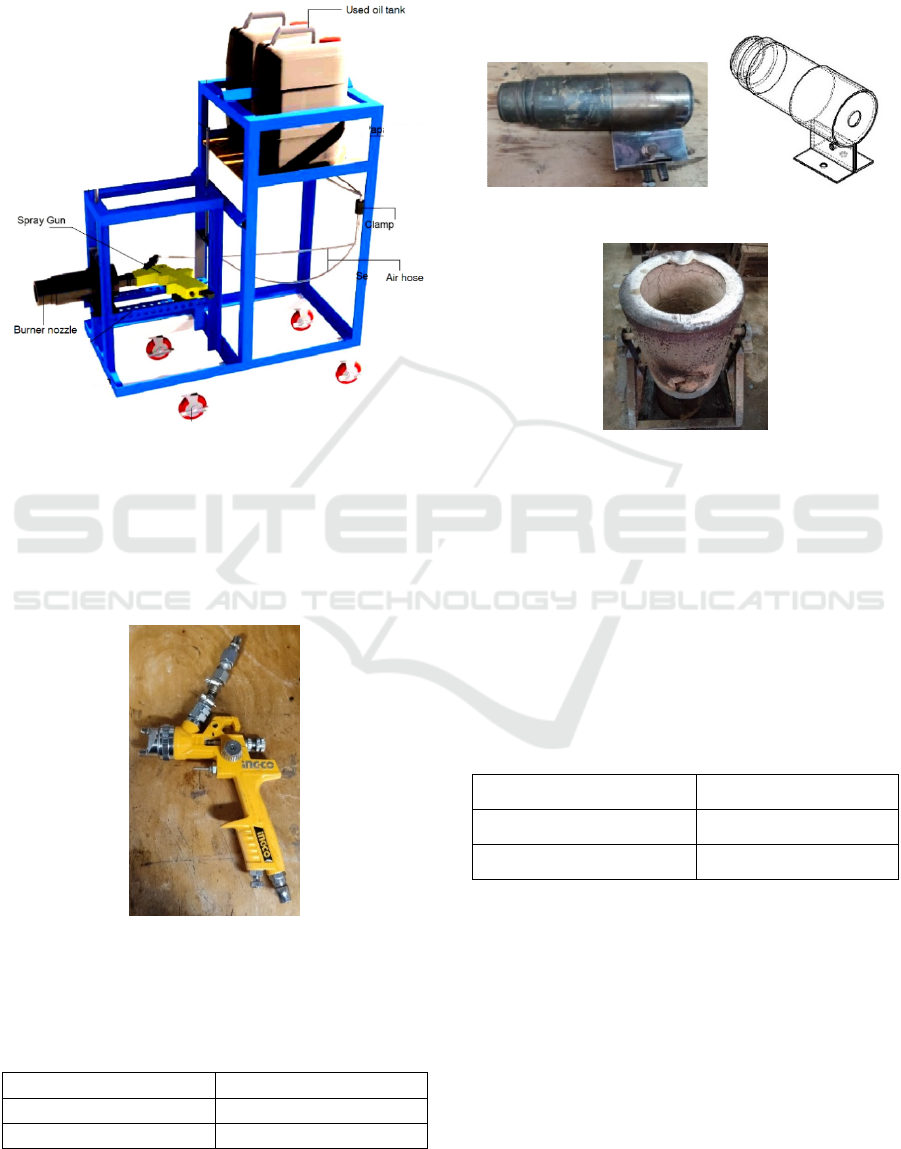

Figure 1: Experiment setup and design.

The test is carried out using a burner fuelled by used

oil. Tests using LPG were also carried out as a

comparison. Used oil is placed in the tank at the top.

Oil is supplied by an 8 mm diameter pipe to the spray

gun. Used oil flows by gravity. Spray gun is used for

mixing used oil and air before combustion.

Figure 2: Spray gun for mixing oil and air.

The specifications of the spray gun used are as

follows:

Table 1: Specification spray gun.

Standard nozzle: 1.4 mm

Operating pressure 2-3.5 bar

Air flow control 119-200 l/min

The nozzle of the spray gun is aimed at the burner

to produce a flame that is directed to the aluminium

smelting furnace. The cone-shaped burner is made of

stainless steel with a diameter of 70 mm at the back

and a diameter of 50 mm at the front.

Figure 3: Burner nozzle.

Figure 4: Aluminium melting furnace.

The furnace used has a diameter of 40 cm, a

height of 25 cm and a thickness of 5 cm. The furnace

is made of refractory cement and is used to melt 3 kg

Aluminium

2.2 Experiment Material

In this experiment, Aluminium ingots were used as

the metal to be melted. Aluminium ingot is a material

that is re-melted to make various products.

Table 2: Characteristics and properties of Aluminium.

Density 2,70 gram per cm

3

Melting point 660,32

0

C,

Boiling point 2519

0

C

At 660

0

C the aluminium was completely molten and

the temperature increased more rapidly (Furu,

Buchholz, Bergstrøm, & Marthinsen, 2010).

Furnaces with two different fuels are used to melt

the Aluminium. The first experiment was using used

oil, the second experiment was using LPG. The

specifications of used oil are as follows (Saputra, I.

Guhhri, Ainul. Septiadi, 2017):

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1002

Table 3: Used oil specifications.

Flash point 77

0

C

Fire point 90

0

C

Kinematic Viscosity 15.921 centistoke

LHV 39.316MJ/kg

HHV 41.855MJ/kg

Meanwhile, the LPG used is the production of PT

Pertamina. The composition of LPG contains 50%

Propane and 50% Butane. The LPG specifications

used are as follows (ESDM, 2020):

Table 4: LPG specifications.

Steam pressure 5,0 – 6.2 kg/cm2

Specific gravity 2,01

HHV 48.836,27 kJ/kg

LHV 46.043, 37 kJ/kg

2.3 Test Procedure

This study uses a burner that has a spray gun, burner

and smelting furnace. An air flow of 119-200 L/min

is directed to the spray gun. Before entering the spray

gun, the air is compressed by a compressor with a

pressure of 3 bar. Setting the spray gun is done to

produce an optimal air and oil mixture. The optimal

mixture produces the flame with the longest burst.

The ignition of used oil is preceded by a heat trigger

that comes from the combustion of a mixture of used

oil and gasoline. The used oil and gasoline mixture is

ignited for 30 seconds to heat the burner nozzle. The

flame from the burner nozzle is directed to the

smelting furnace.

The temperature measurement was carried out

using an Amprobe IR 750 thermo gun. The

temperature was measured at the edge of the melting

container. Temperature is recorded every 2.5 minutes.

Oil and gas consumption is measured during the

smelting process.

3 RESULT AND DISCUSSION

3.1 Heating Rate

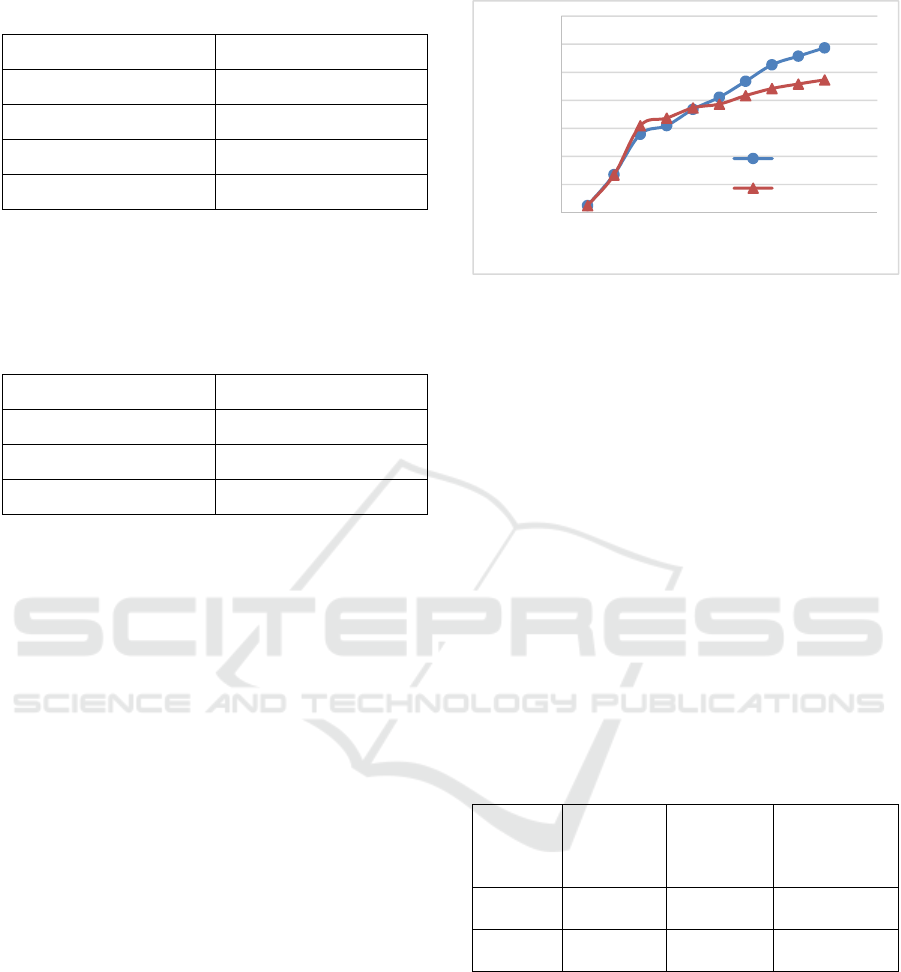

The results of temperature measurements are

presented in Figure 4.

Figure 5: Furnace temperature with used oil vs LPG.

Figure 2 shows the experimental results of used

oil and LPG. The maximum temperature of used oil

is higher than that of LPG. This happens because the

design of the used oil burner produces a larger fire. In

terms of combustion energy, burning used oil

produces more energy. This is because the mass flow

rate of used oil is greater than the mass flow rate of

LPG (Table 5). Heating with LPG produces a higher

rate at the beginning but then decreases. This is

because the fire from LPG is hotter than the fire from

used oil. The lower energy rate causes the heat

increase not to be proportional to the increase in the

amount of heat wasted.

The consumption of used oil and LPG is

measured during the smelting process. Table 5 below

is a comparison between the mass of gas and oil

burned. The energy produced from burning used oil

is also shown in table 5.

Table 5: Combustion energy.

Fuel

Mass flow

rate (gr/s)

Heating

value

(kJ/g)

Power

Equivalent

(kW)

Used oil 0.513 41.855 21.471

LPG 0.333 48.836 16.279

3.2 Combustion in Smelting Furnace

Figure 5 shows the combustion of LPG and used oil.

Judging from the colour of the fire, burning with LPG

produces a blue white flame while the used oil flame

is orange. This shows that the fire from LPG has a

higher temperature than the fire that comes from

burning used oil. The colour of the flame indicates the

temperature, the blue flame has a higher temperature

than the red color.

0

200

400

600

800

1000

1200

1400

0 5 10 15 20 25 30

Tempratur (C)

time (minute)

Waste oil

LPG

Technical and Economical Study of Using Used Oil as Fuel for Aluminium Smelting Furnace

1003

(a)

(b)

Figure 6: Combustion results at the nozzle burner (a) LPG,

(b) Used oil.

Figure 6 shows the colour temperature chart.

Based on the colour match of the flame, the flame

colour of LPG gas has a temperature of around 1500

C while the flame of used oil is around 1100 C.

Figure 7: Colour temperature chart.

Figure 7 shows a fire surrounding an aluminium

crucible. Flames from used oil tend to be darker,

while flames from LPG are lighter. This is because of

the different characteristics of fire as discussed

earlier.

(a) (b)

Figure 8: Flame surrounding crucible (a) used oil, (b) LPG.

3.3 Fuel Cost Comparison

The cost comparison between 3 kg aluminium

smelting with gas fuel and used oil is presented in the

table 6 and 7:

Table 6: Used oil cost.

Used oil

Description

Usage

amount

Unit price Cost

Used oil 950 gr

0.16

USD/kg

0.15 USD

Electricity

cost for

compressor

0,75 kW x

25 min

0.1

USD/kWH

0.03 USD

Total 0.18 USD

Table 7: LPG cost.

LPG

Description

Usage

amount

Unit price Cost

LPG 500 gr 1.2 USD/kg 0.6 USD

Based on tables 6 and 7, the use of used oil is

much cheaper than using LPG, which is 330%

cheaper. Although the resulting heating rate is lower.

This condition can be overcome by increasing the

capacity of the spray gun used so as to increase the

rate of energy being burned.

4 CONCLUSIONS

From the research and discussion that has been done,

it can be concluded as follows:

1. The heat generated by the combustion of used

oil can reach a higher temperature than LPG,

but the heat increase from LPG is faster than

used oil.

2. The cost of smelting Aluminium with used

fuel oil is much cheaper than using gas fuel.

ACKNOWLEDGEMENTS

Thank you to the Banjarmasin State Polytechnic for

funding this research.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1004

REFERENCES

Elnajjar, E., Al Omari, S. A. B., Hamdan, M. O., Ghannam,

M., & Selim, M. Y. E. (2021). Characteristics of

external furnace combustion of used lube oil with

different percentages of diethyl ether additives burned

with liquefied petroleum gas. Biofuels, 12(10), 1233–

1243. https://doi.org/10.1080/17597269.2019.1608035

ESDM, K. (2020). Keputusan Direktur Jenderal Minyak

dan Gas Bumi Nomor 116.K/10/DJM/2020 tentang

Standar dan Mutu (Spesifikasi) Bahan Bakar Gas Jenis

Liquefied Petroleum Gas yang Dipasarkan di Dalam

Negeri. Jakarta.

Furu, J., Buchholz, A., Bergstrøm, T. H., & Marthinsen, K.

(2010). Heating and melting of single Al ingots in an

aluminium melting furnace. TMS Light Metals, 679–

684.

Lekpradit, T., & Namkhat, A. (2017). Two-stage

combustion burner using used engine oil as fuel. Key

Engineering Materials, 751 KEM, 442–448.

https://doi.org/10.4028/www.scientific.net/KEM.751.4

42

Osarenmwinda, J. O. (2015). Fabrication and performance

evaluation of oil – fired crucible furnace using locally

sourced materials, 5(3), 29–33.

Saputra, I. Guhhri, Ainul. Septiadi, W. (2017). Daur Ulang

Oli Bekas Menjadi Bahan Bakar Diesel Dengan Proses

Pemurnian Menggunakan Media Asam Sulfat Dan

Natrium Hidroksida. Logic : Jurnal Rancang Bangun

Dan Teknologi, 17(1), 73–79. Retrieved from

http://ojs.pnb.ac.id/index.php/LOGIC/article/view/509

Tamaki, N. (2003). Study on Development of Waste Oil

Combustion Burner for Energy Saving and Low-

Pollution (II). Journal of the Japan Institute of Energy,

82(10), 780–785.

Yulianti, F., & Wahdah, R. (2019). Pengembangan

Kewirausahaan Berbasis Potensi Lokal Pada Usaha

Kerajinan Tanggui Kelurahan Alalak Kecamatan

Banjarmasin …. In … Manajemen Indonesia (FMI ….

Retrieved from http://eprints.stiei-kayutangi-

bjm.ac.id/1035/

Moore, R., Lopes, J. (1999). Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

Smith, J. (1998). The book, The publishing company.

London, 2

nd

edition.

Technical and Economical Study of Using Used Oil as Fuel for Aluminium Smelting Furnace

1005