Different CO

2

Capture Methods Based on Metal-Organic Frameworks

Bingxun Zhao

*

Ulink Educational Group Shanghai, Shanghai 201615, China

Keywords:

Carbon Capture, Methods, MOFs, Application.

Abstract: The increasing human production activities have led to an increase in carbon dioxide (CO

2

) emissions year

by year, and the CO

2

concentration in the general atmosphere has continued to increase. The increase in the

concentration of CO

2

in the atmospheric environment brings a series of environmental problems, which in

turn destroys the earth’s ecology. How to remove CO

2

from the atmosphere has become the focus of the

current research field. In this research, the advantages and disadvantages of traditional CO

2

capture materials,

and the advantages of MOFs itself were introduced, and followed by the introduction of M

2

(dobdc) which act

as an MOFs type, and the related carbon capacity as well as preparation step, physical and chemical properties

of MOF-801/PEBA with its performance and experimental data for carbon capture. The rht-MOF-7 that

modified by amine and triazine functional groups shows high affinity for CO

2

, and the capture capacity of

MOFs when working with amine and fluorine are also mentioned. And the CAU-1 can achieve a modest CO

2

uptake with a high adsorption due to equal heat. The description of pore size adjustment and active site

distribution effecting carbon capture is also discussed.

1 INTRODUCTION

Industrial production and anthropogenic emissions

have caused a sharp rise in atmospheric carbon

dioxide (CO

2

) levels. The amount of CO

2

in the

atmosphere is expected to continue to grow, and

experts are still unable to address large-scale

emissions. The continued increase in the

concentration of carbon dioxide in the atmosphere has

brought about a series of knock-on effects. For

example, rising CO

2

concentrations lead to global

warming, causing serious damage to the earth’s

ecological environment. Global warming is directly

responsible for different serious problems, such as sea

level rise and food security. In order to avoid further

damage to the earth's ecological environment,

reducing carbon dioxide emissions or removing CO

2

already in the atmosphere has received increasing

attention.

During the daily industrial process, a diverse of

various functional materials have to capture CO

2

being emitted and then through regeneration

(

Sumida, 2012)

. First step needs accurate selectivity

and high affinity between materials and the gas to

make sure CO

2

is completely removed. And the

second step requires abundant energy to break the

binds, let material gets rid of CO

2

. In addition, the

amine method to capture CO

2

holds several

advantages, such as simple operation and high CO

2

removal efficiency. Moreover, they are commercially

available and improvements on the method have been

made over time. For instance, the absorption

performance of the whole method will be further

improved if a mixture of various solvents is used as

the absorption liquid for CO

2

, achieving the best

carbon capture performance. However, the existing

amine method does have various problems and

limitations. Firstly, such capture process is very

energy-consuming, specifically in the regeneration of

absorbents. Due to the high stability of products

formed in the chemisorption process, the backward

reaction, which is the desorption process, is not

favored, therefore high energy is required for

regeneration of the aqueous alkanolamine absorbents.

Furthermore, the corrosive nature of amine solutions

toward the vessels limits the concentration of

alkanolamine species. And it is required to be heated

to a regeneration temperature, leading to great

regeneration energy and derived costs. The amine

method also has limitations like relatively low

stability towards heating and decomposition of amine

overt time, leading to lower performance in

absorption over time.

Although these methods are very effective, there

Zhao, B.

Different CO2 Capture Methods Based on Metal-Organic Frameworks.

DOI: 10.5220/0012002900003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 93-99

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

93

are still some problems. For example, the problem is

that the existing methods for removal CO

2

will lead

to high cost and concerns about the efficiency and

stability of the whole process. In addition, due to the

energy-intensive nature of current processes, new

technologies are required to reduce energy require-

ments. Porous materials have been studied, aiming to

replace aqueous absorbents, as they have the potential

to greatly reduce the energy costs in carbon capture

processes as well as increasing the efficiency of such

processes (Belmabkhout, 2016). Zeolites are

microporous aluminosilicate minerals, which have

high chemical and thermal stability. Most

importantly, as solids, zeolites have much lower heat

capacity as compared to aqueous alkanolamine

solutions, thereby resulting in a lower energy penalty

for regeneration. Moreover, zeolites have a well-

developed structural chemistry, which would lead to

optimized zeolites for carbon capture processes.

However, zeolites’ main limitation is the hydrophilic

nature, so water vapor would compete with CO

2

for

adsorption sites and the porous materials will get

saturated with water vapor eventually, leading to

lower adsorption capacity for CO

2

over time.

Activated carbons are carbons produced from

carbonaceous source materials, possessing pores.

Compared to zeolites, activated carbons are

hydrophobic, therefore the issues from water vapor

are not main concerns. Activated carbons have high

surface areas and therefore high adsorption capacity.

However, due to the uneven distribution of pores and

the various pore sizes in activated carbons, they are

more suitable for high-pressure gas separation

applications compared to low-pressure carbon

capture processes, such as trace CO

2

capture.

Although both zeolites and activated carbons can be

used to achieve efficient carbon capture, there are

some disadvantages. For zeolites, they are

outstanding in many aspects but it can be easily

saturated by water vapor. For activated carbon, the

pores for activated carbon do not have uniform size,

even though it has high surface area, but the

adsorption capacity in low pressure condition is not

satisfactory.

To this end, the development of new high-

efficiency carbon capture materials has become a

current research focus. Moreover, different types of

carbon capture functional materials have also been

gradually developed, such as metal-organic

frameworks (MOFs). MOFs are a kind of compounds

with one, two- or three-dimensional structures formed

by the coordination of metal ions or clusters with

organic ligands. People use MOFs for gas storage

because of the pores in it. MOFs may help increase

the energy density of the gas stored in the tank,

thereby increasing travel distance or reducing the

space required for the tank, rather than increasing the

pressure in the tank, which results in high tank weight

and compression costs. Compared with the two

porous materials introduced above (zeolites and

activated carbons), the use of MOFs shows great

advantages in carbon capture because they are tunable

in both porosity and chemical functionality. For

example, in the carbon capture process, there are

synergistic effect that can result in rapid and strong

adsorption of CO

2

in the pores, excluding larger and

smaller molecules, make the material has high

selectivity for CO

2

when compared with Reactive

amine-containing materials or complete molecular

sieves. As a result, MOFs are expected to replace

zeolite and activated carbon for carbon capture in the

future.

In general, this research will mainly introduce the

synthesis of several typical MOFs materials and their

performance regulation. On this basis, the carbon

capture performance of these MOFs materials was

further systematically analyzed.

2 MOFS-BASED CO

2

CAPTURE

MOFs materials have been widely used in the

selective separation of gases and show attractive

application prospects, due to its highly coordinatively

unsaturated metal surface sites. One notable example

is the use of the prepared Mg

2

(dobdc) for gas

separation (

Sumida, 2012)

. As the CO

2

molecule

features electronegative O atoms and an

electropositive C atom, any metal site that could

donate or accept electrons would be great adsorption

choices, as shown in Fig. 1. However, many current

materials with such features perform rather average

(Liu, 2019), such as Cu-BTC which had only modest

carbon capture capabilities, due to low isosteric heat

of CO

2

. Even the best adsorption capacity reported,

Mg-MOF-74, was comparable to other sorbents like

zeolites (Liu, 2019). However, strongly basic metals

with unsaturated coordination sites like Mg and Cu

have great potential as building blocks for the

preparation of new MOFs-based functional materials

to capture CO

2

. Increasing the number of open metal

sites allows greater opportunities for gas-MOF

interactions, with metals with multiple oxidation

states yielding some of the best CO

2

adsorption

values (Aniruddha, 2020).

For instance, MOF-801 resembles UiO-66 in

terms of its backbone architecture and exhibits a high

affinity for CO

2

as a result of the coordination of

FSB 2022 - The International Conference on Food Science and Biotechnology

94

Figure 1: Application of MOFs materials for CO

2

capture (Liu, 2019).

hydroxyl groups to Zr clusters (Sun, 2019). The

MOF-801/PEBA composite membrane had much

better CO

2

permeability and selectivity. MOF-801

particles are created via a multi-step process. In an

autoclave, fumaric acid and and ZrOCl

2

was

dissolved in a mixture of N, N-dimethylformamide

(DMF) and formic acid (20:7 by volume). The

hydrothermal synthesis was place in an autoclave at

130 °C for 6 hours, after which the white particles

were precipitated and washed at least three times with

DMF and methanol. The cleaned particles underwent

solvent exchange with methanol and three DMF

rinses per day for three days in a row. To create the

activated MOF-801, the solvent exchange particles

were vacuum dried at 150 °C for 12 hours. An

ethanol/water solvent was used to disperse MOF-801

nanoparticles, and the mixture was agitated and

sonicated for two hours. The PEBA was then

combined with the MOF-801 dispersion at 80 °C

while being stirred and refluxed for two hours. A

mixed matrix composite membrane made of MOF-

801/PEBA was created. In order to create a pure

PEBA composite membrane as a control, the PEBA

solution was spin-coated on the PAN support under

the same circumstances. The PTFE petri dish also

develops a thick layer. The films were dried for two

to three days at ambient temperature, the solvent was

then removed and vacuum dried. The weight of MOF

divided by the sum of the weights of MOF and PEBA

was used to calculate the loading of MOF-801 in the

film.

The capacity of mixes is assessed through

measurements of gas permeation. A constant volume

system was used to measure the permeability of pure

gas at 20 °C. Before measuring each gas, the

membrane and permeation system accumulated

overnight. Under a specific pressure, gas is pumped

into the gas reservoir, and the sensor records the

permeability’s change as a function of pressure. The

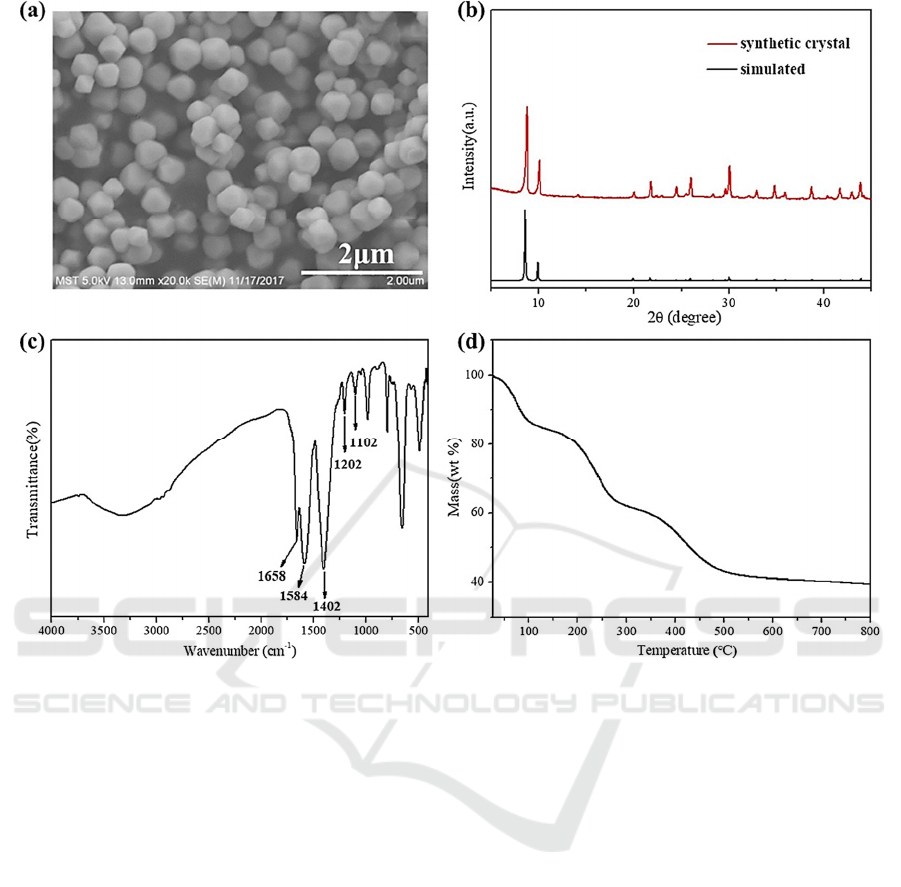

prepared MOFs was characterized by using SEM,

XRD, FT-IR and TGA, as shown in Fig. 2. The

synthetic MOF-801 octahedral structure had a

homogeneous particle size distribution according to

the SEM images. These tiny nanoparticles make it

easier to create mixed-matrix composite films that are

uniformly thin. XRD was further used to examine the

crystal structure of the produced materials, and the

thermogravimetric analysis (TGA) was used to

examine the thermal stability of the produced

materials. The outcomes demonstrate that at 500 °C,

the synthesized MOF-801 goes through three steps of

mass loss. The first minimal weight loss of the

activated sample occurred prior to 100 °C and was

brought on by the elimination of moisture. The

second weight loss occurred at about 250 °C and was

caused by the evaporation of visitor molecules from

the pores of MOF-801. These molecules included

solvents like DMF and methanol. The final

breakdown points of MOF-801 shows at about 500 °C

after additional heating, proving the substance’s high

thermal stability. Although MOF-801 has a greatly

enhanced affinity and adsorption capacity for CO

2

, it

has a relatively low adsorption capacity for N

2

. The

adsorption capacity of CO

2

grew significantly as the

adsorption operating pressure increased, whereas the

adsorption capacity of N

2

barely changed. This

behaviour suggests that particular CO

2

gas adsorption

sites exist, proving that CO

2

has a greater affinity than

N

2

. The outcomes demonstrate the potential of MOF-

801 as a N

2

-selective CO

2

adsorbent.

Different CO2 Capture Methods Based on Metal-Organic Frameworks

95

Figure 2: SEM, XRD, FT-IR and TGA characterization of the prepared MOFs materials (Sun, 2019).

If some active functional groups are introduced in

the preparation of MOFs materials, the prepared

MOFs materials can exhibit better carbon capture

effect. For example, the prepared rht-MOF-7

displayed high affinity for CO

2

(Sun, 2019), where

the added functional groups including amine and

triazine functional groups enhanced attraction

towards CO

2

. Enhancement of CO

2

capture can be

achieved with functional groups, where the

introduced different functional groups can donate

electrons. The outer orbital of the N atom in the amine

group has a pair of electrons that can be used for

contribution. Two approaches to tethering amine

units to MOFs to enhance CO

2

capture are achievable,

but amine corrosion is not something that most MOFs

can experience, so the stability of MOFs is

particularly important. For example, it is to attach

amine groups to organic ligands. In the pores of Cu-

BTTri, the N atom in the amine is bound to the C atom

of CO

2

through the strong Coulomb force, and the O

atom of CO

2

is bound to the copper atom of the

unsaturated site (

Sumida, 2012)

. Apparently, the

amine-grafted Cu-BTC could not over-absorb a

satisfactory amount of CO

2

. At higher CO

2

partial

pressure, the amine units blocked the small pores and

reduced the absorption capacity compared with bare

materials. Therefore, some mesoporous MOFs were

used for the modification of amines. A family of fcu-

MOFs that were based on ligands that were rare earth

metals, fluorinated and non-fluorinated and either

included or excluded hetero-functionality was

analyzed. This enabled fine-tuning of the MOFs such

as the fact that earth metals were electron rich and

possessed high charge density that was localized. An

MOF that contains open metal sites but no tetrazolate

and fluoro groups, Y-pek-MOF-1 showed one of the

highest CO

2

volume adsorption till today.

Zn

4

O(BDC)

3

has functionalized ligand analogues by

differing the substitution of linear dicarboxylate

linkers, and are also referred to as IRMOFs, which are

distinguished by different pore sizes and

functionalities (

Sumida, 2012)

.

FSB 2022 - The International Conference on Food Science and Biotechnology

96

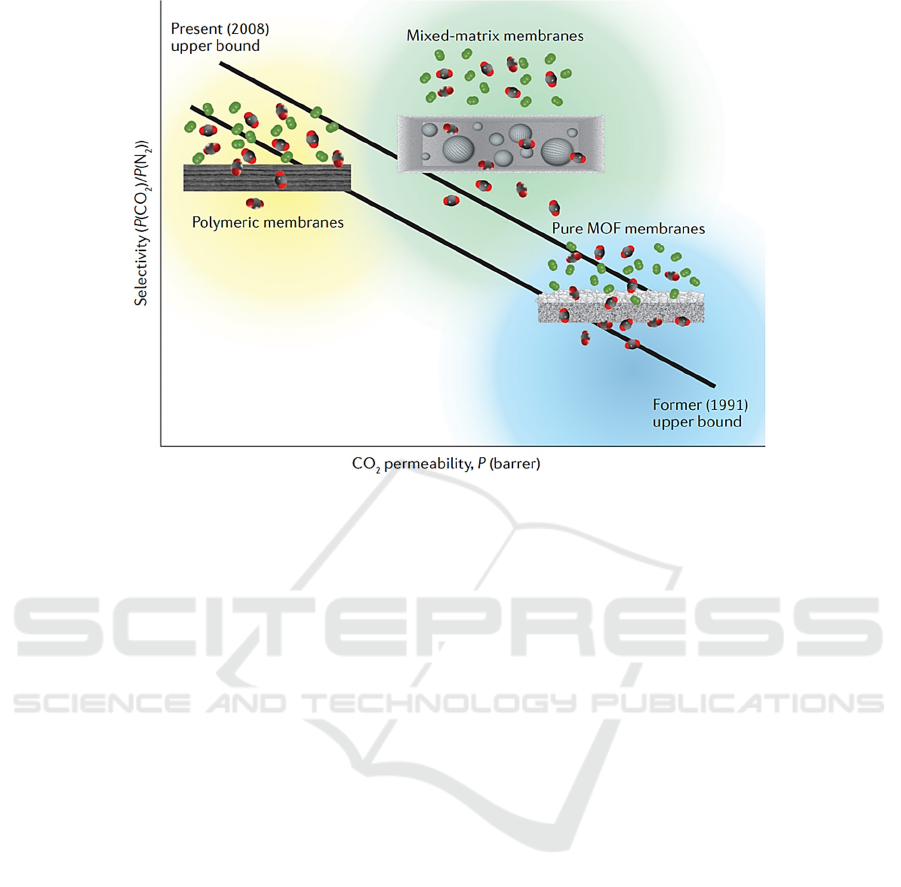

Figure 3: The selectivity and permeability of CO

2

with the prepared MOFs materials (

Trickett, 2017).

The inclusion of heteroatoms, atoms which are not

carbon, usually those which are nucleophilic, serve as

strong interactors with CO

2

. Amines are of great

interest, and one such MOF, CAU-1 achieved a

modest CO

2

uptake with a high isosteric heat of

adsorption (

Trickett, 2017)

. As shown in Fig. 3, the

as-prepared MOFs material exhibits excellent

performance in carbon dioxide selectivity and

permeability. In addition, according to the relevant

research, the CAU-1 was synthesized by

solvothermal method (Zhong, 2021). The samples

were heated to 125 °C in an autoclave for 5 h, cooled

to room temperature, and rinsed three times with

CH

3

OH. The impurities in the channels were then

completely removed by three purifications (5-6 h with

magnetic stirring) with deionized water.

SiFSiX features ultra-micropores, whose size can

be precisely fine-tuned by trying different

combinations of organic ligands and metal cations in

the overall structure. For example, SiFSiX-3-M was

made from MSiF6 and features a uniform distribution

of adsorptive sites due to its one-dimension channel

which is tailored for CO

2

capture. Isostructural

analogues of these MOFs also show phenomenal CO

2

capture capabilities. CALF-20 provides nanosized

pores which form weak but preferential binding to

CO

2

over water. It prevents the issue of contaminants

ruining the entire process by inhibiting the formation

of hydrogen bonds to water, preventing water from

adsorbing onto the material and blocking CO

2

adsorption. The key highlights of CALF-20 is that it

features a massive surface area, displays selective

CO

2

physisorption at high capacities and has low

energy requirement (Ozin, 2022). Due to its tailored

one-dimensional channels and uniformly distributed

adsorption sites, SiFSiX-3-Cu exhibits a CO

2

capture

capacity of 1.24 mmol/g. When using NbOF clusters,

the obtained NbOFFIVE-1-Ni is more attractive to

CO

2

than SiFSIX-3-Cu because the attraction of

negatively charged fluoride anions and positively

charged carbon atoms can form a one-dimensional

chain to attract CO

2

. In addition, the results show that

the small pores in it allow the MOFs to possess a

strong CO

2

capture capability. Therefore, when CO

2

passes through the small hole, special deformation

occurs, which slows down the gas propagation. The

uniform distribution of fluoride anions also helps

SiFSIX-3-Cu and NiOFFive-1-Ni achieve strong

ability when capture. The high affinity of Florine ions

attracts C cations in CO

2

, increasing the mutual

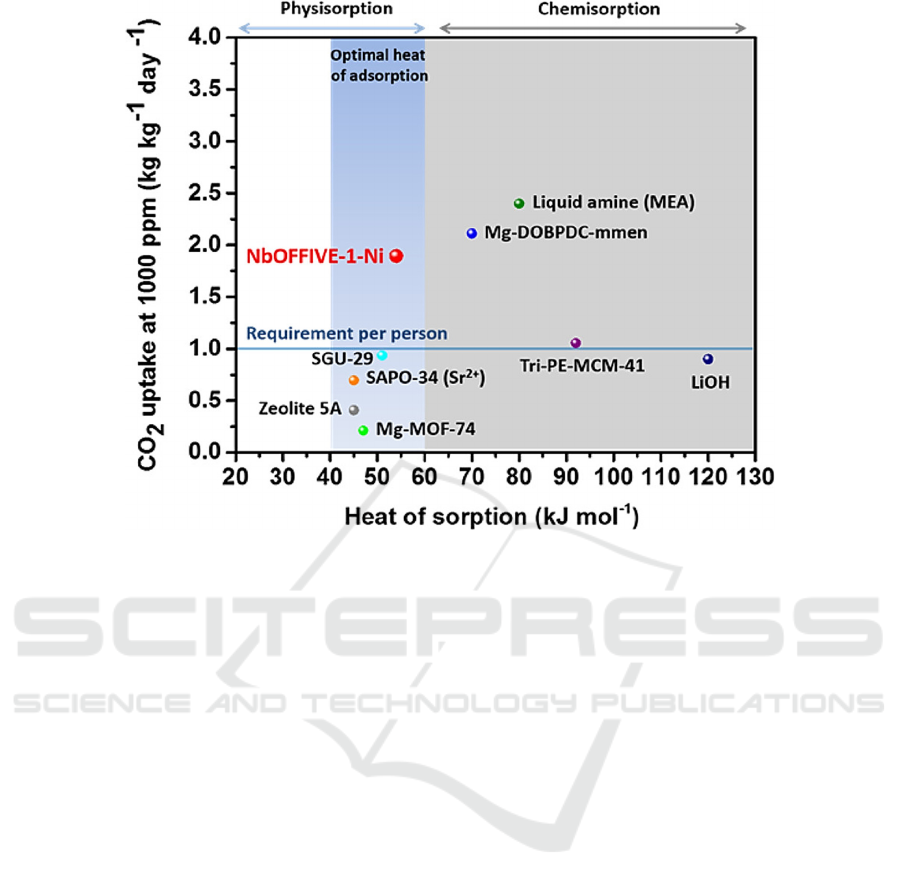

adsorption and reaction rates (Bhatt, 2016). As shown

in Fig. 4, compared with other porous materials, the

prepared MOF materials also showed excellent

performance in CO

2

absorption. Of course, in order to

improve the CO

2

adsorption capacity of the MOFs

material, the open metal sites of the MOFs material

can also be regulated (Montoro, 2012).

3 CONCLUSION

This research introduces the synthesis methods of

Different CO2 Capture Methods Based on Metal-Organic Frameworks

97

Figure 4: Performance of the heat of adsorption-CO

2

uptake with different porous materials (Bhatt, 2016)

different MOFs materials and their performance in

carbon capture. To further improve the carbon

capture efficiency of MOFs materials, different

preparation strategies were used, such as surface

modification. In the future, as more and more solid

sorbents, especially porous materials, are researched

and produced, key parameters need to be evaluated to

discover the optimal solid sorbent carbon capture

process. First, the adsorption capacity of the solid

adsorbent needs to be high. Second, the adsorption

kinetics should favor the separation of CO

2

from

other gaseous components such as nitrogen, oxygen,

and carbon monoxide. The adsorption rate should

also be relatively high, resulting in higher industrial

efficiency. In addition, the adsorption should have

high selectivity to CO

2

, which not only can capture a

higher proportion of CO

2

, but also ensure the high

purity of the captured CO

2

. From the perspective of

energy demand and cost, the regeneration conditions

should be mild, so the temperature and energy

required for the regeneration of solid sorbents are

relatively low, which is advantageous compared to

traditional aqueous sorbents. However, there is a

trade-off between the working capacity and the

regeneration requirement, as the higher the adsorption

enthalpy, the more favorable the adsorption of CO

2

,

but also the higher heat required for the desorption

process. In addition, the solid adsorbent should have

high stability, especially against steam and other

impurities such as NO

x

and H

2

S. Therefore, if the

material is to be used in real industrial applications,

life cycle and performance analysis should not be

performed under N

2

/CO

2

mixed conditions, but more

engineering evaluation should be performed in a

dynamic environment. Finally, when it comes to

industrial applications, it is always important to scale

up the yield of various porous materials, as well as the

cost per process.

REFERENCES

Aniruddha, R., Sreedhar, I., & Reddy, B. M. (2020) MOFs

in carbon capture-past, present and future. Journal of

CO

2

Utilization, 42, 101297.

Belmabkhout, Y., Guillerm, V., & Eddaoudi, M. (2016)

Low concentration CO

2

capture using physical

adsorbents: are metal-organic frameworks becoming

the new benchmark materials? Chemical Engineering

Journal, 296, 386-397.

Bhatt, P. M. et al. (2016) A Fine-Tuned Fluorinated MOF

Addresses the Needs for Trace CO

2

Removal and Air

Capture Using Physisorption. J. Am. Chem. Soc. 138,

9301-9307.

Jiajia Sun, Qianqian Li, Guining Chen, Jingui Duan,

Gongping Liu, Wanqin Jin. (2019) MOF-801

incorporated PEBA mixed-matrix composite

membranes for CO

2

capture. Separation and

Purification Technology, 217, 229-239.

FSB 2022 - The International Conference on Food Science and Biotechnology

98

Liu, J., Wei, Y., & Zhao, Y. (2019) Trace carbon dioxide

capture by metal-organic frameworks. ACS Sustainable

Chem. Eng. 7 (1), 82-93.

Montoro, C. et al. (2012) Functionalisation of MOF Open

Metal Sites with Pendant Amines for CO

2

Capture. J.

Mater. Chem. 22, 10155-10158.

Ozin, Geoffrey. “Calf-20: A Carbon Capture Success

Story.” Advanced Science News, January 26, 2022.

https://www.advancedsciencenews.com/calf-20-a-carb

on-capture-success-story/.

Sumida, K., et al. (2012) Carbon dioxide capture in

metal–organic frameworks. Chemical reviews,

112(2), 724-781.

Trickett, C., Helal, A., Al-Maythalony, B. et al. (2017)

The chemistry of metal–organic frameworks for CO

2

capture, regeneration and conversion. Nat Rev

Mater, 2, 17045.

Zhong X, Liang W, Wang H, et al. (2021) Aluminum-based

metal-organic frameworks (CAU-1) highly efficient

UO

2

2+

and TcO

4

−

ions immobilization from aqueous

solution. Journal of Hazardous Materials, 407: 124729.

Different CO2 Capture Methods Based on Metal-Organic Frameworks

99